Académique Documents

Professionnel Documents

Culture Documents

Safe Work Permits: R. Chiodi 03/25/1997 Rev 04/16/2001

Transféré par

amir khaledDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Safe Work Permits: R. Chiodi 03/25/1997 Rev 04/16/2001

Transféré par

amir khaledDroits d'auteur :

Formats disponibles

Safe Work Permits

R. Chiodi 03/25/1997 rev 04/16/2001

1

Safe Work Permits

Why are we here?

The company requires evaluation of very hazardous,

nonroutine jobs for which there are no Safe Job Procedures

or approved Job Safety Plans.

Certain jobs always require that a Safe Work Permit be issued by

a qualified individual.

R. Chiodi 03/25/1997 rev 04/16/2001

2

Safe Work Permits

Goals and Objectives:

At the end of this session you will:

- be familiar with jobs requiring safe work permits.

- be generally familiar with the Safe Work Permit system.

- pass a quiz with a score of 100%.

R. Chiodi 03/25/1997 rev 04/16/2001

3

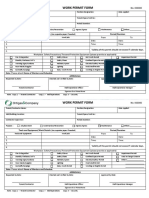

Safe Work Permits

Cutting / Welding

Permit Confined Space Entry Permit

Location and description of confined space:

Safe Work Permit

Reason for entry: Permit #

Location: Job issued

Permit No. to:

SupervisorsType:

Name:(hot work, confined space, line break, etc..... location:

Attendants name:

Permit issuers name:

Valid __/___/___ ____ __/___/___ ____ Issued to:

% oxygen: From: M % lower

D Yexplosive

time limit:

to M ppm D CO:

Y H2S:

time

Date: Job No.

Work Description: ________________________________

Requirements

____________________________________________ Supervisors Signature Print name

____________________________________________

Emergency Rescuer yes no

____________________________________________ Work Order No.

Continuous Gas Monitor yes no

Barrier for ground openings yes no

Atm Combustible vapors or gases (<10%) Oxygen Concentration (>19.5% & <21%) Toxic Material Concentration

Warning Signs yes no

Tests

Precautions Always Required:

There are currently three documents which are called

safe work permits.

R. Chiodi 03/25/1997 rev 04/16/2001

4

Safe Work Permits

Cutting / Welding The Hot Work Permit is a form

Permit

of Safe Work Permit issued by

Location: Job No. the Fire Marshal or other person

responsible for fire safety.

Date: Job No.

Location & Building: Floor

Nature of Job:

This permit is required for all

Welders Name: situations which may result in

The above location has been examined. The precautions checked

on the reverse of this card have been taken to prevent fire.

fires or explosions.

Permission is granted for this work.

Permit Date: Time:

Expires AM

PM

R. Chiodi 03/25/1997 rev 04/16/2001

5

Safe Work Permits

Confined Space Entry Permit

Location and description of confined space:

Reason for entry:

Permit issued to:

Supervisors Name:

Attendants name:

Permit issuers name:

% oxygen: % lower explosive limit: ppm CO: H2S:

Requirements

Emergency Rescuer yes no

CAUTION Continuous Gas Monitor yes no

Barrier for ground openings yes no

Opening in Ground Warning Signs yes no

Safety Harness with life line yes no

Keep Out ! Tripod / Hoist / Pulley yes no

The Confined Space Entry

Permit is another form of

safe work permit regulating

entry into pits, tanks, and vessels.

R. Chiodi 03/25/1997 rev 04/16/2001

6

Safe Work Permits

Cutting / Welding

Permit Confined Space Entry Permit

Location and description of confined space:

Location: Job No.

Reason for entry:

Permit issued to:

Supervisors Name:

Attendants name:

Permit issuers name:

Date: Job No.

% oxygen: % lower explosive limit: ppm CO: H2S:

Requirements

Emergency Rescuer yes no

Continuous Gas Monitor yes no

Barrier for ground openings yes no

Warning Signs yes no

Confined Space Entry Permits and Hot Work Permits

will be discussed in detail in other training sessions.

