Académique Documents

Professionnel Documents

Culture Documents

Inventory Planning

Transféré par

vimalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Inventory Planning

Transféré par

vimalDroits d'auteur :

Formats disponibles

R12 Replenishment Fundamentals

Copyright © 2007, Oracle. All rights reserved.

Objectives

After completing this module, you should be able to do the

following:

• Perform forecasting

• Explain reorder-point planning

• Perform min-max planning

• Perform replenishment counting

• Generate kanban cards

• Set up inventory planning profile options

• Identify Implementation Considerations

Copyright © 2007, Oracle. All rights reserved.

Overview of Inventory Planning

Time to replenish

• Min-Max planning

• Reorder-point planning

• Kanban replenishment

• Replenishment counting

Copyright © 2007, Oracle. All rights reserved.

Order Planning

Order time Order size

“When should I order?” “How much should I order?”

Planning methods

“Which planning method should I use?”

Copyright © 2007, Oracle. All rights reserved.

How Much to Order

Carrying costs

Order costs

Expected

Demand

Copyright © 2007, Oracle. All rights reserved.

Replenishment Process for Intra-Org Supply

Sources

Create allocations

Replenishment move for inventory to be

order automatically moved

created

Print move

order pick slip

Transact move order

Copyright © 2007, Oracle. All rights reserved.

Replenishment Process for Supplier Supply

Sources

External purchase

requisition created

Run requisition

import

Auto create Approve Receive material

purchase order purchase order from supplier

Copyright © 2007, Oracle. All rights reserved.

Replenishment Process for Inter-Org Supply

Sources

Internal purchase Run Requisition Run Order import

requisition created import

Receive material

Pick release internal Ship confirm from other

sales order internal sales order organization

Copyright © 2007, Oracle. All rights reserved.

Replenishment Process for Product Supply

Sources

Work order created Release work order

Complete work order

when assembly finished

Copyright © 2007, Oracle. All rights reserved.

Replenishment Methods

Replenishment Methods

Available Supply

Reorder-point

Available to

Promise

Min-max

Planning setup

Replenishment

counting

Planning profile

options

Kanban

replenishment

Copyright © 2007, Oracle. All rights reserved.

Overview of Inventory Forecasting

Inventory forecasting is the process of extrapolating the

expected demand of an item over a number of periods in

the future.

Supply Demand

Copyright © 2007, Oracle. All rights reserved.

Forecast Types

Statistics Time period

Demand

Copyright © 2007, Oracle. All rights reserved.

Forecast Setup and Maintenance

Focus and Statistical forecast

setup and maintenance steps

1 Define forecast set

2 Define forecast rules

3 Generate forecasts

4 Maintain forecasts

5 Use forecasts

Copyright © 2007, Oracle. All rights reserved.

Oracle Inventory Replenishment Methods

Reorder-point Planning

• Safety stock

• Replenishment lead time

• Item demand

• Order cost

• Carrying cost

Min-Max Planning

• Minimum inventory level

• Maximum inventory level

Kanban Replenishment

Replenishment by visual cue

Replenishment Counting

• Nontracked subinventories

• Locators in subinventories

Copyright © 2007, Oracle. All rights reserved.

Replenishment Methods Levels

Planning Method Organization Subinventory

Reorder-point Yes No

Min-Max Yes Yes

Replenishment Counting No Yes

Kanban N/A N/A

Copyright © 2007, Oracle. All rights reserved.

Safety Stock

Planning of Item

Base Level of Inventory

Fluctuations in Demand

Copyright © 2007, Oracle. All rights reserved.

Economic Order Quantity

2 x annual demand x avg cost of order preparation

EOQ =

Annual inventory carrying cost percentage x unit cost

Copyright © 2007, Oracle. All rights reserved.

Overview of Reorder-Point Planning

Reorder Point = Safety Stock+Forecast demand during lead time

Quantity

Reorder-Point

Safety Stock

Time

Copyright © 2007, Oracle. All rights reserved.

Uses of Reorder-Point Planning

By Organization Independent Demand

Item Definition Inexpensive Items

Copyright © 2007, Oracle. All rights reserved.

Reorder-Point Planning Steps

Enter item planning

1 attributes.

2 Forecast item demand.

3 Define safety stocks.

Run Reorder-point

4 report.

Copyright © 2007, Oracle. All rights reserved.

