Académique Documents

Professionnel Documents

Culture Documents

Transmission Line

Transféré par

Tarun Aggarwal100%(1)100% ont trouvé ce document utile (1 vote)

336 vues53 pagescomplete

Titre original

Transmission line

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentcomplete

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

336 vues53 pagesTransmission Line

Transféré par

Tarun Aggarwalcomplete

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 53

TRANSMISSION TOWER

Tarun Aggarwal, Larsen and Toubro ,Saudi LCC

Tarun Aggarwal 1

2 Tarun Aggarwal

3 Tarun Aggarwal

Power in UAE..?

Production capacity 18.74 GW. (lack in peak seasonal times)

Lack of natural gas

Gulf Cooperation Council UAE, Kuwait, Qatar, Bahrain, Saudi Arabia & Oman

GCC began region-wide power grid demand

UAE has no spare power capacity

Phase 3 of GCC grid to southern system of UAE

In Dec2009 $20 billion contract to Korean Electric Power 4 nuclear reactors

1

st

reactor may 2017 each reactor 1400 MW

4 Tarun Aggarwal

Electric power transmission..?

The bulk transfer of electrical energy, from generating power

plants to substations

Power is usually transmitted through overhead power lines

Underground power transmission has a significantly higher cost

and greater operational limitations - urban & sensitive areas

Overhead Power lines..?

An electric power transmission line suspended by

towers

It is the lowest-cost method of transmission for large

quantities of electric energy (most of insulation by air)

The bare wire conductors on the line are generally

made of aluminum

5 Tarun Aggarwal

Transmission tower..?

Tall structure usually a Steel lattice tower, used

to support an overhead power line

Electricity pylon UK & parts of Europe

Ironman Australia

Hydro tower in parts of Canada

6 Tarun Aggarwal

7 Tarun Aggarwal

TOWER GEOMENTRY

ANATOMY

BRACINGS

EXTENSIONS

8 Tarun Aggarwal

Tower Anatomy

Peak - supports G.W

Cage - b/w peak & tower

body

Cross Arm - Support

Conductor/G.W

Boom supports power

conductors (horizontal)

Tower body main portion,

connects cage/boom to

foundation/(leg/body

)extensions

9 Tarun Aggarwal

10 Tarun Aggarwal

Bracings

Provided for interconnecting the legs

To afford desired slenderness ratio for economical tower

design

Framing angle b/w bracings & main leg members shall not

be < 15 degree

Patterns are

a) Single web system

b) Double web or warren system

c) Pratt system

d) Portal system

e) Diamond Bracing system

f) Multiple Bracing System

11 Tarun Aggarwal

1.Struts are designed

in compression &

Diagonals in tension

2.NARROW BASE

3.66Kv single circuit

1.Tension diagonal

give eff.support to

compression one @

pt of connections

2.Used in both large

and small towers

1.Shear carried by

diagonal member(t)

2.Large deflection

under heavy loads

3.Unequal shears at

top of four stubs for

design

12 Tarun Aggarwal

1.1half of Horizontal

member in T &

another C

2.Advantageous to

use it in BOTTOM

panel

3.Extensions &

Heavy river crossing

1. Similar to waran

system

2.Horizontal member

carry no primary

loads designed as

redundant supports

1.Increse in strenght

reducing member

sizes

2.Increase in No.of

bolts, fabrication &

erection cost,

3.Overal reduction in

Wt & cost of steel

13 Tarun Aggarwal

Tower Extension

Body Extension

Leg Extension

Body Extension

Used to Increase the height of tower to obtain the reqd min Ground clearance & over

road crossings, river crossings, ground obstacles

Body extensions upto 7.5m height in steps 2.5m can be used & thus form a part of

standard tower

Extensions having greater heights (25m) the suitability is checked by reducing span

length and angle of deviation. Practice in tower industry is also to specify negative body

extension (portion of tower body is truncated)

14 Tarun Aggarwal

Leg Extension

Tower Leg extensions are required when the tower was spotted in the undulated

surface / Hilly terrain.

