Académique Documents

Professionnel Documents

Culture Documents

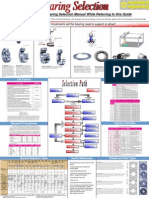

What Loads or Movements Will The Bearing Need To Support or Allow?

Transféré par

SarvagnaMNTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

What Loads or Movements Will The Bearing Need To Support or Allow?

Transféré par

SarvagnaMNDroits d'auteur :

Formats disponibles

Please Reference Bearing Selection Manual While Referring to this Guide

There are many types of bearings, each used for different purposes. These include ball bearings, roller bearings, ball thrust bearings, roller thrust bearings, tapered roller thrust bearings and linear bearings.

What loads or movements will the bearing need to support or allow?

In a ball bearing, the load is

transmitted from the outer race to the

ball, and from the ball to the inner

race. Since the ball is a sphere, it

only contacts the inner and outer race

at a very small point, which helps it

spin very smoothly. But it also means

that there is not very much contact

area holding that load, so if the

bearing is overloaded, the balls can

deform or squish, ruining the bearing.

Roller bearings like the one illustrated

above are used in applications like conveyer

belt rollers, where they must hold heavy

radial loads. In these bearings, the roller is a

cylinder, so the contact between the inner

and outer race is not a point but a line. This

spreads the load out over a larger area,

allowing the bearing to handle much greater

loads than a ball bearing. However, this type

of bearing is not designed to handle much

thrust loading.

Tapered roller bearings are used in car hubs, where they

are usually mounted in pairs facing opposite directions so

that they can handle thrust in both directions.

Roller thrust bearings like the one illustrated

below can support large thrust loads. They are

often found in gear sets like car transmissions

between gears, and between the housing and the

rotating shafts. The helical gears used in most

transmissions have angled teeth -- this causes a

thrust load that must be supported by a bearing.

Ball thrust bearings like the one

shown below are mostly used for

low-speed applications and

cannot handle much radial load.

Barstools and Lazy Susan

turntables use this type of

bearing.

Life Factors

Linear bearings are used primarily where something needs to be moved along a straight line with

high accuracy. In other words, the object needs to only translate in one direction, and possibly move

back to its starting position with high repeatability. The implications for robotic pick-and-place are

obvious, as are uses for optical test fixturing and calibration.

Fit Tolerances

What You Know or

Need to Know

Selection

What Kinds of Loads

are Present?

Maximum Static and

Dynamic Loads

Bearing Life

Expectancy

Suitable Range of Bearing Sizes

determined

The life of a rolling element bearing depends to a large extent on the smoothness of the

contacting surfaces the balls, rollers, and races. Typical surface roughness dimensions for

production bearings are as follows:

Balls 2 3 in. rms

Ball races 610 in. rms

Rollers 812 in. rms

Roller races 1020 in. rms

These are in terms of micro-inches or millionths of an inch.The unit of measurement of the

surface roughness is rms which stands for root-mean-square height. This value is obtained

by drawing a diamond point instrument over the surface with a magnified readout. These

measurements are taken at equidistant points on the profile, squaring these values, adding

them, dividing the sum by the number of readings taken and taking the square root of this

average.

Final Bearing Size Selected.

Allowable Space

(Shaft or Housing)

Material Selection of Bearing

Operating Environment

(Dust, Corrosions, etc.)

General PV Guidelines

Typical Lubricants

Closure type Determined

(Shield or Seal)

Rotational Performance

(Runout, Perpendicularity, etc)

Torque Requirements

ABEC/RBEC Grade Determined

Mounting Method- Fits

(Bearing Tolerances)

(Tolerances Needed)

Radial Play Determined

Assembly Characters

(Bearing Geometry Selection)

(Preload, Stiffness, Contact angle)

Lubrication Type

Operating Temperature,

Lubricant Life

Noise?

Rotational Speed

Final Bearing

-www.3Dcontentcentral.com

- Mechanical Engineering Design 5th

Edition, Shigley and Mischke

-www.howstuff works.com

-www.skf.com

-www.dynaroll.com/bearing-selection

-If you are going to incorporate bearings

into your solid modeling this website

provides free SolidWorks Downloads of

different bearings. They can be found

under the CAD Data icon :

http://www.tec.nsk.com/

ZS TYPE SHIELD The ZS shield is identical to the fixed Z type shield, except that it

is retained by an external snap wire that locates in a groove inside the rim of the

bearing outer race. This is only an advantage if the user needs to remove the shield

after manufacture of the bearing.

