Académique Documents

Professionnel Documents

Culture Documents

Chapter 1

Transféré par

mohsinali100%(1)100% ont trouvé ce document utile (1 vote)

62 vues31 pagesTitre original

chapter 1.pptx

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

62 vues31 pagesChapter 1

Transféré par

mohsinaliDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 31

Chapter 1

UNDERSTANDING THE

SUPPLYCHAIN

Copyright ©2013 Pearson Education. 1-1

Learning Objectives

1. Discuss the goal of a supply chain and explain

the impact of supply chain decisions on the

success of a firm.

2. Identify the three key supply chain decision

phases and explain the significance of each

one.

3. Describe the cycle and push/pull views of a

supply chain.

4. Classify the supply chain macro processes in a

firm.

Copyright ©2013 Pearson Education. 1-2

What is a Supply Chain?

• All stages involved, directly or indirectly, in

fulfilling a customer request

• Includes manufacturers, suppliers, transporters,

warehouses, retailers, and customers

• Within each company, the supply chain includes

all functions involved in fulfilling a customer

request (product development, marketing,

operations, distribution, finance, customer

service)

Copyright ©2013 Pearson Education. 1-3

What is a Supply Chain?

Figure 1-1

Copyright ©2013 Pearson Education. 1-4

What is a Supply Chain?

• Customer is an integral part of the supply chain

• Includes movement of products from suppliers to

manufacturers to distributors and information,

funds, and products in both directions

• May be more accurate to use the term “supply

network” or “supply web”

• Typical supply chain stages: customers,

retailers, distributors, manufacturers, suppliers

• All stages may not be present in all supply

chains (e.g., no retailer or distributor for Dell)

Copyright ©2013 Pearson Education. 1-5

Flows in a Supply Chain

Figure 1-2

Copyright ©2013 Pearson Education. 1-6

The Objective of a Supply Chain

• Maximize overall value created

Supply Chain Surplus

= Customer Value – Supply Chain Cost

Copyright ©2013 Pearson Education. 1-7

The Objective of a Supply Chain

• Example: a customer purchases a wireless

router from Best Buy for $60 (revenue)

• Supply chain incurs costs (information, storage,

transportation, components, assembly, etc.)

• Difference between $60 and the sum of all of

these costs is the supply chain profit

• Supply chain profitability is total profit to be

shared across all stages of the supply chain

• Success should be measured by total supply

chain profitability, not profits at an individual

stage

Copyright ©2013 Pearson Education. 1-8

The Objective of a Supply Chain

• Customer the only source of revenue

• Sources of cost include flows of

information, products, or funds between

stages of the supply chain

• Effective supply chain management is the

management of flows between and among

supply chain stages to maximize total

supply chain surplus

Copyright ©2013 Pearson Education. 1-9

Importance of

Supply Chain Decisions

• Wal-Mart, $1 billion sales in 1980 to $408 billion

in 2010

• Seven-Eleven Japan, ¥1 billion sales in 1974 to

¥3 trillion in 2009

• Webvan folded in two years

• Borders, $4 billion in 2004 to $2.8 billion in 2009

• Dell, $56 billion in 2006, adopted new supply

chain strategies

Copyright ©2013 Pearson Education. 1-10

Decision Phases of a Supply Chain

• Supply chain strategy or design

– How to structure the supply chain over the

next several years

• Supply chain planning

– Decisions over the next quarter or year

• Supply chain operation

– Daily or weekly operational decisions

Copyright ©2013 Pearson Education. 1-11

Supply Chain Strategy or Design

• Decisions about the structure of the supply chain

and what processes each stage will perform

• Strategic supply chain decisions

– Locations and capacities of facilities

– Products to be made or stored at various locations

– Modes of transportation

– Information systems

• Supply chain design must support strategic

objectives

• Supply chain design decisions are long-term and

expensive to reverse – must take into account

market uncertainty

Copyright ©2013 Pearson Education. 1-12

Supply Chain Planning

• Definition of a set of policies that govern

short-term operations

• Fixed by the supply configuration from

previous phase

• Starts with a forecast of demand in the

coming year

Copyright ©2013 Pearson Education. 1-13

Supply Chain Planning

• Planning decisions:

