Académique Documents

Professionnel Documents

Culture Documents

APM 2017 Poster 1

Transféré par

Anish KumarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

APM 2017 Poster 1

Transféré par

Anish KumarDroits d'auteur :

Formats disponibles

Integrated Handlebar Clamp Plastic Triple Tree/Yoke Design,

Analysis and Development

for Motorcycle

Anish Kumar

LARPM-CIPET

Abstract: This paper presents the design and substitution of metal part of automobile with plastic part. Plastic components in automotive has become popular

over the last decades. Plastic components are used for body interior as well as exterior. The most important advantage of plastics part is its lower weight, more

anish83007@yahoo.com

economical design and low manufacturing cost. In this project, a new model of motorcycle triple tree made of plastic material has been designed and developed.

A triple tree/yoke attaches the fork tubes to the frame via steering head bearings, which allow the fork assembly to pivot from side to side, and therefore steer the

motorcycle. Most bikes have upper and lower triple trees, providing two solid clamping points that keeps the fork tubes parallel, while also connecting the forks to

the frame via the steering head bearings. Triple clamp converts the steering force applied by rider on handlebar into steering torque which steers the front wheel

of motorcycle. The currently used triple tree of general purpose motorcycle is made of metal and its alloys having four or more assembling components. In this

improved design introduced here, assembling components are integrated to achieve better mechanical reliability and performance of new model. Motorcycle

handling and stability have also been analysed during design of the model. The dimensions of model have been optimized to achieve maximum allowable stress.

The steering torque and steering force have been analysed, simulations and experimental tests are carried out in order to validate the performance of new model.

The durability and performance of new designed model is parallel to the metal and alloys triple tree currently used in motorcycles. The present redesigned model

of plastic triple tree is as reliable as metal triple tree.

INTRODUCTION PROBLEMS DEFINITION

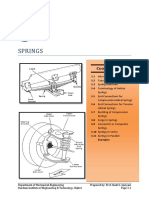

A triple tree/yoke attaches the fork tubes to the Figure(1) shows a schematic representation of triple tree

frame via steering head bearings, which allow model. This design features two vertical clamps for mounting

the fork assembly to pivot from side to side, handlebar on the top of triple tree.

and therefore steer the motorcycle. This design is then attempts to redesign the integrated

Most bikes have upper and lower triple trees, handlebar clamps triple tree. In an attempts to integrate these

providing two solid clamping point that keeps clamps, these are fixed with the base plate of the triple tree.

the fork tubes parallel, while also connecting This is shown in figure (2).

the forks to the frame via the steering head In order to avoid the twisting of clamps and achieving

bearings. maximum steering torque in front forks during application of

With the tendency to employ fork tubes with force on handlebar, the two ribs of height 25 mm and

single action damping, fork triple trees need to thickness 3 mm are provided. These ribs also provide strength

be reinforced more than when the forks shared to the base plate when rider apply load on handlebar. This

both damping roles, because the rigidity of the design is depicted in figure (3).

triple trees are relied upon to distribute the The focus of preliminary design is to determine steering

forces within the forks without flex. torque, load limit, stresses developed and other physical

The existing triple tree used in most motorcycle characteristics for an optimum triple tree design, which best

is made of metal and its alloy having four and maximize scores for competition.

more connecting components. The complexity of the operating variable can be simplified by

The newMODELS

designedFORmodel of plastic

TRIPLE TREE triple tree taking(1) appropriate assumption.

(2) This help (3)

to develop a

has integrated assembly components which

Steering torque preliminary design.

have only one connecting component for RESULTS

Stress Analysis

attaching handlebar.

