Académique Documents

Professionnel Documents

Culture Documents

Engineering Materials

Transféré par

Vinoth Malaikani0 évaluation0% ont trouvé ce document utile (0 vote)

66 vues7 pagesMetal materials can be classified as ferrous and nonferrous. Ferrous materials include steel and cast iron, while nonferrous materials include aluminum, magnesium, and titanium alloys. Each material is further classified according to standards that specify alloy composition and processing. Steel classification considers composition, strength level, product shape, finishing process, and quality descriptors. Material selection depends on factors like load requirements, manufacturing considerations, electrical/thermal properties, corrosion resistance, and economic feasibility.

Description originale:

Classification of Engineering Materials, Design and Selection of Materials

Copyright

© © All Rights Reserved

Formats disponibles

PPT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMetal materials can be classified as ferrous and nonferrous. Ferrous materials include steel and cast iron, while nonferrous materials include aluminum, magnesium, and titanium alloys. Each material is further classified according to standards that specify alloy composition and processing. Steel classification considers composition, strength level, product shape, finishing process, and quality descriptors. Material selection depends on factors like load requirements, manufacturing considerations, electrical/thermal properties, corrosion resistance, and economic feasibility.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

66 vues7 pagesEngineering Materials

Transféré par

Vinoth MalaikaniMetal materials can be classified as ferrous and nonferrous. Ferrous materials include steel and cast iron, while nonferrous materials include aluminum, magnesium, and titanium alloys. Each material is further classified according to standards that specify alloy composition and processing. Steel classification considers composition, strength level, product shape, finishing process, and quality descriptors. Material selection depends on factors like load requirements, manufacturing considerations, electrical/thermal properties, corrosion resistance, and economic feasibility.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 7

Engineering materials

Metal / Metallic materials

Generally classified as ferrous and

nonferrous

Ferrous materials consist of steel and cast

iron

Eg. Carbon steel, high alloy steel,

stainless steel

Nonferrous materials consist of the rest

of the metals and alloys

Eg. Aluminum, magnesium, titanium &

their alloys

Materials from each group are further

classified and given certain designation

according to the ASTM standard

Engineering materials

Each has their own unique number/code

that represent main alloying elements,

cast or wrought and in case of plain

carbon amount of Carbon.

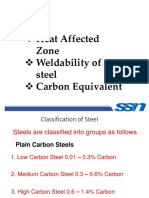

Steel can be classified or grouped

according to some common

characteristic.

The most common classification is by

their

i. Composition

Example : 10xx, 15xx

ii. Strength

Most common material used in

construction of structure such as

bridge, building and ships

Engineering materials

Low yield strength, less < 40 ksi

Eg : A36 Carbon steel plates,

bars and shapes

High strength, between 40 ksi and

120 ksi

Eg. A440- Carbon steel plates,

bars and shapes of high tensile

strength

Ultra-high strength > 200 ksi

iii. Product shape, finish processing and

quality descriptors

Typical product classification of flat hot-

rolled carbon & low alloy steel

According to the thickness and width

Engineering materials

For shape product forms

eg. I beam and special shapes (

designed for specific application ),

bar ( also included round, squares,

hexagon in cross section )

Finishing process

The last processing that the steel

undergone.

The mot common are hot-rolled,

coldrolled or cold finished,

annealed, normalized, quenched and

tempered, coating process.

Engineering materials

Design and selection for metals

One of the major issues for structural

components is deflection under service load.

A function of the applied forces and

geometry, and also stiffness of material.

So suitable material and design are

needed.

Load carrying capacity of component can be

related to the yield strength, fatigue

strength or creep strength depending on

loading & service condition.

All are structure sensitive.

Changed, chemical composition of the

alloy, method and condition of

manufacturing, as well as heat treatment

Engineering materials

Electrical & thermal conductivities

Thermal conductivity, K

Is measure of the rate at which heat is

transferred through a material

Q T

k

A x

Manufacture of component where electrical

conductivity is primary requirement

Al & Co

Corrosion resistance & specific gravity limits

the materials.

Engineering materials

Manufacturing consideration

Wrought material /structure usually stronger

and more ductile than cast.

Precision / size tolerances, surface finish,

heat treatment stress relief etc., other

secondary treatment & finishing.

Weldability a function of material

composition. So structure involve welding of

the components need to consider. Also for

other joining means.

