Académique Documents

Professionnel Documents

Culture Documents

Working Principle of Diesel Engine

Transféré par

ShahzaibUsmanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Working Principle of Diesel Engine

Transféré par

ShahzaibUsmanDroits d'auteur :

Formats disponibles

Muhammad Umar Chauhdhary

Presented By:

The purpose of this presentation is to

explain the EDG Design, operations and

other basic details to improve the skills of

the operating team.

Design Data

Working Principle

Operation of EDG

Start up and Shut Down

Emergency trip settings

ENGINE POWER 2.8MW

RATED RPM 750

FUEL CONSUMPTION 240 L/MW-hr

ENGINE EFFICIENCY 42.4%

GENERATOR EFFICIENY 94%

COMPRESSION RATIO 13:1

NO. OF CYLINDERS 12

FREQUENCY 50 Hz

VOLTAGE 11 KV

JACKETED WATER OUTLET 90 C

AFTER COOLER WATER 56 C

AIR FLOW (@ 25C, 96 kPa) 15558 m3/hr

AIR MASS FLOW 17354 kg/hr

COMP OUTLET PRESSURE 202.5 kPa

COMP OUTLET TEMP. 174.3 C

INLET PRESSURE 200.1 kPa

INLET TEMPERATURE 61.8 C

EX. STACK TEMPERATURE 402.2 C

EX. GAS MASS FLOW 17931 kg/hr

Diesel engine works on diesel cycle

also known as constant pressure

cycle. A diesel engine uses high

compression into a very small space

inside each cylinder causing extreme

heat, this is called 'Heat Of

Compression' which ignites a very fine

high pressure mist of diesel fuel that is

injected into the cylinder at the exact

time.

The induction stroke in a Diesel engine is

used to draw in a new volume of charge air

into the cylinder. As the power generated

in an engine is dependent on the quantity

of fuel burnt during combustion and that in

turn is determined by the volume of air

(oxygen) present, most diesel engines use

turbochargers to force air into the cylinder

during the induction stroke.

The compression stroke begins as the inlet

valve closes and the piston is driven upwards

in the cylinder bore by the momentum of the

crankshaft and flywheel.

The purpose of the compression stroke in a

Diesel engine is to raise the temperature of

the charge air to the point where fuel injected

into the cylinder spontaneously ignites

The power stroke begins as the injected

fuel spontaneously ignites with the air in

the cylinder. As the rapidly burning mixture

attempts to expand within the cylinder

walls, it generates a high pressure which

forces the piston down the cylinder bore.

The linear motion of the piston is

converted into rotary motion through the

crankshaft.

The exhaust stroke is as critical to the smooth

and efficient operation of the engine as that of

induction. As the name suggests, it's the

stroke during which the gases formed during

combustion are ejected from the cylinder.

This needs to be a complete process as

possible, as any remaining gases displace an

equivalent volume of the new charge air and

leads to a reduction in the maximum possible

power.

Diesel Engine must be pre-lubed before the engine is started. A minimum

pre-lube pressure must be reached before the air starting motor is allowed to

engage.

The pre-lube pump may be driven by air or the pump may be operated

electrically.

An air starting motor is used in order to turn the engine flywheel with enough

rpm in order to start the engine. Operation of the air starting motor is

controlled by the Engine Supervisory System.

The air starting motor will engage when the requirements for pre-lube have

been met.

Revolutions 1500 rpm

Volumetric flow 31m/h

Operating pressure 30 bar

Power consumption 7.5kW

No. of cylinders 1

No. of stages 2

Cooling Air

Heat dissipation 7.5kW

Technical data

Construction air receiver:

Nominal capacity 1000 liter

Working pressure 30 bar

Design pressure 33 bar

Test pressure 50 bar

Design temperature 0/+50 C

Diameter 650 mm

Length over flanges approx. 3560 mm

Weight without valve head approx. 780 kg

Manually from Allen bredlay PLC

Manually from Enercon PLC

From DCS

EDG

Areva

K42

K39

STG

K38

GTG

B

K28

GTG

A

K06

Emergency bus bar

Bus bar A Bus bar B

EDG

Areva

K42

K39

STG

K38

GTG

B

K28

GTG

A

K06

Bus bar A Bus bar B

Emergency bus bar

EDG

Areva

K42

K39

STG

K38

GTG

B

K28

GTG

A

K06

Bus bar A Bus bar B

Emergency bus bar

Fuel passes through the injector at speeds of

nearly 1500 miles per hour - as fast as a jet plane

at top speed.