Dynamic load on front wheel (Nf), Normal Trail (tn)

Stress in Handlebar Connectors

Von Mises stress on application Von Mises stress on

of steering torque application

of force

Deformation Analysis

Design parameters

Loads on Baseplate Component Symbol Quantity Unit

Length (l) 58 mm

Width (b) 25 mm

Total deformation on application Total deformation on

Height (h) 35 mm

Handlebar

connector of load application

w

Shear stress at A (A) 3.575 MPa

Shear stress at B (B) 9.431 MPa CONCLUSION of steering

Torque (T) 112 N-m In this project, the triple clamp has beentorque

redesigned to provide better

Overall length 220 mm mechanical reliability and performance. This has been achieved by

Baseplate Overall Width 92.5 mm replacing the connecting components with integral connectors. The

Offset (O )f 42.5 mm dimensions of the triple tree have optimized to provide maximum

Wheelbase (W) 1255 mm allowable stress. Different types of load acting on the triple clamp

Front wheel radius (R )f 431.8 mm through handlebar and fork has analysed and stresses are calculated,

Caster angle () 26.5 degree the maximum shear stress in handlebar clamp is 9.5 MPa at a torque

Others

Steering angle () 20 degree of 112 N-m. The forces and torque have been analysed and compared

Spring deflection (x) 120 mm with metal part. The design is validated in a digital simulation and

Front centre of mass (w) 70 kg mathematical analysis. The durability and performance of new design

is parallel to the metal and alloys triple clamps currently used in

7. V. Cossalter, R. Lot, M. Massaro and M. Peretto, Motorcycle Steering Torque Decomposition, Proceedings of the World Congress on

References motorcycles.

EngineeringThe

2010 Volpresent redesigned

II, WCE 2010, June model

30 - July 2, 2010, London, of plasticISSN:triple

U.K. ISBN: 978-988-18210-7-2, 2078-0958 tree is 2078-

(Print); ISSN: as

1. Katrina Szeteiova, Automotive Materials: Plastics in Automotive Markets Today, Slovak University of Technology, 0966 (Online).

Bratislava. reliable

8. Myer metal

as triple

Kutz, Mechanical Engineerstree.

Handbook, Vol-1 [Materials and Mechanical Design], 3e, John Wiley & Sons, Inc, 2006, pp. 356.

2. Gautam Jodh, Kaustubh Gothe, Saurabh Kale, Dinesh Tiwari Vaibhav Paunikar, Design, Modeling & Simulation of Hub 9. ASM International, Characterization and Failure Analysis of Plastics. 1e print, 2003, pp. 19.

Center Steering Mechanism, International Journal of Research in Aeronautical and Mechanical Engineering, (ISSN 10. Peter A. Callaluca, John F. Fuller, Donald W. Conn, Adjustable Motorcycle Triple Tree, Patent US 5967538 Oct 19, 1999.

11. Gary D. George, Triple-Tree and Riser Structure for a Motorcycle, Patent US 6176503B1 Jan 23, 2001.

ONLINE: 2321-3051) Vol.2 Issue.3, March 2014, Pg: 146-15.

12. Johnny Law, Motorcycle Handlebar Mounting System, Patent US 7121568B2 Oct 17, 2006.

3. http://auto.ihs.com/news/newsletters/auto-mar04-auto-recycling.htm (cit. on 30.4.2010). 13. R. S. Sharp, Motorcycle Steering Control by Road Preview, Journal of Dynamic Systems, Measurement, and Control (ASME) 129 (July

4. R. C. Hibbeler, Mechanics of Materials, ISBN 13: 978-0-13-602230-5, pp. 222. 2007): 373381.

5. M. S. Gallego, Analysis of Dynamic Handling of Motorcycle using Simulations Tools, AGH University of Science and 14. Foale, Tony, Motorcycle Handling and Chassis Design, Tony Foale Designs. ISBN 978-84-933286-3-4.

Technology, Project Thesis, 2011. 15. Vance C. Strader, Erik F. Buell, Motorcycle Triple Tree Having Integral Handlebar Mounts, Patent US 20030006083A1 Jan 09, 2003.

6. J. Fajans, Steering in Bicycles and Motorcycles, American Journal of Physics, Vol. 68, No. 7, pp. 654659, July 2000. 16. R. S. Sharp, The Stability and Control of Motorcycles, Journal of Mechanical Engineering Science, Vol. 13, No. 5 (1971), pp. 316-329.

