Académique Documents

Professionnel Documents

Culture Documents

QFD Case Study

Transféré par

Hunny BhagchandaniDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

QFD Case Study

Transféré par

Hunny BhagchandaniDroits d'auteur :

Formats disponibles

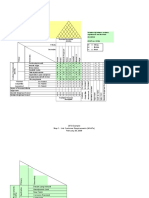

QFD Case Study

House Of Quality

The first phase in the implementation of the

Quality Function Deployment process involves

putting together a "House of Quality.

The HOQ translates the VOC into design

requirements that meet specific target values

and matches that against how an organization

will meet those requirements .

Many managers and engineers consider the HOQ

to be the primary chart in quality planning. The

structure of QFD can be thought of as a

framework of a house.

Building the House Of

Quality

Step 1List Customer

Requirements (WHATs)

The list of customer requirements is divided

into a hierarchy of primary, secondary, and

tertiary

customer

requirements.

For

example, a primary customer requirement

might

be

dependability

and

the

corresponding

secondary

customer

requirements

could

include

reliability,

longevity, and maintainability.

Case Study: Application of QFD

in Automobile Industry

Performance Aesthetics

Customer Requirements

(WHATs)

Reasonable Cost

Aerodynamic Look

Nice Finish

Corrosion Resistant

Lightweight

Strength

Durable

Tertiary

Secondary

Primary

A company that manufactures bicycle

components such as cranks, hubs,

rims, etc., wants to expand their

product line by also producing

handlebar stems for mountain bikes.

The target here is to design this ,

keeping customer requirements in

mind.

Step 2List Technical

Descriptors (HOWs)

Material

Selection

Manufacturing

Process

Technical Descriptors

(HOWs)

Steel

Aluminum

Titanium

Welding

Die Casting

Sand Casting

Forging

Powder Metallurgy

Tertiary

Primary

Secondary

The goal of the house of quality is to design or

change the design of a product in a way that

meets or exceeds the customer expectations. The

QFD team must come up with engineering

characteristics or technical descriptors (HOWS)

that will affect one or more of the customer

requirements.

Step 3Develop a Relationship Matrix

between WHATs and HOWs

Relationship Matrix

Technical Descriptors

(HOWs)

Material Manufacturing

Process

Lightweight

Strength

Durable

Sand Casting

Steel

Aluminum

Titanium

Welding

Die Casting

Secondary

Aesthetics

Reasonable Cost

Aerodynamic Look

Nice Finish

Corrosion Resistant

Performance

Customer Requirements

(WHATs)

Primary

Secondary

Forging

Powder Metallurgy

Primary Selection

Relationship between

Customer Requirements and

Technical Descriptors

WHATs vs. HOWs

+9

+3

Strong

Medium

+1

Weak

Adding relationship matrix to the house of quality

Step 4Develop an Interrelationship Matrix

between HOWs

Interrelationship between Technical

Descriptors (correlation matrix)

HOWs vs. HOWs

Technical Descriptors

(HOWs)

Sand Casting

Die Casting

Titanium

W elding

Aluminum

Steel

Secondary

Prim ary

Perform ance Aesthetics

Customer Requirements

(W HATs)

Secondary

Strong Positive

+3

-3

Positive

Negative

Strong Negative

-9

Forging

Pow der Metallurgy

Primary

Material Manufacturing

Selection

Process

+9

Reasonable Cost

Aerodynamic Look

Nice Finish

Corrosion Resistant

Lightweight

Strength

Durable

Adding interrelationship matrix to the

house of quality

Relationship between

Customer Requirements and

Technical Descriptors

WHATs vs. HOWs

+9

+3

Strong

Medium

+1

Weak

Step 5Competitive Assessments

Interrelationship between Technical

Descriptors (correlation matrix)

HOWs vs. HOWs

Negative

Strong Negative

Material

Selection

Manufacturing

Process

Secondary

3

4

4

4

3

3

3

Reasonable Cost

Aerodynamic Look

Nice Finish

Corrosion Resistant

Lightweight

Strength

Durable

Our Product

As Product

Bs Product

Relationship between

Customer Requirements and

Technical Descriptors

WHATs vs. HOWs

0

0

5

5

0

0

0

5

0

0

0

4

5

5

0

0

0

0

0

0

0

0

0

0

4

5

5

4

4

3

3

+9

Strong

+3

Medium

+1

Weak

2

3

3

2

2

4

4

O u r P ro d u c t

C u s to m e r

C o m p e t i t Ai v es P r o d u c t

A ssessm ent

B s P ro d u c t

Technical

Competitive

Assessment

S e co n d ary

a ry

P e r f o r m aAn ec se t h e t Pic rs i m

C u s to m e r R e q u ire m e n ts

(W H A T s)

