Académique Documents

Professionnel Documents

Culture Documents

15ME3112 Design of Machine Elements

Transféré par

likhith sai0 évaluation0% ont trouvé ce document utile (0 vote)

39 vues29 pagesThe document summarizes the design of different types of shaft couplings, including sleeve or muff couplings, clamp or compression couplings, and flange couplings. It provides the purposes of shaft couplings, describes the components and design procedures for each type of coupling, and gives typical proportions used. The key points covered are the materials, stresses, and dimensions involved in properly designing couplings to transmit torque between connected shafts.

Description originale:

Couplings

Titre original

2017 Couplings

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document summarizes the design of different types of shaft couplings, including sleeve or muff couplings, clamp or compression couplings, and flange couplings. It provides the purposes of shaft couplings, describes the components and design procedures for each type of coupling, and gives typical proportions used. The key points covered are the materials, stresses, and dimensions involved in properly designing couplings to transmit torque between connected shafts.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

39 vues29 pages15ME3112 Design of Machine Elements

Transféré par

likhith saiThe document summarizes the design of different types of shaft couplings, including sleeve or muff couplings, clamp or compression couplings, and flange couplings. It provides the purposes of shaft couplings, describes the components and design procedures for each type of coupling, and gives typical proportions used. The key points covered are the materials, stresses, and dimensions involved in properly designing couplings to transmit torque between connected shafts.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 29

15ME3112

Design of Machine Elements

Session-20

Design of Shaft coupling

DVA Ramasastry

Associate Professor

ME department

dvarsastry@kluniversity.in

Session Outcome & plan

Session Outcome: Design of simple machine elements for

combined steady and variable loads

Time Teaching – Learning

Topic BTL

(min) Method

Coupling

• Shafts are usually available up to 7 metres length

due to inconvenience in transport. In order to have a

greater length, it becomes necessary to join two or

more pieces of the shaft by means of a coupling.

Purposes

• Shaft couplings are used in machinery for

several purposes, the most common of which are

the following :

• To provide for the connection of shafts of units that are

manufactured separately such as a motor and generator

and to provide for disconnection for repairs or

alternations.

• To provide for misalignment of the shafts or to introduce

mechanical flexibility.

• To reduce the transmission of shock loads from one shaft

to another.

• To introduce protection against overloads.

• It should have no projecting parts.

Types of Shafts Couplings

Shaft couplings are divided into two main groups as follows:

1. Rigid coupling. It is used to connect two shafts which are

perfectly aligned. Following types of rigid coupling are

important from the subject point of view :

• Sleeve or muff coupling.

• Clamp or split-muff or compression coupling, and

• Flange coupling.

2. Flexible coupling. It is used to connect two shafts having both

lateral and angular misalignment. Following types of flexible

coupling are important from the subject point of view

• Bushed pin type coupling,

• Universal coupling, and

• Oldham coupling.

• In this course, only Rigid couplings are dealt with.

1.Sleeve or Muff-coupling

• It is the simplest type of rigid coupling, made of

cast iron. It consists of a hollow cylinder whose

inner diameter is the same as that of the shaft. It is

fitted over the ends of the two shafts by means of a

gib head key.

• The power is transmitted from one shaft

to the other shaft by means of a key and a sleeve. It

is, therefore, necessary that all the elements must be

strong enough to transmit the torque.

The usual proportions of a cast iron sleeve coupling are as follows :

Outer diameter of the sleeve, D = 2d + 13 mm

and length of the sleeve, L = 3.5 d

where d is the diameter of the shaft.

Design procedure for sleeve or

muff-coupling:

1. Design for sleeve:

• The sleeve is designed by considering it as a hollow

shaft.

2. Design for key:

The width and thickness of the coupling key is obtained from

the proportions. The length of the coupling key is at least

equal to the length of the sleeve (i.e. 3.5 d). The coupling key

is usually made into two parts so that the length of the key in

each shaft,

• Note: The depth of the keyway in each of the shafts

to be connected should be exactly the same and the

diameters should also be same. If these conditions

are not satisfied, then the key will be bedded on one

shaft while in the other it will be loose. In order to

prevent this, the key is made in two parts which

may be driven from the same end for each shaft or

they may be driven from opposite ends.

