Académique Documents

Professionnel Documents

Culture Documents

Course Delivery Plan MD-I

Transféré par

Pankaj AgarwalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Course Delivery Plan MD-I

Transféré par

Pankaj AgarwalDroits d'auteur :

Formats disponibles

Amity School of Engineering & Technology

Machine Design-I

B.Tech. (M & AE) & All Dual Degree, V Sem.

BTM-501

Pankaj Agarwal

Amity School of Engineering and Technology

Amity School of Engineering & Technology

Course Title: Machine Design-I

Course Code: BTM-501

Program Name: B.Tech. M&AE(B) & All Dual Degree

Semester: V

Credit Units: 3

Classroom Teaching: 3 hr/week

No. of Lectures Planned: 42

No. of Tutorials Planned: 0

Chamber Consultation: 2 Hrs./week

Email id: pagarwal@jpr.amity.edu

Amity School of Engineering & Technology

Prerequisite for this course

Elements of Mechanical Engineering

Materials Science and Metallurgy

Mechanics of Solids

Amity School of Engineering & Technology

Course Objectives

The objective of this course is to help students apply

concepts learned in the mechanics, structure,

material and manufacturing courses. This course

offers working knowledge in the use of proper failure

theories under steady and variable loading, design of

mechanical elements, such as shaft, coupling, power

screws, and detachable, permanent and welded

connections.

Amity School of Engineering & Technology

Learning Outcomes

The theory will be taught and practical should be carried out in such

a manner that students are able to acquire required learning

outcomes in cognitive, psychomotor and affective domain to

demonstrate following course outcomes:

Identify appropriate analytical models to describe and predict the

behaviour of standard machine components;

Apply stress analysis theory, fatigue theory and appropriate criteria

of failure to the design of simple machine elements;

Analyse and evaluate forces and stresses within machine elements.

Amity School of Engineering & Technology

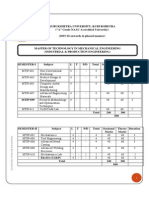

Session-wise distribution of course

No. of Modules : 6

Module No.

I

II

III

IV

V

VI 8

Total :

No. of Lectures

6

5

7

9

7

42 Sessions

Amity School of Engineering & Technology

Module I: Variable Stresses in Machine Parts

Session No. Topics to be covered

1

fatigue, fluctuating stresses, fatigue failure

Endurance limit, factors of endurance limit, S-N curve, S- N curve for

steel, S- N curve for nonferrous material

Low cycle fatigue and high fatigue cycle, Effect of various factors on

endurance limit, Introduction of stress concentration, causes of stress

concetration

Stress Concentration due to Holes and Notches, Stress Concentration

factors, Methods of Reducing Stress Concentration, Factors to be

Considered while Designing Machine Parts to Avoid Fatigue Failure,

Fatigue Stress Concentration Factor

5

6

Notch sensitivity, Gerber Method, Goodman Method, numerical

practice

Soderberg Method for combination of stresses, numerical practice

Home Assignment 1

Amity School of Engineering & Technology

Module II: Power Screws

Session No. Topics to be covered

10

11

12

13

Introduction of power screw, advantages and disadvantages

of power screw, applications, Types of screw threads, advantages and

disadvantages of different types threads, derive equation to Torque

required to raise the load

Derive equation to Torque required to lower the load,

Efficiency of square threaded screw, numerical practice

Maximum Efficiency of Square Threaded Screws, Efficiency vs.

Helix Angle, numerical practice

Overhauling and self locking screw, stresses in power screw,

numerical practice

Design of screw jack and numerical practice

14

Home Assignment. 2

Amity School of Engineering & Technology

Module III: Cotter and Knuckle Joint

Session No.

17

18

19

20

21

22

23

Topics to be covered

Introduction, Types of cotter joints, Design of Socket and Spigot Cotter

Joint.

