Académique Documents

Professionnel Documents

Culture Documents

FAA Supplier Control Audit

Transféré par

Mani Rathinam RajamaniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FAA Supplier Control Audit

Transféré par

Mani Rathinam RajamaniDroits d'auteur :

Formats disponibles

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

Federal Aviation Administration

Supplier Control Audit (SCA)

Presented by: Ed Bayne

Boeing Enterprise and Industry Interface Representative

Prepared by:

Brian Simons

Boeing Oversight Representative

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

What is an SCA?

FAA Order 8120.2, Part 3, section 124. Certificate Management Activity:

Certificate management activity will be focused on the Production

Approval Holders (PAH) control of its suppliers.

The FAA will determine if a PAH (e.g. The Boeing Company) is

complying with its supplier control system by performing the following

activities:

b. Supplier Control Audit. The Principle Inspector (PI) will

determine that the supplier complies with purchase order and/or

quality requirements.

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

What is an SCA? (Cont.)

FAA Order 8120.2, Part 6. Supplier Control Audit, section 139. General:

A SCA is conducted as part of the Certificate Management of the

PAH (e.g. The Boeing Company PC700).

Evaluates the outside sources (e.g. supplier) system to control

parts, materials, supplies, and services.

The SCA determines that the supplier complies with purchase order

and/or quality requirements, including any statistical sampling that

may be utilized.

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

What are the results of an SCA?

FAA Order 8120.2, Part 3, section 125. Determination of Supplier Control:

The PI determines whether a PAH is controlling its suppliers by

reviewing the results of the supplier control audits.

The PI looks for evidence that may indicate a system breakdown in

supplier control by the PAH.

Corrective action is requested for a system breakdown.

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

What are the results of an SCA? (Cont.)

If the FAA identifies evidence indicating a system breakdown in supplier

control, a Letter of Investigation (LOI) or Surveillance Evaluation Report

(SER) is issued to the PAH.

LOI vs. SER depends on the severity of the issue(s)

The LOI/SER informs the PAH that the FAA is investigating the matter.

The LOI/SER describes each of the identified nonconformances as follows:

Required Condition (e.g. AS9100 requirement, supplier procedure, etc.)

Encountered Condition (e.g. PAH failed to ensure AS9100was implemented

at supplier)

Example (e.g. specific evidence collected during SCA: un-calibrated inspection

tools, past due internal audits or management reviews, incomplete corrective actio

missing training records, etc., etc., etc.)

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

What are the results of an SCA? (Cont.)

The PAH is requested to provide a response containing:

Additional evidence or statements addressing the conditions or

examples

Mitigating circumstances relevant to the case

Nonconformance cause, and action to correct and prevent recurrence

Response is typically due within 20 working days, upon receipt of LOI

This language sounds like legalese, because it is!

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

What are the results of an SCA? (Cont.)

The PAH, and its suppliers, are required to maintain a quality

management system per Code of Federal Regulations, 14 CFR

21.165.

The PAHs Production Certificate is at risk during every SCA

The PAH is at risk for civil penalties stemming from LOIs

By law, 14 CFR 13.14; Each violation is subject to civil penalty of

not more than $25,000 per occurrence. (i.e. each individual bolt

improperly torqued, each part improperly heat treated)

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

What are the results of an SCA? (Cont.)

Past supplier Issues resulting in a civil penalty have included:

Special Manufacturing Processes (9100 clause 7.5.2) Improper Heat Treating

Design Control (clause 7.3) Revision Control of Drawings & Specifications,

Parts Manufactured Without Proper Engineering Approval

Material Control (clause 8.3) Level of Control Over Non-conforming Product

Parts Not Properly Identified for Scrap

Tool & Gauge Control (clause 7.6) Non-compliance of Calibration/Certification

System

Inspection System (clause 8.2.4) Control of Sampling System (Lack Training,

Audits)

Manufacturing Control (clause 7.5.1) Inadequate Work Instructions

Certifications (clause 6.2.2) Employees Not Properly Certified Performing

Operations

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

Why should the Certification Bodies (CBs)

and their auditors care about SCA results?