While spotting the tower locations in hilly areas requires more benching or revetment

or both are involved , but suitable hill side (leg extensions) can be used to minimize

benching or revetment or both.

Two types of Leg extension :

i) Universal leg extension

ii) Individual leg extension

15 Tarun Aggarwal

Types of Tower

5) No. of Circuits

Single Circuit

Double Circuit

Multi-Circuit

6) Deviation Angle.

Ranges from 0 to 90 deg.

1) Type of Insulator

Suspension

Tension/Dead end

Transposition

2) Type of Support

Self Supporting

Guyed

3) Shape at the base

Square

Rectangle

4) kV Rating.

Ranges from 33 to 1200

kV

HVDC

Tarun Aggarwal

EDRC-TL Design

Vertical Configuration Horizontal Configuration

17 Tarun Aggarwal

Tension Tower

Suspension Tower

18 Tarun Aggarwal

Guy Towers

19 Tarun Aggarwal

Conductor Configuration

20 Tarun Aggarwal

66 kv 132 kv 220 kv 400 kv

21 Tarun Aggarwal

66 kv 132 kv 220 kv 400 kv

22 Tarun Aggarwal

Tower Nomenclature

Sr.

No.

Nomenclature Deviation Remark

1 A/DA/S/SLC/T0/TDL/QA/SA/V 0-2

0

Suspension Tower

2 B/DB/AT/DLB/TD2/QB/X 0-30

0

Used Small angle tower.

Used as a Section Tower

3 C/DC/BAT/DLC/TD3/QC/CZ 30-60

Used as Medium Angle

Tower

Used as a Transposition

4 D/DD/BAT/DE/TD6/TDT/QD/DE

60-

90

0

/Dead

End

Used as a large angle Tower

Used as a Dead End

Tower

23 Tarun Aggarwal

Height of Tower Structure

24

4 3 2 1 h h h h H

Height of tower is determine by-

h

1

=Minimum permissible ground clearance

h

2

=Maximum sag

h

3

=Vertical spacing between conductors

h

4

=Vertical clearance between earth wire

and top conductor

Tarun Aggarwal

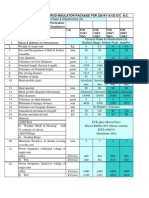

ELECTRICAL CLEARANCES

Sr.

No

Type of Clearance 132 kV 220 kV 400 kV 765 kV

1 Ground Clearance 6.1 m 7.0 m 8.84 m 15.5 m

2 Live Metal Clearance in mm Swing

132 /

220

400 /

765

Suspension insulator 15 15 1530 1980 3050 4400 (25)

30 30 1370 1830 1860 1300 (55)

45 - 1220 1675 -

60 1070 - -

Tension Insulator 0 0 1530 2130 3050

Jumper 10 20 1530 2130 3050 4400

20 40 1070 1675 1860 1300

30 - 1070 - - -

3 Mid Span Clearance (m) 6.1 8.5 9.0 12.4

4 Shielding Angle (Deg) 30 30 20 20

5 Phase to Phase Clearance Vertical 3.9 m 4.9 m

Horizontal 6.8 m 8.4 m

25 Tarun Aggarwal

Right of Way :

Sr.

No

Type of Clearance 132 kV 220 kV 400 kV 765 kV

1 ROW width

27 m 35 m 52 m 85 m

26 Tarun Aggarwal

DESIGN PARAMETERS

Transmission Voltage

Number Of Circuits

Climatic Conditions

Environmental and Ecological Consideration

Conductor

Earth Wire

Insulators

Span

27 Tarun Aggarwal

Economic Voltage of Transmission of Power

E = Transmission voltage (KV) (L-L).

L = Distance of transmission line in KM

KVA=Power to be transferred 150 6 . 1

5 . 5

KVA L

E

28 Tarun Aggarwal

Conductor

Aluminum is used

it has about half the weight of copper for the

same resistance, as well as being cheaper

Types:

AAC : All Aluminium conductors.

