Académique Documents

Professionnel Documents

Culture Documents

Industrial Engineering Services Prsentation MD - Shadikul Huq Shezan

Transféré par

MD Shadikul Huq Shezan0 évaluation0% ont trouvé ce document utile (0 vote)

20 vues11 pagesha

Titre original

IES[1]

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentha

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

20 vues11 pagesIndustrial Engineering Services Prsentation MD - Shadikul Huq Shezan

Transféré par

MD Shadikul Huq Shezanha

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 11

IES

industrial engineering services

Prsentation

Md.Shadikul huq shezan

• Testing is the process of evaluation and

classified as:Destructive and Non-Destructive.

• What is NDT?

• NDT is the process of evaluation of the

conditions of the raw materials,components

or the equpments without any damage

physically,structurally,and dimentionally.

ULTRASONIC TESTING

Now we are talk about UT-Ultrasonic testing:

Ultrasonic testing is one of the NDT method,which

is generally used for detection

1.Internal defects in

forgings,castings,rolling,welding,pipes and tubes.

2.Thikness mesasurment of pipelines,pressure

vassels and ships.

3.Lack of bonding of overlay weld,lack of bonding at

the interface between the claded material and

bearing shell and lamination in plates and sheets.

PRINCIPLE OF ULTRASONIC TESTING

Ultrasonic is the sound energy having frequency above theh audible

range(20 to 20000Hz)transmitted in the matrials through piezo-

electric crystals in different modes(longitudinal,transverse and

surface).when the transmitted energy reach at the back surface of

the materil get reflected back received by the piezo-electric

element which supply to the receiver and desplay on the CRT as

thikness or path travel.if there is some defect,refleceted back and

give the indication at position corresponding to the relative path

travel,which is earlier than the back surface reflection .from the

indicantion,we can get two two information,one is the location or

depth of defect from the position and another is the size of the

f=dfect from the amplitude of indication corresponding to the

amount of reflected energy.

ADVNTAGES OF ULTRASONIC TESTING

• The following are the advantages of ultrasonic

testing.

1.One surface access is suffciant for testing.

2.It can cover few meters of length or thikness.

3.It can give exact location or depth of the

defect.

4.Instant result.

5.No hazard

CONTENTS OF ULTRASONIC TESTING

First contents:ULTRASONIC?Ultra means

beyond;Sonic means audible range of sound.

Then ultrasonic is the sound energy having the

frequnency beyond the of audible sound.

What is frequency of audible sound?

20 to 20000Hz.or 20 Hz to 20KHz. Is the range of

frequency of audible sound.Then Ultrasonic is

sound energy having frequncy above 20,000Hz or

20KHz.The sound is the the vibration means back

and forth movements.

• They are many modes of ultrasonic vibrations which

will travel through solids.The modes most wiedly used

in ultrasonic testing are :longitudional,shear,surface

and plate waves.Each mode,or wave type,causes a

specific movement in the element of medium.

• Longitudinal waves produce vibration in the same

direction(parallel)to the motion of the sound.

• Shear wave:A wave having particle vibration

perpendicular (normal)to the direction of wave motion

is called a shear or transvers wave .

• Surface:surface wave occurs when the particle motion

is elliptical with the major axis at right angel to the

direction of propagation and it travels through solid

only.

• Plate :plate wave produced in the sheets when

beaming is done by angel probe at perticular

angle.plate or lamb waves are two types-Symmetrical

an Asymetrical.the particale motion is elliptical on both

the surfaces,where is in the centre it is longitudional

for symmetrical and transverse for asymmetrical

waves.they are used for testing of thin plates, for

detection of lamination and debonding in cladded

materials.

Acoustic Impedance

• Acoustic impedance is the factor which

controls the propagation of an ultasonic wave

at boundary interface. It is the product of the

materail density and th acoustic wave velocity

within the material,denoted by Z.

• Acoustic impedance(z)=density(ρ) x

velocity(v).

Couplants

• In order to transmit the ultrasonic energy from probe o

the test sample th air has to be totally removed as we

know that the air is a bad conductor and good eflector

of the energy.so a liqued medium is used to remove

that air interface between the probe and work piece to

transmit the sound energy.the liquid medium is known

as couplent….