Performing Reorder-Point Planning

Planning

Forecast On-order quantity Information

information

Creating

requisitions

Report

Submission

Copyright © 2007, Oracle. All rights reserved.

Overview of Min-Max Planning

Minimum Maximum

inventory level inventory level

Below minimum! Time to order

Copyright © 2007, Oracle. All rights reserved.

Uses of Min-Max Planning

Structure Items

Independent

Entire Organization Demand

Subinventory Tightly Controlled

Copyright © 2007, Oracle. All rights reserved.

Min-Max Planning

Determine minimum Enter minimum

and maximum quantity

quantities

Enter maximum

quantity

Do you want Yes Enter fixed lot

specific lot increments

increments?

Enter minimum

No

order quantity

Run Min-max Enter maximum

report order quantity

Copyright © 2007, Oracle. All rights reserved.

Min-Max Planning: How Much to Order?

The following equation represents how much you should

order:

Order quantity = (maximum quantity) - [(on-hand

quantity) + (quantity on order) ]

= - +

Copyright © 2007, Oracle. All rights reserved.

Min-Max Planning Steps

Enter item planning

1 attributes.

Define subinventory-

2 level min-max

information (optional).

Run the Min-max

3 report.

Copyright © 2007, Oracle. All rights reserved.

Item Planning Attributes

Item planning attributes include setting up general

planning attributes for either the organization or the

subinventory in which you want to use Min-max planning.

Copyright © 2007, Oracle. All rights reserved.

Min-Max Planning Setup Procedure

Set up the appropriate Select an inventory

profile value for planning method.

requisition approval.

Specify a planning level

(either organization or

subinventory).

Enter the following:

• Min-max minimum quantity

• Min-max maximum quantity

• Fixed-lot-size multiplier

• Minimum order quantity

• Maximum order quantity

Copyright © 2007, Oracle. All rights reserved.

Selecting a Planning Level

You can select min-max planning as the inventory planning

method for each item. If you select the min-max planning

method for an item, Oracle performs min-max planning for

that item at both the organization and subinventory levels.

To perform min-max planning at both the organization and

the subinventory levels, you need to enter minimum and

maximum quantities for each level.

Copyright © 2007, Oracle. All rights reserved.

Entering Planning Attributes

Select an inventory Enter min-max

planning method. minimum quantity.

Enter min-max Specify a fixed-lot-size

maximum quantity. multiplier.

Specify a minimum Specify a maximum

order quantity. order quantity.

Copyright © 2007, Oracle. All rights reserved.

Submitting the Min-Max Planning Requests

Set up item planning attributes

Submit concurrent process

Generate min-max planning report

Copyright © 2007, Oracle. All rights reserved.

Overview of Replenishment Counting

Organization

Subinventories

Replenishment Counting is a method of ordering items for

non-tracked subinventories.

Copyright © 2007, Oracle. All rights reserved.

Uses of Replenishment Counting

Buyer

Item

Subinventory

Copyright © 2007, Oracle. All rights reserved.

Replenishment Planning Steps

1 2

Specify requisition

Define subinventory.

approval status.

3 Define subinventory 4

Enter replenishment

replenishment

counts.

information.

5 Validate and process

6

Create requisitions.

replenishment counts.

Copyright © 2007, Oracle. All rights reserved.

Subinventories Window

You utilize the Subinventories window to define

subinventories for which you want to perform

replenishment counts.

Copyright © 2007, Oracle. All rights reserved.

Item Subinventories Window

Use the Item Subinventories window to enter minimum and

maximum quantities for each item that you store in a

subinventory.

Minimum Quantity

Maximum Quantity

Copyright © 2007, Oracle. All rights reserved.

Item Subinventories: Order Modifier Tab

In the Order Modifier tabbed region of the Item

Subinventories window, you specify the following

information:

• Fixed-lot-size multiplier

• Minimum order quantity

• Maximum order quantity

Copyright © 2007, Oracle. All rights reserved.

Replenishment Count Headers

You can enter counts to replenish subinventories. Oracle

Inventory replenishes subinventories according to the

method that you use to enter counts. Oracle Inventory

does not store on-hand quantity information for

non-tracked subinventories.

On hand quantity Subinventory

Copyright © 2007, Oracle. All rights reserved.

