Académique Documents

Professionnel Documents

Culture Documents

2 Concrete

Transféré par

Yashika Bhathiya Jayasinghe0 évaluation0% ont trouvé ce document utile (0 vote)

84 vues41 pagesabncd

Copyright

© © All Rights Reserved

Formats disponibles

PPT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentabncd

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

84 vues41 pages2 Concrete

Transféré par

Yashika Bhathiya Jayasingheabncd

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 41

Concrete Structures

Introduction to design methods in reinforced

concrete

Sustainable construction is concrete

green?

Possibilities in concrete structure

Technical concepts:

-

Bending moment diagrams

Reinforced vs. prestressed concrete

Strut and tie method of design

Outline

Introduction to concrete as a material

Stresses in bending

Reinforced concrete vs. prestressed concrete

Design methods

Environmental issues

Design possibilities

Conclusions

Unreinforced Concrete

Same as masonry: it must act in compression

(no resistance to tension)

Roman Pantheon, 126 AD

Beginnings of Reinforced Concrete

Bending Stresses in a Beam

Steel Reinforcing in Concrete

Design Basis for Reinforced Concrete

Reinforced vs. Prestressed Concrete

Principles of Reinforcing

Two design methods for concrete

Conventional design:

-

Determine moment diagram

Specify steel in areas of tension

Strut and tie models:

-

Define internal forces in tension and

compression (ties and struts)

Specify steel in areas of tension

Strut and Tie Modeling

Strut and Tie Modeling

Strut and Tie Modeling

Strut and Tie Modeling

What is concrete?

Is concrete a green material?

Construction and the Environment

In the United States, buildings account for:

36% of total energy use

(65% of electricity consumption)

30% of greenhouse gas emissions

30% of raw materials use

30% of waste output (136 million tons/year)

12% of potable water consumption

-US Green Building Council (2001)

Construction Waste

US Environmental

Protection Agency (EPA)

estimates that 136 million

tons of waste is generated

by construction each year

Most results from

demolition/renovation

and nearly half the

weight is concrete

Embodied Energy per Stiffness

Energy required for concrete

Corrosion of Reinforced Concrete

Reinforced Concrete Corrosion

Corrosion of RC

In the United States, the overall costs of

reinforcing steel corrosion have been

estimated at more than $150 billion per year.

A particular problem for highway bridges

due to de-icing salts

Corrosion Prevention of RC

Simplest method: Maintain concrete in

compression and provide greater cover of

concrete over rebar

More complicated and more expensive:

-

Protect steel (with epoxy coating) or by using

stainless steel rebar

Use non-metallic reinforcing, such as carbon or

kevlar, but these materials are expensive and

energy-intensive

Structural Design in RC

Maintain concrete in compression as much

as possible

Follow moment diagram to minimize

material use

Detailed design

-

Prevent water infiltration

Protect steel

Specify use of fly ash

Recycle old concrete

Fly Ash in Concrete

Fly ash is a byproduct of coal burning: 600

million tons are produced per year and over

80% goes to the landfill

Up to 50% of cement (by volume) can be

replaced with fly ash (15-35% is typical)

Today only about 10% of available fly ashis

used in concrete

Why use fly ash in concrete?

Reduce environmental impact

Improve workability (better finish)

Increase corrosion resistance

Improve long term concrete strength

Good practice in concrete design

Consider pre-cast concrete systems which can use

considerably less concrete.

Specify fly ash, which can improve workability and

strength, as well as help to recycle waste.

Use concrete waste as fill whenever possible around

buildings or as aggregate under parking lots and

driveways.

Reduce waste through design by eliminating

unnecessary concrete (i.e. use smaller transfer

beams in the Stata Center)

Precast Planks in Concrete

Tilt-Up Concrete Construction

Hanging Model by Heinz Isler

Tension Model by Heinz Isler

Compression Model by Heinz Isler

Post-tensioned Box Grider

Greater Depth Gives Greater Stiffness

Conclusions

Concrete will continue to be a dominant

construction material

Reinforced concrete must crack in order for

reinforcing to work lower durability because

steel can corrode

Prestressed concrete prevents cracking

Two powerful design methods: moment diagrams

or strut and tie models

Environmental impact can be reduced through

design

Ecological Profile of Materials

Material Properties

Material Properties

Vous aimerez peut-être aussi

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesD'EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- 2 ConcreteDocument41 pages2 ConcretebsudhareddyPas encore d'évaluation

- 2 ConcreteDocument41 pages2 ConcreteHarish LakshminarayananPas encore d'évaluation