AAAC : All Aluminium Alloy conductors

ACSR : Aluminium conductors, Steel-Reinforced

ACAR : Aluminium conductor, Alloy-Reinforced

Bundle conductors are used to reduce corona

loses & audible noise

It consists of several conductors cables

connected by non-conducting spacers

It is used to increase the amount of current

that may be carried in line

As a disadvantage, the bundle conductors

have higher wind loading

Spacers must resist the forces due to wind,

and magnetic forces during a short-circuit

29 Tarun Aggarwal

spacers

30 Tarun Aggarwal

Earth Wire

Earth wire provided above the phase conductor across the line and

grounded at every tower.

It shield the line conductor from direct strokes

Reduces voltage stress across the insulating strings during lightning strokes

Galvanized steel earth wires are used

Aerial marker balls (>600mm dia) (Red, Orange, White)

Shield angle

25-30 up to 220 KV

20 for 400 KV and above

31 Tarun Aggarwal

Tarun Aggarwal 32

Insulators

Insulator are required to support the line

conductor and provide clearance from

ground and structure.

Insulator material-

High grade Electrical Porcelain

Toughened Glass

Fiber Glass

Type of Insulator-

Disc Type

Strut Type

Long Rod Insulator

33 Tarun Aggarwal

Insulator Strings

Disc insulator are joint by their ball

pins and socket in their caps to form

string.

No of insulator disc is decided by

system voltage, switching and lighting

over voltage amplitude and pollution

level.

Insulator string can be used either

suspension or tension.

Two suspension string in parallel

used at railways, road and river

crossing as statutory requirement.

Swing of suspension string due to

wind has to be taken into consider.

single string

Double string

34 Tarun Aggarwal

Design Span lengths

1.Basic Span

Most economic span

Line is designed over level ground

The requisite ground clearance is obtained

at maximum specified temperature

35 Tarun Aggarwal

2.Ruling Span

Assumed design span that will produce,

between dead ends

It is used to calculate the horizontal

component of tension (which is applied to all

spans b/w anchor pts)

Tower spotting on the profile is done by

means of sag template, (which is based on

ruling span)

Ruling span = ( L1^3 + L2^3 +.+L6^3 / L1 + L2 + + L6)

3.Average Span

Mean span length between dead ends

It is assumed that the conductor is

freely suspended such that each

individual span reacts to change in

tension as a single average span

Average span = (L1+ L2+...+L6) /6

36 Tarun Aggarwal

4.Wind Span

5.Weight Span

Horizontal distance between the

lowest point of conductor, on the two

spans adjacent to the tower

The lowest point is defined as point

at which the tangent to sag curve

It is used in design of cross-arms

Half the sum of the two spans,

adjacent to support

It is assumed that the conductor is

freely suspended such that each

individual span reacts to change in

tension as a single average span

Wind span = 0.5(L1 + L2)

Weight span = a1 + a2

37 Tarun Aggarwal

38

Determination of Base Width

The base width(at the concrete level) is the distance between the centre of

gravity at one corner leg and the centre of gravity of the adjacent corner

leg.

A particular base width which gives the minimum total cost of the tower and

foundations.

The ratio of base width to total tower height for most towers is generally

about one-fifth to one-tenth.

38

Ryle

Formula

Tarun Aggarwal

Determination of Weight of tower

Rough approximation

From knowledge of the positions of conductors & ground wire above ground level

& overturning moments

Ryle gives empirical formula in term of its height & maximum overturning moment

at base

132 kv 1.7 metric tones

220 kv 2.5 metric tones

400 kv 7.7 metric tones

765 kv 14 metric tones

Approximate values

39 Tarun Aggarwal

LOADINGS

Loads are applied in all three directions namely Transverse ( FX ),

Vertical ( FY) and Longitudinal (FZ) direction.

Transverse loads consists of

Wind on Conductor

Wind on Insulator

Component of Wire Tension in Transverse Direction

(Deviation Load)

Wind on Tower Body

Vertical Load consists of

Weight of Wire

Weight of Insulator

Weight of Line man & Tools

Self Weight of Tower

Longitudinal Load Consist of

Component of Unbalanced pull of the wire in the

longitudinal direction.