– Which markets will be supplied from which locations

– Planned buildup of inventories

– Subcontracting, backup locations

– Inventory policies

– Timing and size of market promotions

• Must consider in planning decisions demand

uncertainty, exchange rates, competition over

the time horizon

Copyright ©2013 Pearson Education. 1-14

Supply Chain Operation

• Time horizon is weekly or daily

• Decisions regarding individual customer orders

• Supply chain configuration is fixed and operating

policies are determined

• Goal is to implement the operating policies as

effectively as possible

• Allocate orders to inventory or production, set

order due dates, generate pick lists at a

warehouse, allocate an order to a particular

shipment, set delivery schedules, place

replenishment orders

• Much less uncertainty (short time horizon)

Copyright ©2013 Pearson Education. 1-15

Process View of a Supply Chain

• Cycle View: processes in a supply chain are

divided into a series of cycles, each performed

at the interfaces between two successive supply

chain stages

• Push/Pull View: processes in a supply chain are

divided into two categories depending on

whether they are executed in response to a

customer order (pull) or in anticipation of a

customer order (push)

Copyright ©2013 Pearson Education. 1-16

Cycle View

of Supply

Chain

Processes

Figure 1-3

Copyright ©2013 Pearson Education. 1-17

Cycle View of

Supply Chain Processes

Figure 1-4

Copyright ©2013 Pearson Education. 1-18

Push/Pull View of

Supply Chain Processes

• Supply chain processes fall into one of two

categories depending on the timing of their

execution relative to customer demand

• Pull: execution is initiated in response to a

customer order (reactive)

• Push: execution is initiated in anticipation of

customer orders (speculative)

• Push/pull boundary separates push processes

from pull processes

Copyright ©2013 Pearson Education. 1-19

Push/Pull View of Supply Chains

Figure 1-5

Copyright ©2013 Pearson Education. 1-20

Push/Pull View of

Supply Chain Processes

• Useful in considering strategic decisions relating

to supply chain design – more global view of

how supply chain processes relate to customer

orders

• Can combine the push/pull and cycle views

– L.L. Bean

– Dell

• The relative proportion of push and pull

processes can have an impact on supply chain

performance

Copyright ©2013 Pearson Education. 1-21

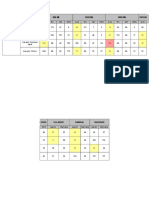

Customer

Order Cycle

Procurement,

Manufacturing,

Replenishment

Cycle

Copyright ©2013 Pearson Education. 1-22

Customer

Order and

Manufacturing

Cycle

Procurement

Cycle

Copyright ©2013 Pearson Education. 1-23

Supply Chain Macro Processes

• Supply chain processes discussed in the

two views can be classified into

– Customer Relationship Management (CRM)

– Internal Supply Chain Management (ISCM)

– Supplier Relationship Management (SRM)

• Integration among the above three macro

processes is critical for effective and

successful supply chain management

Copyright ©2013 Pearson Education. 1-24

Supply Chain Macro Processes

Figure 1-8

Copyright ©2013 Pearson Education. 1-25

Examples of Supply Chains

• Gateway and Apple

• Zara

• W.W. Grainger and McMaster-Carr

• Toyota

• Amazon

Copyright ©2013 Pearson Education. 1-26

Gateway and Apple

1. Why did Gateway choose not to carry any finished-product

inventory at its retail stores? Why did Apple choose to carry

inventory at its stores?

2. Should a firm with an investment in retail stores carry any

finished-goods inventory? What are the characteristics of

products that are most suitable to be carried in finished-goods

inventory? What characterizes products that are best

manufactured to order?

3. How does product variety affect the level of inventory a retail

store must carry?

4. Is a direct selling supply chain without retail stores always less

expensive than a supply chain with retail stores?

5. What factors explain the success of Apple retail and the failure

of Gateway country stores?

Copyright ©2013 Pearson Education. 1-27

Zara

1. What advantage does Zara gain against the competition by having

a very responsive supply chain?

