Académique Documents

Professionnel Documents

Culture Documents

3er DOMICILIARIO REACTOR SEMIBATCH LEVI ZUTA TAFUR

Transféré par

Levi Zuf0 évaluation0% ont trouvé ce document utile (0 vote)

28 vues14 pagesTitre original

3er DOMICILIARIO REACTOR SEMIBATCH LEVI ZUTA TAFUR - copia.pptx

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

28 vues14 pages3er DOMICILIARIO REACTOR SEMIBATCH LEVI ZUTA TAFUR

Transféré par

Levi ZufDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 14

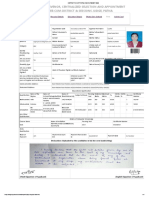

UNI- Facultad de Ingeniera Qumica y Textil

DETERMINACIN DEL TAMAO

DEL REACTOR Y TIEMPO DE

OPERACIN REQUERIDO PARA

LA PRODUCCIN DE ZEOLITA A

EN UN REACTOR POR LOTES.

Presentado por: Lev Zuta Tafur

DETERMINATION OF HOLDING TIME

AND REACTOR SIZE REQUIREMENTS

FOR THE PRODUCTION OF ZEOLITE A

IN A BATCH REACTOR

2017 Cintica Qumica y diseo de Reactores 2

Zeolites are hydrous aluminosilicates that are widely used as

catalysts in the chemical process industry. Zeolite A is

usually synthesized in the sodium form from aqueous

solutions of sodium silicate and sodium aluminate. Kerr and

Liu studied an alternative method of synthesis from

amorphous sodium aluminosilicate substrate and aqueous

sodium hydroxide solution. The reaction (essentially a

crystallization or recrystallization process) can be viewed as:

2017 Cintica Qumica y diseo de Reactores 3

Lius description of the kinetics of the zeolite formation

process can be formulated in terms of the following equation:

Where:

2017 Cintica Qumica y diseo de Reactores 4

Since the total weight of solids in a batch reactor must satisfy

an overall material balance, we require that the quantity be a

constant equal to the total weight of the charge divided by the

effective reactor volume. Note that the reaction is catalyzed

by the presence of product in that the zeolite concentration

appears in the numerator of the rate expression.

Consequently, it is desirable to include some zeolite in the

feed to the reactor to enhance the reaction rate. Reactions of

this type are labeled as autocatalytic.

At 100C the following values of the rate constants are

appropriate for use:

2017 Cintica Qumica y diseo de Reactores 5

a. If one utilizes a slurry containing 1 kgm of zeolite and

24 kgm of amorphous substrate, determine the time

necessary to achieve 98% conversion of the substrate to

zeolite A in a well-stirred batch reactor. The conditions to

be considered are isothermal operation at 100C and a

hydroxide concentration of 1.5 kmolm.

2017 Cintica Qumica y diseo de Reactores 6

SOLUCIN

a) Se tienen los siguientes datos:

Como se trata de una suspensin, el volumen del reactor ser

considerado constante:

Ecuacin de diseo

De las etapas de reaccin:

2017 Cintica Qumica y diseo de Reactores 7

Sumando ambas, se obtiene la reaccin global:

Reaccin autocataltica

Inicio:

Reaccin:

Final:

Con esto:

2017 Cintica Qumica y diseo de Reactores 8

Reemplazando todo en la ecuacin cintica se tiene:

2017 Cintica Qumica y diseo de Reactores 9

Reemplazando en la ecuacin de diseo, para

Resolviendo:

2017 Cintica Qumica y diseo de Reactores 10

b) Assuming the reaction conditions noted in part a, determine

the reactor size and total weight of charge necessary to

produce zeolite A at an average rate of 2000 kg/day. Only one

reactor is to be used, and it will be necessary to shut down for

0.5 hours between batches for removal of product, cleaning,

and startup. The zeolite to be recycled to the reactor will come

from the 2000 kg produced daily.

2017 Electroqumica Industrial 11

SOLUCIN

b) Para el 98% de conversin, el reactor requiere 0.982 h de

tiempo de operacin. El reactor requiere, adems, 0.5 horas

de espera entre cargas (vaciado, limpieza y puesta en marcha)

es por esto que, el tiempo total de produccin en el reactor

ser 1.482 h.

Para producir 2000 Kg de zeolita A por da:

2017 Cintica Qumica y diseo de Reactores 12

Para calcular el volumen de un reactor batch, utilizaremos

la densidad de la zeolita A:

NOTA: Obsrvese que en este caso el reactor discontinuo est

funcionando en modo de produccin slo dos tercios del

tiempo.

Esta situacin no es extraordinaria, as que para satisfacer los

requisitos de diseo debern tenerse debidamente en cuenta los

tiempos de inactividad.

2017 Cintica Qumica y diseo de Reactores 13

Bibliografa

Hill, C., & Root, T. (2014). Introduction to Chemical Engineering

Kinetics and Reactor Design 2nd edition. University of Wisconsin

- Madison: Wiley. Page 227.