40 Tarun Aggarwal

Loads on Tower

Normal Condition

Broken Wire Condition

41 Tarun Aggarwal

Loads are calculated as per the guide lines furnished in

specification/standard.

Standards for Calculation of Loads

IS 802 1977

IS 802 1995

DIN VDE 0210

ASCE Manual

IEC 826

The loads are calculated for following Conditions.

Reliability / Working condition

Security / Broken wire condition

Safety / Erection & maintenance Condition

42 Tarun Aggarwal

ANALYSIS & DESIGN

Analysis is carried out by finite element software

STAAD

Required FOS is provided in input file to find out ultimate

force

The critical compression and tension in each member

group is found out

Members and Connections are designed for these forces.

Iterations are carried out for the optimum usage of tower.

43 Tarun Aggarwal

44 Tarun Aggarwal

45 Tarun Aggarwal

46 Tarun Aggarwal

FOUNDATION

It costs 10-30 % of overall cost of

tower

It is the last step in designing process

but precedes the construction

Overload factors assumed in designs

are 2.2 under Normal condition & 1.65

under broken-wire conditions

Data's for foundation design

47 Tarun Aggarwal

0.5 to 2m dia

Shaft depth 3 to 15m

Skin friction between

ground & shaft resists

uplift

Used in usa,

acceptance for wide

use in India

Uplift loads are

resisted by undistrube

material

Develop uplift load of

2 to 3times that of an

iidentical footing

without undercut

Non-cohesive soil

For non-cohesive soils

such as uncemented

sand or gravel

Provide pad footing

without undercut

Usually followed in

INDIA at present

48 Tarun Aggarwal

Adopted in firm

cohesive soils

Undercut on the pads

Experience shows that

this type of footing

develop resistance to

uplift 2 to 3 times that

given footing without

undercut

Hybrid design

Large uplift force are

to be resisted

SBC is low

Augered footing with

more than one bulb is

used to increase the

uplift capacity

35m long under

reamed to 2.5 times

dia of shaft

Clayey black cotton

soils & medium dense

sandy soils

49 Tarun Aggarwal

In usa ,canada

Steel corroded,

periodic excavation &

maintanence

Medium dry sand, clay

or sandy caly soils (no

special precautions

necessary)

The steel is treated

with one coat of

bituminous paint &

top coat of asphalt

Suitable in areas with

rock out crop

Based on uplift, the

anchor be single bar

or group of bars

welded to tower leg

Vertical bars below

stub angle form cage

for footing

Grouted to a depth of

about 50 times dia

into the rock

Special circumstances

River crossing towers

& towers on

embankments

The raft at bottom

makes the foundation

substantially rigid to

minimize differential

settlement

50 Tarun Aggarwal

Raft foundation

51 Tarun Aggarwal

Pyramid chimney type foundation

Important steps in tower

erection

The stubs are set with the help

of stub setting templates

Excavated pits are lean

concreted to correct level

Stubs are placed on lean

concrete pad

Alignment is carried by four

plumb bobs hung from centre of

the horizontal bracing

If any pit over excavated by

mistake, the extra depth should

be filled by concreting

After the stub is set, the heel

distance of four faces of the

tower and two diagonals should

be checked

52 Tarun Aggarwal

Stub-setting

Tarun Aggarwal 53

Vous aimerez peut-être aussi

- Mechanical Design of Transmission Lines PDFDocument53 pagesMechanical Design of Transmission Lines PDFAkhilesh MendonPas encore d'évaluation

- Span and Ruling SpanDocument12 pagesSpan and Ruling SpanTanveer Ul HaqPas encore d'évaluation

- Bus Swicthing Scheme & Substation Layout - KksarkarDocument44 pagesBus Swicthing Scheme & Substation Layout - Kksarkarsantoshnarinoi241100% (2)

- Analysis of Transmission Tower With Different ConfigurationDocument11 pagesAnalysis of Transmission Tower With Different ConfigurationPankaj_Taneja_9684Pas encore d'évaluation