Primary

Technical Descriptors

(HOWs)

T it a n i u m

W e ld in g

-9

S te e l

A lu m in u m

-3

F o r g in g

P o w d e r M e t a ll u r g y

Positive

S a n d C a s t in g

Strong Positive

+3

D ie C a s t i n g

+9

Adding customer and technical competitive assessment to

the house of quality

Step 6Develop Prioritized Customer

Requirement

Absolute Weight and Percent

Finally, the absolute weight is calculated by

multiplying the importance to customer, scale-up

factor, and sales point:

Absolute Weight = (Importance to Customer)

(Scale-up Factor)(Sales Point)

After summing all the absolute weights, a percent

and rank for each customer requirement can be

determined. The weight can then be used as a guide

for the planning phase of the product development.

Step 7Develop Prioritized Technical

Descriptors

Interrelationship between Technical

Descriptors (correlation matrix)

HOWs vs. HOWs

Negative

Strong Negative

F o r g in g

P o w d e r M e t a ll u r g y

Durable

0

0

5

1

5

5

0

0

6

5

0

5

0

9

5

0

0

4

4

4

5

5

0

7

5

0

0

0

3

0

0

0

0

6

0

0

0

0

9

0

As Product

Bs Product

Degree of Technical Difficulty

Target Value

Absolute Weight and Percent

168 227193 92 162122132125

Relative Weight and Percent

251 401303167 213 203165171

Prioritized Technical

Descriptors

+1

Weak

8

5

5

2

7

5

3

4 1.3 1.5 16

4 1 1.5 8

4 1 1 5

4 1 1 2

4 1.3 2 18

3 1 1 5

3 1 1 3

Adding prioritized technical descriptors & prioritized customer

requirements to the house of quality

P rio ritiz e d C u s to m e r

R e q u ire m e n ts

Lightweight

Strength

2

3

3

2

2

4

4

Strong

Medium

S a le s P o in t

A b s o lu te W e ig h t a n d P e rc e n t

Aerodynamic Look

Nice Finish

Corrosion Resistant

4

5

5

4

4

3

3

+9

+3

S c a le -u p F a c to r

3

4

4

4

3

3

3

Reasonable Cost

Our Product

Relationship between

Customer Requirements and

Technical Descriptors

WHATs vs. HOWs

T a r g e t V a lu e

T it a n i u m

W e ld in g

Secondary

S a n d C a s t in g

Manufacturing

Process

D ie C a s t i n g

Material

Selection

C u s t o m e Or u r P r o d u c t

C o m p e t i t iAv e s P r o d u c t

A ssessm ent

B s P ro d u c t

Im p o rta n c e to C u s to m e r

Technical

Competitive

Assessment

S e c o n d ary

ary

P e r f o r m a An ec se t h e t icP rs i m

C u s to m e r R e q u ire m e n ts

(W H A T s)

Primary

Technical Descriptors

(HOWs)

A lu m in u m

-3

-9

Strong Positive

Positive

S te e l

+9

+3

Calculation of Absolute Weight

and Relative Weight

Absolute Weight and Percent

The absolute weight for the jth technical descriptor is then

given by

where aj= row vector of absolute weights for the technical

descriptors

(j = 1,..., m)

Rij = weights assigned to the relationship matrix (i = 1 ,...,

n,

j = 1,..., m)

The absolute weight for each technical descriptor

is determined by taking the dot product of the

column in the relationship matrix and the column

for importance to customer. For instance, for

aluminum the absolute weight is 98 + 15 +

95 + 92 + 97 + 35 + 33 = 227. The

greater values of absolute weight indicate that

the handlebar stem should be an aluminum die

casting.