Machinability improvement by heat

treatment or alloying elements.

Economic aspects - perform function at

lowest cost.

Vous aimerez peut-être aussi

- The Arcane Formulas or Mental AlchemyDocument121 pagesThe Arcane Formulas or Mental AlchemyTim Boire100% (1)

- Piping Material - GuidanceDocument17 pagesPiping Material - GuidanceAlfon50% (2)

- Engineering MaterialsDocument16 pagesEngineering MaterialsYosef Ganang Jati NugrohoPas encore d'évaluation

- Tractors OverviewDocument100 pagesTractors OverviewVinoth Malaikani100% (1)

- Carbon and Alloy Steel Properties GuideDocument51 pagesCarbon and Alloy Steel Properties Guidebs2002Pas encore d'évaluation

- 0 Introduction To MetalDocument139 pages0 Introduction To MetalMichael TanjayaPas encore d'évaluation

- Welded Joint Design and ProductionDocument116 pagesWelded Joint Design and ProductionGilbertoUGOPas encore d'évaluation

- Structural Steel Design Course OverviewDocument20 pagesStructural Steel Design Course OverviewImani LughoPas encore d'évaluation

- Alloy & Special SteelsDocument33 pagesAlloy & Special Steelstanishka narayanPas encore d'évaluation

- Application of Stainless SteelDocument13 pagesApplication of Stainless Steelsweety1188Pas encore d'évaluation

- The Essentials of Material Science and Technology for EngineersD'EverandThe Essentials of Material Science and Technology for EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Alloy Steels: Dr. Indika de SilvaDocument25 pagesAlloy Steels: Dr. Indika de SilvaChandima K PriyamalPas encore d'évaluation

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- List of Electronics Manufacturing Companies in Noida - ElectronicsmediaDocument2 pagesList of Electronics Manufacturing Companies in Noida - ElectronicsmediaBlue Oceon50% (4)

- Tes P 119 10 R0 PDFDocument43 pagesTes P 119 10 R0 PDFAbin Meetu100% (4)

- HEAT TREATMENT OF TOOL STEELDocument20 pagesHEAT TREATMENT OF TOOL STEELعزت عبد المنعمPas encore d'évaluation

- SECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSDocument2 pagesSECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSMuhammad Tahir QamarPas encore d'évaluation

- Aircraft Materials Guide: Properties, Selection & ProcessingDocument78 pagesAircraft Materials Guide: Properties, Selection & ProcessingyihesakPas encore d'évaluation

- OSC - 2015 - Revised - Oct (Power Cables) PDFDocument118 pagesOSC - 2015 - Revised - Oct (Power Cables) PDFIván P. MorenoPas encore d'évaluation

- Ferrous Alloys Classification and Types GuideDocument36 pagesFerrous Alloys Classification and Types GuideNipun HarshaPas encore d'évaluation

- Faculty Development Program Supports ExcellenceDocument65 pagesFaculty Development Program Supports ExcellencerlinaoPas encore d'évaluation

- Training Needs Analysis (Managing Training & Development)Document78 pagesTraining Needs Analysis (Managing Training & Development)Henrico Impola100% (1)

- Applications and Processing of Metals and Alloys: Module-09Document19 pagesApplications and Processing of Metals and Alloys: Module-09Ricky SarkarPas encore d'évaluation

- MpA Lecture - Materials For ArchitectureDocument54 pagesMpA Lecture - Materials For ArchitectureGenPas encore d'évaluation

- Ferrous and Non Ferrous MetalsDocument31 pagesFerrous and Non Ferrous MetalsadinamdarPas encore d'évaluation

- CH 1: Basics of Engineering Materials: Mr. Kashif NaveedDocument11 pagesCH 1: Basics of Engineering Materials: Mr. Kashif NaveedYour EntertainerPas encore d'évaluation

- Bme - Part 1Document49 pagesBme - Part 1Sumanth ChallaPas encore d'évaluation

- Metals & Material ScienceDocument21 pagesMetals & Material ScienceJaveed A. KhanPas encore d'évaluation

- MZ FS Unit - 1Document27 pagesMZ FS Unit - 1Jai KumarPas encore d'évaluation

- 5 Applications and Processing of Metal AlloysDocument31 pages5 Applications and Processing of Metal AlloysJeffersonTalanPas encore d'évaluation