Design of Sleeve and Cotter Joint, Design of Gib and Cotter Joint for

Strap End of a Connecting Rod, numerical practice

Design of Gib and Cotter Joint for Square Rods, numerical practice

Design of Cotter Joint to ConnectPiston Rod and Crosshead, Design of

Cotter Foundation Bolt, numerical practice

Various Parts of the Knuckle Joint, Methods of Failure of Knuckle Joint

Design Procedure of Knuckle Joint, numerical practice

Numerical practice and doubt solving session

Home Assignment No. 3

Amity School of Engineering & Technology

Module IV: Riveted and Welded Joints

Session No. Topics to be covered

25

Introduction, Methods of Riveting, Material of Rivets, Essential Qualities of a Rivet,

26

Types of Rivet Heads, Types of Riveted Joints, Lap Joint, numerical practice

27

28

29

30

31

32

33

Butt Joint, Terms Used in Riveted Joints, Caulking and Fullering, Failures of a Riveted Joint,

Strength of a Riveted Joint, Efficiency of a Riveted Joint

Numerical practice

Introduction, Advantages and Disadvantages of Welded Joints over Riveted Joints, Types of

Welded Joints

Lap Joint, Butt Joint, fillet joint, Basic Weld Symbols, numerical practice

Strength of Transverse Fillet Welded Joints, Strength of Parallel Fillet Welded Joints, Special

Cases of Fillet Welded Joints, numerical practice

Strength of Butt Joints, numerical practice

Numerical practice and doubt solving session

Home Assignment 4

10

Amity School of Engineering & Technology

Module V: Keys & Couplings

Session No.

Topics to be covered

34

introduction, Types of Keys, Sunk Keys, Saddle Keys,

tangent Keys, Round Keys, Splines

Forces acting on a Sunk Key, Strength of a Sunk Key,

Effect of Keyways, Numericals

35

Shaft Couplings, Requirements of a Good Shaft Coupling,

Types of Shaft Couplings, Sleeve or Muff Coupling,

numerical

36

Clamp or Compression Coupling, Flange Coupling

37

Design of Flange Coupling, Flexible Coupling, Bushed Pin

Flexible Coupling, numerical practice

38

Oldham Coupling, Universal Coupling, numerical practice

39

Numerical practice and doubt solving session

33

Home Assignment 5

11

Amity School of Engineering & Technology

Module VI: Drives

Session No.

33

34

Topics to be covered

Introduction, Selection of a Belt Drive, Types of Belt Drives, Types of Belts, Material used for

Belts, Working Stresses in Belts

Density of Belt Materials, Belt Speed, Coefficient of Friction Between Belt and Pulley, Standard

Belt Thicknesses and Widths, Belt Joints, Types of Flat Belt Drives, Velocity Ratio of a Belt

Drive

36

Slip of the Belt, Creep of Belt, Length of an Open Belt Drive, Length of a Cross Belt Drive,

numerical practice

Power transmitted by a Belt, Ratio of Driving Tensions for Flat Belt Drive, Centrifugal Tension,

Maximum Tension in the Belt, Condition for Transmission of Maximum Power, Initial Tension

in the Belt

37

Types of V-belts and Pulleys, Standard Pitch Lengths of V-belts, Advantages and

Disadvantages of V-belt Drive over Flat Belt Drive, Ratio of Driving Tensions for V-belt, V-flat

Drives

35

38

39

40

rope drive, introduction and detail types and construction of rope drive, Numerical practice

Chain drives, advantages and disadvantages of Chain drives

Numerical Practice and doubt solving session

Home Assignment 6

12

Amity School of Engineering & Technology

Teaching Methodology

Lectures

Tutorials

Quiz

Home Assignments

Chamber consultation- 2 hrs/week

Daily practice problem

Lab practice

13

Amity School of Engineering & Technology

Text & Reference Books

Text & Refrence Books:

J.E. Shigley, Mechanical Engineering Design.

Sadhu Singh, Machine Design

R.S. Khurmi & J.K. Gupta, Machine design

D.K. Aggarwal & P.C. Sharma, Machine Design

V B Bhandari , Design of Machine Elements

Robert L. Norton , Machine Design An Integrated Approach

14

Amity School of Engineering & Technology

Evaluation Scheme

S. No Evaluation

Component

Weight

(%)

Date for

Evaluation

Learning

Outcome

Evaluated

Date of

Completion of

Evaluation

1.

Home

Assignment

3rd , 8th,10th

week

1-3

Within 2-3 days

2.