R. Chiodi 03/25/1997 rev 04/16/2001

7

Safe Work Permits

Safe Work Permit Permit #

Type: (hot work, confined space, line break, etc.... location:

Valid __/___/___ ____ __/___/___ ____ Issued to:

From: M D Y time to M D Y time

Work Description: ________________________________

____________________________________________ Supervisors Signature Print name

____________________________________________

____________________________________________ Work Order No.

Atm Combustible vapors or gases (<10%) Oxygen Concentration (>19.5% & <21%) Toxic Material Concentration

Tests

Precautions Always Required:

The objective of the Safe Work Permit system is to

identify hazards associated with a nonroutine job, and

to develop precautions required to control each hazard

identified.

R. Chiodi 03/25/1997 rev 04/16/2001

8

Safe Work Permits

Lets begin with a

look at the hazards

associated with

specific jobs, and

examine how Safe

Work Permits can

help to prevent

them from causing

damage or injury.

R. Chiodi 03/25/1997 rev 04/16/2001

9

Safe Work Permits

Examples of jobs requiring permits are:

1. Hot Work - the use of open flame, oxyacetylene burning,

tar kettles, etc...., and the use of portable spark or heat producing

equipment in flammable storage or handling areas.

2. Confined Space Entry

3. Excavations

4. Blasting

5. Whenever required by existing company or contractor procedures

or required in the contractors Project Safety Plan.

6. Use of internal combustion engines, or vehicles

with internal combustion engines inside company buildings.

7. Use of company owned equipment, such as personnel lifts,

fork trucks, vehicles, etc., by employees of a contractor

R. Chiodi 03/25/1997 rev 04/16/2001

10

Safe Work Permits

Excavations can result in:

head Injuries from materials

falling from overhead surfaces,

rupture of high pressure hydraulic

lines used on backhoes, shovels,

and drills.

excessive noise from concrete

breaking and cutting equipment,

and collapse of excavation walls and piles due to poorly secured soil, sudden

weather changes, or other factors.

Permits are written to ensure that necessary equipment is present and in

good working order.

R. Chiodi 03/25/1997 rev 04/16/2001

11

Safe Work Permits

Excavations :

Poorly planned excavations can result in

damage to underground services, such as

electrical lines, natural gas lines, water

lines, sewers and drains.

The consequence of damaged service lines

is often complete shutdown of operations

resulting in major business losses.

Permits are written to prevent damage to

underground equipment and services.

R. Chiodi 03/25/1997 rev 04/16/2001

12

Safe Work Permits

Excavations may expose hazardous materials, which have leaked and are

contaminating the soil.

Permits ensure that procedures to protect workers from exposure to toxic

substances have been identified. 13

R. Chiodi 03/25/1997 rev 04/16/2001

Safe Work Permits

Blasting can cause damage

to adjacent operations and

personnel.

Permits are issued to ensure

procedures are followed that

prevent injury to neighboring

facilities, equipment and

employees.

R. Chiodi 03/25/1997 rev 04/16/2001

14

Safe Work Permits

Internal combustion engines produce poisonous gases

such as carbon monoxide, and oxides of nitrogen.

Permits ensure that procedures are followed that will prevent

equipment emissions from contaminating air inside buildings

and confined spaces.

R. Chiodi 03/25/1997 rev 04/16/2001

15

Safe Work Permits

Unauthorized use of company

equipment can result in lost

production and injury to untrained

operators.

Permits prevent company equipment

from being taken by contractors

without the permission of area

management, and require

verification of equipment operator

training.

R. Chiodi 03/25/1997 rev 04/16/2001

16

Safe Work Permits

Work which ordinarily does not require safe work

permits may be included at the discretion of the

Safety Representative, the Contractor, or the Contract

Administrator.

R. Chiodi 03/25/1997 rev 04/16/2001

17

Safe Work Permits

Following are examples of situations which may require

discretionary safe work permits.

There could be many others:

R. Chiodi 03/25/1997 rev 04/16/2001

18

Safe Work Permits

Movement of

large pieces of equipment,

especially while other personnel

are working nearby, can result

in employee injury.