Relative Weight and Percent

In a similar manner, the relative weight for the jth

technical descriptor is then given by replacing the

degree of importance for the customer

requirements with the absolute weight for

customer requirements. It is

where bj = row vector of relative weights for the

technical descriptors (j = 1,..., m)

di = column vector of absolute weights for the

customer requirements (i = 1,..., n)

Higher absolute and relative ratings identify

areas where engineering efforts need to be

concentrated. The relative weight for each

technical descriptor is determined by taking the

dot product of the column in the relationship

matrix and the column for absolute weight in the

prioritized customer requirements. The greater

values of relative weight also indicate that the

handlebar stem should be an aluminum die

casting.

Vous aimerez peut-être aussi

- Quality Function DeploymentDocument32 pagesQuality Function DeploymentPrakashRaiPas encore d'évaluation

- Customer Needs Kano Garvin & QFDDocument42 pagesCustomer Needs Kano Garvin & QFDmadhubooradaPas encore d'évaluation

- Ob AssigmentDocument2 pagesOb Assigmentpraveen rajPas encore d'évaluation

- DFMA I Design For Manufacturing & AssemblyDocument22 pagesDFMA I Design For Manufacturing & AssemblyRam ChandranPas encore d'évaluation

- QFD Powerpoint TemplateDocument2 pagesQFD Powerpoint Templatesvachon2000Pas encore d'évaluation

- Are You Solving The Right ProblemDocument6 pagesAre You Solving The Right ProblemVikas MahendraPas encore d'évaluation

- World Class Manufacturing Performance Measurements: Buker, IncDocument22 pagesWorld Class Manufacturing Performance Measurements: Buker, IncNaresh DeshpandePas encore d'évaluation

- A Living From Dyeing Revised 12.12Document47 pagesA Living From Dyeing Revised 12.12amlogan48Pas encore d'évaluation

- Accenture 2013 Global Manufacturing Study Full ReportDocument44 pagesAccenture 2013 Global Manufacturing Study Full ReportFerry TriwahyudiPas encore d'évaluation

- Quality and System Management: Final Assignment Unit 1 Prof. Mrs. Areeba ZafarDocument20 pagesQuality and System Management: Final Assignment Unit 1 Prof. Mrs. Areeba ZafarNabeel Afzal0% (1)

- Agile-Stage-Gate For Manufacturers: Research-Technology ManagementDocument11 pagesAgile-Stage-Gate For Manufacturers: Research-Technology ManagementFreyja SigurgisladottirPas encore d'évaluation

- House of QualityDocument8 pagesHouse of QualityAudreyPas encore d'évaluation

- Research Proposal - JITDocument4 pagesResearch Proposal - JITChandni PatelPas encore d'évaluation

- Ann GildroyDocument1 pageAnn GildroynpfnowplayingPas encore d'évaluation

- Key Concepts of Supply Chain ManagementDocument28 pagesKey Concepts of Supply Chain ManagementMASROOR ALI SOOMROPas encore d'évaluation

- Multi Attribute Value AnalysisDocument75 pagesMulti Attribute Value AnalysispatrickafchainPas encore d'évaluation

- Designing Global Supply Chain NetworksDocument8 pagesDesigning Global Supply Chain NetworksaasthaPas encore d'évaluation

- Maintenance Management: Total Productive Maintenance (TPM)Document41 pagesMaintenance Management: Total Productive Maintenance (TPM)Anvesh DwivediPas encore d'évaluation

- Lean Manufacturing Case StudyDocument25 pagesLean Manufacturing Case StudyMohamed Farag Mostafa0% (1)

- Supply Chain Overview Spend Analysis - tcm244 537232 - en PDFDocument18 pagesSupply Chain Overview Spend Analysis - tcm244 537232 - en PDFwaleedPas encore d'évaluation

- Ben and JerryDocument4 pagesBen and JerryDeji LipedePas encore d'évaluation

- Kano Model of HDFC BankDocument9 pagesKano Model of HDFC BankAnkit KapilaPas encore d'évaluation

- Inventory Control Models - Eoq & JitDocument31 pagesInventory Control Models - Eoq & Jitfaraheee100% (1)

- Tinpm Merged 2Document218 pagesTinpm Merged 2Akshay MehtaPas encore d'évaluation

- Individual Assignment Negotiate Interests, Not PositionsDocument2 pagesIndividual Assignment Negotiate Interests, Not PositionsrizqighaniPas encore d'évaluation