Mid Term Test

15

As per

schedule

1-2

Within a week

3.

Quiz

6th and 11th

week

1-3

Within 2-3 days

4.

Attendance

Through out

the semester

Before End- Semester

Exam

5.

End-Semester

Examination

70

As

per 1-3

schedule

Within two week

Total

100

15

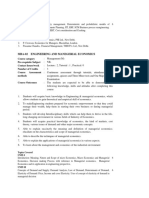

Amity School of Engineering & Technology

Evaluation Scheme cont...

Continuous evaluation will be conducted for 30 marks. It is continuous and spread

throughout the course.

Component I- Home Assignment (5 marks)

Home assignments provide the students, useful pre selected reading material and

problem sets. Carefully selected assignments encourage the students to put in

independent work in the course and highly conducive to learning.

Guidelines:

1.Logical and descriptive questions will be given.

2.Programs may also be given for practice.

3.It will be compulsory to submit promptly and properly all the Home assignment

on time.

Component II- Mid Term Test(15 marks)

This is an individual activity which test students basic knowledge in the given

subject and by this component we can assess student- instructor performance.

Amity School of Engineering & Technology

Evaluation Scheme cont...

Component III Quiz (5 Marks)

This is an individual activity to test students basic concepts and knowledge for

each topic.

Guidelines:

1.The objective type questions and short questions will be asked in quiz.

2.Fill in the blanks , True / False questions may be asked in quiz.

3.There will be no negative marking.

Component IV- Attendance(5 marks)

Guidelines:

1.It is expected from all students to be present in all lectures and lab sessions.

2.But due to some unavoidable circumstances, he/she may be exempted for

25% lectures/lab sessions.

3.Medical leaves will be counted in rest 25% leaves only.

4.A student must normally maintain 75% attendance in each of the course

5.If a student does not maintain requisite attendance (75%) by the end of the

semester, he may be debarred.

Amity School of Engineering & Technology

Evaluation Scheme cont...

Component V:- End semester examination(70 marks)

The end semester examination is conducted at the end of the semester and is

comprehensive enough to include the whole course.

Amity School of Engineering & Technology

Course Title:

Machine Design I Lab

Course Code: BTM 520

Course Title: Machine Design Lab

Credit Units: 1

Practical/Lab Hours: 2 hrs/week

Total No. of Lab Programs Planned: 12

19

Amity School of Engineering & Technology

Academic Integrity Policy

Students are expected to follow Rules of Conduct

and Academic Behavior Standards as detailed in

the Student Regulations. Failure to comply with

these rules may result in disciplinary actions as

stipulated in the Students Regulations.

20

Amity School of Engineering & Technology

General Guidelines for Students

1. It is expected from all students to be present in all lectures/

labs.

2. Entry in the classroom or lab will not be entertained after 5

minutes of commencement of lecture/lab.

3. Teaching notes may be provided on

hardcopy or

amizone.net as and when required.

4. Home assignments need to be submitted on time.

Assignments accepted after the scheduled date will lead to

deduction in internal marks as it is an internal evaluation

criteria.

21

Amity School of Engineering & Technology

THANK

YOU

22

Vous aimerez peut-être aussi

- Design of Machine Elements (MCT 3214)Document20 pagesDesign of Machine Elements (MCT 3214)Abdin YousifPas encore d'évaluation

- Course Title Course Level: UG Credit Units: Course Code: MAE301Document3 pagesCourse Title Course Level: UG Credit Units: Course Code: MAE301Himanshu JangidPas encore d'évaluation

- MACHINE DESIGN COURSE OVERVIEWDocument1 pageMACHINE DESIGN COURSE OVERVIEWSanjay GomastaPas encore d'évaluation

- 48e31machine Design SyllabusDocument1 page48e31machine Design Syllabusrajkumargupta5Pas encore d'évaluation

- MA505-N-C Modern Manufacturing ProcessesDocument3 pagesMA505-N-C Modern Manufacturing Processeshrana287Pas encore d'évaluation

- Exploring Mechatronics: Developing Skills in Mechatronics TechnologiesDocument12 pagesExploring Mechatronics: Developing Skills in Mechatronics TechnologiesalaahejerPas encore d'évaluation