2.Clamp or Compression Coupling:

• It is also known as split muff coupling. In this case, the

muff or sleeve is made into two halves and are bolted

together.

• The shaft ends are made to abut each other and a single

key is fitted directly in the keyways of both the shafts.

One-half of the muff is fixed from below and the other

half is placed from above. Both the halves are held

together by means of mild steel studs or bolts and nuts.

The number of bolts may be two, four or six. The nuts

are recessed into the bodies of the muff castings. This

coupling may be used for heavy duty and moderate

speeds. The advantage of this coupling is that the

position of the shafts need not be changed for

assembling or disassembling of the coupling.

The usual proportions of the muff for the clamp or compression

coupling are :

Diameter of the muff or sleeve, D = 2d + 13 mm

Length of the muff or sleeve, L = 3.5 d

where d = Diameter of the shaft.

In the clamp or compression coupling, the power is

transmitted from one shaft to the other by means of key and

the friction between the muff and shaft.

Design procedure:

1. Design of muff and key: The muff and key are designed in

the similar way as discussed in muff coupling

2. Design of clamping bolts:

Let T = Torque transmitted by the shaft,

d = Diameter of shaft,

db = Root or effective diameter of bolt,

n = Number of bolts,

σt = Permissible tensile stress for bolt material,

μ = Coefficient of friction between the muff and shaft, and

L = Length of muff.

We know that the force exerted by each bolt

3.Flange Coupling

• A flange coupling usually applies to a coupling

having two separate cast iron flanges. Each flange is

mounted on the shaft end and keyed to it. The faces

are turned up at right angle to the axis of the shaft.

One of the flange has a projected portion and the

other flange has a corresponding recess This helps

to bring the shafts into line and to maintain

alignment. The two flanges are coupled together by

means of bolts and nuts. The flange coupling is

adopted to heavy loads and hence it is used on large

shafting.

The flange couplings are of the following three types :

1. Unprotected type flange coupling.

2. Protected type flange coupling.

3. Marine type flange coupling.(not dealt in this course)

1. Unprotected type flange coupling.

In an unprotected type flange coupling, each shaft is keyed to

the boss of a flange with a counter sunk key and the flanges

are coupled together

by means of bolts. Generally, three, four or six bolts are used.

The keys are staggered at right angle along the circumference

of the shafts in order to divide the weakening effect caused

by keyways. The usual proportions for an unprotected type

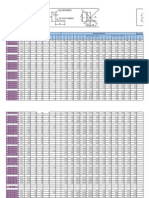

cast iron flange couplings

Unprotected type flange

If d is the diameter of the shaft or inner diameter of the hub,

then Outside diameter of hub, D = 2 d

2. Protected type flange coupling. In a protected type flange

coupling the protruding bolts and nuts are protected by flanges

on the two halves of the coupling, in order to avoid danger to

the workman.

The thickness of the

protective

circumferential flange

(tp) is taken as 0.25d.

The other proportions

of the coupling are

same as for

unprotected type

flange coupling.

Design of Flange Coupling:

Consider a flange couplings as shown in Fig.

Let d = Diameter of shaft or inner diameter of hub,

D = Outer diameter of hub,

d1 = Nominal or outside diameter of bolt,

D1 = Diameter of bolt circle,

n = Number of bolts,

tf = Thickness of flange,

τs, τb and τk = Allowable shear stress for shaft, bolt and key

material respectively

τs = Allowable shear stress for the flange material i.e. cast

iron,

σcb, and σck = Allowable crushing stress for bolt and key

material respectively.

The flange coupling is designed as discussed below :

1. Design for hub:

The hub is designed by considering it as a hollow shaft,

transmitting the same torque (T) as that of a solid shaft.

The outer diameter of hub is usually taken as twice the

diameter of shaft. Therefore from the above relation, the

induced shearing stress in the hub may be checked. The length

of hub (L) is taken as 1.5 d.