PAH supplier approval is based on 9100 certification recognition

The majority of tier 1 and tier 2 aerospace suppliers are 9100 certified

The supplier QMS processes assessed during the SCA are the same

ones assessed by the CB during initial and surveillance activity

FAA verbal comment following a recent SCA audit, regarding a certified

supplier that did not have an established FAI process, per AS9100

clause 8.2.4.2 requirements:

He (FAA auditor) is concerned that they are CRB approved and it

apparently wasnt identified as an issue by the approving CRB

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

SCA Statistics (The Big Picture Show)

FAA supplier control audits conducted at Boeing Commercial Airplane

(BCA) division suppliers from October 2005 through March 2007:

52 clients (9100 certified suppliers)

28 domestic / 24 non-domestic clients

21 clients had at least 1 identified QMS nonconformance

40% of total

86 total nonconformances identified

Average per client: 4

Top client: 9

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

SCA Statistics (The Good, The Bad, The Ugly)

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

SCA Statistics

Top Nonconforming 9100 Clauses

FAA SCAs conducted at BCA division suppliers from October 2005 through

March 2007:

7.5.1 Control of Production and Service Provision (13)

8.2.4 Monitoring and Measurement of Product (8)

8.2.4.2 First Article Inspection (7)

7.5.1.1 Production Documentation (6)

7.5.5 Preservation of Product (6)

4.2.3 Control of Documents (5)

4.2.1 Documentation Requirements (4)

4.2.2 Quality Manual (4)

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

7.5.1 Control of Production and Service Provision

Production work order issues:

Obsolete/inaccurate drawing and specification call-out

Missing or omitted manufacturing/inspection operation entries

Different part counts between operations (Part accountability)

Manufacturing/inspection practice does not match operation instruction

Manufacturing practice does not meet engineering/specification requirements

Recommendations for CB auditor:

Increase audit time in manufacturing/inspection areas

Increase production work order sample size during audits

Review for part accountability, required entries, evidence of operation completion

Compare work order to drawing/specification requirements

Witness manufacturing/inspection practice vs. work order, drawing,

specification, instruction, etc.

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

The Loud and Clear Message

Aerospace QMS certification/registration scheme:

The FAA allows the PAH to use other-parties to perform supplier assessments,

surveillance, and certification. It is an earned privilege, not guaranteed.

FAA perception of effectiveness is based on facts collected during SCA activity

Certification body management and auditor responsibilities:

Ensure the integrity of the audit process and the validity of the issued certificate

Recognize the inherent conflict of interest perception (Clients pay for certificates)

Demonstrate ethical behavior to build trust and confidence with the PAH and FAA

(i.e. no soft grading of nonconformances, thorough CA verification, etc.)

CB auditors role is critical for PAHs Certificate Management

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

Proposed Process Improvements

Direct communication of SCA results from PAH to responsible CB

OASIS feedback loop

Formal PAH report (e.g. Boeing Strengths and Issues document)

Participation by CB in LOI corrective action response

Participation of CB auditor, along with PAH personnel, during a SCA

Direct communication of SCA results to accreditation body (e.g. ANAB)

for CB oversight planning and auditing activity

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

The Reality of the Civil Aviation Industry.......

PAH and FAA personnel:

Are not as constrained by audit agendas/plans or time during their audit

activity

Audit trails can be methodically followed and investigated, allowing

greater possibility of exposing process nonconformances

Spend the majority of audit time focused on manufacturing/inspection

processes

Shouldnt the Certification Body Personnel:

Ensure audit planning policies and CB/Client agreements meet the intent

of AS9104 clause 8.2.2 Duration of Assessment:

It is anticipated that the requirements of the AQMS Standards shall

add on-site assessment time

Justify and utilize additional on-site assessment time to emphasize

manufacturing/inspection documentation, personnel competence, and

process conformance

Registration Management Committee (RMC)

Workshop June 21 - 22, 2007

Regulatory Requirements

Supplier Control Audit - SCA

Questions or clarifications?

Comments?

Discussion?

Email feedback to brian.d.simons@boeing.com

FAA CFR's and Orders: http://www.faa.gov/

Vous aimerez peut-être aussi

- Corrective Action FormDocument1 pageCorrective Action FormAmine ChahiPas encore d'évaluation

- 9104 2a FormdDocument3 pages9104 2a Formdkarthi keyan100% (1)

- First Article Inspection Report FormsDocument5 pagesFirst Article Inspection Report FormsSivananthaa MurtheePas encore d'évaluation

- ARP4249-Bearing Corrosion Test MethodDocument8 pagesARP4249-Bearing Corrosion Test MethodJicheng PiaoPas encore d'évaluation

- Fatigue and Damage Tolerance: Edward Herba, January 29,2004Document38 pagesFatigue and Damage Tolerance: Edward Herba, January 29,2004Nagaraj RamachandrappaPas encore d'évaluation