- Analysis and Design of 220kv Transmission Line Tower in Different Zones I & V With Different Base Widths A Comparative StudyDocument9 pagesAnalysis and Design of 220kv Transmission Line Tower in Different Zones I & V With Different Base Widths A Comparative StudyVaibhav JainPas encore d'évaluation

- Basics of TL DesignDocument71 pagesBasics of TL Designamankhurana1602100% (1)

- 12-II.2. Tower SpottingDocument16 pages12-II.2. Tower Spottingashok10577Pas encore d'évaluation

- Technical Session Transmission Line - IIIDocument80 pagesTechnical Session Transmission Line - IIIKaushal Ghimire100% (2)

- KPTCL Design of Ehv Transmission LineDocument48 pagesKPTCL Design of Ehv Transmission LineCharan Raj100% (1)

- Transmission LinesDocument44 pagesTransmission Linessssssqwerty12345Pas encore d'évaluation

- Transmission Line: Ravi Shankar Singh (E6S304)Document44 pagesTransmission Line: Ravi Shankar Singh (E6S304)amit143263Pas encore d'évaluation

- Design of Transmission Line Using MatlabDocument12 pagesDesign of Transmission Line Using Matlabdensus88 densus89Pas encore d'évaluation

- PGCIL GIS Specification - Rev 4 (June-14)Document74 pagesPGCIL GIS Specification - Rev 4 (June-14)Travis Wood100% (1)

- 33 KV Transmission Line Design Drawings PDFDocument265 pages33 KV Transmission Line Design Drawings PDFkapilsharma404Pas encore d'évaluation

- Manual On Transmission Line TowersDocument79 pagesManual On Transmission Line TowerselsayedPas encore d'évaluation

- Transmission Line Design & ConstructionDocument38 pagesTransmission Line Design & Constructionapi-2588520096% (24)

- Substation DesignDocument2 pagesSubstation DesignMohammad Belal HossainPas encore d'évaluation

- 1 Normal Tower 2 +3M Extn. Only 3 +6M Extn Only 4 StubDocument11 pages1 Normal Tower 2 +3M Extn. Only 3 +6M Extn Only 4 StubSrinivasarao MorampudiPas encore d'évaluation

- Substation Design and LayoutDocument9 pagesSubstation Design and Layoutsurag1982Pas encore d'évaluation

- Switchyard Design Basis ReportDocument19 pagesSwitchyard Design Basis Reportrukmagoud67% (3)

- Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Document167 pagesDesingconstructionof33kv11kvlines 150329033645 Conversion Gate01Akshaya AroraPas encore d'évaluation

- Layout of Sub StationDocument31 pagesLayout of Sub StationVenugopal Patnaik100% (2)

- Minimum Clearance in SubstationDocument5 pagesMinimum Clearance in Substationprabowo aris putro100% (2)

- Overhead Line Design Standard Transmission Distribution SystemDocument38 pagesOverhead Line Design Standard Transmission Distribution Systemchirag_cs7100% (2)

- Designing 400 KV Transmission LineDocument61 pagesDesigning 400 KV Transmission LineMohammed K Hawa92% (12)

- Substation Design - NotesDocument10 pagesSubstation Design - NoteskarthikdotePas encore d'évaluation

- Boq 132 - 33kv GssDocument14 pagesBoq 132 - 33kv GssMathur DineshPas encore d'évaluation

- Substation & Switchyard Structure'sDocument57 pagesSubstation & Switchyard Structure'snestlejin80% (10)

- Tender document for Bahrabise projectDocument55 pagesTender document for Bahrabise projecttanujaayerPas encore d'évaluation

- My Learnings On Transmission TowerDocument53 pagesMy Learnings On Transmission TowerSaravanan Ramalingam100% (3)

- Basics On Transmission LinesDocument44 pagesBasics On Transmission Linesras_job100% (3)

- Basics On Transmission LinesDocument44 pagesBasics On Transmission LinesDayan Yasaranga100% (1)

- Transmission Line Basic PresentationDocument141 pagesTransmission Line Basic PresentationSomiran Das100% (3)

- 1 Chapter One Part 2Document34 pages1 Chapter One Part 2Arazw AbdulrahmanPas encore d'évaluation