• There are varity of couplent and according to the

condition proper couplent should be used:

• 1.surface finish of the test pice:smooth flat sirface and

rough,vertical,overhead and curved surface.

• 2.high surface tempreture.

2nd contents:

• Share wave theory:

The charicteristics of reflection and mode coversion are

crated as ultrasound passed through an interface

between materials that have different acoustical

properties.the four result of striking through an

interface are reflection ,transmission,refraction,and

mode conversion.All of these are important aspects of

interface reaction.then our need to know First critical

angle: when the incident beam in reaches at particular

angel,at which the rfracted longitudinal…

Vous aimerez peut-être aussi

- Module 4 Ultrasonic TestingDocument112 pagesModule 4 Ultrasonic TestingSajeesh SajiPas encore d'évaluation

- U5 - Ultrasonic InspectionDocument83 pagesU5 - Ultrasonic InspectionSuraj B SPas encore d'évaluation

- Ultrasonic Flaw Detection: KnowledgeDocument6 pagesUltrasonic Flaw Detection: KnowledgeShifali GowdaPas encore d'évaluation

- The Fast Track to Understanding Ham Radio PropagationD'EverandThe Fast Track to Understanding Ham Radio PropagationPas encore d'évaluation

- Ultrasound Basic: Manual UT Principal & WorkingDocument65 pagesUltrasound Basic: Manual UT Principal & WorkingVarun DubeyPas encore d'évaluation

- Basics of Communication & Astronomy: APTMU Books, #1D'EverandBasics of Communication & Astronomy: APTMU Books, #1Pas encore d'évaluation

- Ultrasonic Flaw DetectionDocument15 pagesUltrasonic Flaw DetectionLeonardo.martinezPas encore d'évaluation

- Intro To UltrasonicsDocument57 pagesIntro To UltrasonicsBhuvanesh PonnanPas encore d'évaluation

- UNIT 4 Complete Notes With MCQDocument76 pagesUNIT 4 Complete Notes With MCQshrimanPas encore d'évaluation

- NDT CompleteDocument57 pagesNDT CompleteabdulazizPas encore d'évaluation

- Ultrasonic TestingDocument42 pagesUltrasonic TestingAppu MukundanPas encore d'évaluation

- Ultrasonic Flow Detection: Miii-1Document10 pagesUltrasonic Flow Detection: Miii-1jishnusajiPas encore d'évaluation

- ppt1 PDFDocument48 pagesppt1 PDFOmar SalihPas encore d'évaluation

- Unit-02 NDTDocument20 pagesUnit-02 NDT19114 GovindPas encore d'évaluation

- Module 4 PDF Ultrasonic TestingDocument61 pagesModule 4 PDF Ultrasonic Testingjesna mohammedPas encore d'évaluation

- Ut IntrDocument25 pagesUt IntrJeevana Sugandha WijerathnaPas encore d'évaluation

- Ultrasonic Testing General Basics Fundam 17-20Document4 pagesUltrasonic Testing General Basics Fundam 17-20Kevin HuangPas encore d'évaluation

- Ultrasonic TestingDocument36 pagesUltrasonic TestingWika RatnasariPas encore d'évaluation

- Ultasonic Wave ApplicationDocument38 pagesUltasonic Wave ApplicationVarah ORlandosPas encore d'évaluation

- Ultrasonic Testing Slides 1Document47 pagesUltrasonic Testing Slides 1ngtchungPas encore d'évaluation

- WITCO - UT PresentationDocument51 pagesWITCO - UT PresentationJohn OLiverPas encore d'évaluation

- Module 4 Ultrasonictesting and AE TestingDocument10 pagesModule 4 Ultrasonictesting and AE Testingujwalroy119Pas encore d'évaluation

- Ironscan - UT Study Material - FinalDocument115 pagesIronscan - UT Study Material - FinalselvamPas encore d'évaluation

- WITCO - UT PresentationDocument51 pagesWITCO - UT PresentationJohn Eric OliverPas encore d'évaluation