- AC7101.1 Rev G 2Document37 pagesAC7101.1 Rev G 2Namelezz ShadowwPas encore d'évaluation

- As9100D Gap Analysis Tool 9. Evaluation Gap Analysis QuestionnaireDocument6 pagesAs9100D Gap Analysis Tool 9. Evaluation Gap Analysis Questionnairechandravel sankarakumar100% (1)

- Aerospace Coatings Quality ManualDocument89 pagesAerospace Coatings Quality ManualhenryPas encore d'évaluation

- Maintain Safety with Alerts on Aircraft Parts IssuesDocument123 pagesMaintain Safety with Alerts on Aircraft Parts IssuesEstevam Gomes de AzevedoPas encore d'évaluation

- Asqr01 Form1Document17 pagesAsqr01 Form1Jim ToddPas encore d'évaluation

- CQI and IRCA Certified ISO 9001:2015 Lead Auditor Training CourseDocument6 pagesCQI and IRCA Certified ISO 9001:2015 Lead Auditor Training CourseMukesh YadavPas encore d'évaluation

- BF Aerospace QA ManualDocument46 pagesBF Aerospace QA ManualJoginder Kaur100% (2)

- SMS/QMS Awareness Course ICAA/EASA AmmanDocument5 pagesSMS/QMS Awareness Course ICAA/EASA AmmanHusam FPas encore d'évaluation

- FAA Order 8110 49 W-CHG 2Document84 pagesFAA Order 8110 49 W-CHG 2Chris1715Pas encore d'évaluation

- 03 T HVP PDFDocument6 pages03 T HVP PDFkimikien1Pas encore d'évaluation

- Goodrich Proprietary - This Document Is Subject To The Controls and Restrictions On The Title Page. U. S. Export Classification: EAR 9E991Document2 367 pagesGoodrich Proprietary - This Document Is Subject To The Controls and Restrictions On The Title Page. U. S. Export Classification: EAR 9E991duythienddtPas encore d'évaluation

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveD'EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectivePas encore d'évaluation

- Auditor Qualification CriteriaDocument10 pagesAuditor Qualification CriteriaMani Rathinam RajamaniPas encore d'évaluation

- Interface control document The Ultimate Step-By-Step GuideD'EverandInterface control document The Ultimate Step-By-Step GuidePas encore d'évaluation

- IAQG SCMH-3.4.2-Foreign-Object-Damage-FOD-Prevention-Program-Guidance-Material-Rev-C-Dated-17APR2018Document32 pagesIAQG SCMH-3.4.2-Foreign-Object-Damage-FOD-Prevention-Program-Guidance-Material-Rev-C-Dated-17APR2018LiherPas encore d'évaluation

- Director Aerospace Quality Regulatory Compliance in Seattle WA Resume Karl FanusDocument3 pagesDirector Aerospace Quality Regulatory Compliance in Seattle WA Resume Karl FanusKarlFanusPas encore d'évaluation

- AQAP 2070-Ed2-En PDFDocument56 pagesAQAP 2070-Ed2-En PDFFabrizio FalcioniPas encore d'évaluation

- NATO Quality Assurance Requirements for Design, Development and ProductionDocument21 pagesNATO Quality Assurance Requirements for Design, Development and ProductionHilalPas encore d'évaluation

- FAA Flight Engineer Practical Test StandardDocument49 pagesFAA Flight Engineer Practical Test Standardkisakye alexPas encore d'évaluation

- Quality Training Courses ListDocument1 pageQuality Training Courses ListMani Rathinam RajamaniPas encore d'évaluation

- Faa Ir M 8040 - 1C PDFDocument77 pagesFaa Ir M 8040 - 1C PDFபிரேம் ஆனந்த்Pas encore d'évaluation

- Gilberto Trivelato - IMADocument9 pagesGilberto Trivelato - IMACarlos Gonzalez AriasPas encore d'évaluation

- Service Bulletin (SB) : Service Bulletins Provide Information ForDocument6 pagesService Bulletin (SB) : Service Bulletins Provide Information ForShandy AvisenaPas encore d'évaluation

- Product Safety Awareness Guidance 23APR2021 3.9.2Document27 pagesProduct Safety Awareness Guidance 23APR2021 3.9.2Mani Rathinam RajamaniPas encore d'évaluation

- General RevisionDocument195 pagesGeneral Revisionw_tahanPas encore d'évaluation