TS TYPE SEAL The TS type seal is made from glass-reinforced Teflon. It is

retained by an external snap wire to the bearing outer ring, but also lightly

contacts the inner race land. This gives a high degree of protection from

contamination, with a modest increase in torque.

D TYPE SEAL The D type seal consists of a molded Buna-N rubber lip seal

with a steel insert. This provides maximum protection to the bearing against

outside contamination. However, the high pressure of the lip seal itself results

in greatly increased torque and friction losses that can cause heat build-up in

higher speed applications. The seal material itself is rated to a maximum of

250 F. This type of seal is only available for larger-sized bearings (R3 and

above)

Single Shield - Code Z

Double Shield - Code ZZ

-Quality Bearing and Components

Catalog B605

Z TYPE SHIELD This is the most common type of shield. It is non-removable, being

permanently staked to the bearing outer race with a small gap of approximately .

005 inches between the inside diameter of the shield and the bearing inner ring.

Since there is no contact with the inner ring, the torque and speed limitations are

virtually unaffected and the performance of the bearing is almost identical to that of

an open bearing. Standard material is 300 series stainless steel. Plastic fixed

shields are also available on a limited basis. Most Dynaroll shielded bearings have

metal Z type shields.

Single Shield - Code ZS

Double Shield - Code ZZS

-Bearing Selection Guide (Found in Mind

Works)

Shields and Seal Types

Single Seal - Code TS

Double Seal - Code TTS

Useful References

Single Seal - Code D

Double Seal - Code DD

General Selection Table

Vous aimerez peut-être aussi

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionD'EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionPas encore d'évaluation

- General Bearing Basics: SKF NotesDocument37 pagesGeneral Bearing Basics: SKF NotesVinod Varadan SPas encore d'évaluation

- Chapter 4 Bearing PDFDocument41 pagesChapter 4 Bearing PDFMaitri ViratPas encore d'évaluation

- 1 3 Rolling Contact Bearings RNR 25012021Document31 pages1 3 Rolling Contact Bearings RNR 25012021potnuru Jaivanth100% (1)

- Basic Rolling Bearing TechnologyDocument75 pagesBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreD'EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MorePas encore d'évaluation

- Ball Bearing Classification PDFDocument5 pagesBall Bearing Classification PDFshihabjamaan50% (2)

- Bearing SelectionDocument5 pagesBearing SelectionSantosh Kumar VishwakarmaPas encore d'évaluation

- Roller BearingsDocument58 pagesRoller BearingsNuruzzaman SakiPas encore d'évaluation

- Bearing CalculationDocument11 pagesBearing CalculationKishor Kumar Vishwakarma100% (1)

- BearingDocument18 pagesBearingraghav_bhatt8817100% (1)

- Bearing SelectionDocument5 pagesBearing SelectionMujibul AnamPas encore d'évaluation

- BearingsDocument16 pagesBearingsayush100% (2)

- Bearing Instal at Ion and Maintenance GuideDocument130 pagesBearing Instal at Ion and Maintenance GuideTeodoru Horia Adrian75% (4)

- FAG - Mounting and Dismounting of Rolling BearingsDocument114 pagesFAG - Mounting and Dismounting of Rolling BearingsCagatay Tulunay100% (1)

- Condition Monitoring EssentialsDocument44 pagesCondition Monitoring Essentials4358213100% (2)

- Centrifugal Pumps Bearings - Part 1Document23 pagesCentrifugal Pumps Bearings - Part 1visitabhinav80% (5)

- Hydrodynamic BearingsDocument14 pagesHydrodynamic BearingsShobhit MishraPas encore d'évaluation

- Bearing HandbookDocument92 pagesBearing HandbookFarhan TalibPas encore d'évaluation

- Industrial Shaft Seals PDFDocument308 pagesIndustrial Shaft Seals PDFFabiano RogérioPas encore d'évaluation

- Rolling Contact BEARINGS - Part1: ME 308 Machine Elements IiDocument58 pagesRolling Contact BEARINGS - Part1: ME 308 Machine Elements Iixxx100% (1)

- Root Cause Failure Analysis - BearingDocument117 pagesRoot Cause Failure Analysis - BearingFaisal Tariq100% (6)

- Hydraulic Troubleshooting GuideDocument9 pagesHydraulic Troubleshooting Guideusamaperwez100% (1)