Replenishment Count Lines

You can select one of three replenishment count types for

each item:

On hand Quantity

Order Maximum

Order Quantity

Copyright © 2007, Oracle. All rights reserved.

Processing Replenishment Counts

The replenishment processor performs the calculations

that are necessary to verify whether Oracle Inventory

should create requisitions. You can either choose to

process the replenishment counts or save your changes

and run the replenishment processor later.

Copyright © 2007, Oracle. All rights reserved.

Mobile Replenishment Count Overview

Kanban Replenishment PAR

Replenishment Count Count

Copyright © 2007, Oracle. All rights reserved.

Overview of PAR Counting

Organization

Subinventories

Locators

Copyright © 2007, Oracle. All rights reserved.

Processing PAR Counts

Organization

Subinventory

PAR count is locator-level replenishment count

Locator 1 Locator 2 Locator 3 Locator 4

Copyright © 2007, Oracle. All rights reserved.

Reorder Quantity for PAR Count

PAR Level Quantity Count Type Reorder

Quantity

100 25 On-hand Quantity 75

100 Not applicable Order PAR 100

100 25 Order Quantity 25

Copyright © 2007, Oracle. All rights reserved.

Overview of Kanban Replenishment

CM1148 Full Bin CM1123

CM1148 CM1148

Ready to Replenish Bin in Use

Copyright © 2007, Oracle. All rights reserved.

Kanban Cards

Part A

KANBAN

Part B

KANBAN

• Shorter lead times

• Reduced inventory

Copyright © 2007, Oracle. All rights reserved.

Kanban Planned Items

Set Release Time Fence

Item Attribute to Kanban

KANBAN

Define the Pull sequence

and generate new

kanban cards

Copyright © 2007, Oracle. All rights reserved.

Kanban Cards

Subinventory

KANBAN Item

Locator

Copyright © 2007, Oracle. All rights reserved.

Kanban Supply Status

New

Full

Wait

KANBAN

In-Transit

Empty

In-Process

Copyright © 2007, Oracle. All rights reserved.

Kanban Replenishment Sources

Inter-Org

Intra-Org

Production

KANBAN

Supplier

Flow Schedules

User Defined

Copyright © 2007, Oracle. All rights reserved.

Kanban Card Printing

KANBAN

Copyright © 2007, Oracle. All rights reserved.

Planning and Replenishment Reports

Report Description

Min-Max Planning Report Use this report to show planning

information for all items, or items

with on-hand balances either below

or above their assigned minimum or

maximum on-hand quantities.

Planner Listing Use this report to list material

planners or planning entities. You

assign planners to inventory items

when you define items.

Reorder Point Report Use this report to show planning

information for items for which the

Inventory Planning Method is set to

Reorder Point.

Copyright © 2007, Oracle. All rights reserved.

Planning and Replenishment Reports (Cont)

Report Description

Forecast Rule Listing Use this report to view the data you

entered for forecast rules.

Item Replenishment Count Report Use this report to review the counts

you entered for items before creating

requisitions. You can also use the

report to validate the source

information for the replenishment

before you run the requisition

process.

PAR Replenishment Count Worksheet This report addresses requirements

that relate to the health care industry.

This report is similar to the Item

Replenishment Count Report, but in

addition captures information that is

specific to hospitals.

Copyright © 2007, Oracle. All rights reserved.

Profile Options

Profile Option Description

INV: fill Kanban on Partial Move Determines whether or not a kanban

Order Receipt card can be considered filled if the

move order created to fill it was only

partially transacted.

INV: Replenishment Move Order Enables you to create only one move

Grouping order header per request.

TP: INV Enter Replenishment Count Indicates processing control in the

Form Enter Replenishment Count window.

INV: Replenishment Count Indicates the status of Subinventory

Requisition Approval Replenishment requisitions created

by the replenishment processor.

Copyright © 2007, Oracle. All rights reserved.

Profile Options (Cont)

Profile Option Description

INV Replenishment Count Line Indicates the action taken when a

Failure failure is detected while processing a

replenishment count line.

INV: Minmax Reorder Approval Indicates the status of requisitions

created by the Min-Max Planning

Report.

INV: Round Reorder Quantity provides the min-max reporting

process with rounding options for

reorder quantity.

Copyright © 2007, Oracle. All rights reserved.

Implementation Considerations

Items

Make Buy

Copyright © 2007, Oracle. All rights reserved.