Permits may be issued to ensure

the use of procedures that will

prevent employee injury from

falling material, or being struck

by rigging equipment.

R. Chiodi 03/25/1997 rev 04/16/2001

19

Safe Work Permits

Abandoned tanks, pipe lines,

drums, and vessels may contain

hazardous vapors and gases.

Permits may be issued to prevent

toxic or corrosive exposures to workers

when working on abandoned

equipment, complementing hot work

and confined space permits.

R. Chiodi 03/25/1997 rev 04/16/2001

20

Safe Work Permits

Many construction processes

create noise levels high enough

to cause hearing loss.

Permit requirements may be issued

to reduce noise to acceptable limits,

or to provide both construction and

other employees with required

hearing protection.

R. Chiodi 03/25/1997 rev 04/16/2001

21

Safe Work Permits

Boilers, high pressure

vessels, tanks, and reactors

can undergo sudden failure

resulting in disastrous

consequences.

Permits may be issued requiring

precautions and equipment to

prevent system failures not

covered by safe job procedures

or project safety plans.

R. Chiodi 03/25/1997 rev 04/16/2001

22

Safe Work Permits

Permits may be required

where the consequence

of noncompliance with

fall protection requirements

is severe, or where dropped

materials may endanger

other workers below.

R. Chiodi 03/25/1997 rev 04/16/2001

23

Safe Work Permits

Permits are required

before work begins near

energized lines which cannot

be shut off if there is danger

of fire, shock or electrocution.

R. Chiodi 03/25/1997 rev 04/16/2001

24

Safe Work Permits

CAUTION

Hazardous Materials!

Safe Work Permit Required!

Permits are mandatory where signs are

posted which require them.

R. Chiodi 03/25/1997 rev 04/16/2001

25

Safe Work Permits

Safe Work Permit Permit #

Type: (hot work, confined space, line break, etc.... location:

Valid __/___/___ ____ __/___/___ ____ Issued to:

From: M D Y time to M D Y time

Work Description: ________________________________

____________________________________________ Supervisors Signature Print name

____________________________________________

____________________________________________ Work Order No.

Permits are issued:

- for a specific date and time range,

- for a specific job,

- and to specific individuals.

R. Chiodi 03/25/1997 rev 04/16/2001

26

Safe Work Permits

Safe Work Permit Permit #

-------------------------------------------------------------------------------------------------------------------------------------------------------------------

Work Description: ________________________________

____________________________________________ Supervisors Signature Print name

____________________________________________

____________________________________________ Work Order No.

Atm. Combustible Vapors or gases (<10%) Oxygen Concentration ( >19.5% & < 21%) Toxic Material Concentration

Tests

Permit Issued by: _________________________/____/___ Work Area Manager Approval _______________/___/__

Permits must be reviewed and signed by:

- the safety representative issuing the permit,

- the workers supervisor,

- affected workers,

- and the work area manager.

R. Chiodi 03/25/1997 rev 04/16/2001

27

Safe Work Permits

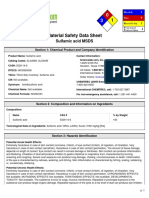

Safe Work Permit

----------------------------------------------------------------------

Precautions Always required:

o Emergency procedures review by:

o Emergency equipment & location review by:

o Area inherent hazards review by:

o Material Safety Data Sheet(s) review by:

Workers must be informed of required emergency procedures, location

and operation of emergency equipment,and area inherent hazards.

Material Safety Data Sheets must be supplied and special

precautions reviewed with workers and their supervision.