- MCE 417 Course CompactDocument7 pagesMCE 417 Course CompactKEHINDE BABALOLAPas encore d'évaluation

- Southern Polytechnic State University MET 1321 - Machining and WeldingDocument4 pagesSouthern Polytechnic State University MET 1321 - Machining and WeldingIbraheem KhressPas encore d'évaluation

- Coursework Structural Integrity 2023-24Document7 pagesCoursework Structural Integrity 2023-24Yacine HalwanePas encore d'évaluation

- Syllabus DFM 2014Document29 pagesSyllabus DFM 2014sudheer920% (1)

- Machine Design 1Document4 pagesMachine Design 1rajdecoratorsPas encore d'évaluation

- Machine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDocument16 pagesMachine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDeekshaomarPas encore d'évaluation

- Course OutlineDocument3 pagesCourse OutlineLIM ChanthaPas encore d'évaluation

- AAiT Machine Elements Design CourseDocument2 pagesAAiT Machine Elements Design CourseWolelaw FikaduPas encore d'évaluation

- Module Welding TechnologyDocument5 pagesModule Welding TechnologySurendra SenanayakePas encore d'évaluation

- Md2 Syl PDFDocument3 pagesMd2 Syl PDFHimanshu JangidPas encore d'évaluation

- Course Outline MFG IIDocument2 pagesCourse Outline MFG IIAbrham ChaniePas encore d'évaluation

- Mecsyll 49 51Document3 pagesMecsyll 49 51Prakhyath MPas encore d'évaluation

- Machine Shop - SyllabusDocument4 pagesMachine Shop - SyllabusvirupakshaPas encore d'évaluation

- Mechatronics SyllabusDocument41 pagesMechatronics SyllabusElstonD'cruzPas encore d'évaluation

- Syllabus Vjti Structural EnggDocument276 pagesSyllabus Vjti Structural EnggPravin AwalkondePas encore d'évaluation

- Manufacturing Technology SyllabusDocument4 pagesManufacturing Technology Syllabushrana287Pas encore d'évaluation

- Sessional On Solid Mechanics and Machine Design Course No. - ME 2222 (Machine Shop & Mechanics Lab)Document24 pagesSessional On Solid Mechanics and Machine Design Course No. - ME 2222 (Machine Shop & Mechanics Lab)Somnath SomadderPas encore d'évaluation

- MTech Machine Design PDFDocument41 pagesMTech Machine Design PDFswapnilPas encore d'évaluation

- Nba mp-1Document5 pagesNba mp-1krunal07786Pas encore d'évaluation

- Workshop & Machineshop Practice Lab Manual: (18MEL38A/48A)Document101 pagesWorkshop & Machineshop Practice Lab Manual: (18MEL38A/48A)MAN MOHAN VATSPas encore d'évaluation

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullPas encore d'évaluation

- ABETsyllabus Design 2Document3 pagesABETsyllabus Design 2melihPas encore d'évaluation

- Applied Mechanics Course Delivery PlanDocument11 pagesApplied Mechanics Course Delivery PlanArunkuma81Pas encore d'évaluation

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PPas encore d'évaluation

- Machine Design 1 Course OverviewDocument3 pagesMachine Design 1 Course OverviewmelihPas encore d'évaluation

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghPas encore d'évaluation

- 2.2. Teaching - Learning Processes (100) 2.2.1. Describe Processes Followed To Improve Quality of Teaching & LearningDocument8 pages2.2. Teaching - Learning Processes (100) 2.2.1. Describe Processes Followed To Improve Quality of Teaching & LearningMalleswara RaoPas encore d'évaluation

- NIMS Machining Level I Preparation Guide Milling: © 2003 National Institute For Metalworking Skills, IncDocument31 pagesNIMS Machining Level I Preparation Guide Milling: © 2003 National Institute For Metalworking Skills, IncMFPas encore d'évaluation

- Me Vtu DFM Syllabus CBCS SchemeDocument2 pagesMe Vtu DFM Syllabus CBCS SchemeNitheeshPas encore d'évaluation

- Foundry and Forging Laboratory ManualDocument110 pagesFoundry and Forging Laboratory Manualvampiredraak2712Pas encore d'évaluation

