Académique Documents

Professionnel Documents

Culture Documents

Basics of Vibration and Vibration Measurement

Transféré par

Anand KumarDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Basics of Vibration and Vibration Measurement

Transféré par

Anand KumarDroits d'auteur :

Formats disponibles

Basics of Vibration and

Vibration Measurement

R P SHUKLA

Basics of Vibration and Vibration

Measurement

Co-Relationship

Predictive

Maintenance

Condition

Monitoring

Vibration

Monitoring

Considered to be one of the most

effective measurements for monitoring

the condition of Rotating Machinery 2

Basics of Vibration and Vibration

Measurement

Why Vibration?

Machine Inherent Characteristic: Language of

the Machines

Inaccuracies More : Vibration More

Mal-function Diagnosis : Frequency Correlation

Protection : Machine, Man, Surrounding

Basics of Vibration and Vibration

Measurement

Vibration Monitoring Cycle

Vibration Monitoring

Repair

Machine

No

Measurement exceeds

alarm limit

Yes

Schedule

Repair

Vibration Analysis

Problem Identification

Increase

Measurement

Interval

Bad/ good

Vibration level

reduction by 50%

MCR 3 to 5 times

Including power

saving

Basics of Vibration and Vibration

Measurement

Condition Monitoring Parameters For

Rotating Machines

1. Performance/ Operation Parameters: Flow,

Pressure, Temperature, Load, Torque, Voltage, Speed,

etc.

2. Lubricating Oil Analysis/ Parameters: Wear-debris,

Oil temperature/ pressure/ viscosity, etc.

3. Thermography, Motor Current Analysis

4. Special techniques like SEE, HFD, SPM,

Sound analysis, etc.

5. Vibration analysis

etc.

Basics of Vibration and Vibration

Measurement

Vibration Concept

Basics of Vibration and Vibration

Measurement

Understanding Simple Harmonic Motion

Basics of Vibration and Vibration

Measurement

Understanding Simple Harmonic

Motion

Basics of Vibration and Vibration

Measurement

Relationship: Amplitude Parameters

Displacement x (t) = X Sin (2ft)

Velocity v (t) = dx/dt = V Cos (2ft)

Acceleration a (t) = d2x/dt2 = - A Sin (2ft)

Basics of Vibration and Vibration

Measurement

What is Phase?

10

Basics of Vibration and Vibration

Measurement

Understanding Phase

11

Basics of Vibration and Vibration

Measurement

Understanding Phase

12

Basics of Vibration and Vibration

Measurement

Understanding Phase

13

Basics of Vibration and Vibration

Measurement

Understanding Phase

14

Basics of Vibration and Vibration

Measurement

Understanding Phase

Summary:

During the 360o shaft revolution, the sensor experiences its

maximum positive force when the shafts heavy spot is 270o

from its initial position (its position when data collection was

initiated by the Tachometer ).

The Phase angle is 270o

15

Basics of Vibration and Vibration

Measurement

Phase Relationship

Horizontal Beam and Vertical Column

moving together

Both beams vibrating 180o out of

phase

16

Basics of Vibration and Vibration

Measurement

Measurable Vibration Characteristics:

Simple Harmonic, Periodic, Randomly varying

1. Vibration Amplitude - displacement

velocity

acceleration

2. Vibration frequency

3. Vibration phase

17

Basics of Vibration and Vibration

Measurement

Units of Amplitude:

Displacement (distance): Microns or mils peak

Microns or mils peak to peak

Velocity (speed): Rate of change of displacement

mm/s or inch/s peak

mm/s or inch/ s RMS

Acceleration : Rate of change of velocity

G peak (G = 9.81 m/s2)

mm/ s2 peak

inch/ s2 peak

18

Basics of Vibration and Vibration

Measurement

Units of Frequency:

CPS/ Hz (cycles/ second or Hertz)

CPM (cycles/ min)

RPM (Revolutions/ min)

Orders of running speed (how many times event occurs per shaft

revolution)

19

Basics of Vibration and Vibration

Measurement

Amplitude parameters relationship (A+ f)

20

Basics of Vibration and Vibration

Measurement

Transmission of forces from Rotor to Stator

The key to a good approach is the understanding that for

maintenance, we are not actually interested in vibration. We really

want to find out how the condition of the machine is changing.

Changes in forces can be caused by direct changes in the work

process or by changes in the properties of the machine elements.

21

Basics of Vibration and Vibration

Measurement

What To Measure ?