- Explanation Kralijc MatrixDocument4 pagesExplanation Kralijc Matrixm_vasilyevaPas encore d'évaluation

- Easa-Icaa Sms m5Document13 pagesEasa-Icaa Sms m5Husam FPas encore d'évaluation

- Faa-Easa Tip Revision 5Document168 pagesFaa-Easa Tip Revision 5Florin NitePas encore d'évaluation

- 5 GRR Calculation Presentation TemplateDocument5 pages5 GRR Calculation Presentation TemplatePradeep ShindePas encore d'évaluation

- Approvals and Standardisation Organisation Approvals Docs Part 145 Annex B B11. TE - CAO.00129 Foreign Part 145 Approvals - Experience LogbookDocument6 pagesApprovals and Standardisation Organisation Approvals Docs Part 145 Annex B B11. TE - CAO.00129 Foreign Part 145 Approvals - Experience LogbookPhellipe CovetousPas encore d'évaluation

- DALculus - Theory and Tool For Development Assurance Level AllocationDocument16 pagesDALculus - Theory and Tool For Development Assurance Level Allocationperry.stamatiouPas encore d'évaluation

- MFC Toolkit Fai Guidebook PDFDocument30 pagesMFC Toolkit Fai Guidebook PDFREVDPas encore d'évaluation

- First Article Inspection FAI AS9102 PresentationDocument28 pagesFirst Article Inspection FAI AS9102 PresentationaldiPas encore d'évaluation

- The Grid 2: Blueprint for a New Computing InfrastructureD'EverandThe Grid 2: Blueprint for a New Computing InfrastructurePas encore d'évaluation

- Aircraft Hydraulic System Components GuideDocument24 pagesAircraft Hydraulic System Components Guideavijayakumar_1964Pas encore d'évaluation

- Aqs 9000Document4 pagesAqs 9000sairam0504664l9887Pas encore d'évaluation

- Romaqua Group - Risk MatrixDocument4 pagesRomaqua Group - Risk MatrixBogdan AndreiPas encore d'évaluation

- Cross Matrix ISO-AsDocument13 pagesCross Matrix ISO-Asprabha_1Pas encore d'évaluation

- Basic LEAN Tools-Rockwell CollinsDocument54 pagesBasic LEAN Tools-Rockwell CollinsraePas encore d'évaluation

- AS9120 AQMS Auditor Application User GuideDocument11 pagesAS9120 AQMS Auditor Application User GuideBenjamin GalvezPas encore d'évaluation

- PowerPoint Presentation FAI AS9102Document29 pagesPowerPoint Presentation FAI AS9102Danny Fydm OliveiraPas encore d'évaluation

- Order8100 7C - An Aircraft Certification Systems Evaluation ProgramDocument156 pagesOrder8100 7C - An Aircraft Certification Systems Evaluation Programjoshua_sx1100% (2)

- NASA Protective Coating StandardDocument53 pagesNASA Protective Coating StandardanafadoPas encore d'évaluation

- Framework Procedure For DDPMASDocument112 pagesFramework Procedure For DDPMASzach rogersPas encore d'évaluation

- ESDS BasicsDocument12 pagesESDS BasicspontooPas encore d'évaluation

- Nadcap Customer Support Initiative (NCSI) For NewcomersDocument94 pagesNadcap Customer Support Initiative (NCSI) For NewcomersAli Mohsin100% (1)

- CPK GuidelinesDocument2 pagesCPK GuidelinesNavnath Tamhane100% (1)

- Install and stake spherical bearings properlyDocument1 pageInstall and stake spherical bearings properlykamaleshaiahPas encore d'évaluation

- 7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Document4 pages7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Moti Ben-ZurPas encore d'évaluation

- Counterfeit Parts Standards and Certifications GuideDocument38 pagesCounterfeit Parts Standards and Certifications GuideVenkateswararao GantaPas encore d'évaluation

- Quality Assurance Audit Area: Audit Plan Product (Aircraft) Audit Y12E, 9N-AKU Audit ObjectivesDocument4 pagesQuality Assurance Audit Area: Audit Plan Product (Aircraft) Audit Y12E, 9N-AKU Audit ObjectivesKisna BhurtelPas encore d'évaluation

- Aviation Windshield ErrorDocument10 pagesAviation Windshield ErrorAnanda FitrianiPas encore d'évaluation

- ProgramDocument1 pageProgramMani Rathinam RajamaniPas encore d'évaluation

- Catalog For Bearing DesignDocument70 pagesCatalog For Bearing DesignHameer ReddyPas encore d'évaluation