2. Why has Inditex chosen to have both in-house manufacturing and

outsourced manufacturing? Why has Inditex maintained

manufacturing capacity in Europe even though manufacturing in

Asia is much cheaper?

3. Why does Zara source products with uncertain demand from local

manufacturers and products with predictable demand from Asian

manufacturers?

4. What advantage does Zara gain from replenishing its stores

multiple times a week compared to a less frequent schedule? How

does the frequency of replenishment affect the design of its

distribution system?

5. Do you think Zara’s responsive replenishment infrastructure is

better suited for online sales or retail sales?

Copyright ©2013 Pearson Education. 1-28

W.W. Grainger and McMaster-Carr

1. How many DCs should be built and where should they be located?

2. How should product stocking be managed at the DCs? Should all DCs carry

all products?

3. What products should be carried in inventory and what products should be

left with the supplier to be shipped directly in response to a customer order?

4. What products should W.W. Grainger carry at a store?

5. How should markets be allocated to DCs in terms of order fulfillment? What

should be done if an order cannot be completely filled from a DC? Should

there be specified backup locations? How should they be selected?

6. How should replenishment of inventory be managed at the various stocking

locations?

7. How should Web orders be handled relative to the existing business? Is it

better to integrate the Web business with the existing business or to set up

separate distribution?

8. What transportation modes should be used for order fulfillment and stock

replenishment?

Copyright ©2013 Pearson Education. 1-29

Toyota

1. Where should plants be located, what degree

of flexibility should each have, and what

capacity should each have?

2. Should plants be able to produce for all

markets?

3. How should markets be allocated to plants?

4. What kind of flexibility should be built into the

distribution system?

5. How should this flexible investment be valued?

6. What actions may be taken during product

design to facilitate this flexibility?

Copyright ©2013 Pearson Education. 1-30

Amazon and Independent

Merchants

1. Why did Amazon decide to allow other merchants to use

its supply chain expertise?

2. What advantages do merchants have when partnering

with Amazon?

3. Should Amazon stock every product it sells?

4. What advantage can bricks-and-mortar players derive

from setting up an online channel? How should they use

the two channels to gain a maximum advantage?

5. What advantages or disadvantages do large book

retailers gain by letting Amazon manage their supply

chain?

6. For which products does the online channel offer the

greatest advantage relative to retail stores? What

characterizes these products?

Copyright ©2013 Pearson Education. 1-31

Vous aimerez peut-être aussi

- Understanding the Evolution of Supply Chain ManagementDocument31 pagesUnderstanding the Evolution of Supply Chain ManagementAhmed AbdullahPas encore d'évaluation

- Diagnostic Laboratory TestsDocument6 pagesDiagnostic Laboratory TestsKiana Mae Wong Diwag100% (1)

- Introduction To Supply Chain ManagementDocument37 pagesIntroduction To Supply Chain ManagementPradeep Biradar100% (1)

- Rizwan Khan Assistant Professor: Supply Chain ManagementDocument34 pagesRizwan Khan Assistant Professor: Supply Chain ManagementMahnoor ZahidPas encore d'évaluation

- Transformers Classics: UK Vol. 3 PreviewDocument10 pagesTransformers Classics: UK Vol. 3 PreviewGraphic PolicyPas encore d'évaluation

- Supply Chain Management: Strategy, Planning, and Operation: Seventh Edition, Global EditionDocument39 pagesSupply Chain Management: Strategy, Planning, and Operation: Seventh Edition, Global Editionasim100% (1)

- Understanding SCM: Supply Chain Strategy and DesignDocument48 pagesUnderstanding SCM: Supply Chain Strategy and Designpartha080Pas encore d'évaluation

- Logistics in Manufacturing, Supply Chain, and DistributionD'EverandLogistics in Manufacturing, Supply Chain, and DistributionPas encore d'évaluation

- SCM 1-18 PPTDocument801 pagesSCM 1-18 PPTMr Boda Saikiran IPEPas encore d'évaluation

- Understanding The Supply ChainDocument34 pagesUnderstanding The Supply ChainNauryzbek MukhanovPas encore d'évaluation