- Mit - BetonDocument41 pagesMit - BetonRada IoanPas encore d'évaluation

- Precast and Pre Stressed Concrete YB070120Document3 pagesPrecast and Pre Stressed Concrete YB070120Desheng LiPas encore d'évaluation

- Concrete Sustainable DevelopmentDocument10 pagesConcrete Sustainable Developmentddm145Pas encore d'évaluation

- Steel Conc. Comp. ContDocument35 pagesSteel Conc. Comp. ContDeepak SinghPas encore d'évaluation

- Reinforced Concrete Design Lecture-1-2Document32 pagesReinforced Concrete Design Lecture-1-2Harold Jackson Mtyana100% (1)

- Innovation in Composite ConstructionDocument6 pagesInnovation in Composite ConstructionnicholasPas encore d'évaluation

- Thesis: Comparison Between Steel Buildings and RCC (Reinforced Cement Concrete) BuildingsDocument9 pagesThesis: Comparison Between Steel Buildings and RCC (Reinforced Cement Concrete) BuildingsB45Raj Kumar ThakurPas encore d'évaluation

- 2022 CCC2022 Co2Document10 pages2022 CCC2022 Co2Juhász KPPas encore d'évaluation

- Composite Structure (31-38)Document48 pagesComposite Structure (31-38)Badri DadiPas encore d'évaluation

- Reinforced ConcreteDocument12 pagesReinforced ConcretehistorymakeoverPas encore d'évaluation

- Reinforcement C-WPS OfficeDocument7 pagesReinforcement C-WPS OfficeNoah Oluwatoyin AderiyikePas encore d'évaluation

- Building Green With ConcreteDocument6 pagesBuilding Green With Concretemugu12Pas encore d'évaluation

- Full-Paper 117Document10 pagesFull-Paper 117jasson.lopezPas encore d'évaluation

- ConstructionSpecifier Studcast 07Document7 pagesConstructionSpecifier Studcast 07Roberto FernandesPas encore d'évaluation

- Fibers: Reinforcement Systems For Carbon Concrete Composites Based On Low-Cost Carbon FibersDocument21 pagesFibers: Reinforcement Systems For Carbon Concrete Composites Based On Low-Cost Carbon FibersJaveria AfzalPas encore d'évaluation

- Production of Precast ConcreteDocument7 pagesProduction of Precast ConcreteDragosPatrascuPas encore d'évaluation

- SteelDocument28 pagesSteelAshfaq SaudagarPas encore d'évaluation

- Metals in ArchitectureDocument13 pagesMetals in ArchitectureRajat PathakPas encore d'évaluation

- Concrete Structures3Document11 pagesConcrete Structures3citizenkanegPas encore d'évaluation

- Advantages CFSTDocument14 pagesAdvantages CFSTprajjwal patidarPas encore d'évaluation

- A Comparison of Concrete Steel and Timber Construction EssayDocument4 pagesA Comparison of Concrete Steel and Timber Construction EssayJordan Kurt S. Gu100% (3)

- Concrete Structures1Document10 pagesConcrete Structures1citizenkanegPas encore d'évaluation

- Production of Precast ConcreteDocument7 pagesProduction of Precast ConcreteDragosPatrascuPas encore d'évaluation

- College of Engineering and Technology University of Sargodha Design of Structures (Ce-409) 01-Credit HourDocument17 pagesCollege of Engineering and Technology University of Sargodha Design of Structures (Ce-409) 01-Credit HourShahrukh NiazPas encore d'évaluation

- REU Course - Tower and Foundation - June 2011Document46 pagesREU Course - Tower and Foundation - June 2011Elena DamocPas encore d'évaluation

- Steel Structures: Choosing The Ideal Structural MaterialDocument3 pagesSteel Structures: Choosing The Ideal Structural MaterialZenaida VoiculetPas encore d'évaluation

- Nature-Inspired Optimization of Tubular Joints For Metal 3D PrintingDocument5 pagesNature-Inspired Optimization of Tubular Joints For Metal 3D PrintingAlper KzPas encore d'évaluation

- Chapter Five Composite Structures (Concrete and Steel)Document15 pagesChapter Five Composite Structures (Concrete and Steel)Assefa Nigussie100% (1)

- RCC2Document18 pagesRCC2Mangam RajkumarPas encore d'évaluation

- 2007d 4 Service Live Design (Adv PDFDocument65 pages2007d 4 Service Live Design (Adv PDFHyunkyoun JinPas encore d'évaluation

- Purpose of Provision of Concrete CoverDocument17 pagesPurpose of Provision of Concrete CoverHiren DesaiPas encore d'évaluation