Sht. 1

Single degree of freedom System : Resonance : belowdisplacement, at- velocity, above- acceln.

Mechanical Consideration : Rotor Vs Housing

Rotor Related : unbalance, misalignment, surge, cavitation,

worn out bearings/coupling/seals/gears/balancing drumdisc, coupling lock-up, radial & axial rubs,bowed rotor,

improperly assembled rotor, oil whirl/whip,seal whirl,

lubrication related, looseness, resonances,cracked

shaft/blades/vanes.

Housing Related : bearing support, excessive piping forces,

casing/foundation resonances, poor foundation support

(m.f.), poor m/c Installation, thermal casing warpage

sht.1.

Mal-function Diagnosis : Frequency Correlation

22

Protection : Machine, Man, Surrounding

Basics of Vibration and Vibration

Measurement

Single Degree of Freedom Model

Forced Vibration with viscous damping:

a) If force F(t) is harmonic

F(t) = F0 Sin t

= kx + c.dx/dt + md2x/dt2

b) If displacement vector

lags force vector by

the solution of the above

equation :

x = X Sin (t - )

23

Basics of Vibration and Vibration

Measurement

Single Degree of Freedom Model (vectors)

Inertia force + Dumping force +

spring force + impressed force =

0

m 2 X sin (t - ) cX sin (t

+ /2) - kX sin ( t - ) + Fo

sin t = 0

1. The Displacement lags the impressed force by the angle , which can vary

between 0 to 180 deg

2. The spring force is always opposite in direction to the displacement

3. The damping force lags the displacement by 90 deg. and hence is opposite

in direction to the velocity

4. The inertia force is in phase with the displacement and opposite in direction 24

to

the acceleration

Basics of Vibration and Vibration

Measurement

What To Measure ?

Sht. 2

Mechanical Impedance :

stiffness/mass/damping. Characteristic of

rotor/bearing & their support. lube oil

p.t.,alignment, preloads, speed, phase lag.

Bearing Consideration : Hydrodynamic,

Rolling element (finite life, high frequency)

Transducer Consideration + Environment +

Frequency + Circuitry (integration Vs

differentiation)

25

Basics of Vibration and Vibration

Measurement

Variation of response with frequency

26

Basics of Vibration and Vibration

Measurement

Process Machineries : Transducers type

Sr.

No

Type of machinery

Speed range, rpm

Bearings

Centrifugal compressors vertically

split

Casing to rotor mass

ratio

Sleeve / tilting

pad, etc.

Rolling

Provision for no

contact probe

100000toto30000

13000

10000

20 to 45

Centrifugal compressors horizontally

split

4000 to 8000

10 to 20

Condensing steam turbines main

drivers

4000 to 13000

8 to 25

Centrifugal pumps built to API

standard

1500

1500toto45000

4500

10 to 20

Auxiliary steam turbines; back pressure

type

1500

1500toto45000

4500

4 to 10

HT motor (50 Hz)

300 to 3000

2 to 5

LT motor (50 Hz)

1000 to 3000

2 to 5

Screw compressors (50Hz)

1000 to 3000

8 to 10 (all screws)

Reciprocating compressors (50Hz)

10

Gear boxes special purpose

300 to 750

Cylinder / piston

assy. + covers 8 to

15 Frame

/crankshaft +2/3

con. Rod

6 to 15

1500 to 13000

1.5 to 4.0 (gear +

pinion basis)

27

Basics of Vibration and Vibration

Measurement

Selection of Vibration Parameters/Transducers

28

Basics of Vibration and Vibration

Measurement

Non Contact Proximity Probe

29

Basics of Vibration and Vibration

Measurement

Non Contact Proximity Probe:

Calibration Curve

Eddy

30

Basics of Vibration and Vibration

Measurement

Velocity Pick up

31

Basics of Vibration and Vibration

Measurement

Accelerometer, Compression Type

32

Basics of Vibration and Vibration

Measurement

Measurement Point Identification on Motor

33

Basics of Vibration and Vibration

Measurement

Overall Vibration

Frequency, Vibration instruments, Scale Factors

Trending : overall amplitude, phase, spectral

bands.

Standards : ISO 2372, 2373, 3945

IS 4729

BS 4675

VDI 2056, 2059

IRD / SKF/ Inst. Manf. charts

Developed In- house.