Fuel is injected into the combustion chamber in

less than 1.5 milliseconds, the same time it takes

for a camera flash to go off.

The minimum amount of fuel injected into a diesel

engine is one cubic millimeter, about the same

volume as the head of a pin.

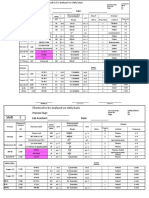

Sr

. #

Description Alarm set

point

Time delay Tripping

1 Air start pressure low alarm 750KPa 20 sec

2 Lube oil temperature high

alarm

92C 5 sec 92C

3 Fuel to engine pressure low

alarm

260KPa 5 sec 260KPa

4 Engine over speed shutdown 847RPM 50 msec 847RPM

5 Low lube oil pressure 105 KPa 3 sec 105 KPa

6 J.W high temperature 103C 3 sec 109 C

7 Generator bearing temp DE 85C 5 sec 95 C

8 Generator bearing temp

NDE

85C 5 sec 95 C

Vous aimerez peut-être aussi

- 16012878-Case Cx330 Cx350 Crawler Excavator Service Repair Manual PDFDocument623 pages16012878-Case Cx330 Cx350 Crawler Excavator Service Repair Manual PDFOleg Kuryan100% (6)

- CAT C13 Engine PDFDocument114 pagesCAT C13 Engine PDFMihai Popa100% (4)

- H1 Service ManualDocument864 pagesH1 Service ManualFrank Ch Ccaico50% (2)

- High Lexis Words For Writing Task 2Document2 pagesHigh Lexis Words For Writing Task 2ShahzaibUsman100% (2)

- Engine Fuel System Troubleshooting GuideDocument19 pagesEngine Fuel System Troubleshooting GuidePablo Rojas Valenzuela100% (1)

- GSX-R750 1996-'99 Parts ListDocument102 pagesGSX-R750 1996-'99 Parts ListCarlos Gustavo Flores TalaveraPas encore d'évaluation

- Introduction to Mechanical EngineeringDocument17 pagesIntroduction to Mechanical EngineeringDaniel Naoe FestinPas encore d'évaluation

- Design of Air Conditioning and Ventilation System For A Multi Storey Office BuildingDocument5 pagesDesign of Air Conditioning and Ventilation System For A Multi Storey Office BuildingIppiPas encore d'évaluation

- Mechanical Technology Lab ReportDocument16 pagesMechanical Technology Lab ReportBilal Akhundzada100% (2)

- Evolution and Components of Diesel Power PlantsDocument51 pagesEvolution and Components of Diesel Power PlantsJed Alcantara100% (2)

- 3-Vapour Compression SystemsDocument18 pages3-Vapour Compression SystemsUtkarsh SinghPas encore d'évaluation

- Ice PlantDocument101 pagesIce PlantZa Yon100% (5)

- EME4096 Assignment 2 (Final Answer)Document3 pagesEME4096 Assignment 2 (Final Answer)Mohammed IslamPas encore d'évaluation

- Rotary PumpsDocument31 pagesRotary PumpsalbertPas encore d'évaluation

- Chapter 1 SpecificationDocument4 pagesChapter 1 SpecificationBasil BautistaPas encore d'évaluation

- Diesel Power PlantDocument11 pagesDiesel Power PlantDr. B. Ramesh100% (2)

- Pec Answers 401 To 500Document11 pagesPec Answers 401 To 500Edward Roy “Ying” AyingPas encore d'évaluation

- Correction ElementDocument20 pagesCorrection ElementKelvin Oscar nsituPas encore d'évaluation

- RefrigerantDocument59 pagesRefrigerantObula Reddy KPas encore d'évaluation

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDocument14 pagesLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezPas encore d'évaluation

- FlywheelDocument24 pagesFlywheelDivye SethiPas encore d'évaluation

- Engine Formulas: Cylinder Swept Volume (VDocument7 pagesEngine Formulas: Cylinder Swept Volume (VDhanraj PatilPas encore d'évaluation

- M.E. Laws, Contracts and Ethics PresentationDocument28 pagesM.E. Laws, Contracts and Ethics PresentationLeo Paulo Del Rosario0% (1)

- TemplifierDocument8 pagesTemplifiermdalt9180100% (1)

- MEP 435 – FUELS AND HEAT POWER: FUEL LOSSESDocument5 pagesMEP 435 – FUELS AND HEAT POWER: FUEL LOSSESnaytpuri montemayorPas encore d'évaluation

