Académique Documents

Professionnel Documents

Culture Documents

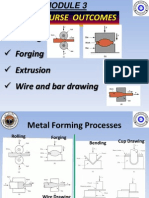

Metal Forming Processes

Transféré par

Prateek MadaanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metal Forming Processes

Transféré par

Prateek MadaanDroits d'auteur :

Formats disponibles

METAL FORMING

PROCESSES

BY PRATEEK MADAAN

CONTENTS

INTRODUCTION

PRIMARY METAL FORMING PROCESSES

ROLLING

CHANGE IN GRAIN STRUCTURE IN ROLLING

SALIENT POINTS ABOUT ROLLING

PRESSURE DURING ROLLING

ROLL CONFIGURATIONS IN ROLLING MILLS

FORGING

OPEN AND CLOSED DIE FORGING

GAIN ORIENTATION IN FORGING

INTRODUCTION

Practically all the metals which are not used in the cast

form are reduced to some standard shapes for the

subsequent processing.

Manufacturing companies producing metals supply metals

in the form of ingots which are obtained by casting liquid

metal into a square cross section.

Sometimes continuous casting methods are also used to

cast the liquid metals into slabs , billets or blooms.

These shapes are further processed through hot rolling,

forging or the extrusion, to produce the materials in their

standard form such as plates, sheets, rods, tubes and

structural sections

Primary metal forming

processes

Rolling

Forging

Extrusion

Tube and wire drawing

Deep drawing

Although punching and blanking operations

are not metal forming processes, however

these will be covered due to similarity with

deep drawing processes.

ROLLING

Change in the grain structure in

rolling

SALIENT POINTS ABOUT ROLLING

Rolling is the most extensively used metal forming process and

its share is roughly 90 %.

The material to be rolled is drawn by the means of the friction

into the two revolving roll gap.

The compressive forces applied by the rolls reduce the

thickness of the material or changes its cross section area.

The geometry of the product depend on the contour of the roll

gap.

Roll materials are cast iron, cast steel and forged steel because

of high strength and the wear resistance requirements.

Hot rolls are generally rough so that they can bite the work,

and cold rolls are grounded and polished for good finish.

In rolling the crystals get elongated in the rolling direction. In cold

rolling the crystal more or less retain the elongated shape but in hot

rolling they start reforming after coming out from the deformation

zone.

The peripheral velocity of rolls at entry exceeds that of the strip,

which is dragged in if the interface friction is high enough.

In the deformation zone the thickness of the strip gets reduced and it

elongates. This increases the linear speed of the rolls at the exit.

Thus there exists a neutral point where roll speed and the strip

speeds are equal. At this point the direction of the friction reverses.

When the angle of the contact W exceeds the friction angle Q the roll

cannot draw fresh strip.

Roll torque, power etc. increase with increase in roll work contact

length or the roll radius.

Pressure during rolling

Typical pressure variation along the

contact length in flat rolling. The

peak pressure is located at the

neutral point. The area beneath the

curve represents the roll force.

Friction in rolling: It depends on

lubrication, work material and also

on the temperature. In the cold

working, the value of the coefficient

of friction is around 0.1 and in hot

working it is around 0.2. In hot

rolling it is around 0.4. In hot rolling

the sticking friction condition is also

seen and then the coefficient of

friction is observed upto 0.7. In

sticking the hot surface adheres to

roll and thus the central part of the

strip undergoes severe deformation.

Roll Passes to get a 12 mm rod from

100 x 100 mm billet

Roll Configurations in Rolling

Mills

Two -high and three- high rolling mills are

generally used for initial and intermediate

passes during the hot rolling, while fourhigh and cluster mills are used for the

final passes.

Last two arrangements are preferred for

the cold rolling because roll in these

configurations are supported by back-up

rolls which minimise the deflections and

produce better tolerances.

Various Roll Configurations (a) Two

high (b) Three high (c) Three high

(d) Cluster mill (e) Tandem mill

Other deformation processes

related to rolling

FORGING

Forging is perhaps the oldest metal working process and was

known even during the pre-historic days when metallic tools were

made by heating and hammering.