34

Basics of Vibration and Vibration

Measurement

Amplitude Descriptor

35

Basics of Vibration and Vibration

Measurement

AVERAGE Vs RMS

T

X

average

RMS

= 1

-T

= 1

-T

x(t)

dt

O

T

x2 (t) dt

36

Basics of Vibration and Vibration

Measurement

Vibration Trend Chart

37

Basics of Vibration and Vibration

Measurement

Vibration Severity Chart

38

Vous aimerez peut-être aussi

- Vibration PDFDocument74 pagesVibration PDFshobhan1984Pas encore d'évaluation

- Vibration BasicsDocument120 pagesVibration Basicspradeep.selvarajan100% (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- Basic Machinery VibrationsDocument181 pagesBasic Machinery Vibrationsxtremewhiz100% (1)

- Vibration AnalysisDocument125 pagesVibration AnalysisAshutosh Patra100% (7)

- 2 Vibn Analysis BasicsDocument117 pages2 Vibn Analysis BasicsTanoj PatroPas encore d'évaluation

- Basic Vibration AnalysisDocument43 pagesBasic Vibration AnalysisAshwani Dogra89% (9)

- Rotordynamics TutorialDocument59 pagesRotordynamics TutorialAmbrish SinghPas encore d'évaluation

- Mechanical Vibrations and Condition MonitoringD'EverandMechanical Vibrations and Condition MonitoringÉvaluation : 5 sur 5 étoiles5/5 (1)

- Vibration DiagnosticsDocument54 pagesVibration Diagnosticsahadryk80% (5)

- Vibration Introduction CourseDocument76 pagesVibration Introduction CourseAbderrahim Abaray100% (4)

- Day-1 Basic of Vibration Analysis & DiagnosticsDocument136 pagesDay-1 Basic of Vibration Analysis & DiagnosticsVarun MishraPas encore d'évaluation

- Structural Health MonitoringD'EverandStructural Health MonitoringDaniel BalageasPas encore d'évaluation

- Basics of Vibration AnalysisDocument36 pagesBasics of Vibration Analysisbagusindarto86% (7)

- 5 Successful Predictive Vibrations - March - 2012Document28 pages5 Successful Predictive Vibrations - March - 2012jorgemegok1860Pas encore d'évaluation

- Vibration Assessment QuizDocument2 pagesVibration Assessment QuizJose Luis RattiaPas encore d'évaluation

- Vibration NotesDocument95 pagesVibration NotesHaitham Youssef100% (1)

- Tunisia Bently Presentation DayDocument208 pagesTunisia Bently Presentation DayHamdi Mohamed100% (1)

- Vibration MonitoringDocument67 pagesVibration MonitoringApurv Khandelwal100% (4)

- Orbits and SCL PresentationDocument18 pagesOrbits and SCL PresentationChad Hunt100% (3)

- Bump TestDocument5 pagesBump Testwsjouri2510Pas encore d'évaluation

- Analisis de Vibraciones Mecanicas SKFDocument31 pagesAnalisis de Vibraciones Mecanicas SKFJhonathan GarciaPas encore d'évaluation

- Vibration Analysis Measurement ManualDocument215 pagesVibration Analysis Measurement Manualronfrend100% (1)

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookDocument8 pagesAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- Basic Vibration (Read-Only)Document139 pagesBasic Vibration (Read-Only)jawadhussain1100% (13)

- Modal TestingDocument120 pagesModal TestingGuilherme Vaz100% (1)

- A Review of Enveloping and Demodulation TechniquesDocument6 pagesA Review of Enveloping and Demodulation TechniquesMohamed WahidPas encore d'évaluation

- Vibration Diagonistic Chart PDFDocument1 pageVibration Diagonistic Chart PDFnarimenePas encore d'évaluation

- Monitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005Document60 pagesMonitoring Gear Boxes With Peakvue: Presentation at Niagara Falls Vibration Institute Chapter January 20, 2005eko bagus sunaryo100% (2)

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvuesebastianPas encore d'évaluation

- Aria VibrationDocument1 pageAria VibrationalxmaasPas encore d'évaluation

- Machine Vibration (A Beginners Guide)Document151 pagesMachine Vibration (A Beginners Guide)mavric44493% (30)

- Advance VibrationDocument263 pagesAdvance VibrationSurya Pratap SinghPas encore d'évaluation

- Vibration Field Guide (For the Newbie Vibration Analyst)D'EverandVibration Field Guide (For the Newbie Vibration Analyst)Pas encore d'évaluation

- Handbook of Rotordynamics - Fredric F. EhrichDocument470 pagesHandbook of Rotordynamics - Fredric F. EhrichAgustín Erasmo Juárez MartínezPas encore d'évaluation