- History: Ultrasonic Testing (UT) Is A Family ofDocument3 pagesHistory: Ultrasonic Testing (UT) Is A Family ofGowrisanthosh PalikaPas encore d'évaluation

- 4 Ultrasonic TestingDocument86 pages4 Ultrasonic TestingmohammedPas encore d'évaluation

- An Introduction To Ultrasonic Flaw DetectionDocument7 pagesAn Introduction To Ultrasonic Flaw DetectionDeePas encore d'évaluation

- Ultrasonic TestingDocument5 pagesUltrasonic TestinggalihPas encore d'évaluation

- Ultrasonics Demo 11Document299 pagesUltrasonics Demo 11Ayesha GePas encore d'évaluation

- 8.1.ultra Sonic-Testing-Part-1Document37 pages8.1.ultra Sonic-Testing-Part-1Mohanad AlmalahPas encore d'évaluation

- UltrasoundDocument2 pagesUltrasoundgundam_freedomPas encore d'évaluation

- MM 212 Materials Evaluation Techniques Fall Semester 2020, FMCE, GIKIDocument30 pagesMM 212 Materials Evaluation Techniques Fall Semester 2020, FMCE, GIKIElbert VonVerimPas encore d'évaluation

- Ultrasonic Testing Guide BookDocument81 pagesUltrasonic Testing Guide BookManoj Kumar100% (1)

- What Ultrasonic Waves Are, and How They PropagateDocument17 pagesWhat Ultrasonic Waves Are, and How They PropagateZahir Rayhan JhonPas encore d'évaluation

- UTT Study GuideDocument18 pagesUTT Study GuideJan Borskey Neal67% (3)

- Ultrasonic Testing: Department of Mechanical Engineering, SJCITDocument22 pagesUltrasonic Testing: Department of Mechanical Engineering, SJCITgabrielPas encore d'évaluation

- Basics of Ultrasonic Test Ultrasonic Wave Modes Snell's Law Acoustic ImpedanceDocument7 pagesBasics of Ultrasonic Test Ultrasonic Wave Modes Snell's Law Acoustic ImpedanceHimanshu TiwaryPas encore d'évaluation

- Module 4Document47 pagesModule 4Tihor NalimPas encore d'évaluation

- Ultrasound NDTDocument25 pagesUltrasound NDTSai Ram Shyam SundarPas encore d'évaluation

- Basic Ultrasonic Principles: P.J Suryavamshi Nde-HzwDocument26 pagesBasic Ultrasonic Principles: P.J Suryavamshi Nde-HzwSonu GeorgePas encore d'évaluation

- Intro To UltrasonicsDocument23 pagesIntro To UltrasonicsJaspreet SinghPas encore d'évaluation

- Basic Principles of Ultrasonic TestingDocument46 pagesBasic Principles of Ultrasonic TestingSheed AsherPas encore d'évaluation

- Ultrasonic TestingDocument36 pagesUltrasonic TestingMuhammad Rahim UsmanPas encore d'évaluation

- NDT - Ultrasonic Examination: Date: July 2008Document51 pagesNDT - Ultrasonic Examination: Date: July 2008Ad Man GeTigPas encore d'évaluation

- UT PresentaitonDocument38 pagesUT PresentaitonK JeevanPas encore d'évaluation

- Fundamentals of Ultrasonic Imaging and Flaw Detection - NI-Tutorial-3368-EnDocument5 pagesFundamentals of Ultrasonic Imaging and Flaw Detection - NI-Tutorial-3368-Enafsajghfd1Pas encore d'évaluation

- 2 Intro - To - Ultrasonics 03092013 OKDocument43 pages2 Intro - To - Ultrasonics 03092013 OKferyPas encore d'évaluation

- Basic Principles of Ultrasonic Testing PDFDocument73 pagesBasic Principles of Ultrasonic Testing PDFSisira Chandrasoma100% (1)

- Ultrasonics Demo PDocument10 pagesUltrasonics Demo PGoverdhan ShresthaPas encore d'évaluation