- Materials: The Choice of Material Is Governed by Following ConsiderationsDocument7 pagesMaterials: The Choice of Material Is Governed by Following ConsiderationsrezzdezzPas encore d'évaluation

- Selective Hardening MethodsDocument47 pagesSelective Hardening MethodsvishnuPas encore d'évaluation

- Chapter2 Lecture OkDocument39 pagesChapter2 Lecture OkAlaaPas encore d'évaluation

- Steel in Industrial Construction: Jyoti Chaurasiya Priyanka Siddharth Agarwal Zeenat ParveenDocument14 pagesSteel in Industrial Construction: Jyoti Chaurasiya Priyanka Siddharth Agarwal Zeenat ParveenSanjay SaxenaPas encore d'évaluation

- Material Science NotesDocument11 pagesMaterial Science NotesRyan Ryan RyanPas encore d'évaluation

- Classification of Materials: Metals, Alloys, Ceramics & MoreDocument29 pagesClassification of Materials: Metals, Alloys, Ceramics & MoreEsmail AnasPas encore d'évaluation

- MSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)Document15 pagesMSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)rakeshpatkar332Pas encore d'évaluation

- Lecture 2 - ECE 2215 PDFDocument24 pagesLecture 2 - ECE 2215 PDFRando ClintonPas encore d'évaluation

- Chemical & Mechanical Properties of Steel GuideDocument13 pagesChemical & Mechanical Properties of Steel GuideAddrien DanielPas encore d'évaluation

- Materials QuestionsDocument30 pagesMaterials QuestionsMatheus SouzaPas encore d'évaluation

- 10020dep-Notice 11042020Document32 pages10020dep-Notice 11042020Shivam VermaPas encore d'évaluation

- RSW-BT-YONGDocument10 pagesRSW-BT-YONGfraniancis0922Pas encore d'évaluation

- Module-5: Typical Engineering MaterialsDocument39 pagesModule-5: Typical Engineering Materialssrinidhi kulkarniPas encore d'évaluation

- Core ThingsDocument11 pagesCore ThingsVigneshPas encore d'évaluation

- Final MT-4 & 5Document31 pagesFinal MT-4 & 5RajasekharKosuruPas encore d'évaluation

- Stainless Steel Electrical ApplicationsDocument9 pagesStainless Steel Electrical ApplicationsUmang SoniPas encore d'évaluation

- Materials Classification GuideDocument38 pagesMaterials Classification GuideMohanrajRajangamPas encore d'évaluation

- Areola Topic1Document5 pagesAreola Topic1simeon tayawaPas encore d'évaluation

- Presenter: Sanket Kumar Rout Mpo 1 Year Student Institute of Rehabilitation Sciences Isic, Vasantkunj, NewdelhiDocument37 pagesPresenter: Sanket Kumar Rout Mpo 1 Year Student Institute of Rehabilitation Sciences Isic, Vasantkunj, NewdelhiSanket RoutPas encore d'évaluation

- Esdep Lecture Note (Wg2)Document26 pagesEsdep Lecture Note (Wg2)Rahul ShrivastavaPas encore d'évaluation

- Break ElongationDocument3 pagesBreak ElongationPHILIPANTHONY MASILANGPas encore d'évaluation

- Engineering Materials: Metals and Their Alloys Ceramics Polymers CompositesDocument53 pagesEngineering Materials: Metals and Their Alloys Ceramics Polymers CompositesSyed Muhammad AliPas encore d'évaluation

- Uddeholm Heat Treatment of Tool Steel 06.2012 E8Document20 pagesUddeholm Heat Treatment of Tool Steel 06.2012 E8tecnico0104Pas encore d'évaluation

- Heat Affected Zone and Weldability of Carbon SteelsDocument24 pagesHeat Affected Zone and Weldability of Carbon SteelsShruthick MurugesanrajaganapathyPas encore d'évaluation

- Manufacturing Materials ColouredDocument20 pagesManufacturing Materials Colouredramu reddyPas encore d'évaluation

- Modern Steel Manufacturing MethodsDocument16 pagesModern Steel Manufacturing MethodsAli AbidPas encore d'évaluation

- 11 Engineering MaterialsDocument20 pages11 Engineering MaterialsAbdul Hai MohammedPas encore d'évaluation