Forging basically involves the plastic deformation of the material

between two dies to achieve the desired configuration. Depending

upon the complexity of the part, forging is carried out as open die

forging and the closed die forging.

In open die forging, the metal is compressed by repeated blows by

a mechanical hammer and shape is manipulated manually.

In closed die forging, the desired configuration is obtained by

squeezing the workpiece between two shaped and closed dies

On squeezing the die cavity gets completely filled and the excess

material comes out around the periphery of the die as flash which

is later trimmed.

Press forging and drop forging are the two popular methods in

closed die forging.

In press forging the metal is squeezed slowly by a hydraulic or

mechanical press and the component is produced in a single

Open and closed die forging and

grain orientation in forging

FORGING

MACHINING

Vous aimerez peut-être aussi

- Hot Cold WorkingDocument40 pagesHot Cold Workingpatel ketanPas encore d'évaluation

- Excel Sheet For Price CalculationDocument8 pagesExcel Sheet For Price CalculationMichael AgnaelPas encore d'évaluation

- Aircraft ToolsDocument98 pagesAircraft ToolsAdrian Aquino100% (3)

- Metal Forming ProcessesDocument40 pagesMetal Forming ProcessesRyat AtmadjaPas encore d'évaluation

- QUEST® Parts List PDFDocument332 pagesQUEST® Parts List PDFMontserrat GuPas encore d'évaluation

- 10 Types of Fasteners ExplainedDocument16 pages10 Types of Fasteners Explainedrecep1Pas encore d'évaluation

- Rolling FundamentalsDocument20 pagesRolling FundamentalsJo100% (6)

- 1 - Rolling of Metals Flat Rolling and Shape RollingDocument29 pages1 - Rolling of Metals Flat Rolling and Shape RollingThulasi RamPas encore d'évaluation

- Extrusión-Rolling and Forming ProcessDocument50 pagesExtrusión-Rolling and Forming Processquiron2010Pas encore d'évaluation

- What Is Stellite SteelDocument11 pagesWhat Is Stellite SteelRathnakrajaPas encore d'évaluation

- ZZ - Electricity & MagnetismDocument137 pagesZZ - Electricity & Magnetismvenkyrocker777750% (4)

- Forging: Shaping Metal Through CompressionDocument81 pagesForging: Shaping Metal Through CompressionsuneethaPas encore d'évaluation

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkD'EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkPas encore d'évaluation

- Rolling: Metal Working ProcessDocument63 pagesRolling: Metal Working ProcessRohit SinghalPas encore d'évaluation

- General Exercise Questions API 1104 160708Document14 pagesGeneral Exercise Questions API 1104 160708Tarek Yehia100% (2)

- Metal Forming Processes GuideDocument32 pagesMetal Forming Processes GuideWalid DamoniPas encore d'évaluation

- Versatile Router Table Handles Any Cutting TaskDocument6 pagesVersatile Router Table Handles Any Cutting Taskpvm_manu100% (3)

- Metal FormingDocument40 pagesMetal Formingsreeeram100% (1)

- Unit - Iii: Metal Forming ProcessesDocument63 pagesUnit - Iii: Metal Forming ProcessesRohith RoPas encore d'évaluation

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsD'EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsPas encore d'évaluation

- DIN 915 EN-1980 Hexagon Socket Set Screws With Dog PointDocument4 pagesDIN 915 EN-1980 Hexagon Socket Set Screws With Dog Pointthachpn100% (1)

- RollingDocument22 pagesRollingSahil JhambPas encore d'évaluation

- Wire Drawing Shearing Processes FinalDocument19 pagesWire Drawing Shearing Processes FinalJairam AtluriPas encore d'évaluation

- Metal RollingDocument22 pagesMetal RollingNishith100% (2)

- DIN and ISO Technical Standards for Mechanical FastenersDocument11 pagesDIN and ISO Technical Standards for Mechanical FastenersGökhan AnliPas encore d'évaluation

- Causes of Casting Defects With RemediesDocument6 pagesCauses of Casting Defects With RemediesKavita KalePas encore d'évaluation

- Machining Rule of ThumbDocument2 pagesMachining Rule of ThumbKamlesh DalavadiPas encore d'évaluation

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesD'EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesPas encore d'évaluation