- Role of MEs - 2019Document16 pagesRole of MEs - 2019Rogelio S. ManingdingPas encore d'évaluation

- Assignment 2Document5 pagesAssignment 2Noraishah Syahirah Azhar100% (1)

- Code of Mechanical EngineeringDocument3 pagesCode of Mechanical Engineeringrolly_acul50% (2)

- Fans and BlowersDocument19 pagesFans and BlowersBabylyn AustriaPas encore d'évaluation

- Air Changes Per HourDocument4 pagesAir Changes Per HourDIPAK S100% (1)

- Performance of Internal Combustion EngineDocument45 pagesPerformance of Internal Combustion EngineAnurag BansalPas encore d'évaluation

- Carbon ResidueDocument3 pagesCarbon ResidueBonifacio67% (3)

- AIRCONDITIONINGDocument13 pagesAIRCONDITIONINGrini0026Pas encore d'évaluation

- Diesel Power PlantDocument3 pagesDiesel Power PlantdinnykumarPas encore d'évaluation

- Optimal Power Flow with Frequency ConstraintsDocument3 pagesOptimal Power Flow with Frequency ConstraintsLeela KrishnaPas encore d'évaluation

- TORRES Exp 6 PDFDocument27 pagesTORRES Exp 6 PDFRodolfo Rey TorresPas encore d'évaluation

- Power Plant EconomicsDocument27 pagesPower Plant EconomicsAyman Esa0% (1)

- Fire SafetyDocument13 pagesFire SafetyJanssen Gerardo ValbuenaPas encore d'évaluation

- RAC Case StudyDocument11 pagesRAC Case StudyshubhamPas encore d'évaluation

- Tidal Power PlantDocument13 pagesTidal Power PlantSam AndersonPas encore d'évaluation

- DieselPower PlantDocument12 pagesDieselPower PlantJC ElarmoPas encore d'évaluation

- Philippines Wind FarmDocument13 pagesPhilippines Wind FarmRommel TottocPas encore d'évaluation

- ME Lab 2 Module No. 5 PDFDocument24 pagesME Lab 2 Module No. 5 PDFIsmaeli KielPas encore d'évaluation

- Natural RubberDocument16 pagesNatural RubberQoe IooNkPas encore d'évaluation

- General Requirements: Philippine Mechanical Code 2008Document72 pagesGeneral Requirements: Philippine Mechanical Code 2008Li RePas encore d'évaluation

- Air CompressorDocument13 pagesAir CompressorAnyamanee SiripojanakulPas encore d'évaluation

- MEPF Design Guide for Mix-Use BuildingsDocument119 pagesMEPF Design Guide for Mix-Use BuildingsHorhe LacanilaoPas encore d'évaluation

- Don Mariano Marcos Memorial State University Mid La Union Campus College of EngineeringDocument1 pageDon Mariano Marcos Memorial State University Mid La Union Campus College of EngineeringCharlyn FloresPas encore d'évaluation

- Electronics IndustrialDocument6 pagesElectronics IndustrialhongPas encore d'évaluation

- Thermal Physics ModuleDocument96 pagesThermal Physics Module3334333Pas encore d'évaluation

- Process Control Trainer Project Report - Original1Document42 pagesProcess Control Trainer Project Report - Original1Augustine paulPas encore d'évaluation

- Bend Test Determines Ductility of Reinforcing Steel BarsDocument14 pagesBend Test Determines Ductility of Reinforcing Steel BarsJohn Henry SalvadoPas encore d'évaluation

- Cash Flow and Equivalence PDFDocument6 pagesCash Flow and Equivalence PDFIscandar Pacasum DisamburunPas encore d'évaluation

- Difference Between 2 Stroke and 4 Stroke EngineDocument9 pagesDifference Between 2 Stroke and 4 Stroke EnginesaadPas encore d'évaluation

- Calculation of Cooling of Commercial BuildingDocument39 pagesCalculation of Cooling of Commercial BuildingFareed AlamPas encore d'évaluation

- Types of Air Conditioning Systems ExplainedDocument9 pagesTypes of Air Conditioning Systems ExplainedJohn ApeladoPas encore d'évaluation

- Ice PlantDocument25 pagesIce PlantAbenliciousPas encore d'évaluation

- Diesel CycleDocument52 pagesDiesel CycleTyler O'connor100% (4)

- Understand Torsion and Springs with this Unit III GuideDocument4 pagesUnderstand Torsion and Springs with this Unit III Guidel8o8r8d8s8i8v8100% (1)