2017 Cintica Qumica y diseo de Reactores 14

Vous aimerez peut-être aussi

- Excel Electro Zinc AlcalinoDocument3 pagesExcel Electro Zinc AlcalinoLevi ZufPas encore d'évaluation

- 2do Domiciliario Reactor BatchDocument14 pages2do Domiciliario Reactor BatchLevi ZufPas encore d'évaluation

- Improving ABE Fermentation and Recovery Using Gas StrippingDocument9 pagesImproving ABE Fermentation and Recovery Using Gas StrippingLevi ZufPas encore d'évaluation

- 2 Relación Tripartita PDFDocument71 pages2 Relación Tripartita PDFLevi ZufPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Affidavit of 2 Disinterested Persons (Haidee Gullodo)Document1 pageAffidavit of 2 Disinterested Persons (Haidee Gullodo)GersonGamasPas encore d'évaluation

- 6th GATEDocument33 pages6th GATESamejiel Aseviel LajesielPas encore d'évaluation

- Adjective: the girl is beautifulDocument15 pagesAdjective: the girl is beautifulIn'am TraboulsiPas encore d'évaluation

- DesignWS P1 PDFDocument673 pagesDesignWS P1 PDFcaubehamchoi6328Pas encore d'évaluation

- Dinflo DFCSDocument2 pagesDinflo DFCSvictorharijantoPas encore d'évaluation

- Facebook TemplateDocument2 pagesFacebook Templateapi-352106462Pas encore d'évaluation

- jk2 JAVADocument57 pagesjk2 JAVAAndi FadhillahPas encore d'évaluation

- Drug Delivery Technologies and Future DirectionsDocument14 pagesDrug Delivery Technologies and Future Directionsraju1559405Pas encore d'évaluation

- A Short Example Presentation On Molecules Slash Molecular Chemistry in LatexDocument8 pagesA Short Example Presentation On Molecules Slash Molecular Chemistry in LatexintangibilidadePas encore d'évaluation

- GF26.10-S-0002S Manual Transmission (MT), Function 9.7.03 Transmission 716.6 in MODEL 639.601 /603 /605 /701 /703 /705 /711 /713 /811 /813 /815Document2 pagesGF26.10-S-0002S Manual Transmission (MT), Function 9.7.03 Transmission 716.6 in MODEL 639.601 /603 /605 /701 /703 /705 /711 /713 /811 /813 /815Sven GoshcPas encore d'évaluation

- Conics, Parametric Equations, and Polar CoordinatesDocument34 pagesConics, Parametric Equations, and Polar CoordinatesGARO OHANOGLUPas encore d'évaluation

- Business Law & TaxationDocument3 pagesBusiness Law & TaxationD J Ben UzeePas encore d'évaluation

- A Study On Consumer Buying Behaviour Towards ColgateDocument15 pagesA Study On Consumer Buying Behaviour Towards Colgatebbhaya427Pas encore d'évaluation

- Homeroom Guidance Grade 12 Quarter - Module 4 Decisive PersonDocument4 pagesHomeroom Guidance Grade 12 Quarter - Module 4 Decisive PersonMhiaBuenafe86% (36)

- Chapter 63 Standard Integration: EXERCISE 256 Page 707Document9 pagesChapter 63 Standard Integration: EXERCISE 256 Page 707Khaerul UmamPas encore d'évaluation

- Case NoDocument13 pagesCase NoLaurente JessicaPas encore d'évaluation

- The Diffusion of Microfinance: An Extended Analysis & Replication ofDocument33 pagesThe Diffusion of Microfinance: An Extended Analysis & Replication ofNaman GovilPas encore d'évaluation

- Rieka Fitri Sutrisno-CGK-SXBHSY-BTH-FLIGHT - ORIGINATINGDocument2 pagesRieka Fitri Sutrisno-CGK-SXBHSY-BTH-FLIGHT - ORIGINATINGfairuz fanaPas encore d'évaluation

- LEONI Dacar® 110 enDocument1 pageLEONI Dacar® 110 engshock65Pas encore d'évaluation

- OWASP Dependency-Check Plugin: DescriptionDocument10 pagesOWASP Dependency-Check Plugin: DescriptionFelipe BarbosaPas encore d'évaluation

- Reference Letter For Employment AustraliaDocument8 pagesReference Letter For Employment Australiabcqy21t7100% (2)

- Primary Checkpoint - Science (0846) October 2016 Paper 2 MSDocument12 pagesPrimary Checkpoint - Science (0846) October 2016 Paper 2 MSdinakarc78% (9)

- Asset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MDocument23 pagesAsset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MSirSmirkPas encore d'évaluation

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalPas encore d'évaluation

- Introduction To Machine Learning Top-Down Approach - Towards Data ScienceDocument6 pagesIntroduction To Machine Learning Top-Down Approach - Towards Data ScienceKashaf BakaliPas encore d'évaluation

- 30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingDocument21 pages30-99!90!1619-Rev.0-Method Statement For Pipeline WeldingkilioPas encore d'évaluation

- 2018 JC2 H2 Maths SA2 River Valley High SchoolDocument50 pages2018 JC2 H2 Maths SA2 River Valley High SchoolZtolenstarPas encore d'évaluation

- How To Retract BPS Data Back To R3 When There Is No Standard RetractorDocument3 pagesHow To Retract BPS Data Back To R3 When There Is No Standard Retractorraphavega2010Pas encore d'évaluation

- Texas LS Notes 19-20Document2 pagesTexas LS Notes 19-20Jesus del CampoPas encore d'évaluation