- Jharkhand Steel Casting CompaniesDocument6 pagesJharkhand Steel Casting CompaniesCatherine Jovita50% (2)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyD'EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyPas encore d'évaluation

- Metal Forming Processes and TechniquesDocument19 pagesMetal Forming Processes and TechniquesAtulPas encore d'évaluation

- Lecture 05 (Metal Forming Processes)Document37 pagesLecture 05 (Metal Forming Processes)Mubashar ZahidPas encore d'évaluation

- BMP - (Class 18 - Class-23) - Metal FormingDocument58 pagesBMP - (Class 18 - Class-23) - Metal FormingAsesh PramanikPas encore d'évaluation

- L5 - Ta201p (05.07.2021)Document84 pagesL5 - Ta201p (05.07.2021)quick winnerPas encore d'évaluation

- Bulk Deformation Processes in MetalworkingDocument147 pagesBulk Deformation Processes in MetalworkingHassanPas encore d'évaluation

- L8 - Bulk Deformation ProcessingDocument70 pagesL8 - Bulk Deformation ProcessingAstha PantPas encore d'évaluation

- FormingDocument70 pagesFormingarya ladhaniPas encore d'évaluation

- Hot and Cold Working of MetalsDocument20 pagesHot and Cold Working of MetalsVitthal GawhalePas encore d'évaluation

- Manufacturing Process 1 2Document70 pagesManufacturing Process 1 2MD Al-Amin100% (1)

- Chapter 3 Metal Forming ProcessesDocument103 pagesChapter 3 Metal Forming Processesdagimawgchew777Pas encore d'évaluation

- Teknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Document62 pagesTeknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Aszhari AszhariPas encore d'évaluation

- Rolling of Metals Rolling of MetalsDocument22 pagesRolling of Metals Rolling of MetalsRamuliu SelcuPas encore d'évaluation

- Casting, Rolling, Forging, ExtrusionDocument60 pagesCasting, Rolling, Forging, ExtrusionHARIKRISHNAN SRPas encore d'évaluation

- Manufacturing Technology forging and extrusion processesDocument41 pagesManufacturing Technology forging and extrusion processesBrandonPas encore d'évaluation

- Lecture 7 - Common Manufacturing Processes IIDocument41 pagesLecture 7 - Common Manufacturing Processes IIKamal SurenPas encore d'évaluation

- Metal RollingDocument22 pagesMetal RollingNesaralamPas encore d'évaluation

- Unit Iii Bulk Processes Bulk DeformationDocument77 pagesUnit Iii Bulk Processes Bulk DeformationAkash akPas encore d'évaluation

- Unit III - Bulk Deformation ProcessesDocument48 pagesUnit III - Bulk Deformation ProcessesRavitej SuraparajuPas encore d'évaluation

- ExtrusionDocument28 pagesExtrusionAkash SavaliyaPas encore d'évaluation

- Rolling of MetalsDocument22 pagesRolling of MetalsKush DewanganPas encore d'évaluation

- MFG II 3182 Chapter 1Document58 pagesMFG II 3182 Chapter 1Naol EmanaPas encore d'évaluation

- Casting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingDocument44 pagesCasting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingRaj PatelPas encore d'évaluation

- Ch13 Rolling Fall 2021 021021Document29 pagesCh13 Rolling Fall 2021 021021Moustapha MneimnehPas encore d'évaluation

- Rolling of MetalsDocument22 pagesRolling of MetalsraniksrPas encore d'évaluation

- Chapter 3 Metal Forming Rev1Document42 pagesChapter 3 Metal Forming Rev1Dinie Zulhusni ArsadPas encore d'évaluation

- Forging Processes GuideDocument51 pagesForging Processes GuideShovan KarmakarPas encore d'évaluation

- Processes Used To Form Metallic MaterialsDocument23 pagesProcesses Used To Form Metallic MaterialsHimanshu GuptaPas encore d'évaluation

- ManufacturingDocument38 pagesManufacturingKunal KapurPas encore d'évaluation

- Unit-2 (1) MPDocument70 pagesUnit-2 (1) MPVishvas SinghhPas encore d'évaluation