2. Design for key:

The key is designed with usual proportions and then checked

for shearing and crushing stresses. The material of key is

usually the same as that of shaft. The length of key is taken

equal to the length of hub.

3. Design for flange:

The flange at the junction of the hub is under shear while

transmitting the torque. Therefore, the torque transmitted,

T = Circumference of hub × Thickness of flange ×

Shear stress of flange × Radius of hub

The thickness of flange is usually taken as half the diameter of

shaft. Therefore from the above relation, the induced shearing

stress in the flange may be checked.

4. Design for bolts:

The bolts are subjected to shear stress due to the torque

transmitted. The number of bolts (n) depends upon the

diameter of shaft and the pitch circle diameter of bolts (D1) is

taken as 3 d.

Vous aimerez peut-être aussi

- Structural Health MonitoringD'EverandStructural Health MonitoringDaniel BalageasPas encore d'évaluation

- CC2 Topic 6 Keys and Couplings - Lecture NoteDocument34 pagesCC2 Topic 6 Keys and Couplings - Lecture NoteChristian Breth BurgosPas encore d'évaluation

- Key& CouplingsDocument7 pagesKey& CouplingsRamanathan DuraiPas encore d'évaluation

- Machine Design PresentaionDocument24 pagesMachine Design PresentaionAwais RaoPas encore d'évaluation

- ABB Drive Selection GuideDocument12 pagesABB Drive Selection Guideprasad_rvsPas encore d'évaluation

- WWW Mechanicalengineeringblog Com 2Document6 pagesWWW Mechanicalengineeringblog Com 2Mashudi FikriPas encore d'évaluation

- Selecting A Belt Slide: Technical InformationDocument3 pagesSelecting A Belt Slide: Technical InformationawemetalPas encore d'évaluation

- Review On Design and Analysis of Jaw Abstract Plate of Jaw-CrusherDocument10 pagesReview On Design and Analysis of Jaw Abstract Plate of Jaw-CrusherCarlos Ediver Arias RestrepoPas encore d'évaluation

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghPas encore d'évaluation

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesPas encore d'évaluation

- Papers - Some Design Aspects For Selection of Heavy Duty Apron FeedersDocument5 pagesPapers - Some Design Aspects For Selection of Heavy Duty Apron FeedersarsaniosePas encore d'évaluation

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsDocument42 pagesDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaPas encore d'évaluation

- Designn of Tranmission SystemDocument4 pagesDesignn of Tranmission Systemsathiskumar411Pas encore d'évaluation

- Belt ConveyorsDocument10 pagesBelt ConveyorsRaja PalasaPas encore d'évaluation

- Spur GearDocument11 pagesSpur GearvenkatkavinPas encore d'évaluation

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDocument22 pagesFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramPas encore d'évaluation

- Apron Feeders: High Return On Investment Low Maintenance Costs Low Production CostsDocument8 pagesApron Feeders: High Return On Investment Low Maintenance Costs Low Production CostsarsaniosePas encore d'évaluation

- Belt Tension TheoryDocument6 pagesBelt Tension TheoryPedro ViegasPas encore d'évaluation

- Machine Design ProjectDocument1 pageMachine Design Projectنور القرأنPas encore d'évaluation

- Understanding T2 Tensioning Requirements and The PhilosophieDocument4 pagesUnderstanding T2 Tensioning Requirements and The PhilosophieWaris La Joi WakatobiPas encore d'évaluation

- Design and Fabrication of Pneumatic Crane StartDocument6 pagesDesign and Fabrication of Pneumatic Crane StartHimani MahetaPas encore d'évaluation

- Application of Chain Drive and Its Selection Method in AutomobileDocument18 pagesApplication of Chain Drive and Its Selection Method in AutomobileSumedh sonawanePas encore d'évaluation

- Internal GearsDocument4 pagesInternal GearsBranislav DjordjevicPas encore d'évaluation

- Roller Chains Design GuidelinesDocument6 pagesRoller Chains Design GuidelinesDrew TwitchPas encore d'évaluation