- IslahDocument2 pagesIslahnecdet_karagüllePas encore d'évaluation

- Alloy SteelsDocument9 pagesAlloy SteelsAileen Joy CananiaPas encore d'évaluation

- Elevated Temperatures & MaterialsDocument20 pagesElevated Temperatures & MaterialspjuvvadiPas encore d'évaluation

- Format Classtest 2 SteelDocument5 pagesFormat Classtest 2 SteelVaibhav BhosalePas encore d'évaluation

- Tensile Strength of Steel (Group 4.2Document20 pagesTensile Strength of Steel (Group 4.2Chelsiemea VargasPas encore d'évaluation

- Metals: Types of Metals AlloysDocument9 pagesMetals: Types of Metals AlloysIslam ElhabshePas encore d'évaluation

- 18-6 Theoretical PartsDocument11 pages18-6 Theoretical Partshayder1920Pas encore d'évaluation

- All Written Paper Solution..Sanjay MohapatraDocument137 pagesAll Written Paper Solution..Sanjay MohapatraJohn PaulPas encore d'évaluation

- Carbon steelDocument9 pagesCarbon steelArfanAliPas encore d'évaluation

- Design FormatDocument1 pageDesign FormatVinoth MalaikaniPas encore d'évaluation

- TNPSC Answer Key 1Document3 pagesTNPSC Answer Key 1Vinoth MalaikaniPas encore d'évaluation

- GE8261-Engineering Practices Lab - MECH PDFDocument74 pagesGE8261-Engineering Practices Lab - MECH PDFMohamed BasheerPas encore d'évaluation

- Journal paperDocument10 pagesJournal paperVinoth MalaikaniPas encore d'évaluation

- Unit Iii Hydromatic Drive: Fluid Coupling ConverterDocument44 pagesUnit Iii Hydromatic Drive: Fluid Coupling ConverterGuruLakshmiPas encore d'évaluation

- !!!!!!!!!!!!! !!!!!!!!!!!!! !!!!!!!!!!!!! !!!!!!!!!!!!!ose Je! Ose Je! Ose Je! Ose Je!.... ! ! ! !Document93 pages!!!!!!!!!!!!! !!!!!!!!!!!!! !!!!!!!!!!!!! !!!!!!!!!!!!!ose Je! Ose Je! Ose Je! Ose Je!.... ! ! ! !Narveena Servai VadiveluPas encore d'évaluation

- jkpo;ehL Mrphpah; fy;tpapay; gy;fiyf;fofkDocument116 pagesjkpo;ehL Mrphpah; fy;tpapay; gy;fiyf;fofkVinoth MalaikaniPas encore d'évaluation

- Lecture 9 Farm Tractor PDFDocument4 pagesLecture 9 Farm Tractor PDFsujan paudel100% (1)

- Basics of Vehicle Aerodynamics: University of Rome La Sapienza" 2002Document31 pagesBasics of Vehicle Aerodynamics: University of Rome La Sapienza" 2002Vinoth MalaikaniPas encore d'évaluation

- CentroidsDocument118 pagesCentroidsMaxneil QuijanoPas encore d'évaluation

- Certificate No. IIDocument3 pagesCertificate No. IIbirrajPas encore d'évaluation

- 7 Force AnalysisDocument19 pages7 Force AnalysisEn Eskay100% (1)

- Composite SystemsDocument14 pagesComposite Systemsvinoth9657tycoonPas encore d'évaluation

- Automotive MaterialsDocument45 pagesAutomotive MaterialsVinoth MalaikaniPas encore d'évaluation

- Review of Aerodynamic Drag Reduction Devices For Heavy Trucks and BusesDocument65 pagesReview of Aerodynamic Drag Reduction Devices For Heavy Trucks and BusesVinoth MalaikaniPas encore d'évaluation

- AT6503 VDC Question BankDocument8 pagesAT6503 VDC Question BankVinoth MalaikaniPas encore d'évaluation

- Vehicle Tracking SystemDocument22 pagesVehicle Tracking SystemVinoth MalaikaniPas encore d'évaluation

- Turbines - Hydraulic MachinesDocument26 pagesTurbines - Hydraulic MachinesVinoth MalaikaniPas encore d'évaluation

- Control Systems in Automobile PDFDocument36 pagesControl Systems in Automobile PDFVinoth MalaikaniPas encore d'évaluation