R. Chiodi 03/25/1997 rev 04/16/2001

28

Safe Work Permits

Safe Work Permit

----------------------------------------------------------------------

Special Precautions Required:

o Buddy System o Sprinklers in Service

Required special precautions

o Cleaning of _________ o Purging of ________ must be clearly indicated and

o Remove materials from ___________________

o Piping o Drain o Disconnect o Blank off / Capped communicated to workers,

o Clean o Ventilate

o Remove combustibles from other side of wall.

and their supervision.

o Floor Swept Clean of Combustibles

o Clean area within 35 feet. o Wet down floor.

o Adjacent areas: __________________________ It is the safety representatives

o Cover floor with: __________________________

o Non-combustible Tarpaulins or Metal Shields Over:

responsibility to determine if

o Electrical Switches or Valves off, locked-out, and Tagged: and when special measures

o Electrical Grounding of: ________________________

o Atmosphere monitored during work for: ____________ are required.

periodically: __________ continuously: __________

o Safety Monitor(s) present from _________ to _________

o Fire Watch Present during work and for 30 minutes after...

o Respirator to be worn____ or be readily available ___

R. Chiodi 03/25/1997 rev 04/16/2001

29

Safe Work Permits

Safe Work Permit

----------------------------------------------------------------------

Safety Equipment Required

o safety glasses

o hard hat Personal protective equipment

o face shield

o safety shoes and other safety equipment required

o fire extinguishers - type ___ #___ size ___

o fire hose is specified.

o supplementary illumination

o warning signs

o barricades

o non-sparking tools For each hazard present at the work

o explosion proof equipment

o safety harness site, the safety representative must

o life line

o tripod emergency escape unit specify a hazard control.

o 2-way radio or phone

o respirators

o impervious gloves

o protective clothing _____________________

o mechanical ventilation

o shower & eyewash

o self contained breathing apparatus

o ground fault circuit interrupter

o ladder / lift / scaffold

o other________________________________

R. Chiodi 03/25/1997 rev 04/16/2001

30

Safe Work Permits

The safety representative must verify

that all underground utilities have

been located and staked out.

Provisions must be made to

barricade the open trench, prevent

collapse of trench walls, provide

employees with a means of exit,

Safe Work Permit

reroute ground water, and all other

----------------------------------------------------------------------

EXCAVATION PRECAUTIONS REQUIRED: requirements of excavating.

o Underground / Underfloor Utility Hazard Review

o Soil Excavation Reviewed If soil is contaminated, the safety

o Underground Utility Stakeout Performed

o Excavation cut back 1/1, or walls reinforced representative will ask for a written

o Means of exiting within 25 feet.

safety and health plan.

R. Chiodi 03/25/1997 rev 04/16/2001

31

Safe Work Permits - SUMMARY

- Hot work, confined space entry, excavations, blasting,

use of internal combustion engines inside of buildings,

use of company owned or leased equipment, and areas where

Safe Work Permit Required signs are posted always require

a safe work permit.

- Other safe work permits may be required at the discretion

of the Safety Representative, the Contract Administrator,

or the Contractor.

- Permits will be issued by a qualified safety representative.

- Hot work permits are issued by the Fire Marshal.

- Permits are issued to specific persons for a specific time

period and for a specific job.

- Permits must be signed at the time issued by the safety

representative, job supervisor, affected workers, and

the manager of the area in which work is being done.

R. Chiodi 03/25/1997 rev 04/16/2001

32

Where to Get Help?

Your supervisor is responsible for providing equipment

necessary to comply with Safe Work Permit requirements.

The safety representative is responsible for completing

the job hazard analysis and issuing the permit.

R. Chiodi 03/25/1997 rev 04/16/2001

33

Vous aimerez peut-être aussi

- Top 5 Reasons For A Roof Consultant To Conduct Your InspectionD'EverandTop 5 Reasons For A Roof Consultant To Conduct Your InspectionPas encore d'évaluation

- Permit To Work: Tuaman Engineering LimitedDocument30 pagesPermit To Work: Tuaman Engineering LimitedKARMAVEERPas encore d'évaluation

- PTW - Safe Work PermitsDocument33 pagesPTW - Safe Work PermitsFOZCANPas encore d'évaluation

- Safe Work Permit 1Document33 pagesSafe Work Permit 1Vikas SinghPas encore d'évaluation

- Work Safe Permit To Work SystemDocument33 pagesWork Safe Permit To Work Systemg5nbPas encore d'évaluation