- Gears: Looking For GATE Preparation Material? Join & Get Here Now!Document8 pagesGears: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniPas encore d'évaluation

- Bearing Fits BrgfitsDocument10 pagesBearing Fits BrgfitsAl7amdlellahPas encore d'évaluation

- Belleville Disk Washer FormulaDocument2 pagesBelleville Disk Washer FormulajarnebergPas encore d'évaluation

- Chain Drive: Guided By:-Prof. P.D. Wadile Presented By: - Hemraj C. Thakare Roll No: - 52Document17 pagesChain Drive: Guided By:-Prof. P.D. Wadile Presented By: - Hemraj C. Thakare Roll No: - 52Hemraj Thakare100% (1)

- The Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxDocument24 pagesThe Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxSURAJ MAHATOPas encore d'évaluation

- Machine Design Project ReportDocument11 pagesMachine Design Project ReportMuhammad Abdullah100% (1)

- Note On Gear BoxDocument32 pagesNote On Gear BoxanupbagPas encore d'évaluation

- BoltDocument30 pagesBoltsumit100% (1)

- PowerPack+brochure+ (V1 0)Document2 pagesPowerPack+brochure+ (V1 0)Khánh VũPas encore d'évaluation

- Jaw and Gyratory CrushersDocument11 pagesJaw and Gyratory CrushersPratik PathakPas encore d'évaluation

- Mechanical Engineeering Machine ElementsDocument25 pagesMechanical Engineeering Machine ElementsHüseyinYılmazPas encore d'évaluation

- Sprocket Guide123456789Document17 pagesSprocket Guide123456789Ramsai ChigurupatiPas encore d'évaluation

- Ypt Paletli Brosur 3 PDFDocument4 pagesYpt Paletli Brosur 3 PDFarsaniosePas encore d'évaluation

- Noncircular GearsDocument6 pagesNoncircular GearsRăzvan NicolaePas encore d'évaluation

- Belt Jointing ProcedureDocument5 pagesBelt Jointing ProcedureproxywarPas encore d'évaluation

- Tech Spec. of EOT CraneDocument7 pagesTech Spec. of EOT CraneSuresh MuttaPas encore d'évaluation

- Design of Machine Members II R5320305 Set 3Document2 pagesDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiPas encore d'évaluation

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Document16 pagesZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamPas encore d'évaluation

- Chapter 2 Lecturer - Belt DriveDocument38 pagesChapter 2 Lecturer - Belt DriveNadz ReenPas encore d'évaluation

- Mechanical MaintenanceDocument12 pagesMechanical MaintenanceJoniPas encore d'évaluation

- Series: The Reliable Brand!Document6 pagesSeries: The Reliable Brand!Cristian J. MejíaPas encore d'évaluation

- Design of ShaftDocument5 pagesDesign of Shaftmanmohansinghlotey100% (1)

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatPas encore d'évaluation

- Cbs CatalogueDocument195 pagesCbs Cataloguemadaboutalfa8168Pas encore d'évaluation

- Conveyor Belt Engineering TablesDocument5 pagesConveyor Belt Engineering Tablestaohung1120Pas encore d'évaluation

- Calculations For Gear Box Selection For 7Document3 pagesCalculations For Gear Box Selection For 7Jiten Kumar BiswalPas encore d'évaluation

- Drive-Non Drive Pulley Shaft Dia Calculation of Belt Feeder - IS 11592Document1 pageDrive-Non Drive Pulley Shaft Dia Calculation of Belt Feeder - IS 11592BISWAJIT DASPas encore d'évaluation

- Md-17 Shaft Design StepsDocument12 pagesMd-17 Shaft Design StepsRamji RaoPas encore d'évaluation

- Belt Conveyor Design DunlopDocument161 pagesBelt Conveyor Design DunlopByron MontejoPas encore d'évaluation

- Force Distributions in Lathe PartsDocument23 pagesForce Distributions in Lathe Partskarthick rajPas encore d'évaluation

- Pin Bush CouplingDocument1 pagePin Bush CouplingVinod Kumar VermaPas encore d'évaluation