- 6th Sem - 7 - Mechanical Engineering PDFDocument39 pages6th Sem - 7 - Mechanical Engineering PDFÃrghýã MåjïPas encore d'évaluation

- Infrastructure Construction and Management Syllabus PDF FormatDocument52 pagesInfrastructure Construction and Management Syllabus PDF Formatharsha sPas encore d'évaluation

- Visvesvaraya Technological University, Belgaum: M.TECH. Machine Design I SemesterDocument71 pagesVisvesvaraya Technological University, Belgaum: M.TECH. Machine Design I SemesterVasudeva BhattarPas encore d'évaluation

- Lesson Planning VAPatelDocument13 pagesLesson Planning VAPatelabhay_15865099Pas encore d'évaluation

- IIW Diploma - WPE1 Course NotesDocument300 pagesIIW Diploma - WPE1 Course NotesBilly Tan100% (12)

- CNC & Casting Simulation LabDocument13 pagesCNC & Casting Simulation LabJayadev EPas encore d'évaluation

- MT234 Mechanical Testing LabDocument1 pageMT234 Mechanical Testing LabMerrin John VarkeyPas encore d'évaluation

- Course Module (VI Sem)Document7 pagesCourse Module (VI Sem)Vijay KumawatPas encore d'évaluation

- ME401 Machine Elements Design CourseDocument3 pagesME401 Machine Elements Design CourseAnirudh Madhav KakkadPas encore d'évaluation

- SMAW Welding GuideDocument3 pagesSMAW Welding GuideOdlnayer Allebram100% (2)

- ME1 Course Outline 43526Document2 pagesME1 Course Outline 43526Abi Dem0% (1)

- Mechanical Tech Pneumatic Hydraulic Systems2Document106 pagesMechanical Tech Pneumatic Hydraulic Systems2Mohan Shanmugam100% (1)

- 6th Sem - 7 - Mechanical Engineering - 2 PDFDocument39 pages6th Sem - 7 - Mechanical Engineering - 2 PDFfotickPas encore d'évaluation

- IME Eng Design 1 EIM 216 Course OutlineDocument5 pagesIME Eng Design 1 EIM 216 Course OutlineKeith Tanaka MagakaPas encore d'évaluation

- Dme Question Bank by Syam Prasad AmmineniDocument22 pagesDme Question Bank by Syam Prasad AmmineniDharmendra SharmaPas encore d'évaluation

- 5th Sem SyllabusDocument14 pages5th Sem SyllabusOmkarPas encore d'évaluation

- AutomotiveDocument39 pagesAutomotiveyathin KLPas encore d'évaluation

- MMM Lab 18mel47bDocument47 pagesMMM Lab 18mel47bSachin PrabhaPas encore d'évaluation

- Mee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFDocument2 pagesMee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFAK PRODUCTIONSPas encore d'évaluation

- Reference: Workshop Technology 3 NoteDocument1 pageReference: Workshop Technology 3 NoteAmar ZalleePas encore d'évaluation

- Manufacturing Practices FinalDocument65 pagesManufacturing Practices FinalRoman ReignPas encore d'évaluation

- DKOM Lab ManualDocument24 pagesDKOM Lab Manualaakash chakrabortyPas encore d'évaluation

- Mec223:Design of Machine Elements-I: Course OutcomesDocument2 pagesMec223:Design of Machine Elements-I: Course OutcomesDeepak MehtaPas encore d'évaluation

- Swarm Intelligence Approach To Safe Ship Control: Agnieszka LazarowskaDocument7 pagesSwarm Intelligence Approach To Safe Ship Control: Agnieszka LazarowskaPankaj AgarwalPas encore d'évaluation

- ANSYS Composite PrepPost Users GuideDocument370 pagesANSYS Composite PrepPost Users Guideagrbovic100% (1)

- Design and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesDocument7 pagesDesign and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesPankaj AgarwalPas encore d'évaluation

- Call For Papers Template: (Example of Topic) (Example of Topic) (Example of Topic) (Example of Topic)Document3 pagesCall For Papers Template: (Example of Topic) (Example of Topic) (Example of Topic) (Example of Topic)Pankaj AgarwalPas encore d'évaluation