17. Matthew Mrdeza, Joseph Gschweng, Motorcycle Rake and Trail Adjuster, Patent US 7438306B2 Oct 21, 2008.

18. Peter G. Rambo, Flush Mount Fork Tube Cap Nut for the Triple of a Motorcycle, Patent US 6994366B2 Feb 07, 2006.

Vous aimerez peut-être aussi

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainD'EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Analysis and Substitution of Metal Triple Tree/Yoke of Motorcycle With Plastic Triple TreeDocument9 pagesAnalysis and Substitution of Metal Triple Tree/Yoke of Motorcycle With Plastic Triple TreeRasbin SharmaPas encore d'évaluation

- Parameters Optimization of Motorcycle FrameDocument16 pagesParameters Optimization of Motorcycle FrameVani AdigaPas encore d'évaluation

- 5.eng Design and Analysis of Helical Springs in Two Wheeler Suspension SystemDocument14 pages5.eng Design and Analysis of Helical Springs in Two Wheeler Suspension SystemImpact JournalsPas encore d'évaluation

- Palanivendhan 2020 IOP Conf. Ser.: Mater. Sci. Eng. 993 012129Document8 pagesPalanivendhan 2020 IOP Conf. Ser.: Mater. Sci. Eng. 993 012129faizPas encore d'évaluation

- Design of Helical SpringDocument11 pagesDesign of Helical SpringMathews P RejiPas encore d'évaluation

- Brake Drum (Journal)Document6 pagesBrake Drum (Journal)Dr. Aung Ko LattPas encore d'évaluation

- Design and Analysis of Helical Springs in Two Wheeler Suspension SystemDocument10 pagesDesign and Analysis of Helical Springs in Two Wheeler Suspension SystemkrishnaPas encore d'évaluation

- MBE3010 - Brakes and ClutchesDocument29 pagesMBE3010 - Brakes and ClutchesShafi NibrajPas encore d'évaluation

- Stress and Design Analysis of Triple Reduction Gearbox CasingDocument6 pagesStress and Design Analysis of Triple Reduction Gearbox CasingdilipPas encore d'évaluation

- Chapter 3 - Tires - Introduction To Automotive EngineeringDocument2 pagesChapter 3 - Tires - Introduction To Automotive EngineeringDinku Seyoum ZelekePas encore d'évaluation

- Lecture 3 - Belts and Belt DrivesDocument6 pagesLecture 3 - Belts and Belt DrivesSteven Claude DigamonPas encore d'évaluation

- Artigo Tese v4 Versao Fenix PDFDocument10 pagesArtigo Tese v4 Versao Fenix PDFRajath UpadhyaPas encore d'évaluation

- 202 PDFDocument5 pages202 PDFtsegayPas encore d'évaluation

- Design and Comparative Analysis of Non-Pneumatic Tires For A TractorDocument7 pagesDesign and Comparative Analysis of Non-Pneumatic Tires For A TractorAlia KhanPas encore d'évaluation

- Analysis and Optimization of Engine Mounting Bracket: Monali Deshmukh, Prof. K R SontakkeDocument6 pagesAnalysis and Optimization of Engine Mounting Bracket: Monali Deshmukh, Prof. K R SontakkehadiPas encore d'évaluation

- Three Wheeled StabilityDocument8 pagesThree Wheeled StabilityandualemPas encore d'évaluation

- Chassis Design For Baja SAEDocument9 pagesChassis Design For Baja SAEVaibhav BansalPas encore d'évaluation

- Fiber Direction and Stacking Sequence Design For Bicycle Frame Made of Carbon Epoxy Composite LaminateDocument10 pagesFiber Direction and Stacking Sequence Design For Bicycle Frame Made of Carbon Epoxy Composite LaminateRubenPas encore d'évaluation

- Modeling and Analysis of FSAE Car Disc Brake Using FEMDocument7 pagesModeling and Analysis of FSAE Car Disc Brake Using FEMsachinphalswal19Pas encore d'évaluation

- Vishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479Document4 pagesVishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479divjak70Pas encore d'évaluation

- Materials Today: Proceedings: A. Eakambaram, P. Baskara Sethupathi, M.A. Saibalaji, A. BaskarDocument9 pagesMaterials Today: Proceedings: A. Eakambaram, P. Baskara Sethupathi, M.A. Saibalaji, A. BaskarB01Aadarsh SharmaPas encore d'évaluation