- Introduction To Ultrasonic Testing TechniqueDocument52 pagesIntroduction To Ultrasonic Testing TechniqueDr. Akshay JainPas encore d'évaluation

- Ultrasonic Testing PROCEDUREDocument37 pagesUltrasonic Testing PROCEDUREWALID100% (1)

- Wave Motion and Its ApplicationsDocument24 pagesWave Motion and Its ApplicationsDivya SoodPas encore d'évaluation

- Ultrasonic TestingDocument36 pagesUltrasonic TestingRaj Kumar100% (4)

- UT Testing-Section 4Document146 pagesUT Testing-Section 4Charlie Chong100% (1)

- Ultrasonic Testing in NDTDocument22 pagesUltrasonic Testing in NDTSatheesh Sekar100% (1)

- Guided Waves IDocument85 pagesGuided Waves IDeepjyoti Das100% (1)

- MD - Akibur Sheikh WQTDocument2 pagesMD - Akibur Sheikh WQTMD Shadikul Huq ShezanPas encore d'évaluation

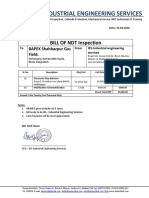

- BILL OF NDT Inspection: To From IES-Industrial Engineering ServicesDocument2 pagesBILL OF NDT Inspection: To From IES-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Sujan Das PT Test ReportDocument2 pagesSujan Das PT Test ReportMD Shadikul Huq ShezanPas encore d'évaluation

- 30-11-2021 UT ReportDocument3 pages30-11-2021 UT ReportMD Shadikul Huq ShezanPas encore d'évaluation

- MD - Akibur Sheikh PT Test ReportDocument2 pagesMD - Akibur Sheikh PT Test ReportMD Shadikul Huq ShezanPas encore d'évaluation

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanPas encore d'évaluation

- UT REport For Nornal Probe Shah CementDocument1 pageUT REport For Nornal Probe Shah CementMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- IES PadDocument1 pageIES PadMD Shadikul Huq ShezanPas encore d'évaluation

- Heder Boiler Room Hydrolic TestDocument5 pagesHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Heder 02 Hydrolic Test Dyeing Floor DistributionDocument4 pagesHeder 02 Hydrolic Test Dyeing Floor DistributionMD Shadikul Huq ShezanPas encore d'évaluation

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Heder 02 Hydrolic Test Dyeing Floor DistributionDocument4 pagesHeder 02 Hydrolic Test Dyeing Floor DistributionMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Boiler UTG Seperation Wall Burner SideDocument2 pagesBoiler UTG Seperation Wall Burner SideMD Shadikul Huq ShezanPas encore d'évaluation

- Ies-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportDocument1 pageIes-Industrial Engineering Services: Ultrasonoic Thickness Gauge ReportMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

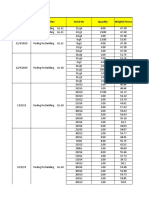

- Date Description Serial No Quantity Weight/ PecessDocument12 pagesDate Description Serial No Quantity Weight/ PecessMD Shadikul Huq ShezanPas encore d'évaluation

- Tested by Ies-Industrial Engineering Services: Data and Test SpecimenDocument7 pagesTested by Ies-Industrial Engineering Services: Data and Test SpecimenMD Shadikul Huq ShezanPas encore d'évaluation

- MailDocument1 pageMailMD Shadikul Huq ShezanPas encore d'évaluation

- Ies-Industrial Engineering Services: BILL OF NDT InspectionDocument1 pageIes-Industrial Engineering Services: BILL OF NDT InspectionMD Shadikul Huq ShezanPas encore d'évaluation

- Help For Report ShezanDocument5 pagesHelp For Report ShezanMD Shadikul Huq ShezanPas encore d'évaluation

- Rotogravure Printing Learn MoreDocument15 pagesRotogravure Printing Learn Moreumangashling100% (1)

- MSDS Anti Scalant LSPE 0114Document1 pageMSDS Anti Scalant LSPE 0114kilin arkalPas encore d'évaluation