- How Does Nature Make Saltwater DrinkableDocument5 pagesHow Does Nature Make Saltwater DrinkableVinoth MalaikaniPas encore d'évaluation

- Nceda 2016Document2 pagesNceda 2016Vinoth MalaikaniPas encore d'évaluation

- Aston Martin IndiaDocument10 pagesAston Martin IndiaVinoth MalaikaniPas encore d'évaluation

- Weight RestrictionDocument3 pagesWeight Restrictionhareesh13hPas encore d'évaluation

- IPCC Chapter on Direct Solar EnergyDocument68 pagesIPCC Chapter on Direct Solar EnergyMARUMO_LEVYPas encore d'évaluation

- Projection of Lines and SolidsDocument28 pagesProjection of Lines and SolidsVinoth MalaikaniPas encore d'évaluation

- Drainage PDFDocument1 pageDrainage PDFSwapnil JainPas encore d'évaluation

- CH - 1Document4 pagesCH - 1Phantom GamingPas encore d'évaluation

- Interview QuestionsDocument3 pagesInterview Questionsاحتشام چوہدری100% (1)

- Curriculum Vitae: Name: Mobile: EmailDocument3 pagesCurriculum Vitae: Name: Mobile: EmailRākesh RakhiPas encore d'évaluation

- Calmark - Birtcher 44 5 10 LF L DatasheetDocument2 pagesCalmark - Birtcher 44 5 10 LF L DatasheetirinaPas encore d'évaluation

- Facts & Figures of Nepalese HydroDocument11 pagesFacts & Figures of Nepalese Hydromark bingPas encore d'évaluation

- Handy 2010 Case StudyDocument6 pagesHandy 2010 Case Studycancer6Pas encore d'évaluation

- 1729Document52 pages1729praj24083302Pas encore d'évaluation

- Configure NTP, OSPF, logging and SSH on routers R1, R2 and R3Document2 pagesConfigure NTP, OSPF, logging and SSH on routers R1, R2 and R3Lars Rembrandt50% (2)

- NCP 1014Document24 pagesNCP 1014rodricaldasPas encore d'évaluation

- Department of Education Region IV-A Business Plan GuideDocument4 pagesDepartment of Education Region IV-A Business Plan GuideSEAN DANIEL AGUARESPas encore d'évaluation

- Critical Thinking Chapter 9Document23 pagesCritical Thinking Chapter 9Desny LêPas encore d'évaluation

- Homework 1 ME 531 2018 WebDocument4 pagesHomework 1 ME 531 2018 WebEhab WilsonPas encore d'évaluation

- Formal Analysis of Timeliness in Electronic Commerce ProtocolsDocument5 pagesFormal Analysis of Timeliness in Electronic Commerce Protocolsjuan david arteagaPas encore d'évaluation

- Formulating and Solving LPs Using Excel SolverDocument8 pagesFormulating and Solving LPs Using Excel SolverAaron MartinPas encore d'évaluation

- PLC SCADA ASSIGNMENT SsDocument10 pagesPLC SCADA ASSIGNMENT SsShadab AhmadPas encore d'évaluation

- Evolution of Computers: A Brief HistoryDocument15 pagesEvolution of Computers: A Brief HistoryshinPas encore d'évaluation

- GulliverDocument8 pagesGulliverCris LuPas encore d'évaluation

- Grupo Stoncor Description - Stonhard Carboline Fibergrate PDFDocument22 pagesGrupo Stoncor Description - Stonhard Carboline Fibergrate PDFAndres OsorioPas encore d'évaluation

- BS (English) Dept of English University of SargodhaDocument36 pagesBS (English) Dept of English University of SargodhaFEROZ KHANPas encore d'évaluation

- Evolution of The Fire SprinklerDocument11 pagesEvolution of The Fire SprinklerPedro DudesonPas encore d'évaluation

- AI Berkeley Solution PDFDocument9 pagesAI Berkeley Solution PDFPrathamGuptaPas encore d'évaluation

- PLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalDocument5 pagesPLTW: Digital Electronics Syllabus For Mrs. Yusufi: Unit 1: Fundamentals of Analog and DigitalTriston DurbinPas encore d'évaluation

- Kevin Chiu - Solving Procrastination v1.1Document2 pagesKevin Chiu - Solving Procrastination v1.1TêteHautePas encore d'évaluation