- Design & Fabrication of Rear Outboard Wheel Assembly For An ATVDocument5 pagesDesign & Fabrication of Rear Outboard Wheel Assembly For An ATVumeshPas encore d'évaluation

- Abstract:: Design Modification and Analysis of V6 Engine Mounting BracketDocument7 pagesAbstract:: Design Modification and Analysis of V6 Engine Mounting BracketInternational Journal of Engineering and TechniquesPas encore d'évaluation

- Belt Conveyor Pulley Design - Why The FailuresDocument9 pagesBelt Conveyor Pulley Design - Why The FailuresWaris La Joi WakatobiPas encore d'évaluation

- Chain DrivesDocument5 pagesChain Drivesabel shimelisPas encore d'évaluation

- Brakes, Clutch and CoplingDocument35 pagesBrakes, Clutch and CoplingJohnPas encore d'évaluation

- 123 - 3 - Cutting Edge Upper Intermediate Teacher's Book - 2013 - 110pDocument9 pages123 - 3 - Cutting Edge Upper Intermediate Teacher's Book - 2013 - 110pМария КонсуловаPas encore d'évaluation

- AbskjhjvhnkjsdhnfkjxnvDocument10 pagesAbskjhjvhnkjsdhnfkjxnvPriyesh SinghPas encore d'évaluation

- Design and Analysis of Rack and Pinion Mechanism: E-Mail IdDocument5 pagesDesign and Analysis of Rack and Pinion Mechanism: E-Mail IdpremanandPas encore d'évaluation

- Centerstand MCDocument11 pagesCenterstand MCMiguel Santillan AzariasPas encore d'évaluation

- Bike Chasis DesignDocument7 pagesBike Chasis Designparth sarthyPas encore d'évaluation

- Static, Dynamic and Impact Stress Analysis of A Bus Body Structure Using Finite Element AnalysisDocument12 pagesStatic, Dynamic and Impact Stress Analysis of A Bus Body Structure Using Finite Element AnalysisTJPRC PublicationsPas encore d'évaluation

- Configuration and Analysis of Bicycle Frames Using ANSYS SoftwareDocument4 pagesConfiguration and Analysis of Bicycle Frames Using ANSYS Softwareabdullah shahidPas encore d'évaluation

- Design, Analysis and Development of Hydraulic Scissor LiftDocument8 pagesDesign, Analysis and Development of Hydraulic Scissor Liftmohit talrejaPas encore d'évaluation

- DESIGN AND ANALYSIS OF A DRIVE SHAFT BY USING COMPOSITE MATERIALS Ijariie11158Document20 pagesDESIGN AND ANALYSIS OF A DRIVE SHAFT BY USING COMPOSITE MATERIALS Ijariie11158Vinit TyagiPas encore d'évaluation

- Design Modification and Analysis of Ford Willy Main PaperDocument8 pagesDesign Modification and Analysis of Ford Willy Main PaperSaim HasanPas encore d'évaluation

- Design Optimization of Bicycle Crank Using (FEA)Document6 pagesDesign Optimization of Bicycle Crank Using (FEA)abhishek dmalePas encore d'évaluation

- Design and Analysis of Train Brake BlocksDocument7 pagesDesign and Analysis of Train Brake BlockscamilaskishorePas encore d'évaluation

- Finite Element Analysis of An Aluminium Bike Frame: Word Count: 1484Document9 pagesFinite Element Analysis of An Aluminium Bike Frame: Word Count: 1484JohnsonPas encore d'évaluation

- Journal of Advanced Mechanical Design, Systems, and ManufacturingDocument12 pagesJournal of Advanced Mechanical Design, Systems, and ManufacturingBrilliant DavidsonPas encore d'évaluation

- Bike SuspensionDocument5 pagesBike SuspensionAnirudh PanickerPas encore d'évaluation

- Non Linear Simulation of Engine Bracket Under Dynamic LoadingDocument11 pagesNon Linear Simulation of Engine Bracket Under Dynamic LoadingmanojalvandarPas encore d'évaluation

- Design Optimization of Automotive Engine Mount System: July 2020Document7 pagesDesign Optimization of Automotive Engine Mount System: July 2020dandavatevvPas encore d'évaluation