Implementation Considerations (Cont)

Supplier Sources

Demand Sources

Documents

Copyright © 2007, Oracle. All rights reserved.

Summary

You should now be able to do the following:

• Perform Forecasting

• Perform Reorder-point planning

• Perform Min-max planning

• Perform replenishment counting

• Generate kanban cards

• Set up Available to Promise (ATP)

• Perform ATP checks

• Set up inventory planning profile options

• Identify the Implementation Considerations

Copyright © 2007, Oracle. All rights reserved.

Vous aimerez peut-être aussi

- Inventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyD'EverandInventory Strategy: Maximizing Financial, Service and Operations Performance with Inventory StrategyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Physical Inventory GuidelinesDocument15 pagesPhysical Inventory GuidelinesVinay Chugh100% (1)

- Inventory ControlDocument25 pagesInventory ControlSuja Pillai100% (1)

- Inventory ManagementDocument20 pagesInventory Managementbabula27100% (6)

- Cost Management - Toyota Boeing ExampleDocument51 pagesCost Management - Toyota Boeing Exampleparam540100% (1)

- Stock Management and ControlDocument57 pagesStock Management and ControlACCOMMODATION CENTREPas encore d'évaluation

- Project On Inventory Mgt.Document69 pagesProject On Inventory Mgt.shivajiraoth7896753Pas encore d'évaluation

- 5 1 Inventory ManagementDocument42 pages5 1 Inventory Managementhrithima100% (13)

- Inventory ManagementDocument40 pagesInventory Managementganesh100% (1)

- Purchasing ProceduresDocument7 pagesPurchasing ProceduresHon Kirimi Mwobobia IIPas encore d'évaluation

- ABC Analysis Inventory ControlDocument13 pagesABC Analysis Inventory ControlAnkz_kapPas encore d'évaluation

- 3 - Inventory ControlDocument122 pages3 - Inventory Controlabhisheksaraf20Pas encore d'évaluation

- Oracle Flow Manufacturing - Process FlowDocument31 pagesOracle Flow Manufacturing - Process FlowPritesh MoganePas encore d'évaluation

- Stores ManagementDocument7 pagesStores ManagementVinay SinghPas encore d'évaluation

- Inventory ManagementDocument68 pagesInventory ManagementSuba Nita0% (1)

- Demand Forecasting LectureDocument68 pagesDemand Forecasting LectureAbhishek Fanse100% (1)

- Inventory Management With Practical ExampleDocument27 pagesInventory Management With Practical Examplepushpa patel97% (32)

- Basics of Supply Chain ManagementDocument44 pagesBasics of Supply Chain Management1983B100% (3)

- Purchasing ManagementDocument21 pagesPurchasing ManagementJiju Justin100% (3)

- Oracle Demand To Plan OverviewDocument53 pagesOracle Demand To Plan Overviewaedsouza100% (1)

- INVENTORY MANAGEMENT TechniquesDocument24 pagesINVENTORY MANAGEMENT TechniquesWessal100% (1)

- Capacity PlanningDocument55 pagesCapacity PlanningSatyajeet Chauhan75% (4)

- Procurement Function Final PDFDocument4 pagesProcurement Function Final PDFJuliet CastroPas encore d'évaluation

- Unit 1 - Introduction To Inventory ManagementDocument17 pagesUnit 1 - Introduction To Inventory ManagementNguyễn Thành NamPas encore d'évaluation

- Inventory Reorder MethodsDocument26 pagesInventory Reorder MethodsmragarwalPas encore d'évaluation

- MRP & ERP IntroductionDocument22 pagesMRP & ERP IntroductionRavi TejaPas encore d'évaluation

- Inventory PPT (EOQ)Document38 pagesInventory PPT (EOQ)drajingoPas encore d'évaluation

- Inventory ManagementDocument114 pagesInventory ManagementSalman HadiPas encore d'évaluation

- Fresh Healthy Juice Boosters, Inc.: Report On Business Process ReviewDocument29 pagesFresh Healthy Juice Boosters, Inc.: Report On Business Process ReviewJanysse CalderonPas encore d'évaluation

- Physical Inventory Adjustment Reverse EngineeringDocument2 pagesPhysical Inventory Adjustment Reverse EngineeringAkashPas encore d'évaluation