- Vibration Analysis and Diagnostic GuideDocument66 pagesVibration Analysis and Diagnostic Guidejunhyol100% (2)

- Vibration ISO Level 1 Module 2Document33 pagesVibration ISO Level 1 Module 2Shambhu Poddar100% (1)

- Vibration Analysis Reports of RM ChemicalsDocument25 pagesVibration Analysis Reports of RM ChemicalsAnant Jain100% (1)

- Application of Full Spectrum of Rotating Machinery DiagnosticsDocument5 pagesApplication of Full Spectrum of Rotating Machinery DiagnosticsMajid SattarPas encore d'évaluation

- Diagnostic Reference ChartDocument4 pagesDiagnostic Reference ChartRao ShahbazPas encore d'évaluation

- Proven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesDocument4 pagesProven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesVILLANUEVA_DANIEL2064Pas encore d'évaluation

- A Practical Introduction To Condition Monitoring of RollingDocument14 pagesA Practical Introduction To Condition Monitoring of Rollingsatya_chagantiPas encore d'évaluation

- Vibration Analysis Level - 1 Updated (Compatibility Mode)Document230 pagesVibration Analysis Level - 1 Updated (Compatibility Mode)jawadhussain189% (9)

- Vibration SchoolDocument194 pagesVibration SchoolHéctor RiveraPas encore d'évaluation

- Iso 10816Document4 pagesIso 10816spbhaskaran28Pas encore d'évaluation

- Basic VibrationDocument76 pagesBasic VibrationJack Adam100% (1)

- Training VibrasiDocument91 pagesTraining VibrasiArfahHamzah100% (5)

- Monarch 1000 ManualDocument10 pagesMonarch 1000 ManualABRIL19Pas encore d'évaluation

- Fault Identification and Monitoring in Rolling Element BearingDocument234 pagesFault Identification and Monitoring in Rolling Element BearingRushikesh DandagwhalPas encore d'évaluation

- Section II - Basic Vibration TheoryDocument85 pagesSection II - Basic Vibration Theoryagiba100% (7)

- VA II TrainingDocument393 pagesVA II Trainingjawadhussain1100% (1)

- Vibration AnalysisDocument75 pagesVibration Analysistylerdurdane100% (12)

- Basic Vibration Seminar: ALPS Maintaineering Services, IncDocument101 pagesBasic Vibration Seminar: ALPS Maintaineering Services, Incbadgeo77Pas encore d'évaluation

- VA II TrainingDocument393 pagesVA II Trainingjawadhussain195% (19)

- VA-12 Datasheet 0907-7Document8 pagesVA-12 Datasheet 0907-7DANE80Pas encore d'évaluation

- Training Program On: WBPDCL SimulatorDocument30 pagesTraining Program On: WBPDCL SimulatorKuntal Satpathi100% (1)

- Training Program On Vibration AnalysisDocument92 pagesTraining Program On Vibration AnalysisDurga Prasad Padhy100% (2)

- Basic Vibration AnalysisDocument43 pagesBasic Vibration Analysisdhaval_trivedi_3Pas encore d'évaluation

- Vibration Nomograph and Vibration CriteriaDocument6 pagesVibration Nomograph and Vibration Criteriaengzues100% (2)

- Torsional Vibration - Measurement and Analysis PDFDocument14 pagesTorsional Vibration - Measurement and Analysis PDFCrystal FrazierPas encore d'évaluation

- DG1Document44 pagesDG1Anand Kumar100% (1)

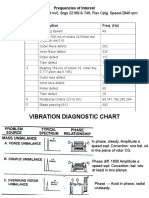

- Vibration Diagnostic Chart1Document16 pagesVibration Diagnostic Chart1Anand KumarPas encore d'évaluation

- Ethanol As Gas Turbine FuelDocument2 pagesEthanol As Gas Turbine FuelAnand Kumar100% (1)

- Tsi FinalDocument41 pagesTsi FinalAnand KumarPas encore d'évaluation

- 338-Audi 2.0l TFSI Engines EA888 SeriesDocument32 pages338-Audi 2.0l TFSI Engines EA888 SerieshyeonPas encore d'évaluation

- List Part Kekurangan PBTDocument6 pagesList Part Kekurangan PBTAde SetiawanPas encore d'évaluation

- V8 Gas Engine For CHP.: MAN NutzfahrzeugeDocument4 pagesV8 Gas Engine For CHP.: MAN NutzfahrzeugeKaiser IqbalPas encore d'évaluation