- Geothermal Power PlantDocument25 pagesGeothermal Power PlantKaren Joy VillamarPas encore d'évaluation

- Automatic pneumatic jack designDocument5 pagesAutomatic pneumatic jack designSaravanan ViswakarmaPas encore d'évaluation

- Mohamad Houri ResumeDocument2 pagesMohamad Houri ResumeMoudi HouriPas encore d'évaluation

- Charge Air System by P.KDocument28 pagesCharge Air System by P.Kkr_abhijeet72356587100% (1)

- Gas Turbine:: A Gas Turbine Also Called A Combustion Turbine, Is A Type of Continuous andDocument7 pagesGas Turbine:: A Gas Turbine Also Called A Combustion Turbine, Is A Type of Continuous andHAMMAD ALIPas encore d'évaluation

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Document4 pagesDoosan Infracore Generator Engine: Ratings (KWM/PS)Carlos David AlmeidaPas encore d'évaluation

- Diesel EnginesDocument15 pagesDiesel EnginesDivyansh kaushalPas encore d'évaluation

- National Immunization Management System: Tracking ID: 100001468Document1 pageNational Immunization Management System: Tracking ID: 100001468aaaaaaaliPas encore d'évaluation

- Osama Hussain COVID - CertificateDocument1 pageOsama Hussain COVID - CertificateShahzaibUsmanPas encore d'évaluation

- Task 1 Invite A Friend To New HomeDocument1 pageTask 1 Invite A Friend To New HomeShahzaibUsmanPas encore d'évaluation

- Vulgarity, A Grave Concern in Pakistan PDFDocument1 pageVulgarity, A Grave Concern in Pakistan PDFShahzaibUsmanPas encore d'évaluation

- Stock Control 16-05-2022 ChromeDocument2 pagesStock Control 16-05-2022 ChromeShahzaibUsmanPas encore d'évaluation

- Sadia Anwar: PHARM D (Doctor of Pharmacy)Document4 pagesSadia Anwar: PHARM D (Doctor of Pharmacy)ShahzaibUsmanPas encore d'évaluation

- Road SafetyDocument1 pageRoad SafetyShahzaibUsmanPas encore d'évaluation

- Business LetterDocument1 pageBusiness LetterShahzaibUsmanPas encore d'évaluation

- SC Exploration & ExpolitationDocument4 pagesSC Exploration & ExpolitationShahzaibUsmanPas encore d'évaluation

- Formula 6 PDFDocument2 pagesFormula 6 PDFShahzaibUsmanPas encore d'évaluation

- Task 1 Invitation LetterDocument1 pageTask 1 Invitation LetterShahzaibUsmanPas encore d'évaluation

- Formula 6 What Do You Like Most About X?Document2 pagesFormula 6 What Do You Like Most About X?ShahzaibUsmanPas encore d'évaluation

- Adventurous Trip To Mysterious Island PDFDocument1 pageAdventurous Trip To Mysterious Island PDFShahzaibUsmanPas encore d'évaluation

- Sample Candidate Writing Scripts and Examiner Comments: Lexical ResourceDocument7 pagesSample Candidate Writing Scripts and Examiner Comments: Lexical ResourceShahzaibUsmanPas encore d'évaluation

- Sahil Double Question Large CitiesDocument1 pageSahil Double Question Large CitiesShahzaibUsmanPas encore d'évaluation

- Shift A: Process Engr: Lab Assistant: DateDocument3 pagesShift A: Process Engr: Lab Assistant: DateShahzaibUsmanPas encore d'évaluation

- Sahil Verma, Problem Solution, TechnologyDocument1 pageSahil Verma, Problem Solution, TechnologyShahzaibUsmanPas encore d'évaluation

- Quotation 3Document2 pagesQuotation 3ShahzaibUsmanPas encore d'évaluation

- Ammar Enterprises - : Debit NoteDocument1 pageAmmar Enterprises - : Debit NoteShahzaibUsmanPas encore d'évaluation

- Benefits and Challenges of Visiting Difficult Tourist DestinationsDocument1 pageBenefits and Challenges of Visiting Difficult Tourist DestinationsShahzaibUsman100% (1)

- Trouble HistoryDocument7 pagesTrouble HistoryShahzaibUsmanPas encore d'évaluation

- Prize You Would Like To WinDocument1 pagePrize You Would Like To WinShahzaibUsmanPas encore d'évaluation

- Task 1 Request InfoDocument1 pageTask 1 Request InfoShahzaibUsmanPas encore d'évaluation