- Ball BearingDocument112 pagesBall BearingJyotibaraje Jadhav100% (1)

- 2 - Rolling Bearing FundamentalsDocument35 pages2 - Rolling Bearing FundamentalsZiggy Gregory100% (1)

- Bearing Basic KnowledgeDocument16 pagesBearing Basic KnowledgeRizaaaPas encore d'évaluation

- Basic Knowledge of Koyo BearingsDocument34 pagesBasic Knowledge of Koyo BearingsJinto A JPas encore d'évaluation

- UBC Guide To BearingsDocument44 pagesUBC Guide To BearingsVirgilioPas encore d'évaluation

- Ener Pac CylindersDocument56 pagesEner Pac Cylindersirac_69Pas encore d'évaluation

- Bearing For Industrial GearboxDocument32 pagesBearing For Industrial Gearboxabhipraya01Pas encore d'évaluation

- Understanding Mechanical SealsDocument42 pagesUnderstanding Mechanical SealsMUHAMMAD SOHAIB UR REHMANPas encore d'évaluation

- Evaluation of Tilting Pad Thrust BearingsDocument10 pagesEvaluation of Tilting Pad Thrust BearingsChristopher Garcia0% (1)

- Basic Knowledge For Using Bearings SafelyDocument40 pagesBasic Knowledge For Using Bearings SafelypibearingPas encore d'évaluation

- Vibration Analysis: Predictive Technologies PDM TechniquesDocument26 pagesVibration Analysis: Predictive Technologies PDM TechniquesShouqi ErmanPas encore d'évaluation

- Sliding Contact and Rolling Contact BearingDocument45 pagesSliding Contact and Rolling Contact BearingorgasandreyPas encore d'évaluation

- Laser AlignmentDocument187 pagesLaser AlignmentEhsanPas encore d'évaluation

- Maintenance Presentation SlideDocument56 pagesMaintenance Presentation Slidekapun kumar nayakPas encore d'évaluation

- Couplings - A Basic Introduction To Different Types of CouplingsDocument38 pagesCouplings - A Basic Introduction To Different Types of CouplingsMohsin MurtazaPas encore d'évaluation

- 5892 - Timken Bearing Damage Analysis PDFDocument36 pages5892 - Timken Bearing Damage Analysis PDFedgarpol100% (1)

- Rotary CompressorsDocument113 pagesRotary Compressorsamrutnerlikar80% (5)

- Bearing Failure AnalysisDocument54 pagesBearing Failure AnalysisFaisal Tariq100% (2)

- Applications of Hydraulics&Pneumatics: Session 6Document12 pagesApplications of Hydraulics&Pneumatics: Session 6Zippygroup ZsgPas encore d'évaluation

- Bearings: - What Is BearingDocument22 pagesBearings: - What Is BearingRizwan Bangash50% (2)

- Ludeca Best Practices Machinery Alignment ShimmingDocument7 pagesLudeca Best Practices Machinery Alignment ShimmingTimber RamPas encore d'évaluation

- 08-Sundyne Presentation - Fs Installation1Document15 pages08-Sundyne Presentation - Fs Installation1joseellargo100% (1)

- Renk MaagDocument12 pagesRenk MaagDhananjay B KPas encore d'évaluation

- AYCCL-Bearing PresentationDocument74 pagesAYCCL-Bearing PresentationKashif Muhammad100% (1)

- Note Bearing PDFDocument77 pagesNote Bearing PDFفايق العرودPas encore d'évaluation

- Mechanical Seal Presentation (2009)Document28 pagesMechanical Seal Presentation (2009)LelosPinelos123100% (5)

- Motor Installation and Maintenance ManualDocument23 pagesMotor Installation and Maintenance ManualVenkat CherukuriPas encore d'évaluation

- Belt Preventive Maintenance ManualDocument67 pagesBelt Preventive Maintenance ManualAbdulrahman AlkhowaiterPas encore d'évaluation

- Timken Thrust and Plain Bearings CatalogDocument140 pagesTimken Thrust and Plain Bearings CatalogAdam GordonPas encore d'évaluation

- Rotodynamic PumpsDocument537 pagesRotodynamic Pumpsadelnaftec100% (10)

- BearingDocument1 pageBearingproxywarPas encore d'évaluation

- What Loads or Movements Will The Bearing Need To Support or Allow?Document1 pageWhat Loads or Movements Will The Bearing Need To Support or Allow?subhampce085Pas encore d'évaluation