- 5 Rolling ProcessDocument48 pages5 Rolling ProcessPratik GhoshPas encore d'évaluation

- Metal Extrusion and Drawing Processes GuideDocument35 pagesMetal Extrusion and Drawing Processes GuideGRAHAM KUNDAI DENGEZAPas encore d'évaluation

- Extrusion ProcessDocument24 pagesExtrusion Processchris mushunjePas encore d'évaluation

- Pipe ProductionDocument22 pagesPipe ProductionPanner2009Pas encore d'évaluation

- Material Processing DefectsDocument52 pagesMaterial Processing DefectsAmeem TariqPas encore d'évaluation

- Forging Process PDFDocument15 pagesForging Process PDFSantoshPas encore d'évaluation

- Sheet Metal Processes: Forming, Bending, Punching & MoreDocument74 pagesSheet Metal Processes: Forming, Bending, Punching & MoreIcookiesPas encore d'évaluation

- Rolling MachingDocument19 pagesRolling MachingPramodPradhanPas encore d'évaluation

- Sheet Metal ProccessesDocument43 pagesSheet Metal ProccessesisharaPas encore d'évaluation

- Plastic Metal Forming of Metals and PowdersDocument20 pagesPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينPas encore d'évaluation

- Manufacturing Engineering II (ch3)Document93 pagesManufacturing Engineering II (ch3)beila.amu.22Pas encore d'évaluation

- NutonraphDocument1 pageNutonraphPrateek MadaanPas encore d'évaluation

- Javascript AdvancedDocument66 pagesJavascript AdvancedPrateek MadaanPas encore d'évaluation

- CRT Display Devices: Raster Scan vs Random ScanDocument19 pagesCRT Display Devices: Raster Scan vs Random ScanPrateek MadaanPas encore d'évaluation

- JavaScript BasicsDocument7 pagesJavaScript BasicsPrateek MadaanPas encore d'évaluation

- Simplicity Is Best Policy ofDocument1 pageSimplicity Is Best Policy ofPrateek MadaanPas encore d'évaluation

- CA FINAL AMA Nov 14 Guideline Answers 15.11.2014Document16 pagesCA FINAL AMA Nov 14 Guideline Answers 15.11.2014Prateek MadaanPas encore d'évaluation

- Jmi Engineering Entrance Exam Chemistry Solved Paper 2010Document5 pagesJmi Engineering Entrance Exam Chemistry Solved Paper 2010Prateek MadaanPas encore d'évaluation

- Simplicity Is Best PolicyDocument1 pageSimplicity Is Best PolicyPrateek MadaanPas encore d'évaluation

- 36.permanent MagnetsDocument4 pages36.permanent MagnetsRammohan MudgalPas encore d'évaluation

- Simplicity Is Best Policy ofDocument1 pageSimplicity Is Best Policy ofPrateek MadaanPas encore d'évaluation

- CBSE Class 12 Hindi Elective Exam Paper 2009 (Delhi)Document7 pagesCBSE Class 12 Hindi Elective Exam Paper 2009 (Delhi)Prateek MadaanPas encore d'évaluation

- Jmi Engineering Entrance Exam Chemistry Solved Paper 2010Document5 pagesJmi Engineering Entrance Exam Chemistry Solved Paper 2010Prateek MadaanPas encore d'évaluation

- Dispersion and SpectraDocument3 pagesDispersion and SpectraDhruv KlerPas encore d'évaluation

- Jee Advanced 2014-1 Fiit JeeDocument28 pagesJee Advanced 2014-1 Fiit JeeImranHashmiPas encore d'évaluation

- 2014 12 02 16 41 49Document21 pages2014 12 02 16 41 49Prateek MadaanPas encore d'évaluation

- Circular Motion Concepts and SolutionsDocument7 pagesCircular Motion Concepts and SolutionsAshish SoniPas encore d'évaluation

- EfluxDocument1 pageEfluxPrateek MadaanPas encore d'évaluation

- CA FINAL AMA Nov 14 Guideline Answers 15.11.2014Document16 pagesCA FINAL AMA Nov 14 Guideline Answers 15.11.2014Prateek MadaanPas encore d'évaluation