- Dell Manufacturing PracticesDocument10 pagesDell Manufacturing PracticesShilpa UnnikrishnanPas encore d'évaluation

- Operations ManagementDocument80 pagesOperations ManagementgopalsakalaPas encore d'évaluation

- Operations Strategy PresentationDocument48 pagesOperations Strategy PresentationYannick Harvey100% (2)

- 4.2 Process CapacityDocument11 pages4.2 Process Capacitysaheb167Pas encore d'évaluation

- CH 01Document18 pagesCH 01Anonymous cHzTiOWm2mPas encore d'évaluation

- Quality GurusDocument13 pagesQuality GurusMuhammad Indra Ramadhan GintingPas encore d'évaluation

- Bni Ar 2008Document366 pagesBni Ar 2008Apsari Gavyn PratantyoPas encore d'évaluation

- Business Process Re-Engineering Case StudiesDocument10 pagesBusiness Process Re-Engineering Case StudiesAlena JosephPas encore d'évaluation

- Implementation of 5S Tools in Bottling Industry To Improvement of ProductivityDocument13 pagesImplementation of 5S Tools in Bottling Industry To Improvement of ProductivityIJRASETPublicationsPas encore d'évaluation

- QFD Case Study 666Document7 pagesQFD Case Study 666BenhassineMedaliPas encore d'évaluation

- QFD (Quality Function Deployment)Document15 pagesQFD (Quality Function Deployment)Kuldeep RawatPas encore d'évaluation

- Operations ManagementDocument175 pagesOperations ManagementAnurag Saikia100% (2)

- Lean Starbucks - DO NOT PRINTDocument9 pagesLean Starbucks - DO NOT PRINTvyjayanthiPas encore d'évaluation

- Chapter 4Document131 pagesChapter 4Ankita HandaPas encore d'évaluation

- 2628 LamsonDocument5 pages2628 LamsonRehan Memon0% (1)

- Decision Making Chapter Summary AssignmentDocument12 pagesDecision Making Chapter Summary AssignmentFezi Afesina Haidir100% (1)

- Zero DefectDocument16 pagesZero DefectStephen Lim Kean Jin100% (1)

- Rondell Data CorporationDocument21 pagesRondell Data CorporationPrerna Bhadani100% (1)

- Babalola2019 PDFDocument33 pagesBabalola2019 PDFMatt SlowikowskiPas encore d'évaluation

- Green Supply Chain ManagementDocument16 pagesGreen Supply Chain ManagementRADHIKA GUPTAPas encore d'évaluation

- Quality Management AssignmentDocument5 pagesQuality Management AssignmentSajjad AliPas encore d'évaluation

- Applying The VRIO Framework2Document2 pagesApplying The VRIO Framework2alansheaper1100% (1)

- Drivers of Green ManufacturingDocument18 pagesDrivers of Green Manufacturinggautam_lele_1Pas encore d'évaluation

- Institute of Business Technology (BIZTEK)Document73 pagesInstitute of Business Technology (BIZTEK)Asad MazharPas encore d'évaluation

- LL GroupNo.3 SectionADocument10 pagesLL GroupNo.3 SectionAAkash PanigrahiPas encore d'évaluation

- House of Quality: Interrelationship Between Technical DescriptorsDocument6 pagesHouse of Quality: Interrelationship Between Technical Descriptorstaran.bhasinPas encore d'évaluation

- QFD MatrixDocument8 pagesQFD MatrixSuryo WiwohoPas encore d'évaluation

- QFD MatrixDocument8 pagesQFD MatrixIrvin Reyes RPas encore d'évaluation

- Module III Lec1Document12 pagesModule III Lec1Srinivasan RamachandranPas encore d'évaluation

- Submitted By: Aruba Badar (8194) Maira Izhar (7659)Document28 pagesSubmitted By: Aruba Badar (8194) Maira Izhar (7659)maira-izhar-3279Pas encore d'évaluation

- QFD FundamentalsDocument40 pagesQFD FundamentalsAvijesh JhaPas encore d'évaluation

- Quality DocumentDocument15 pagesQuality Documenttanto_deep_15Pas encore d'évaluation

- Quality Function DeploymentDocument32 pagesQuality Function DeploymentBittuPas encore d'évaluation