- Discussin + Opinion, 12, Test 7Document1 pageDiscussin + Opinion, 12, Test 7ShahzaibUsmanPas encore d'évaluation

- Chrome plating expense reportDocument4 pagesChrome plating expense reportShahzaibUsmanPas encore d'évaluation

- Task 1 Apology For Not Attending MeeringDocument1 pageTask 1 Apology For Not Attending MeeringShahzaibUsmanPas encore d'évaluation

- TFNG Test 6Document4 pagesTFNG Test 6ShahzaibUsmanPas encore d'évaluation

- O 2 2019 2Document1 pageO 2 2019 2ShahzaibUsmanPas encore d'évaluation

- Career Opportunities: Senior Medical Officer (SPS-9)Document2 pagesCareer Opportunities: Senior Medical Officer (SPS-9)Aamir AbbasPas encore d'évaluation

- Two-stroke engine design typesDocument17 pagesTwo-stroke engine design typesshakti00000Pas encore d'évaluation

- f2 (2) (1) Reviewer Chief Officer Materials.Document20 pagesf2 (2) (1) Reviewer Chief Officer Materials.Alden Almaquer Delizo100% (1)

- The Abc'S of Fire ExtinguishersDocument2 pagesThe Abc'S of Fire ExtinguishersKelly LightbournePas encore d'évaluation

- Valve Clearance Check and AdjustmentDocument3 pagesValve Clearance Check and AdjustmentRodrigo MuñozPas encore d'évaluation

- CH 7 AssignmentDocument3 pagesCH 7 AssignmentUday Prakash SahuPas encore d'évaluation

- The Oil Boom After Spindle Top Pgs 420-424Document5 pagesThe Oil Boom After Spindle Top Pgs 420-424api-293238977Pas encore d'évaluation

- LPG Spark Plug WebDocument93 pagesLPG Spark Plug Webwillgray1Pas encore d'évaluation

- Refrigeration Oil PDFDocument17 pagesRefrigeration Oil PDFChristina PadillaPas encore d'évaluation

- Bitumen RateDocument1 pageBitumen RateSangram MundePas encore d'évaluation

- Petroleum Production Engineering PDFDocument60 pagesPetroleum Production Engineering PDFpiglitPas encore d'évaluation

- OECD Energy Balances Beyond 2020 DocumentationDocument61 pagesOECD Energy Balances Beyond 2020 DocumentationEverett F SargentPas encore d'évaluation

- National PartsDocument64 pagesNational PartsAlejandro GarciaPas encore d'évaluation

- Valve StandardsDocument22 pagesValve StandardsKlubowoloya110% (1)

- ZVB 05 A 15 22 22Document4 pagesZVB 05 A 15 22 22damian_k19Pas encore d'évaluation

- Importance of Petroleum Industry and Training Effectiveness at IOCL Guwahati RefineryDocument13 pagesImportance of Petroleum Industry and Training Effectiveness at IOCL Guwahati Refinerypapia_das876156Pas encore d'évaluation

- Kluberfluid C F 3 UltraDocument2 pagesKluberfluid C F 3 UltraSathykumar MurugesanPas encore d'évaluation

- Oxy Acetylene SopDocument1 pageOxy Acetylene SopLouise BPas encore d'évaluation

- Abbreviations Oil & GasDocument53 pagesAbbreviations Oil & GasMarwan Mahgoub AhmadPas encore d'évaluation

- HW - 9 - 052Document2 pagesHW - 9 - 052Rio Andisa Putra100% (1)

- ESTERSDocument10 pagesESTERSMimie Yasmin KamalPas encore d'évaluation

- Module 2.1 - Basic Flow Assurance PDFDocument13 pagesModule 2.1 - Basic Flow Assurance PDFAyuku KidaPas encore d'évaluation

- OM673L3Document34 pagesOM673L3dromascoPas encore d'évaluation

- Engineering Design Guidelines BTX Extraction Unit Rev01.1webDocument17 pagesEngineering Design Guidelines BTX Extraction Unit Rev01.1webfarukh azeemPas encore d'évaluation

- Energy Audit Energy Conservation Basics - ORIGINALDocument70 pagesEnergy Audit Energy Conservation Basics - ORIGINALAhmed Sherif100% (1)

- Guard Bed Catalysts For Silicon Removal During Hydrotreating of Middle DistillatesDocument39 pagesGuard Bed Catalysts For Silicon Removal During Hydrotreating of Middle DistillatesLaura CarvajalPas encore d'évaluation