- Section 5Document80 pagesSection 5pattan madhuPas encore d'évaluation

- Fundamentals of Bearings and SealsDocument26 pagesFundamentals of Bearings and SealscarlHoughPas encore d'évaluation

- Motor Bearings - ABBDocument8 pagesMotor Bearings - ABBhozipek5599100% (1)

- Kami Export - Rolling Element Bearing-16!9!21Document38 pagesKami Export - Rolling Element Bearing-16!9!21Dr Atul WaghmarePas encore d'évaluation

- Bbasics TranscriptDocument12 pagesBbasics TranscriptjoshuaPas encore d'évaluation

- 61 1 Story Content External Files 2.AdvanceFilterDocument3 pages61 1 Story Content External Files 2.AdvanceFilterSharika AkhtarPas encore d'évaluation

- Class X Kannada Social Science Geography10Document6 pagesClass X Kannada Social Science Geography10SarvagnaMNPas encore d'évaluation

- 61 1 Story Content External Files 16.billDocument17 pages61 1 Story Content External Files 16.billSarvagnaMNPas encore d'évaluation

- 61 1 Story Content External Files 16.masterDocument3 pages61 1 Story Content External Files 16.masterSarvagnaMNPas encore d'évaluation

- Class X Kannada Social Science Geography11Document4 pagesClass X Kannada Social Science Geography11SarvagnaMNPas encore d'évaluation

- Class X Kannada Social Science Geography11Document4 pagesClass X Kannada Social Science Geography11SarvagnaMNPas encore d'évaluation

- Class X Kannada Social Science Geography12Document5 pagesClass X Kannada Social Science Geography12SarvagnaMNPas encore d'évaluation

- Class X Kannada Social Science Geography09Document5 pagesClass X Kannada Social Science Geography09SarvagnaMNPas encore d'évaluation

- BearingDocument3 pagesBearingSarvagnaMNPas encore d'évaluation

- Class X Kannada Social Science Geography02Document5 pagesClass X Kannada Social Science Geography02SarvagnaMNPas encore d'évaluation

- Class X Kannada Social Science Geography07Document10 pagesClass X Kannada Social Science Geography07SarvagnaMNPas encore d'évaluation

- Class X Kannada Social Science Geography08Document8 pagesClass X Kannada Social Science Geography08SarvagnaMNPas encore d'évaluation

- General ThingsDocument4 pagesGeneral ThingsSarvagnaMNPas encore d'évaluation

- BearingDocument3 pagesBearingSarvagnaMNPas encore d'évaluation

- 1st Pad 4th LineDocument1 page1st Pad 4th LineSarvagnaMNPas encore d'évaluation

- 1st Pad 1st LineDocument1 page1st Pad 1st LineSarvagnaMNPas encore d'évaluation

- Notification AMD Technical Officer Scientist and Other PostsDocument8 pagesNotification AMD Technical Officer Scientist and Other PostsRajvardhan JaidevaPas encore d'évaluation

- New Microsoft Office Excel WorksheetDocument11 pagesNew Microsoft Office Excel WorksheetSarvagnaMNPas encore d'évaluation

- Instructions Regarding Written Test Pattern: SL - No. Post Examination PatternDocument1 pageInstructions Regarding Written Test Pattern: SL - No. Post Examination PatternSarvagnaMNPas encore d'évaluation

- 1st Pad 3rd LineDocument1 page1st Pad 3rd LineSarvagnaMNPas encore d'évaluation

- For Pad - 1Document9 pagesFor Pad - 1SarvagnaMNPas encore d'évaluation

- For Pad - 4Document9 pagesFor Pad - 4SarvagnaMNPas encore d'évaluation

- For Pad - 3Document9 pagesFor Pad - 3SarvagnaMNPas encore d'évaluation

- 2.1.1. For 4 Elements 2Document6 pages2.1.1. For 4 Elements 2SarvagnaMNPas encore d'évaluation

- 2.1.1. For 4 Elements 1Document6 pages2.1.1. For 4 Elements 1SarvagnaMNPas encore d'évaluation

- 2.1.1. For 4 ElementsDocument9 pages2.1.1. For 4 ElementsSarvagnaMNPas encore d'évaluation

- 2.1.1. For 4 Elements 2Document3 pages2.1.1. For 4 Elements 2SarvagnaMNPas encore d'évaluation

- 2.1.1 For 4 ElementsDocument28 pages2.1.1 For 4 ElementsSarvagnaMNPas encore d'évaluation