- Product, Process, and Problem Analysis Quality SystemDocument25 pagesProduct, Process, and Problem Analysis Quality SystemMani Rathinam RajamaniPas encore d'évaluation

- List of Certifications DiscontinuedDocument30 pagesList of Certifications DiscontinuedMani Rathinam RajamaniPas encore d'évaluation

- M.SC Result 2017Document1 pageM.SC Result 2017Mani Rathinam RajamaniPas encore d'évaluation

- Leave PlanDocument2 pagesLeave PlanMani Rathinam RajamaniPas encore d'évaluation

- Computer Aided Process Planning Techniques: Mani Rathinam Rajamani PHD RoadmapDocument6 pagesComputer Aided Process Planning Techniques: Mani Rathinam Rajamani PHD RoadmapMani Rathinam RajamaniPas encore d'évaluation

- TL 9000 Quality Management System Measurements Handbook NPR ExamplesDocument7 pagesTL 9000 Quality Management System Measurements Handbook NPR ExamplesMani Rathinam RajamaniPas encore d'évaluation

- D. All of The AboveDocument3 pagesD. All of The AboveramarajanenggPas encore d'évaluation

- Payment Acknowledgment - 180604092233Document1 pagePayment Acknowledgment - 180604092233Mani Rathinam RajamaniPas encore d'évaluation

- LSS Mani Rathinam RajamaniDocument2 pagesLSS Mani Rathinam RajamaniMani Rathinam RajamaniPas encore d'évaluation

- Join The Big Family. Sign Up Is Open For The Time Being... Join Us!!!!Document1 pageJoin The Big Family. Sign Up Is Open For The Time Being... Join Us!!!!Mani Rathinam RajamaniPas encore d'évaluation

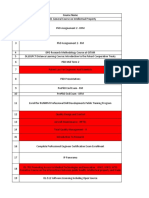

- Learning Plan Dec 2017-Apr 2018Document5 pagesLearning Plan Dec 2017-Apr 2018Mani Rathinam RajamaniPas encore d'évaluation

- AS9100 Certification StatusDocument192 pagesAS9100 Certification StatusMani Rathinam RajamaniPas encore d'évaluation

- Month Wise NC TrendDocument2 pagesMonth Wise NC TrendMani Rathinam RajamaniPas encore d'évaluation

- 3x5 Why Worksheet For SuppliersDocument1 page3x5 Why Worksheet For SuppliersMani Rathinam RajamaniPas encore d'évaluation

- Minitab Print Window PDFDocument1 pageMinitab Print Window PDFMani Rathinam RajamaniPas encore d'évaluation

- Flight 1 Mon, Mar 4: Cathay PacificDocument6 pagesFlight 1 Mon, Mar 4: Cathay PacificMani Rathinam RajamaniPas encore d'évaluation

- Letter acknowledges participation in checklist developmentDocument1 pageLetter acknowledges participation in checklist developmentMani Rathinam RajamaniPas encore d'évaluation

- Fod Compliance & Findings - Bay 1Document2 pagesFod Compliance & Findings - Bay 1Mani Rathinam RajamaniPas encore d'évaluation

- How to Prepare Your Manuscript CertificateDocument1 pageHow to Prepare Your Manuscript CertificateMani Rathinam RajamaniPas encore d'évaluation

- VSM TemplateDocument7 pagesVSM TemplateMani Rathinam RajamaniPas encore d'évaluation

- BCB 201 (IB) - Mar 2019 PDFDocument38 pagesBCB 201 (IB) - Mar 2019 PDFMani Rathinam RajamaniPas encore d'évaluation

- Matecconf Imanee2018 08013Document6 pagesMatecconf Imanee2018 08013Mani Rathinam RajamaniPas encore d'évaluation

- BCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFDocument10 pagesBCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFMani Rathinam RajamaniPas encore d'évaluation

- 09 - Chapter 3Document11 pages09 - Chapter 3Mani Rathinam RajamaniPas encore d'évaluation

- Standards Made Available Free of Cost To Combat COVID-19Document4 pagesStandards Made Available Free of Cost To Combat COVID-19Mani Rathinam RajamaniPas encore d'évaluation

- BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFDocument8 pagesBCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFMani Rathinam RajamaniPas encore d'évaluation

- BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFDocument8 pagesBCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFMani Rathinam RajamaniPas encore d'évaluation