- Inventory Management SystemDocument16 pagesInventory Management Systempratiktamgadge25Pas encore d'évaluation

- Oracle Buy Sell SubcontractingDocument42 pagesOracle Buy Sell SubcontractingSenthilkumar KrishnanPas encore d'évaluation

- Inventory ControlDocument31 pagesInventory ControlAshish Chatrath100% (1)

- Inventory ManagementDocument69 pagesInventory ManagementDeepika SethPas encore d'évaluation

- Ten Ways To Reduce InvDocument4 pagesTen Ways To Reduce InvMurat GüventürkPas encore d'évaluation

- Electrolux Inventory Managt.Document30 pagesElectrolux Inventory Managt.neerajnarayanPas encore d'évaluation

- Wms MFG PickDocument26 pagesWms MFG PickNaveen Shankar MauwalaPas encore d'évaluation

- Inventory Average Cost TransactionsDocument70 pagesInventory Average Cost TransactionsMuhammad Wasim QureshiPas encore d'évaluation

- Material Requirement PlanningDocument23 pagesMaterial Requirement Planningsangaleabhi100% (1)

- Warehouse ProcedureDocument2 pagesWarehouse ProcedureSherry-Ann CallanPas encore d'évaluation

- 5.4 Inventory MagtDocument48 pages5.4 Inventory Magtbha_goPas encore d'évaluation

- Warehouse Layout Giving A Man Space Is Like Giving A Dog A Computer: The Chances Are He Will Not Use It Wisely. (Bette-Jane Raphael)Document4 pagesWarehouse Layout Giving A Man Space Is Like Giving A Dog A Computer: The Chances Are He Will Not Use It Wisely. (Bette-Jane Raphael)Malik SheikhPas encore d'évaluation

- Company Purchase:: Business Organization Goods ServicesDocument14 pagesCompany Purchase:: Business Organization Goods ServicesNoman KhanPas encore d'évaluation

- Inventory Record AccuracyDocument6 pagesInventory Record AccuracyMobeen MughalPas encore d'évaluation

- Planning Budgeting and Forecasting BPDDDocument70 pagesPlanning Budgeting and Forecasting BPDDSrinath BabuPas encore d'évaluation

- Inventory Management in ServicesDocument60 pagesInventory Management in ServicesAAKASH KANAKIAPas encore d'évaluation

- Oracle Inventory: Manufacturing Functional FoundationDocument59 pagesOracle Inventory: Manufacturing Functional Foundationmohammed achatPas encore d'évaluation

- Oracle Purchasing: R12 Financials Functional FoundationDocument52 pagesOracle Purchasing: R12 Financials Functional FoundationSuperb Leone SalamatPas encore d'évaluation

- EDU4072YDSDocument30 pagesEDU4072YDStariqbashirPas encore d'évaluation

- EBusiness Suite OverviewDocument15 pagesEBusiness Suite OverviewEric YimPas encore d'évaluation

- Demand and Supply: ASCP FundamentalsDocument36 pagesDemand and Supply: ASCP FundamentalspavanPas encore d'évaluation

- Order To Cash Lifecycle OverviewDocument14 pagesOrder To Cash Lifecycle OverviewPuneetPas encore d'évaluation

- R12 Inventory Accuracy FundamentalsDocument47 pagesR12 Inventory Accuracy FundamentalsvimalPas encore d'évaluation

- Overview To Advanced Supply Chain Planning: ASCP FundamentalsDocument19 pagesOverview To Advanced Supply Chain Planning: ASCP FundamentalsVenkata Ramanaiah KokaPas encore d'évaluation

- Procure To Pay OverviewDocument417 pagesProcure To Pay Overviewmohan raoPas encore d'évaluation

- Overview of Oracle Project CostingDocument16 pagesOverview of Oracle Project CostingbassembwaPas encore d'évaluation

- Oracle Master Scheduling and Material Requirements Planning: Manufacturing Functional FoundationDocument28 pagesOracle Master Scheduling and Material Requirements Planning: Manufacturing Functional Foundationmohammed achatPas encore d'évaluation

- Procure To Pay Lifecycle OverviewDocument13 pagesProcure To Pay Lifecycle Overviewsuman_formail7823Pas encore d'évaluation

- Overview of Oracle Order Management ProcessDocument22 pagesOverview of Oracle Order Management ProcessAnubhav.MittalPas encore d'évaluation