- Rural Builder Concrete PiersDocument9 pagesRural Builder Concrete PiersFidan DaskalovPas encore d'évaluation

- Precast ConcreteDocument1 pagePrecast ConcreteClarencePas encore d'évaluation

- Report Composite AnkurDocument19 pagesReport Composite AnkurAnkur DubeyPas encore d'évaluation

- Universities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDocument44 pagesUniversities of Leeds, Sheffield and York: Promoting Access To White Rose Research PapersDuta LiviuPas encore d'évaluation

- 1 s2.0 S187770581631476X Main PDFDocument6 pages1 s2.0 S187770581631476X Main PDFTDNPas encore d'évaluation

- Efficient Design of Concrete Filled Steel Tube Columns: SciencedirectDocument6 pagesEfficient Design of Concrete Filled Steel Tube Columns: SciencedirectAnirban PalPas encore d'évaluation

- Comparative Study 01Document1 pageComparative Study 01abhijithavalPas encore d'évaluation

- Advantages of SteelDocument6 pagesAdvantages of SteelJohn Robert BanezPas encore d'évaluation

- Seminar 8th SemDocument27 pagesSeminar 8th SemSumantra BhattacharyaPas encore d'évaluation

- Civil Strcutres - BridgesDocument26 pagesCivil Strcutres - BridgesSina Hafezi Masoomi100% (1)

- Wcee2012 2737 PDFDocument10 pagesWcee2012 2737 PDFAkhil Nath P SPas encore d'évaluation

- CRCP Important Notes PDFDocument132 pagesCRCP Important Notes PDFmustafurade1Pas encore d'évaluation

- CCC22 - FRC StructuresDocument14 pagesCCC22 - FRC StructuresAliz JAMPas encore d'évaluation

- Green Building LibraryDocument21 pagesGreen Building LibraryYadnesh DeorukhkarPas encore d'évaluation

- Topics Seminar Topics For Civil Engineering StudentsDocument6 pagesTopics Seminar Topics For Civil Engineering StudentsawasarevinayakPas encore d'évaluation

- Journal of The South African Institution of Civil EngineeringDocument15 pagesJournal of The South African Institution of Civil Engineeringkranthi142434Pas encore d'évaluation

- 1.1 General: Sheets or Fabrics, Made of Fibers in One or at Least Two Different Directions, RespectivelyDocument4 pages1.1 General: Sheets or Fabrics, Made of Fibers in One or at Least Two Different Directions, Respectivelypujan77Pas encore d'évaluation

- (Prestressed Concrete) Lecture 01 Dr. ZubairDocument38 pages(Prestressed Concrete) Lecture 01 Dr. ZubairAhmed RiadPas encore d'évaluation

- Construction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsDocument16 pagesConstruction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsSAMUEL ALBERTO ZAMBRANA MALDONADOPas encore d'évaluation

- Life-Cycle Cost Assessment of RC and Engineered Cementitous Composite Frames Using Structural OptimizationDocument14 pagesLife-Cycle Cost Assessment of RC and Engineered Cementitous Composite Frames Using Structural OptimizationEric LiuPas encore d'évaluation

- Elastic, Plastic and Yield Design of Reinforced StructuresD'EverandElastic, Plastic and Yield Design of Reinforced StructuresPas encore d'évaluation

- Behavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesD'EverandBehavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesPas encore d'évaluation

- Design of Steel-Concrete Composite Structures Using High-Strength MaterialsD'EverandDesign of Steel-Concrete Composite Structures Using High-Strength MaterialsPas encore d'évaluation

- SCI1307Document71 pagesSCI1307Yashika Bhathiya JayasinghePas encore d'évaluation

- Tec Report Final Latest ADocument8 pagesTec Report Final Latest AYashika Bhathiya JayasinghePas encore d'évaluation

- Technical Evalation-ADocument8 pagesTechnical Evalation-AYashika Bhathiya JayasinghePas encore d'évaluation

- Ke 2 Pilot Paper SiDocument12 pagesKe 2 Pilot Paper SiYashika Bhathiya JayasinghePas encore d'évaluation

- Desalination FinalDocument30 pagesDesalination FinalYashika Bhathiya JayasinghePas encore d'évaluation

- Preliminaryqualificati ADocument1 pagePreliminaryqualificati AYashika Bhathiya JayasinghePas encore d'évaluation

- Post Qualifications ADocument4 pagesPost Qualifications AYashika Bhathiya JayasinghePas encore d'évaluation

- Type BOQ For Construction of 1 Unit Toilet Drawing No.05Document7 pagesType BOQ For Construction of 1 Unit Toilet Drawing No.05Yashika Bhathiya JayasinghePas encore d'évaluation