- Mechanical Design of Transmission LinesDocument46 pagesMechanical Design of Transmission LinesSamundra GurungPas encore d'évaluation

- Transmission Tower TypesDocument56 pagesTransmission Tower TypesApple Electricals100% (1)

- Power System Engineering Lecture 15Document28 pagesPower System Engineering Lecture 15nnvpratap100% (1)

- Transmission LinesDocument15 pagesTransmission LinesHafizulla Sheik100% (1)

- ACE - Module - 5.6 - Transmission TowerDocument35 pagesACE - Module - 5.6 - Transmission Towervikassuresh431997Pas encore d'évaluation

- Electrical Transmission Tower Types and DesignDocument3 pagesElectrical Transmission Tower Types and DesignFatima MirPas encore d'évaluation

- Lecture 4Document62 pagesLecture 4Esaias AberaPas encore d'évaluation

- Transmission Towers Research PaperDocument10 pagesTransmission Towers Research PaperJhn Hnrch TolentinoPas encore d'évaluation

- 132 KV Tower Analysis PDFDocument11 pages132 KV Tower Analysis PDFViswanathan VPas encore d'évaluation

- A Study On Analysis of Transmission Line Tower and Design of FoundationDocument11 pagesA Study On Analysis of Transmission Line Tower and Design of Foundationpawan paudelPas encore d'évaluation

- Transmission TOWERDocument27 pagesTransmission TOWERbhavik goud93% (15)

- Ohe IDocument41 pagesOhe IAnonymous sENwj8nwq100% (11)

- Concept of Energy TransmissionDocument45 pagesConcept of Energy TransmissionUJJAVAL PATELPas encore d'évaluation

- 800 KV TL DesignDocument67 pages800 KV TL Designravi0312150% (2)

- Over-Head Conductors IN Transmission LineDocument33 pagesOver-Head Conductors IN Transmission LineSubhashree SahuPas encore d'évaluation

- Transmission LineDocument7 pagesTransmission LineneyulukPas encore d'évaluation

- Transmission Line Parameters ExplainedDocument30 pagesTransmission Line Parameters ExplainedMirkena kebedePas encore d'évaluation

- 220kV Transmission Line Tower Analysis and DesignDocument10 pages220kV Transmission Line Tower Analysis and DesignPiyushPas encore d'évaluation

- MECHANICAL DESIGN of TRANSMISSION LINEDocument20 pagesMECHANICAL DESIGN of TRANSMISSION LINEkevinmaclatorre80% (5)

- Erection of Transmission Tower and Design of ResidentialDocument40 pagesErection of Transmission Tower and Design of ResidentialBoopathi YoganathanPas encore d'évaluation

- Transmission TowersDocument5 pagesTransmission TowersAwab Ahmed ShariffPas encore d'évaluation

- Underground Power Cable Design and InstallationDocument64 pagesUnderground Power Cable Design and InstallationAnonymous rWZ2WNh4Pas encore d'évaluation

- Over Head Line Conductor: Experiment No. 9Document6 pagesOver Head Line Conductor: Experiment No. 9Faiza IqbalPas encore d'évaluation

- 758analysis and Design of Multi Circuit Transmission Line Tower PDFDocument6 pages758analysis and Design of Multi Circuit Transmission Line Tower PDFBTEPas encore d'évaluation

- Electrical Transmission and DistributionDocument34 pagesElectrical Transmission and DistributionJessica Laine Tumbaga100% (2)

- HTLSC STACIR Rev1Document22 pagesHTLSC STACIR Rev1Sunil RamaPas encore d'évaluation

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Document8 pagesStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderPas encore d'évaluation

- Plot Drawings Qatif Grant-1Document7 pagesPlot Drawings Qatif Grant-1Tarun AggarwalPas encore d'évaluation

- Plot DrawingsDocument6 pagesPlot DrawingsTarun AggarwalPas encore d'évaluation

- 5198ed57 8f3e 4810 B1BF B1dc8080bec7 133138Document35 pages5198ed57 8f3e 4810 B1BF B1dc8080bec7 133138Tarun AggarwalPas encore d'évaluation