- Internal PTW Training Slide For Construction WorkersDocument44 pagesInternal PTW Training Slide For Construction WorkersLion DayPas encore d'évaluation

- Work Permit IifeDocument12 pagesWork Permit IifeKhursheed AhmadPas encore d'évaluation

- Safe Work PermitsDocument35 pagesSafe Work PermitsSourav JaiswalPas encore d'évaluation

- Cli Adis 23-24 Work Permit SystemDocument27 pagesCli Adis 23-24 Work Permit SystemATUL BARABDEPas encore d'évaluation

- PCD-OSH-SF-35 PTW For Confine Space KotaSASDocument2 pagesPCD-OSH-SF-35 PTW For Confine Space KotaSASrizal azizanPas encore d'évaluation

- Safe Work, Operation and Maintenance PermitsDocument31 pagesSafe Work, Operation and Maintenance PermitsJay PanitanPas encore d'évaluation

- PCD-OSH-SF-35 PTW For Confine SpaceDocument2 pagesPCD-OSH-SF-35 PTW For Confine Spacerizal azizanPas encore d'évaluation

- Safe Work PermitDocument33 pagesSafe Work PermitkishpatPas encore d'évaluation

- Safe Work Permit 1Document33 pagesSafe Work Permit 1harish14586Pas encore d'évaluation

- Hotworks PermitDocument1 pageHotworks PermitGloriePas encore d'évaluation

- Form 0005: Hot Work Permit: Section - I Details of The Permit ReciverDocument1 pageForm 0005: Hot Work Permit: Section - I Details of The Permit Reciverasem sawalmehPas encore d'évaluation

- Permit To Work FormDocument4 pagesPermit To Work FormMohammed Shams TabrezPas encore d'évaluation

- Confined Space Permit Rev 00Document3 pagesConfined Space Permit Rev 00Arunava BasakPas encore d'évaluation

- Cme Iraq CF Oi 5 1 Cold Work PermitDocument1 pageCme Iraq CF Oi 5 1 Cold Work Permitmurtadanajem1999Pas encore d'évaluation

- 3rd Floor Building FDocument8 pages3rd Floor Building FJePongPas encore d'évaluation

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- IDI-FRM-HSE-32-01 Permit To Work - Electrical WorkDocument1 pageIDI-FRM-HSE-32-01 Permit To Work - Electrical Workaulia chaniaPas encore d'évaluation

- Permit To WorkDocument1 pagePermit To Workmool rajPas encore d'évaluation

- Eil Permit For Energy Isolation & De-IsolationDocument1 pageEil Permit For Energy Isolation & De-IsolationAvesh ChauahanPas encore d'évaluation

- HSEMS-02-05B - (Permit To Work - Hotworks) New 25.07.2022Document4 pagesHSEMS-02-05B - (Permit To Work - Hotworks) New 25.07.2022Leandro CariasoPas encore d'évaluation

- Procédure Des Permis de TravailDocument48 pagesProcédure Des Permis de TravailMed Hillel Elarouci67% (3)

- General Work PermitDocument1 pageGeneral Work PermitJohn Shane100% (5)

- SHELL Retail Permit To Work System - 5 1 - FormsDocument4 pagesSHELL Retail Permit To Work System - 5 1 - FormsAlberto Sánchez Armenta80% (5)

- 86p$permit To Height WorkDocument2 pages86p$permit To Height WorkATIKUR RAHMANPas encore d'évaluation

- Hot Work PermitDocument1 pageHot Work PermitManesh MPas encore d'évaluation

- SafeworkpmitsDocument27 pagesSafeworkpmitsChewy ChocoPas encore d'évaluation

- Hot Work Permit: Welding Bracing/Cutting/Grinding/SolderingDocument2 pagesHot Work Permit: Welding Bracing/Cutting/Grinding/Solderingsindarth raveendrakrishnan100% (4)

- Form Work PermitDocument1 pageForm Work Permitwelly1980ok100% (6)

- Hot Work PermitDocument1 pageHot Work PermitVijayakumar KarunanidhiPas encore d'évaluation

- General Work PermitDocument2 pagesGeneral Work PermitJareem PeesPas encore d'évaluation