- Quality Function Deployment (QFD)Document12 pagesQuality Function Deployment (QFD)Abel CarrPas encore d'évaluation

- Quality Function Deployment (QFD)Document33 pagesQuality Function Deployment (QFD)anshuldcePas encore d'évaluation

- Introduction - Theoretical FrameworkDocument10 pagesIntroduction - Theoretical FrameworktochexD33% (3)

- Company Profile UsmDocument8 pagesCompany Profile Usmnishantnamdeo75Pas encore d'évaluation

- Iso 9001 - 2015Document16 pagesIso 9001 - 2015QBMontgomeryPas encore d'évaluation

- c1079 USP36 PDFDocument8 pagesc1079 USP36 PDFHassan HoudoudPas encore d'évaluation

- Operation Management ReviewerDocument68 pagesOperation Management ReviewerBryan Lord BatonPas encore d'évaluation

- APQP Process FlowDocument13 pagesAPQP Process Flowkaca82Pas encore d'évaluation

- Nspe Body of Knowledge PDFDocument61 pagesNspe Body of Knowledge PDFArjay AletaPas encore d'évaluation

- Technical BookDocument88 pagesTechnical BookSakib HusainPas encore d'évaluation

- Dry Type+TransformerDocument32 pagesDry Type+TransformeryoPas encore d'évaluation

- Preparing Technical Proposals For Government ContractingDocument12 pagesPreparing Technical Proposals For Government ContractingKhaled Abdelbaki100% (1)

- 2 TQM-Role of The Quality System-NHSDocument86 pages2 TQM-Role of The Quality System-NHSHamka HidayahPas encore d'évaluation

- Process Flow Control Plan WorksheetDocument4 pagesProcess Flow Control Plan WorksheetPuneet SharmaPas encore d'évaluation

- Company Profile Presentation Full ExportDocument45 pagesCompany Profile Presentation Full ExportNurmiaty MyaPas encore d'évaluation

- MGT504 UdDocument17 pagesMGT504 UdnicksneelPas encore d'évaluation

- What Is A Quality Management SystemDocument6 pagesWhat Is A Quality Management Systemsunilkhairnar38Pas encore d'évaluation

- TOTAL QUALITY MANAGEMENT Midterm ModuleDocument28 pagesTOTAL QUALITY MANAGEMENT Midterm ModuleJo MalaluanPas encore d'évaluation

- MazegetDocument73 pagesMazegetwatnaPas encore d'évaluation

- ISO 9001 Quality Manual TemplateDocument43 pagesISO 9001 Quality Manual TemplateNC Rigor Luis92% (13)

- Steps To API Spec Q1 ImplementationDocument6 pagesSteps To API Spec Q1 Implementationrahim80ab0% (1)

- Defects in GarmentsDocument16 pagesDefects in GarmentsarivaazhiPas encore d'évaluation

- TQM BisleriDocument27 pagesTQM BisleriDishank ShahPas encore d'évaluation

- Quality AwardsDocument9 pagesQuality AwardsCalton MungofaPas encore d'évaluation

- Quality Assurance in Halal Food Manufacturing in Malaysia: A Preliminary StudyDocument5 pagesQuality Assurance in Halal Food Manufacturing in Malaysia: A Preliminary StudyAyda AnsahPas encore d'évaluation

- SAP Overview QMDocument50 pagesSAP Overview QMAdityaPandeyPas encore d'évaluation

- Production Management: Same Same But Different, Different Different But Same.Document165 pagesProduction Management: Same Same But Different, Different Different But Same.raviPas encore d'évaluation

- Tuboser CatalogDocument8 pagesTuboser Catalogskynyrd75Pas encore d'évaluation

- 03 Drillmec Mobile Rigs 8175ccd0 f8d4 4e0e 8d0f 40fae963a7c7Document9 pages03 Drillmec Mobile Rigs 8175ccd0 f8d4 4e0e 8d0f 40fae963a7c7Janice MartinPas encore d'évaluation

- Babylon GroupDocument24 pagesBabylon GroupFarzana IshratPas encore d'évaluation

- Vendor EvaluationDocument36 pagesVendor Evaluationluvlinamorya100% (1)

- Samsung Uses Six Sigma To ChangeDocument4 pagesSamsung Uses Six Sigma To ChangeHarold Dela FuentePas encore d'évaluation