- 2014 12 02 13 17 45Document13 pages2014 12 02 13 17 45Prateek MadaanPas encore d'évaluation

- 2014 12 02 17 18 45Document17 pages2014 12 02 17 18 45Prateek MadaanPas encore d'évaluation

- Android TechnologyDocument16 pagesAndroid TechnologyPrateek MadaanPas encore d'évaluation

- Hots A Necessity 2008Document3 pagesHots A Necessity 2008Neeraj RaushanPas encore d'évaluation

- 2014 12 02 16 41 49Document21 pages2014 12 02 16 41 49Prateek MadaanPas encore d'évaluation

- JPT 3 Classroom JEE Adv 26-05-2013 C 0 Sol EnglishDocument12 pagesJPT 3 Classroom JEE Adv 26-05-2013 C 0 Sol EnglishanuragpagariaPas encore d'évaluation

- Aiot Jee Adv Sol Eng 05-05-2013Document16 pagesAiot Jee Adv Sol Eng 05-05-2013Prateek MadaanPas encore d'évaluation

- ALP Solutions Electro Chemistry Chemistry English JEE JPDocument11 pagesALP Solutions Electro Chemistry Chemistry English JEE JPPrateek MadaanPas encore d'évaluation

- Runge-Kutta Type Integration Formulas Including The Evaluation of The Second DerivativeDocument40 pagesRunge-Kutta Type Integration Formulas Including The Evaluation of The Second DerivativePrateek MadaanPas encore d'évaluation

- 2013 PaperDocument14 pages2013 PaperPrasada RaoPas encore d'évaluation

- NC NF NefDocument4 pagesNC NF Nefgeav25653855Pas encore d'évaluation

- Working With Boron Steel NovDec 2005Document4 pagesWorking With Boron Steel NovDec 2005Hugo MoraisPas encore d'évaluation

- Daily Eng Ref TablesDocument26 pagesDaily Eng Ref TablesPalaPas encore d'évaluation

- Mead Steel Comparison GuideDocument14 pagesMead Steel Comparison GuideM Usman RiazPas encore d'évaluation

- Workshop - Objective - QuestionsDocument2 pagesWorkshop - Objective - Questionsविशाल पुडासैनीPas encore d'évaluation

- HW 5 - Me 406-152 Plus SolutionDocument3 pagesHW 5 - Me 406-152 Plus SolutiontrishPas encore d'évaluation

- Micro Lathe Upgrade - 7 Steps - InstructablesDocument16 pagesMicro Lathe Upgrade - 7 Steps - Instructables宛俊Pas encore d'évaluation

- Makita Acc-Cat 2019 20 View V1Document176 pagesMakita Acc-Cat 2019 20 View V1Himanshu GajjarPas encore d'évaluation

- Gmaw WQTDocument23 pagesGmaw WQTDera LesmanaPas encore d'évaluation

- Past Year Machine ToolDocument21 pagesPast Year Machine ToolKif KimiPas encore d'évaluation

- Introduction As FoundryDocument10 pagesIntroduction As FoundrySunil BajpaiPas encore d'évaluation

- Department of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIDocument22 pagesDepartment of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIswarup babalsurePas encore d'évaluation

- ISO15787en - 0112 - Technical Product Documentation - Heattreated Ferrous Parts - Presentation and IndicationsDocument36 pagesISO15787en - 0112 - Technical Product Documentation - Heattreated Ferrous Parts - Presentation and IndicationskarthisekarPas encore d'évaluation

- CNC Programming BasicsDocument53 pagesCNC Programming Basicspramod ChougulePas encore d'évaluation

- Inventario Consumibles LaboratorioDocument8 pagesInventario Consumibles Laboratoriocamilo molanoPas encore d'évaluation

- Request for Steel Structure InspectionDocument4 pagesRequest for Steel Structure InspectionEngr Saeed AnwarPas encore d'évaluation

- How to Design Strippers in 15 Characters or LessDocument33 pagesHow to Design Strippers in 15 Characters or Lessmahdi sakhaeePas encore d'évaluation

- 2 Numericals Bank MP II PDFDocument7 pages2 Numericals Bank MP II PDFThenarasumohanveluPas encore d'évaluation