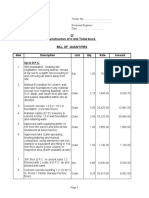

- Estimate For Ms. R.M.Y.K. Rathnayake: No Description Unit Rate Qty AmountDocument7 pagesEstimate For Ms. R.M.Y.K. Rathnayake: No Description Unit Rate Qty AmountYashika Bhathiya JayasinghePas encore d'évaluation

- WPC-UPS Checked 13-1-2014Document2 pagesWPC-UPS Checked 13-1-2014Yashika Bhathiya JayasinghePas encore d'évaluation

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 pagesType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasinghePas encore d'évaluation

- Type BOQ For Construction of 2 Units of Toilet & 1 Unit of Barthroom Drawing No.06Document8 pagesType BOQ For Construction of 2 Units of Toilet & 1 Unit of Barthroom Drawing No.06Yashika Bhathiya JayasinghePas encore d'évaluation

- What Is The Difference Between A Fan Coil Unit and An Air Handling Unit?Document1 pageWhat Is The Difference Between A Fan Coil Unit and An Air Handling Unit?Yashika Bhathiya JayasinghePas encore d'évaluation

- Type BOQ For Construction of 1 Unit Toilet Drawing NO.01Document12 pagesType BOQ For Construction of 1 Unit Toilet Drawing NO.01Yashika Bhathiya Jayasinghe100% (4)

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 pagesType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasinghePas encore d'évaluation

- Malharul Islam AssociationDocument4 pagesMalharul Islam AssociationYashika Bhathiya JayasinghePas encore d'évaluation

- Construction of Drainage System & DevelopmeDocument6 pagesConstruction of Drainage System & DevelopmeYashika Bhathiya JayasinghePas encore d'évaluation

- Repairing Work of Drainage System & Development Work of Roads at 151 Watta, JinthupitiyaDocument8 pagesRepairing Work of Drainage System & Development Work of Roads at 151 Watta, JinthupitiyaYashika Bhathiya JayasinghePas encore d'évaluation

- Concreting Work For Bodhirajarama Subsidiary RoadsDocument5 pagesConcreting Work For Bodhirajarama Subsidiary RoadsYashika Bhathiya JayasinghePas encore d'évaluation

- Reconstruction Work For Susidiary Roads, Sumithrarama RD, Colombo-13Document4 pagesReconstruction Work For Susidiary Roads, Sumithrarama RD, Colombo-13Yashika Bhathiya JayasinghePas encore d'évaluation

- Reconstruction of Susidiary RoadsDocument8 pagesReconstruction of Susidiary RoadsYashika Bhathiya JayasinghePas encore d'évaluation

- Masjidul Muneer Maal MadhrasaDocument4 pagesMasjidul Muneer Maal MadhrasaYashika Bhathiya JayasinghePas encore d'évaluation

- Provincial Council - Western Province Bill Form: Electrical InstallationDocument5 pagesProvincial Council - Western Province Bill Form: Electrical InstallationYashika Bhathiya JayasinghePas encore d'évaluation

- Kalandar Sharhib Jumma MosqueDocument5 pagesKalandar Sharhib Jumma MosqueYashika Bhathiya JayasinghePas encore d'évaluation

- Ihsaniyyah Arabic CollegeDocument4 pagesIhsaniyyah Arabic CollegeYashika Bhathiya JayasinghePas encore d'évaluation

- Bo Sevana ViharayaDocument4 pagesBo Sevana ViharayaYashika Bhathiya JayasinghePas encore d'évaluation

- Constructionsitesafety 111001034447 Phpapp02Document24 pagesConstructionsitesafety 111001034447 Phpapp02Yashika Bhathiya JayasinghePas encore d'évaluation

- Vidyalaya Repair of Building Bill of Quantities Item Description Unit Qty. Rate AmountDocument12 pagesVidyalaya Repair of Building Bill of Quantities Item Description Unit Qty. Rate AmountYashika Bhathiya JayasinghePas encore d'évaluation

- Instute Name Nature of Work Bill of Quantities: Item Description Unit Qty. RateDocument14 pagesInstute Name Nature of Work Bill of Quantities: Item Description Unit Qty. RateYashika Bhathiya JayasinghePas encore d'évaluation

- Construction Site Safety: ©consultnet LTDDocument19 pagesConstruction Site Safety: ©consultnet LTDdroffilcz27Pas encore d'évaluation

- Iso/Osi & Tcp/Ip: Stack StackDocument40 pagesIso/Osi & Tcp/Ip: Stack StackAnushiMaheshwariPas encore d'évaluation