- How to Prepare Your Manuscript CertificateDocument1 pageHow to Prepare Your Manuscript CertificateMani Rathinam RajamaniPas encore d'évaluation

- Methods of Piling ExplainedDocument3 pagesMethods of Piling ExplainedRajesh KhadkaPas encore d'évaluation

- Teradata Version DifferencesDocument3 pagesTeradata Version DifferencesShambuReddy100% (1)

- Learning One-to-One - Book ReviewDocument3 pagesLearning One-to-One - Book Reviewwhistleblower100% (1)

- Types of Commercial CellDocument4 pagesTypes of Commercial CellDavePas encore d'évaluation

- List of Linkages2016Document74 pagesList of Linkages2016engrwho0% (1)

- Phase Locked LoopDocument4 pagesPhase Locked LoopsagarduttaPas encore d'évaluation

- How To Choose Food StarchesDocument20 pagesHow To Choose Food StarchesBoat Tanin100% (3)

- Nord Motors Manual BookDocument70 pagesNord Motors Manual Bookadh3ckPas encore d'évaluation

- Hughes Brothers PDFDocument52 pagesHughes Brothers PDFJavier MaldonadoPas encore d'évaluation

- Dissertation ErsatzteilmanagementDocument7 pagesDissertation ErsatzteilmanagementWriteMyEnglishPaperForMeCanada100% (1)

- Manual Instalaciones Electricas para Centros de ComputoDocument65 pagesManual Instalaciones Electricas para Centros de ComputoJorge Estrada0% (3)

- LNMIIT Course Information Form: A. B. C. D. E. FDocument2 pagesLNMIIT Course Information Form: A. B. C. D. E. FAayush JainPas encore d'évaluation

- August 2017Document72 pagesAugust 2017Treatment Plant Operator MagazinePas encore d'évaluation

- Volume 1 Drafting Design and Presentation StandardsDocument328 pagesVolume 1 Drafting Design and Presentation StandardsAntonio Herrera PérezPas encore d'évaluation

- DIMENSIONAL TOLERANCES FOR COLD CLOSE RADIUS PIPE BENDINGDocument11 pagesDIMENSIONAL TOLERANCES FOR COLD CLOSE RADIUS PIPE BENDINGpuwarin najaPas encore d'évaluation

- Builder's Greywater Guide Branched DrainDocument4 pagesBuilder's Greywater Guide Branched DrainGreen Action Sustainable Technology GroupPas encore d'évaluation

- Adhokshaj Mishra: Thwarting The Surveillance in Online CommunicationDocument24 pagesAdhokshaj Mishra: Thwarting The Surveillance in Online CommunicationGauravRajPas encore d'évaluation

- How The Draganflyer Flies: So How Does It Work?Document5 pagesHow The Draganflyer Flies: So How Does It Work?sav33Pas encore d'évaluation

- GRC Fiori End User Guide Final - V2Document75 pagesGRC Fiori End User Guide Final - V2Subhash BharmappaPas encore d'évaluation

- TM4C129XNCZAD MicrocontrollerDocument2 191 pagesTM4C129XNCZAD Microcontrollermamaligosu1Pas encore d'évaluation

- Conceptual Design Deliverables Latest Rev2Document14 pagesConceptual Design Deliverables Latest Rev2dhanu_lagwankarPas encore d'évaluation

- PV Design WorksheetDocument4 pagesPV Design WorksheetLarry Walker II100% (1)

- CSE Catalog - IndiaDocument67 pagesCSE Catalog - IndiaDheeraj SivadasPas encore d'évaluation

- ISCM World Music Days 2019 - Selected WorksDocument3 pagesISCM World Music Days 2019 - Selected WorksBobPas encore d'évaluation

- QUICK GUIDE ON WRITING PATENT SPECIFICATION v1Document37 pagesQUICK GUIDE ON WRITING PATENT SPECIFICATION v1Muhammad Azuan TukiarPas encore d'évaluation

- Astm D-2361Document4 pagesAstm D-2361Claudia Da Rolt0% (1)

- Waukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsDocument6 pagesWaukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsLUISA FERNANDA TORRES MANOSALVAPas encore d'évaluation

- PLCDocument16 pagesPLCMohit Kinger100% (1)

- Slurry Flo BrochureDocument4 pagesSlurry Flo BrochureChristian Andres Campa HernandezPas encore d'évaluation

- InductorsDocument13 pagesInductorsManish AnandPas encore d'évaluation