- 2.1.1. For 4 Elements 1Document3 pages2.1.1. For 4 Elements 1SarvagnaMNPas encore d'évaluation

- 15 04 0662-02-004a Channel Model Final Report r1Document40 pages15 04 0662-02-004a Channel Model Final Report r1Alex Samuel Ludeña HuamaniPas encore d'évaluation

- Axisymm TutorialDocument15 pagesAxisymm Tutorialmudur6Pas encore d'évaluation

- An Analysis of US School Shooting MassacresDocument15 pagesAn Analysis of US School Shooting MassacresGargaPas encore d'évaluation

- Lpile Description SheetDocument2 pagesLpile Description SheetMed El Hadi AbidiPas encore d'évaluation

- Hw3 Chap4 SolutionDocument13 pagesHw3 Chap4 Solutioncoasterfan13100% (1)

- Bearing Capacity of Grouted and Ungrouted Recessed Ends in Hollow-Core SlabsDocument8 pagesBearing Capacity of Grouted and Ungrouted Recessed Ends in Hollow-Core SlabsFrancisco GoFlesPas encore d'évaluation

- Properties of Ideal GasesDocument32 pagesProperties of Ideal GasesdvanupklePas encore d'évaluation

- Traffic Flow Simulation by Using A Mathematical Model Based OnDocument4 pagesTraffic Flow Simulation by Using A Mathematical Model Based Onhkabir_juPas encore d'évaluation

- Physics 300 PS1Document4 pagesPhysics 300 PS1Justin ThomasPas encore d'évaluation

- Sync 4Document41 pagesSync 4Ankur SharmaPas encore d'évaluation

- Final Exam 2010 SolnDocument7 pagesFinal Exam 2010 SolnSimon AlmeidaPas encore d'évaluation

- Che323 Lecture 2 Humidification Wet BulbDocument19 pagesChe323 Lecture 2 Humidification Wet Bulbifiok100% (1)

- Laminar and Turbulent Flow, Experimental Vs Theoretical Profile in A Wind TurbineDocument12 pagesLaminar and Turbulent Flow, Experimental Vs Theoretical Profile in A Wind Turbinehamza shazibPas encore d'évaluation

- HartfordDocument7 pagesHartfordapi-443631703Pas encore d'évaluation

- DPL - EnsaioDocument14 pagesDPL - EnsaioTimothy CaldwellPas encore d'évaluation

- Lock ShimDocument3 pagesLock ShimJulie WeiPas encore d'évaluation

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aPas encore d'évaluation

- SXXa XSDocument5 pagesSXXa XSraviteja tankalaPas encore d'évaluation

- Mazane MaterialsDocument9 pagesMazane MaterialsOtsile Mos MosweuPas encore d'évaluation

- Lecture 8 Joint Forces IIDocument5 pagesLecture 8 Joint Forces IIVenkatPas encore d'évaluation

- BITS Pilani: Instructor in Charge-Dr. Kalyana Rama J SDocument23 pagesBITS Pilani: Instructor in Charge-Dr. Kalyana Rama J SSaiteja SistlaPas encore d'évaluation

- Vehicle Test Plan Apollo Mission A-004 Spacecraft 002Document160 pagesVehicle Test Plan Apollo Mission A-004 Spacecraft 002Bob AndrepontPas encore d'évaluation

- Producer TheoryDocument8 pagesProducer TheoryOmer KhayyamPas encore d'évaluation

- Pumps and Hydraulic CheckDocument67 pagesPumps and Hydraulic CheckNivas SadhasivamPas encore d'évaluation

- 10th CBSE Science-Compressed PDFDocument337 pages10th CBSE Science-Compressed PDFAbhishekPas encore d'évaluation

- Aryabhata Biography: Major WorksDocument2 pagesAryabhata Biography: Major WorksrajeshPas encore d'évaluation

- Siol Mechanics 2008JUNDocument12 pagesSiol Mechanics 2008JUNAnkit AkPas encore d'évaluation

- Catalogo General TeleH ESPDocument156 pagesCatalogo General TeleH ESPAnonymous MbqTZHLNR9Pas encore d'évaluation

- Tesla 09Document41 pagesTesla 09William NormanPas encore d'évaluation

- Syllabus For Ntse Stage 1: Offline Test Series: MaharashtraDocument1 pageSyllabus For Ntse Stage 1: Offline Test Series: MaharashtraRamakant ChaudhariPas encore d'évaluation