- Sec Approval SwicthgearDocument1 pageSec Approval SwicthgearTarun AggarwalPas encore d'évaluation

- PDF Health - Google SearchDocument5 pagesPDF Health - Google SearchAnonymous 5cKbZBiVsPas encore d'évaluation

- Alfanar Corporate ProfileDocument11 pagesAlfanar Corporate ProfileTarun AggarwalPas encore d'évaluation

- 6613 BusProtection SC 20130912 WebDocument10 pages6613 BusProtection SC 20130912 WebTarun AggarwalPas encore d'évaluation

- 63a9b53f 633D 483a Beb5 8d0e8a7a2f0a 124156Document7 pages63a9b53f 633D 483a Beb5 8d0e8a7a2f0a 124156Tarun AggarwalPas encore d'évaluation

- GisDocument1 pageGisTarun AggarwalPas encore d'évaluation

- UpdateRequestFormV2 PDFDocument2 pagesUpdateRequestFormV2 PDFeceprincePas encore d'évaluation

- Silver Health: Get Yourself and Your Family Covered by Silver Health Today and Sleep EasyDocument2 pagesSilver Health: Get Yourself and Your Family Covered by Silver Health Today and Sleep EasyKumud GandhiPas encore d'évaluation

- SASC-S-14 Barber and Beauty Shops: Referenced Documents Listed at The End of This SectionDocument5 pagesSASC-S-14 Barber and Beauty Shops: Referenced Documents Listed at The End of This SectionTarun AggarwalPas encore d'évaluation

- Public Health Nuisances CodeDocument4 pagesPublic Health Nuisances CodeTarun AggarwalPas encore d'évaluation

- GTP of Insulator 132kV & 220kVDocument3 pagesGTP of Insulator 132kV & 220kVTarun AggarwalPas encore d'évaluation

- Good Health: Prior KnowledgeDocument52 pagesGood Health: Prior KnowledgeEldho unni varghesePas encore d'évaluation

- Kema Ageing Test 5000 Hrs.Document12 pagesKema Ageing Test 5000 Hrs.Tarun AggarwalPas encore d'évaluation

- SaudiDocument52 pagesSaudiTarun AggarwalPas encore d'évaluation

- 1luj000003 Ble 3phpadDocument12 pages1luj000003 Ble 3phpadJose CamachoPas encore d'évaluation

- Silver Health: Get Yourself and Your Family Covered by Silver Health Today and Sleep EasyDocument2 pagesSilver Health: Get Yourself and Your Family Covered by Silver Health Today and Sleep EasyKumud GandhiPas encore d'évaluation

- Data Logger SystemDocument18 pagesData Logger SystemTarun AggarwalPas encore d'évaluation

- Drawing 132kV-70 KN Polymeric InsulatorDocument1 pageDrawing 132kV-70 KN Polymeric InsulatorTarun AggarwalPas encore d'évaluation

- Electrical Monitor April 2014-1200kV Transmission LineDocument8 pagesElectrical Monitor April 2014-1200kV Transmission LinejothipriyadPas encore d'évaluation

- 33 KV Isolator FoundationDocument1 page33 KV Isolator FoundationTarun AggarwalPas encore d'évaluation

- 1luj000003 Ble 3phpadDocument12 pages1luj000003 Ble 3phpadJose CamachoPas encore d'évaluation

- Data Logger SystemDocument18 pagesData Logger SystemTarun AggarwalPas encore d'évaluation

- Switchgear Selection and Application Guide SiemensDocument52 pagesSwitchgear Selection and Application Guide SiemensSahapong NopcharoenPas encore d'évaluation

- GTP Acsr Zebra ConductorDocument3 pagesGTP Acsr Zebra ConductorTarun Aggarwal100% (1)

- ISRO Hypersonic Programs ExploredDocument8 pagesISRO Hypersonic Programs ExploredudhayPas encore d'évaluation

- 2016 12 02 (I Iib) TDocument31 pages2016 12 02 (I Iib) TnsiyamPas encore d'évaluation