- Heavy Maintenance ExecutionDocument18 pagesHeavy Maintenance ExecutionNavin rudraPas encore d'évaluation

- Tour & Travel 16-JulyDocument18 pagesTour & Travel 16-JulySheetal Singh100% (1)

- BSV11102 CW1 D1 22-23 (Project Appraisal & Finance)Document8 pagesBSV11102 CW1 D1 22-23 (Project Appraisal & Finance)Muhammad AhmadPas encore d'évaluation

- Double Entry Cash BookDocument3 pagesDouble Entry Cash BookGyanish JhaPas encore d'évaluation

- 04 Facility LayoutDocument83 pages04 Facility Layoutsakali aliPas encore d'évaluation

- 100 Best Business BooksDocument8 pages100 Best Business BooksGiang Huong VuPas encore d'évaluation

- 300 - PEI - Jun 2019 - DigiDocument24 pages300 - PEI - Jun 2019 - Digimick ryanPas encore d'évaluation

- May 22Document2 pagesMay 22digiloansPas encore d'évaluation

- 300 Business Card Details Updated FileDocument42 pages300 Business Card Details Updated FileDebobrota K. Sarker0% (1)

- Regional IntegrationDocument6 pagesRegional IntegrationPeter DePointPas encore d'évaluation

- Aki Insurance Industry Report 2009Document40 pagesAki Insurance Industry Report 2009cimcim0812Pas encore d'évaluation

- Syntel Placement Paper 2 - Freshers ChoiceDocument3 pagesSyntel Placement Paper 2 - Freshers ChoicefresherschoicePas encore d'évaluation

- GMAP (BSBA Management 2A) Activity 1Document2 pagesGMAP (BSBA Management 2A) Activity 1Neil Francis Frondozo LorioPas encore d'évaluation

- The Ashok Leyland WayDocument15 pagesThe Ashok Leyland WayShreyas HNPas encore d'évaluation

- Technological Services Ltd. TSL: Name Abbreviation Status Established Head OfficeDocument3 pagesTechnological Services Ltd. TSL: Name Abbreviation Status Established Head OfficeTechnological ServicesPas encore d'évaluation

- Internal Rate of ReturnDocument4 pagesInternal Rate of ReturnMaria Ali ZulfiqarPas encore d'évaluation

- Welding Machine Production PlantDocument26 pagesWelding Machine Production PlantJohn100% (1)

- BrochureDocument12 pagesBrochureKundan KushwahaPas encore d'évaluation

- Complete Assignment - Docx (Final)Document15 pagesComplete Assignment - Docx (Final)anmeannPas encore d'évaluation

- WORKING CAPITAL MANAGEMENT of Axis Bank Finance Research 2014Document112 pagesWORKING CAPITAL MANAGEMENT of Axis Bank Finance Research 2014Indu Gupta82% (11)

- Conf 92EC AgendaBook 21821Document384 pagesConf 92EC AgendaBook 21821Tushar ChaudhariPas encore d'évaluation

- Sub ContractingDocument19 pagesSub ContractingPRABESH GAJUREL0% (1)

- Quotation For Steel WorkDocument6 pagesQuotation For Steel Workrayhan100% (1)

- Executive SummaryDocument13 pagesExecutive SummaryKamlesh SoniwalPas encore d'évaluation

- Final Micro Finance ReportDocument89 pagesFinal Micro Finance ReportNilabjo Kanti Paul50% (2)

- Marriott Promo Codes 2014Document4 pagesMarriott Promo Codes 2014Dave Ortiz100% (1)

- A. Adam Sloope: SkillsDocument3 pagesA. Adam Sloope: SkillsasloopePas encore d'évaluation

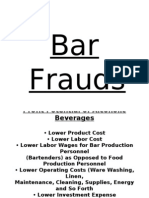

- Bar Frauds & FormsDocument41 pagesBar Frauds & FormsOm Singh100% (6)

- Orca Share Media1547030319812Document523 pagesOrca Share Media1547030319812Maureen Joy Andrada80% (10)

- Pakistan Ordnance FactoriesDocument1 pagePakistan Ordnance FactoriesBDO3 3J SolutionsPas encore d'évaluation

- Executive Summary (Sample)Document4 pagesExecutive Summary (Sample)celfa29100% (2)