- Amortisseur Ressort EtudeDocument11 pagesAmortisseur Ressort EtudeSliim AmiriPas encore d'évaluation

- Bicycle Wheel Spoke Lacing PDFDocument10 pagesBicycle Wheel Spoke Lacing PDFherrnikolicPas encore d'évaluation

- .Design and Analysis of A Shock Absorber by Varying Spring Materials - Analysis Using Fea TechniqueDocument9 pages.Design and Analysis of A Shock Absorber by Varying Spring Materials - Analysis Using Fea TechniqueManjunath ReddyPas encore d'évaluation

- Design and Analysis of Drum Brake: Dr. Kodathalapalli SudheerDocument15 pagesDesign and Analysis of Drum Brake: Dr. Kodathalapalli SudheerThalari VijayarajPas encore d'évaluation

- Design Principles: Crane Sheave BasicDocument6 pagesDesign Principles: Crane Sheave BasicUsman GhaniPas encore d'évaluation

- Ijett V38P253 PDFDocument7 pagesIjett V38P253 PDFKaustubh DwivediPas encore d'évaluation

- Structural Health Monitoring - A Design and Integration IssueDocument13 pagesStructural Health Monitoring - A Design and Integration IssueJose Miguel Atehortua ArenasPas encore d'évaluation

- Design and Analysis of Steering Knuckle PDFDocument7 pagesDesign and Analysis of Steering Knuckle PDFSai Krishna SKPas encore d'évaluation

- Stress and Design Analysis of Triple Reduction Gearbox CasingDocument6 pagesStress and Design Analysis of Triple Reduction Gearbox CasingIJIRSTPas encore d'évaluation

- Analysis of Alternative Front Suspension Systems For MotorcyclesDocument10 pagesAnalysis of Alternative Front Suspension Systems For MotorcyclesRasbin SharmaPas encore d'évaluation

- Composite Suspension Arm Optimization For The City Vehicle XAM 2.0Document17 pagesComposite Suspension Arm Optimization For The City Vehicle XAM 2.0You MajPas encore d'évaluation

- Development of A Dynamic Vibration Absorber To Reduce Frame BeamingDocument11 pagesDevelopment of A Dynamic Vibration Absorber To Reduce Frame Beaminggakada prbPas encore d'évaluation

- DME 3 SpringsDocument29 pagesDME 3 SpringsFenilPas encore d'évaluation

- Mech 3 (Magway)Document5 pagesMech 3 (Magway)Dr. Aung Ko LattPas encore d'évaluation

- 1 5024108Document7 pages1 5024108GamerPas encore d'évaluation

- Polymer Journal ListDocument4 pagesPolymer Journal ListAnish KumarPas encore d'évaluation

- UPTU New Transcript 161015Document2 pagesUPTU New Transcript 161015Anish Kumar0% (1)

- TQM PlanningDocument113 pagesTQM PlanningAnish KumarPas encore d'évaluation

- Literature ReviewDocument6 pagesLiterature ReviewAnish KumarPas encore d'évaluation

- MatStudio Castep - 2Document63 pagesMatStudio Castep - 2Anish Kumar100% (1)

- Refractive Index of PolymersDocument6 pagesRefractive Index of PolymersAnish KumarPas encore d'évaluation

- MatStudio CASTEP GuideDocument219 pagesMatStudio CASTEP GuideAnish KumarPas encore d'évaluation

- Anish KumarDocument2 pagesAnish KumarAnish KumarPas encore d'évaluation

- Thermoplastic Carbonate Groups ToughDocument3 pagesThermoplastic Carbonate Groups ToughAnish KumarPas encore d'évaluation

- Thermoplastic Carbonate Groups ToughDocument3 pagesThermoplastic Carbonate Groups ToughAnish KumarPas encore d'évaluation

- APM Additive Manufacturing FinalDocument4 pagesAPM Additive Manufacturing FinalAnish KumarPas encore d'évaluation

- Anna University Annexure IDocument2 pagesAnna University Annexure IAnish KumarPas encore d'évaluation

- Nanofiller Reinforced NanocompositeDocument247 pagesNanofiller Reinforced NanocompositeAnish KumarPas encore d'évaluation