- Wood Preservation SecondDocument239 pagesWood Preservation SecondJuan Antonio Diaz LopezPas encore d'évaluation

- Testing of Building Stones - Rock Tests On Lab & FieldDocument3 pagesTesting of Building Stones - Rock Tests On Lab & FieldআকাশআহসানPas encore d'évaluation

- Prosses Validation Protocol For EnrofolxacineDocument22 pagesProsses Validation Protocol For Enrofolxacineمحمد عطاPas encore d'évaluation

- Limit Theorems For Generalized Density-Dependent Markov Chains and Bursty Stochastic Gene Regulatory NetworksDocument29 pagesLimit Theorems For Generalized Density-Dependent Markov Chains and Bursty Stochastic Gene Regulatory NetworksGaston GBPas encore d'évaluation

- D6557Document16 pagesD6557moh_ichwanuddinPas encore d'évaluation

- G171.1207962-1 - Standard Test Scratch HardnessDocument7 pagesG171.1207962-1 - Standard Test Scratch HardnessVictor Manuel Florez FrancoPas encore d'évaluation

- Indian Standard For Industrial FlooringDocument10 pagesIndian Standard For Industrial FlooringRamprasad JeyaramPas encore d'évaluation

- Cembrit Cembonit: Exterior CladdingDocument2 pagesCembrit Cembonit: Exterior CladdingIrina SanduPas encore d'évaluation

- Mech Transducer ReportDocument18 pagesMech Transducer ReportHome DecorsPas encore d'évaluation

- Determination of Bendamustine Hydrochloride in Pure and Dosage Forms by Ion-Associative Complex FormationDocument6 pagesDetermination of Bendamustine Hydrochloride in Pure and Dosage Forms by Ion-Associative Complex FormationHeidi HughesPas encore d'évaluation

- Pub - Essentials of Nuclear Medicine Imaging 5th Edition PDFDocument584 pagesPub - Essentials of Nuclear Medicine Imaging 5th Edition PDFNick Lariccia100% (1)

- Mechanical Properties of Carbon Fiber Composite MaterialsDocument2 pagesMechanical Properties of Carbon Fiber Composite MaterialsmehtabpathanPas encore d'évaluation

- Transpiration ResourceDocument33 pagesTranspiration ResourceGgdhdgsg KdhahshhPas encore d'évaluation

- Biology QuestionaireDocument2 pagesBiology Questionairelyll ann100% (1)

- Small Wind Turbine DesignDocument19 pagesSmall Wind Turbine DesignIqbal MeskinzadaPas encore d'évaluation

- Fertilizer CompanyDocument5 pagesFertilizer CompanyParth Patel100% (1)

- Music TherapyDocument13 pagesMusic TherapyXavier KiranPas encore d'évaluation

- 9 Health and SafetyDocument2 pages9 Health and SafetyHéctorPas encore d'évaluation

- Fruit Seed DispersalDocument10 pagesFruit Seed DispersalLim Kew ChongPas encore d'évaluation

- g115 Ws Us PDFDocument60 pagesg115 Ws Us PDFNiku HPas encore d'évaluation

- Filters FPDocument2 pagesFilters FPMAZENPas encore d'évaluation

- Marcet Boiler Lab ReportDocument12 pagesMarcet Boiler Lab ReportShameerSamsuriPas encore d'évaluation

- Naming Inorganic CompoundsDocument29 pagesNaming Inorganic CompoundsLove TakaPas encore d'évaluation

- What Are The Properties of Air Entrained ConcreteDocument2 pagesWhat Are The Properties of Air Entrained ConcretesuryakantamePas encore d'évaluation

- Conexion BlueDocument32 pagesConexion Bluecesardario90Pas encore d'évaluation

- Nanotechnology Roadmap 2007 WG ProcDocument210 pagesNanotechnology Roadmap 2007 WG Proc2mdotyPas encore d'évaluation

- CE 308 - Lec 8 - Admixtures - 2Document22 pagesCE 308 - Lec 8 - Admixtures - 2umair4362Pas encore d'évaluation

- Sol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsDocument6 pagesSol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsahadsajjadiPas encore d'évaluation