- History Development of Art: Prepared By: Mean Coro DotillosDocument23 pagesHistory Development of Art: Prepared By: Mean Coro DotillosCherry Mae Antivo ToloPas encore d'évaluation

- CTMS Admin GuideDocument490 pagesCTMS Admin GuideArshiya BathoolPas encore d'évaluation

- Safety: Important Safety Instructions What Ships in The BoxDocument4 pagesSafety: Important Safety Instructions What Ships in The BoxMarraPas encore d'évaluation

- ASEM2M Iridium SBD Developers GuideDocument59 pagesASEM2M Iridium SBD Developers Guidekira019Pas encore d'évaluation

- Biomimicry in The Built EnvironmentDocument68 pagesBiomimicry in The Built EnvironmentThilluPas encore d'évaluation

- Troubleshooting OSPF (2206!7!5)Document42 pagesTroubleshooting OSPF (2206!7!5)pohseng100% (1)

- Anselm KieferDocument22 pagesAnselm Kieferchnnnna100% (1)

- ResumeDocument3 pagesResumeabreddy2003Pas encore d'évaluation

- 20 Useful Terminal Commands and Tools That You May Need in Ubuntu-Linux MintDocument7 pages20 Useful Terminal Commands and Tools That You May Need in Ubuntu-Linux Mintoral_cuPas encore d'évaluation

- Contoh Descriptive Text About Paris Beserta ArtinyaDocument11 pagesContoh Descriptive Text About Paris Beserta ArtinyaMarhani AmaliaPas encore d'évaluation

- DIY Underground Greenhouse For Organic FarmingDocument29 pagesDIY Underground Greenhouse For Organic Farmingwire-of-Information100% (7)

- Specs PyrostopDocument7 pagesSpecs PyrostopfakemasterkgpPas encore d'évaluation

- Tradeguider Quick Reference Card: Program Function Hot KeyDocument2 pagesTradeguider Quick Reference Card: Program Function Hot KeyPiet NijstenPas encore d'évaluation

- N2 Thermostat Install GuideDocument20 pagesN2 Thermostat Install Guideanon_601173652Pas encore d'évaluation

- Seismic Design Basics For Practicing Architects PDFDocument108 pagesSeismic Design Basics For Practicing Architects PDFJohn DenverPas encore d'évaluation

- Krier-Peter Eisenman DialogueDocument3 pagesKrier-Peter Eisenman DialogueAndreea CarabusPas encore d'évaluation

- List of Useful Keyboard Shortcuts For Command Prompt in WindowsDocument7 pagesList of Useful Keyboard Shortcuts For Command Prompt in WindowsMahmudul HasanPas encore d'évaluation

- Central Support Plan and Parts List: SEESAW ProjectDocument7 pagesCentral Support Plan and Parts List: SEESAW ProjectWarih Wandita WeningPas encore d'évaluation

- Consumption StatementDocument7 pagesConsumption StatementRonnie SinghPas encore d'évaluation

- Micro Exit Bank Reviewer 1Document82 pagesMicro Exit Bank Reviewer 1JinLi ChenPas encore d'évaluation

- Stronghold Crusader Multiplayer Demo ReadmeDocument6 pagesStronghold Crusader Multiplayer Demo ReadmeNara ZweiPas encore d'évaluation

- Electrical Design For HRB-Classroom Seminars Part-2-3Document166 pagesElectrical Design For HRB-Classroom Seminars Part-2-3Ryan RamosPas encore d'évaluation

- Fairy TalesDocument31 pagesFairy Talescameron920Pas encore d'évaluation

- Microsoft Word Document جديد Document8 pagesMicrosoft Word Document جديد qamar archPas encore d'évaluation

- Protocol RP01NDocument19 pagesProtocol RP01NEarthwheel TrackingPas encore d'évaluation

- LOad On Bridge 2Document140 pagesLOad On Bridge 2shamsukarim2009Pas encore d'évaluation

- Eleven40 Style. CSS File Og Genesis Child ThemeDocument84 pagesEleven40 Style. CSS File Og Genesis Child Themepankajbhatt1993Pas encore d'évaluation

- The Principles of DesignDocument44 pagesThe Principles of Designyashusoni100% (1)

- From Mining Region To Industrial Heritage Sites - 50 Years of Documentation, Protection and Management in The Ruhr Area, GermanyDocument21 pagesFrom Mining Region To Industrial Heritage Sites - 50 Years of Documentation, Protection and Management in The Ruhr Area, GermanyDimitrios MavromatidisPas encore d'évaluation