- Caterpillar 793FDocument28 pagesCaterpillar 793FGonzalo Donoso RecasensPas encore d'évaluation

- Caterpillar Service ManualDocument70 pagesCaterpillar Service ManualLAZARO GARCIAPas encore d'évaluation

- Sistemas Avanzados de PotenciaDocument41 pagesSistemas Avanzados de PotenciaMario Wenso Morales CoutiñoPas encore d'évaluation

- VZPR enDocument14 pagesVZPR enoanzarPas encore d'évaluation

- Single Phase and Three Phase Motor QuizDocument3 pagesSingle Phase and Three Phase Motor QuizMeryL AngPas encore d'évaluation

- On The Use of Rotary-Linear Generators in Floating Hybrid Wind and Wave Energy Conversion SystemsDocument6 pagesOn The Use of Rotary-Linear Generators in Floating Hybrid Wind and Wave Energy Conversion Systemsarnika33Pas encore d'évaluation

- 21 Methods of Mounting of Jobs and Cutting Tools in Machine Tools.Document29 pages21 Methods of Mounting of Jobs and Cutting Tools in Machine Tools.PRASAD326100% (3)

- Rulman Ureticisi FirmalarDocument79 pagesRulman Ureticisi FirmalarAmR ZakiPas encore d'évaluation

- Cummins Engine Datasheet: Engine Model 4Bt3.9-G2 Performance Curve FR L003Document5 pagesCummins Engine Datasheet: Engine Model 4Bt3.9-G2 Performance Curve FR L003Encep Zaenal MPas encore d'évaluation

- CV SaefullohDocument2 pagesCV SaefullohOzy NetPas encore d'évaluation

- Benelli BN302 BrochureDocument2 pagesBenelli BN302 BrochureVineel RajuPas encore d'évaluation

- Peugeot Fans Club - Peugeot 406 XU10J2CTE - Electrical and Wiring DiagramDocument5 pagesPeugeot Fans Club - Peugeot 406 XU10J2CTE - Electrical and Wiring Diagramluis vilela100% (1)

- KZ01 PR Pid4Document1 pageKZ01 PR Pid4sanjay masoodPas encore d'évaluation

- 70627-Fault Codes Identification StandardDocument26 pages70627-Fault Codes Identification StandardNovie Rizky71% (7)

- Contents:: Introduction Construction Working Principle Comparison of Rotor ReferencesDocument10 pagesContents:: Introduction Construction Working Principle Comparison of Rotor Referenceskarthikeyan249100% (1)

- 120K Plano HidraDocument4 pages120K Plano Hidrajaime bolivarPas encore d'évaluation

- 2 390F Excavator Electrical SystemDocument33 pages2 390F Excavator Electrical Systemhariz hariz100% (1)

- Project Report TE LabDocument7 pagesProject Report TE LabRadhika GurjarPas encore d'évaluation

- Anti-Gravity Micro MachineDocument21 pagesAnti-Gravity Micro MachineSandip PingalePas encore d'évaluation

- Mechatronics RVKL Y1 S5 ElectricalMotorsDocument35 pagesMechatronics RVKL Y1 S5 ElectricalMotorsVenkat SaiPas encore d'évaluation

- Troubleshooting - E361 High Engine Coolant Temperature - C27 Generator Set GDS00001-UPDocument3 pagesTroubleshooting - E361 High Engine Coolant Temperature - C27 Generator Set GDS00001-UPEdwin FontechaPas encore d'évaluation

- Aircraft Design: Lecture 2: G. Dimitriadis and O. LéonardDocument53 pagesAircraft Design: Lecture 2: G. Dimitriadis and O. LéonardJosue Eleazar Guerrero Duran100% (1)

- Spare Parts List: Hand-Held Gas Saw DS KC80-12"Document20 pagesSpare Parts List: Hand-Held Gas Saw DS KC80-12"mayoo1986Pas encore d'évaluation

- pc250lc 6 1997 (71e)Document12 pagespc250lc 6 1997 (71e)Hanin DitaPas encore d'évaluation

- 7.5 HP 40 RPM Bevel Helical Geared Motor Flange Mouted Am-0832Document1 page7.5 HP 40 RPM Bevel Helical Geared Motor Flange Mouted Am-0832Sanjeevi JagadishPas encore d'évaluation

- Diagrama OKI B930Document19 pagesDiagrama OKI B930jrodriguezb0% (1)

- Vacuum PumpDocument126 pagesVacuum PumpJessicalba Lou100% (1)