- Introduction To Supply Chain ManagementDocument45 pagesIntroduction To Supply Chain ManagementAsha ChikkaputtegowdaPas encore d'évaluation

- Chapter 1 Introduction To Supply ChainDocument28 pagesChapter 1 Introduction To Supply Chainaireen clores0% (1)

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EDocument37 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EZohaib AhmadPas encore d'évaluation

- Supply Chain Transformation: Building and Executing an Integrated Supply Chain StrategyD'EverandSupply Chain Transformation: Building and Executing an Integrated Supply Chain StrategyÉvaluation : 5 sur 5 étoiles5/5 (7)

- Chapter 1 - Understanding The Supply ChainDocument30 pagesChapter 1 - Understanding The Supply ChainJyothi VenuPas encore d'évaluation

- Enterprise Supply Chain Management: Integrating Best in Class ProcessesD'EverandEnterprise Supply Chain Management: Integrating Best in Class ProcessesPas encore d'évaluation

- PDFDocument72 pagesPDFGCMediaPas encore d'évaluation

- CES Wrong Answer SummaryDocument4 pagesCES Wrong Answer SummaryZorg UAPas encore d'évaluation

- Notes On Supply Chain ManagementDocument20 pagesNotes On Supply Chain Managementhgopalkrishnan84% (31)

- Supply Chain Management For Agricultural ProductsDocument41 pagesSupply Chain Management For Agricultural ProductsSangita100% (17)

- City of Manila vs. Hon CaridadDocument2 pagesCity of Manila vs. Hon CaridadkelbingePas encore d'évaluation

- Chapter 1Document33 pagesChapter 1Shahzaib MazherPas encore d'évaluation

- Chopra Scm5 Ch01 GeDocument33 pagesChopra Scm5 Ch01 GeJAVIER ENRIQUE MU„OZ QUIROZPas encore d'évaluation

- Chopra scm5 ch01Document26 pagesChopra scm5 ch01Rizqy Ridho PPas encore d'évaluation

- SCM CH 1Document26 pagesSCM CH 1Dawit HusseinPas encore d'évaluation

- Chopra scm5 ch01Document23 pagesChopra scm5 ch01Shahed MahmudPas encore d'évaluation

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EDocument19 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Chopra and Meindl Supply Chain Management, 5EHassan ArifPas encore d'évaluation

- Understanding The Supply ChainDocument32 pagesUnderstanding The Supply ChainGuarantee International CollegePas encore d'évaluation

- Chapter 1Document33 pagesChapter 1projects_masterz100% (1)

- Chopra Scm5 Ch01 GeDocument31 pagesChopra Scm5 Ch01 Geফয়সাল হোসেন100% (1)

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument33 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanySheena HarrienPas encore d'évaluation

- Chopra Scm5 Ch01Document27 pagesChopra Scm5 Ch01Zohaib AhsonPas encore d'évaluation

- Understanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument20 pagesUnderstanding The Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanysynwithgPas encore d'évaluation

- SCM - CH1 Understanding SCDocument38 pagesSCM - CH1 Understanding SCMrunal ShethPas encore d'évaluation

- Chopra4 PPT ch01Document13 pagesChopra4 PPT ch01Neamat HassanPas encore d'évaluation

- Chapter 1Document25 pagesChapter 1Ankita SinghPas encore d'évaluation

- Lecture1515 - 26553 - Lecture 15 Supply Chain Management BasicsDocument51 pagesLecture1515 - 26553 - Lecture 15 Supply Chain Management BasicsAman kumar singhPas encore d'évaluation

- MENG148 - Module 1Document21 pagesMENG148 - Module 1Reimon DoblonPas encore d'évaluation

- MGMT 655: Chapter 1 Understanding The Supply Chain: Prof. Willem SelenDocument38 pagesMGMT 655: Chapter 1 Understanding The Supply Chain: Prof. Willem SelenAhmedPas encore d'évaluation

- Understanding The Supply ChainDocument21 pagesUnderstanding The Supply ChainJoann TeyPas encore d'évaluation

- Ilovepdf MergedDocument45 pagesIlovepdf MergedAnirudh ArunkumarPas encore d'évaluation