- Walking in Space - Lyrics and Chord PatternDocument2 pagesWalking in Space - Lyrics and Chord Patternjohn smithPas encore d'évaluation

- Formula:: High Low Method (High - Low) Break-Even PointDocument24 pagesFormula:: High Low Method (High - Low) Break-Even PointRedgie Mark UrsalPas encore d'évaluation

- Stentofon Pulse: IP Based Intercom SystemDocument22 pagesStentofon Pulse: IP Based Intercom SystemCraigPas encore d'évaluation

- Agency Canvas Ing PresentationDocument27 pagesAgency Canvas Ing Presentationkhushi jaiswalPas encore d'évaluation

- 1.water, Acids, Bases, Buffer Solutions in BiochemistryDocument53 pages1.water, Acids, Bases, Buffer Solutions in BiochemistryÇağlaPas encore d'évaluation

- Understanding PTS Security PDFDocument37 pagesUnderstanding PTS Security PDFNeon LogicPas encore d'évaluation

- Elpodereso Case AnalysisDocument3 pagesElpodereso Case AnalysisUsama17100% (2)

- Ci Thai RiceDocument4 pagesCi Thai RiceMakkah Madina ricePas encore d'évaluation

- 385C Waw1-Up PDFDocument4 pages385C Waw1-Up PDFJUNA RUSANDI SPas encore d'évaluation

- Cetie Guide No1 EngDocument55 pagesCetie Guide No1 EngJose Manuel Sepulveda RomanPas encore d'évaluation

- Semi Detailed Lesson PlanDocument2 pagesSemi Detailed Lesson PlanJean-jean Dela Cruz CamatPas encore d'évaluation

- Iaea Tecdoc 1092Document287 pagesIaea Tecdoc 1092Andres AracenaPas encore d'évaluation

- EGurukul - RetinaDocument23 pagesEGurukul - RetinaOscar Daniel Mendez100% (1)

- Poetry UnitDocument212 pagesPoetry Unittrovatore48100% (2)

- Grade 9 Science Biology 1 DLPDocument13 pagesGrade 9 Science Biology 1 DLPManongdo AllanPas encore d'évaluation

- Aliping PDFDocument54 pagesAliping PDFDirect LukePas encore d'évaluation

- Alkosign Product CatalogeDocument20 pagesAlkosign Product CatalogeShree AgrawalPas encore d'évaluation

- Random Variables Random Variables - A Random Variable Is A Process, Which When FollowedDocument2 pagesRandom Variables Random Variables - A Random Variable Is A Process, Which When FollowedsdlfPas encore d'évaluation

- Numerical Modelling and Design of Electrical DevicesDocument69 pagesNumerical Modelling and Design of Electrical Devicesfabrice mellantPas encore d'évaluation

- Bad Memories Walkthrough 0.52Document10 pagesBad Memories Walkthrough 0.52Micael AkumaPas encore d'évaluation

- DS Agile - Enm - C6pDocument358 pagesDS Agile - Enm - C6pABDERRAHMANE JAFPas encore d'évaluation

- Modern and Nonlinear OpticsDocument181 pagesModern and Nonlinear Opticssoma_venuPas encore d'évaluation

- Antibiotic Zone Interpretation Guide PDFDocument2 pagesAntibiotic Zone Interpretation Guide PDFFarandy Insan Sejati100% (2)

- Shelly e CommerceDocument13 pagesShelly e CommerceVarun_Arya_8382Pas encore d'évaluation

- Syllabus PDFDocument3 pagesSyllabus PDFBibin Raj B SPas encore d'évaluation

- 5066452Document53 pages5066452jlcheefei9258Pas encore d'évaluation

- List of Some Common Surgical TermsDocument5 pagesList of Some Common Surgical TermsShakil MahmodPas encore d'évaluation

- Predator U7135 ManualDocument36 pagesPredator U7135 Manualr17g100% (1)

- Arduino Uno CNC ShieldDocument11 pagesArduino Uno CNC ShieldMărian IoanPas encore d'évaluation

- Santu BabaDocument2 pagesSantu Babaamveryhot0950% (2)