- Work at Height PermitDocument1 pageWork at Height PermitAldrin MPas encore d'évaluation

- EHSWP004 - Hot Work Permit PDFDocument2 pagesEHSWP004 - Hot Work Permit PDFRand raiPas encore d'évaluation

- Permit To Work: Utracon Construction SDN BHD Utracon Structural Systems SDN BHDDocument2 pagesPermit To Work: Utracon Construction SDN BHD Utracon Structural Systems SDN BHDChe ZahirPas encore d'évaluation

- Work Permit FormDocument1 pageWork Permit FormJomel Carl Ivan TuñacaoPas encore d'évaluation

- General Work Permit - HSEMS-OCP-01-F-01Document2 pagesGeneral Work Permit - HSEMS-OCP-01-F-01rajubiswashsePas encore d'évaluation

- Work PermitDocument2 pagesWork PermitC P TiwariPas encore d'évaluation

- PTW Hot Work Uoko3aDocument3 pagesPTW Hot Work Uoko3aUmair KhanPas encore d'évaluation

- General Work PermitDocument2 pagesGeneral Work PermitAde Mazmur SilabanPas encore d'évaluation

- E - Lototo (E) : Enter General Permit NumberDocument2 pagesE - Lototo (E) : Enter General Permit NumberJojit PalomenoPas encore d'évaluation

- 02 Hot Work PermitDocument2 pages02 Hot Work PermitFaisal Abdul GhaffarPas encore d'évaluation

- A) Job Assessment List Down Job Step by Step in Details. Job Step Description Potential Accidents / Risks / Hazards What To Do To Prevent?Document1 pageA) Job Assessment List Down Job Step by Step in Details. Job Step Description Potential Accidents / Risks / Hazards What To Do To Prevent?NashrulPas encore d'évaluation

- Permit To Hot WorkDocument2 pagesPermit To Hot WorkSaleh AlomariPas encore d'évaluation

- PTW ExcavationDocument1 pagePTW Excavationnorafikatolah1992Pas encore d'évaluation

- Eil Daily Safety ChecklistDocument2 pagesEil Daily Safety ChecklistAvesh ChauahanPas encore d'évaluation

- Rustomjee Work Permit Format - R1Document8 pagesRustomjee Work Permit Format - R1Nikhil ManjrekarPas encore d'évaluation

- PCD-OSH-SF-33 PTW For General WorksDocument1 pagePCD-OSH-SF-33 PTW For General Worksrizal azizanPas encore d'évaluation

- Cold Work PermitDocument3 pagesCold Work Permitnakul kushwahaPas encore d'évaluation

- General Work PermitDocument2 pagesGeneral Work PermitGreg GenovePas encore d'évaluation

- General Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedDocument2 pagesGeneral Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedIonian TribePas encore d'évaluation

- MW-OPS-SP-3.6.13F1 Work Authorization Permit FormDocument3 pagesMW-OPS-SP-3.6.13F1 Work Authorization Permit FormGabriel Tan100% (1)

- Blasting Work PermitDocument2 pagesBlasting Work PermitHariharan MuthukrishananPas encore d'évaluation

- Roof Pipe Line Fire Safety Other: 1. Descrption and Location of Work: UteduaioDocument1 pageRoof Pipe Line Fire Safety Other: 1. Descrption and Location of Work: UteduaioTushar AgarwalPas encore d'évaluation

- Night and Holiday Work PermitDocument1 pageNight and Holiday Work PermitWaqas IslamPas encore d'évaluation

- Safety DocumentsDocument42 pagesSafety Documentsdan sealzaPas encore d'évaluation

- Hot Work permit-REDDocument2 pagesHot Work permit-REDAravind Babu Dasari100% (1)

- MSDS TK170 enDocument8 pagesMSDS TK170 enArnys JosePas encore d'évaluation

- GE EHS SummaryDocument8 pagesGE EHS Summaryvivekshete0% (1)

- DPAK İngDocument86 pagesDPAK İngElmer Arnaldo Sanchez CheroPas encore d'évaluation