- EE Student Resume - Glenn S. BacorroDocument2 pagesEE Student Resume - Glenn S. BacorroglennPas encore d'évaluation

- Template Copyright Transfer AgreementDocument2 pagesTemplate Copyright Transfer AgreementRatriKiranaPrabaningtyasPas encore d'évaluation

- Ds Jh15t17mmd XXX AxxxDocument2 pagesDs Jh15t17mmd XXX Axxxbbbru1Pas encore d'évaluation

- Model:: AE4425Y-GS1ADocument8 pagesModel:: AE4425Y-GS1AEvandro Jva compressoresPas encore d'évaluation

- McBride Iptv N44 PDFDocument117 pagesMcBride Iptv N44 PDFimamrockPas encore d'évaluation

- CFD On HPLCDocument8 pagesCFD On HPLCAshutosh Nath DevaPas encore d'évaluation

- Perl File Handles and I/O TutorialDocument17 pagesPerl File Handles and I/O TutorialYashaswi Venkat NerellaPas encore d'évaluation

- Research MKT 426 FinalDocument13 pagesResearch MKT 426 FinalkemimahamudPas encore d'évaluation

- Hackdecoders - Book by Hitesh MalviyaDocument132 pagesHackdecoders - Book by Hitesh MalviyaNikola StanišićPas encore d'évaluation

- Seat & Seat Bar - S185Document2 pagesSeat & Seat Bar - S185Eider Arturo Garcia OsorioPas encore d'évaluation

- Datasheet LD1117AGDocument15 pagesDatasheet LD1117AGAnand MugalePas encore d'évaluation

- The FlowTube SystemDocument170 pagesThe FlowTube SystemSalvador Parra FernandezPas encore d'évaluation

- FIRE Protection-BOQ R1Document62 pagesFIRE Protection-BOQ R1Santanu MitraPas encore d'évaluation

- Kerry George ResumeDocument3 pagesKerry George ResumemomnpopPas encore d'évaluation

- Sika Padding MortarDocument2 pagesSika Padding MortarKanapol KaewdangPas encore d'évaluation

- ConstructionCatalog2015Document44 pagesConstructionCatalog2015racing.phreakPas encore d'évaluation

- Infineon DT97 3 ART v01 - 00 EN PDFDocument6 pagesInfineon DT97 3 ART v01 - 00 EN PDFkongPas encore d'évaluation

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFSyed Abdul Rawoof100% (2)

- Bank HSBC LTD Atm Card Payment NoticeDocument3 pagesBank HSBC LTD Atm Card Payment NoticeGiriDharan100% (1)

- Allview AX4Document96 pagesAllview AX4Tiberiu IonescuPas encore d'évaluation

- SWMS Surface Condenser WeldingDocument11 pagesSWMS Surface Condenser WeldingPeter AntonyPas encore d'évaluation

- FOIA Appeal WTC 7 Solomon Brothers Building South Side Photos and Video On 911Document23 pagesFOIA Appeal WTC 7 Solomon Brothers Building South Side Photos and Video On 911peterbadgely100% (1)

- Technician Training Needs Analysis at Renault Nissan Automotive IndiaDocument10 pagesTechnician Training Needs Analysis at Renault Nissan Automotive IndiahariPas encore d'évaluation

- Fortigate Managing Devices 60 PDFDocument14 pagesFortigate Managing Devices 60 PDFPrakash RayPas encore d'évaluation

- Library GC Cuny EduDocument2 pagesLibrary GC Cuny Edudorothea333Pas encore d'évaluation

- Install Mikhmon Dan Mikbotam Pada STB (Hg860p b860h) ArmbianDocument2 pagesInstall Mikhmon Dan Mikbotam Pada STB (Hg860p b860h) Armbianhuda33% (3)

- OSI: Physical LayerDocument36 pagesOSI: Physical LayerShai JavierPas encore d'évaluation

- Super Series Digital Torque Wrenches Technical SpecificationDocument3 pagesSuper Series Digital Torque Wrenches Technical SpecificationJulian Andrés Garcia SánchezPas encore d'évaluation