- Faculty schedule by institutionDocument10 pagesFaculty schedule by institutionPankaj AgarwalPas encore d'évaluation

- Impedance Spectroscopy Cell Analysis in Microchannels Impedance Spectroscopy Cell Analysis in MicrochannelsDocument2 pagesImpedance Spectroscopy Cell Analysis in Microchannels Impedance Spectroscopy Cell Analysis in MicrochannelsPankaj AgarwalPas encore d'évaluation

- 7.8 Cutting Tool Materials CompleteDocument15 pages7.8 Cutting Tool Materials CompleteNikhil Batham67% (6)

- Design & Fabrication of A Gravity Powered Light: November 2015Document6 pagesDesign & Fabrication of A Gravity Powered Light: November 2015Chirag SulePas encore d'évaluation

- Devesh Mishra Allahabad University ofDocument1 pageDevesh Mishra Allahabad University ofPankaj AgarwalPas encore d'évaluation

- PaperDocument3 pagesPaperPankaj AgarwalPas encore d'évaluation

- Revised Leave Format 04.07.2017 PDFDocument4 pagesRevised Leave Format 04.07.2017 PDFPankaj AgarwalPas encore d'évaluation

- Accepted Manuscript: Journal of Non-Newtonian Fluid MechanicsDocument16 pagesAccepted Manuscript: Journal of Non-Newtonian Fluid MechanicsPankaj AgarwalPas encore d'évaluation

- Rajasthan Public Service CommissionDocument5 pagesRajasthan Public Service CommissionPooja MeenaPas encore d'évaluation

- Kvs Vice Principal Previous Year Paper Other SiteDocument20 pagesKvs Vice Principal Previous Year Paper Other SitePankaj AgarwalPas encore d'évaluation

- KVS Principal (Previous Year Paper Part-2) PDFDocument12 pagesKVS Principal (Previous Year Paper Part-2) PDFPankaj AgarwalPas encore d'évaluation

- Faculty schedule by institutionDocument10 pagesFaculty schedule by institutionPankaj AgarwalPas encore d'évaluation

- BilllDocument1 pageBilllPankaj AgarwalPas encore d'évaluation

- Ash Complex Variables With Hyper LinksDocument220 pagesAsh Complex Variables With Hyper LinksTu ShirotaPas encore d'évaluation

- Ash Complex Variables With Hyper LinksDocument12 pagesAsh Complex Variables With Hyper LinksPankaj AgarwalPas encore d'évaluation

- Kendriya Vidyalaya Sangathan: Direct Recruitment Examination 2018Document3 pagesKendriya Vidyalaya Sangathan: Direct Recruitment Examination 2018Pankaj AgarwalPas encore d'évaluation

- CFD analysis of laminar flow in a rectangular channelDocument32 pagesCFD analysis of laminar flow in a rectangular channelPankaj AgarwalPas encore d'évaluation

- Sarath Sasikumar Menon Contact No:-7023119007: Career ObjectiveDocument2 pagesSarath Sasikumar Menon Contact No:-7023119007: Career ObjectivePankaj AgarwalPas encore d'évaluation

- How To InstallDocument1 pageHow To InstallPankaj AgarwalPas encore d'évaluation

- Account Details Addition / Modification Request Form (KRA / Trading / DP A/c)Document1 pageAccount Details Addition / Modification Request Form (KRA / Trading / DP A/c)Pankaj AgarwalPas encore d'évaluation

- Darpan's Resume - Mechanical EngineerDocument3 pagesDarpan's Resume - Mechanical EngineerPankaj AgarwalPas encore d'évaluation

- Rent Paid Receipt: Revenue Stamp Rs.1Document1 pageRent Paid Receipt: Revenue Stamp Rs.1Pankaj AgarwalPas encore d'évaluation

- Salary Structure Fresher'sDocument1 pageSalary Structure Fresher'sPankaj AgarwalPas encore d'évaluation

- NOTICE SSR PhotoDocument1 pageNOTICE SSR PhotoPankaj AgarwalPas encore d'évaluation

- Order 2 23 JulyDocument1 pageOrder 2 23 JulyPankaj AgarwalPas encore d'évaluation