- Supply Chain Management: Peeyush Pandey Assistant Professor IIM RohtakDocument30 pagesSupply Chain Management: Peeyush Pandey Assistant Professor IIM RohtakSanyam JainPas encore d'évaluation

- Chopra3 PPT ch01Document25 pagesChopra3 PPT ch01osama haseebPas encore d'évaluation

- Chapter 1 - Understanding The Supply Chain-StDocument31 pagesChapter 1 - Understanding The Supply Chain-StXuân TrườngPas encore d'évaluation

- Topic 1-Understanding The Supply Chain Management IssuesDocument47 pagesTopic 1-Understanding The Supply Chain Management IssueszkillerszPas encore d'évaluation

- Chapter1 Understandingthesupplychain KayDocument28 pagesChapter1 Understandingthesupplychain KayNoor Harlisa Irdina Mohd HasanPas encore d'évaluation

- Building Strategic Framework To Analyze Supply Chains: 1.1. Understanding The Supply ChainDocument42 pagesBuilding Strategic Framework To Analyze Supply Chains: 1.1. Understanding The Supply ChainPrakash TirumaniPas encore d'évaluation

- Supply Chain Stages and FlowsDocument23 pagesSupply Chain Stages and Flowsrajat aggarwalPas encore d'évaluation

- Introduction SCMDocument41 pagesIntroduction SCMsakhawatPas encore d'évaluation

- CH 01Document38 pagesCH 01asd.ksa1090Pas encore d'évaluation

- Week 1-Intro To GSCMDocument34 pagesWeek 1-Intro To GSCMAkhmad YunaniPas encore d'évaluation

- Supply Chain Management: Nikunj Kumar Jain Fellow - IIM Indore, B-Tech (NIT Bhopal) Assistant Professor, IMI DelhiDocument38 pagesSupply Chain Management: Nikunj Kumar Jain Fellow - IIM Indore, B-Tech (NIT Bhopal) Assistant Professor, IMI DelhiSoumak TahPas encore d'évaluation

- 15 - Supply ChainDocument59 pages15 - Supply ChainmanjuPas encore d'évaluation

- Introduction To SCMDocument33 pagesIntroduction To SCMRISHIKA SINHAPas encore d'évaluation

- DR - Debmalya Ghosh: © 2007 Pearson Education 1-1Document23 pagesDR - Debmalya Ghosh: © 2007 Pearson Education 1-1Ruchi KumariPas encore d'évaluation

- Ch1 - Understanding The Supply Chain (Student)Document23 pagesCh1 - Understanding The Supply Chain (Student)Wenhui TuPas encore d'évaluation

- Understanding The Supply ChainDocument42 pagesUnderstanding The Supply ChainGueriillaPas encore d'évaluation

- Lecture 2Document12 pagesLecture 2AhmedPas encore d'évaluation

- Traditional View: Logistics in The Manufacturing FirmDocument32 pagesTraditional View: Logistics in The Manufacturing FirmRedwanul IslamPas encore d'évaluation

- SCM 1Document25 pagesSCM 1Gaurav YadavPas encore d'évaluation

- Unit 1Document53 pagesUnit 1Berlin ShaheemaPas encore d'évaluation

- SCM Session 1 and 2Document34 pagesSCM Session 1 and 2Pranav GargPas encore d'évaluation

- Chap 1Document45 pagesChap 1pink pinkPas encore d'évaluation

- SCM-Module-2 - Strategic FitDocument25 pagesSCM-Module-2 - Strategic FitMuhammed Husain MusaniPas encore d'évaluation

- Lean Distribution: Applying Lean Manufacturing to Distribution, Logistics, and Supply ChainD'EverandLean Distribution: Applying Lean Manufacturing to Distribution, Logistics, and Supply ChainÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- 12 ImamDocument204 pages12 ImammohsinaliPas encore d'évaluation

- Transport FundamentalsDocument32 pagesTransport FundamentalsmohsinaliPas encore d'évaluation

- Supply Chain Drivers and MetricsDocument46 pagesSupply Chain Drivers and MetricsmohsinaliPas encore d'évaluation