- Bentone SDTS-2 MTR Aghs en PDFDocument9 pagesBentone SDTS-2 MTR Aghs en PDFOswaldo Manuel Ramirez MarinPas encore d'évaluation

- E-Learning and CST Status For Personnel On BoardDocument8 pagesE-Learning and CST Status For Personnel On BoardHarman SandhuPas encore d'évaluation

- Msds Sulphamic AcidDocument5 pagesMsds Sulphamic AcidDanu SutantoPas encore d'évaluation

- R911332116 01 IndraL45Document84 pagesR911332116 01 IndraL45DylanPas encore d'évaluation

- Security Risk Analysis: Group 2Document19 pagesSecurity Risk Analysis: Group 2Izuku MidoriyaPas encore d'évaluation

- Medical Transcription NC IIDocument49 pagesMedical Transcription NC IIzninoromeo50% (2)

- Joji Resume PDF UpdatedDocument5 pagesJoji Resume PDF Updatedloveson709Pas encore d'évaluation

- Ferrite DataDocument52 pagesFerrite DataYonny ColquePas encore d'évaluation

- Software Reliability: CIS 376 Bruce R. Maxim UM-DearbornDocument37 pagesSoftware Reliability: CIS 376 Bruce R. Maxim UM-DearbornAlam ShaikhPas encore d'évaluation

- Lafarge Zambia Job Advertisement - Multiple Positions June 2021Document6 pagesLafarge Zambia Job Advertisement - Multiple Positions June 2021Aaron MulengaPas encore d'évaluation

- MINERAL FISPQ - 503 - Ferro Silicon 45% Stabilized - E - REV00 - VS00 - EnglishDocument9 pagesMINERAL FISPQ - 503 - Ferro Silicon 45% Stabilized - E - REV00 - VS00 - EnglishSamir PeraltaPas encore d'évaluation

- Part 5c Annex 1 Price Schedule-PreliminariesDocument20 pagesPart 5c Annex 1 Price Schedule-PreliminarieskumaravajiraPas encore d'évaluation

- OIM - March 2016Document18 pagesOIM - March 2016kewlbluePas encore d'évaluation

- Advanced Driver Assistance SystemsDocument11 pagesAdvanced Driver Assistance SystemsVinit DawanePas encore d'évaluation

- Materials Handling & StorageDocument19 pagesMaterials Handling & StorageJey Lobos100% (1)

- CompaxUG6 99Document200 pagesCompaxUG6 99Cesar Augusto Perez SilvaPas encore d'évaluation

- RASCI Qualifications Pack 0104 - Retail Sales AssociateDocument95 pagesRASCI Qualifications Pack 0104 - Retail Sales Associatekedarleena1002Pas encore d'évaluation

- VERO-S NSE3 Operating ManualDocument68 pagesVERO-S NSE3 Operating Manualyraju88Pas encore d'évaluation

- Koyo Elevator Installation Manual-Only Used For KW2600Document108 pagesKoyo Elevator Installation Manual-Only Used For KW2600Dixon SerranoPas encore d'évaluation

- Importance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyDocument8 pagesImportance of The On Board Crew Trainings and Drills For The Improvement of The Vessels' SafetyilgarPas encore d'évaluation

- Dreamworld Report - Tanisha CliftonDocument8 pagesDreamworld Report - Tanisha CliftonTanishaPas encore d'évaluation

- MSDS Fosroc FlexcellDocument6 pagesMSDS Fosroc FlexcellDarmawan OnradPas encore d'évaluation

- BAM Vave TestingDocument2 pagesBAM Vave TestingRichard HollidayPas encore d'évaluation

- Ifr Com120c Maint ManualDocument29 pagesIfr Com120c Maint ManualErmanno LanzellottoPas encore d'évaluation

- Fall PreventionDocument15 pagesFall PreventionMonika GokarnPas encore d'évaluation

- enDocument22 pagesenAnonymous iI88LtPas encore d'évaluation

- En 149Document3 pagesEn 149jayaprakash D MPas encore d'évaluation