- Hyper Star 19-08-17Document7 pagesHyper Star 19-08-17mohsinaliPas encore d'évaluation

- Channels Internal Audit Report 17-11-16Document1 pageChannels Internal Audit Report 17-11-16mohsinaliPas encore d'évaluation

- NaveedDocument2 pagesNaveedmohsinaliPas encore d'évaluation

- MATHS UNDERSTANDINGDocument15 pagesMATHS UNDERSTANDINGNurul IzzaPas encore d'évaluation

- Ce QuizDocument2 pagesCe QuizCidro Jake TyronPas encore d'évaluation

- Additional Practice Questions on Bonding and Mechanical Properties of MaterialsDocument26 pagesAdditional Practice Questions on Bonding and Mechanical Properties of MaterialsYeo JosephPas encore d'évaluation

- QuizInfo8 6 10Document373 pagesQuizInfo8 6 10Gill BeroberoPas encore d'évaluation

- Potato Tuber CropsDocument103 pagesPotato Tuber CropsNani NazirPas encore d'évaluation

- CARAGA REGIONAL SCIENCE HIGH SCHOOL ASSESSMENT #1Document3 pagesCARAGA REGIONAL SCIENCE HIGH SCHOOL ASSESSMENT #1Joana Jean SuymanPas encore d'évaluation

- Chemistry The Molecular Science 5th Edition Moore Solutions Manual 1Document36 pagesChemistry The Molecular Science 5th Edition Moore Solutions Manual 1josephandersonxqwbynfjzk100% (27)

- SMS Romantis Bhs Inggris Buat Pacar TercintaDocument5 pagesSMS Romantis Bhs Inggris Buat Pacar TercintaAdnan MaruliPas encore d'évaluation

- Air India CpioDocument5 pagesAir India CpioVicky GautamPas encore d'évaluation

- 2017 Climate Survey ReportDocument11 pages2017 Climate Survey ReportRob PortPas encore d'évaluation

- Slope StabilityDocument11 pagesSlope StabilityAhmed MohebPas encore d'évaluation

- June 3rd 1947 Partition PlanDocument2 pagesJune 3rd 1947 Partition PlanZ_Jahangeer88% (16)

- Multiple Choice Questions Class Viii: GeometryDocument29 pagesMultiple Choice Questions Class Viii: GeometrySoumitraBagPas encore d'évaluation

- List of MeriendasDocument17 pagesList of MeriendasKristoffer OgalinoPas encore d'évaluation

- PERTANYAAN INTERVIEW WinaDocument2 pagesPERTANYAAN INTERVIEW WinaDidi SetiadiPas encore d'évaluation

- BiOWiSH Crop OverviewDocument2 pagesBiOWiSH Crop OverviewBrian MassaPas encore d'évaluation

- Alan Ross CV Expert Road Safety AdviserDocument4 pagesAlan Ross CV Expert Road Safety AdviserAnna Sophia YorkPas encore d'évaluation

- Ariston Oven ManualDocument16 pagesAriston Oven ManualJoanne JoannePas encore d'évaluation

- Handouts - Entity Relationship DiagramDocument8 pagesHandouts - Entity Relationship Diagramsecret studetPas encore d'évaluation

- DSME2051CDocument5 pagesDSME2051Choi chingPas encore d'évaluation

- Cambridge IGCSE: Pakistan Studies 0448/01Document4 pagesCambridge IGCSE: Pakistan Studies 0448/01Mehmood AlimPas encore d'évaluation

- Sar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیDocument1 pageSar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیPayman Akhlaghi (پیمان اخلاقی)100% (3)

- UT Dallas Syllabus For Chem2323.001.10s Taught by Sergio Cortes (Scortes)Document9 pagesUT Dallas Syllabus For Chem2323.001.10s Taught by Sergio Cortes (Scortes)UT Dallas Provost's Technology GroupPas encore d'évaluation

- Noise Pollution Control Policy IndiaDocument10 pagesNoise Pollution Control Policy IndiaAllu GiriPas encore d'évaluation

- Joey Cena 2Document1 pageJoey Cena 2api-635313033Pas encore d'évaluation