- Splice Belt DesignDocument9 pagesSplice Belt DesignriteshsamantrayPas encore d'évaluation

- ChainDocument13 pagesChainarga_diwangPas encore d'évaluation

- Catálogo RULMECADocument308 pagesCatálogo RULMECArdgmaxiPas encore d'évaluation

- Design of Shaft CouplingsDocument30 pagesDesign of Shaft CouplingsKrishna VamsiPas encore d'évaluation

- Shaft Lectures - Class4Document21 pagesShaft Lectures - Class4Atalelew ZeruPas encore d'évaluation

- Certificate of RecognitionDocument1 pageCertificate of Recognitionlikhith saiPas encore d'évaluation

- New Doc 2018-10-29Document19 pagesNew Doc 2018-10-29likhith saiPas encore d'évaluation

- Nodia and Company: Gate Solved Paper Aerospace Engineering 2007Document16 pagesNodia and Company: Gate Solved Paper Aerospace Engineering 2007likhith saiPas encore d'évaluation

- Belt and Drive Analysis of Flour MillDocument16 pagesBelt and Drive Analysis of Flour Milllikhith saiPas encore d'évaluation

- Linear Control TheoryDocument1 pageLinear Control TheorySanjay SinhaPas encore d'évaluation

- RK SAR1613 SteelDocument30 pagesRK SAR1613 Steelsathyabama UniversityPas encore d'évaluation

- 32ls3450 Chassis La25cDocument60 pages32ls3450 Chassis La25cioanamonicapaunPas encore d'évaluation

- UFC+3 520 01+Interior+Electrical+SystemsDocument279 pagesUFC+3 520 01+Interior+Electrical+SystemsingeniouPas encore d'évaluation

- Technical (Supply) Offer-Building 3 (SHED-7&8)Document19 pagesTechnical (Supply) Offer-Building 3 (SHED-7&8)pebindigoPas encore d'évaluation

- History of Stainless SteelDocument24 pagesHistory of Stainless SteelSaravanan KanagavelPas encore d'évaluation

- 123 KV Dry Flexible Termination TFD 123: Cable Accessories and ConnectorsDocument2 pages123 KV Dry Flexible Termination TFD 123: Cable Accessories and ConnectorsnarinderPas encore d'évaluation

- Borobudur: Construction MaterialsDocument10 pagesBorobudur: Construction MaterialsBodhinanda ChandraPas encore d'évaluation

- Steel Table SectionsDocument19 pagesSteel Table SectionsKailash ThapliyalPas encore d'évaluation

- CommandsDocument264 pagesCommandsseventhhemanthPas encore d'évaluation

- DK 83997 Ul PDFDocument2 pagesDK 83997 Ul PDFimsayaaPas encore d'évaluation

- Clevo w24h0 W240humb W240huq W241huq W245huq W249huq - 6-7p-w24h5-002Document98 pagesClevo w24h0 W240humb W240huq W241huq W245huq W249huq - 6-7p-w24h5-002Leonardo Gomes0% (1)

- Cp5092 CCT - Unit1 - Part1Document2 pagesCp5092 CCT - Unit1 - Part1tamil_delhiPas encore d'évaluation

- Reference Card Inverter I500 DINA6 en-GBDocument2 pagesReference Card Inverter I500 DINA6 en-GBAnonymous ZLmk6mPPnPas encore d'évaluation

- GEIT 40008GB Widelatitude Film AGFADocument2 pagesGEIT 40008GB Widelatitude Film AGFARolando Nuñez MonrroyPas encore d'évaluation

- Rubber Insulating Sleeves: Standard Specification ForDocument10 pagesRubber Insulating Sleeves: Standard Specification ForPavan KumarPas encore d'évaluation

- An Con Couplers NZDocument16 pagesAn Con Couplers NZSergio Ito SunleyPas encore d'évaluation

- Astm A944 10Document4 pagesAstm A944 10fahidaslam100% (2)

- Midi Mainten GBDocument47 pagesMidi Mainten GBdan antonPas encore d'évaluation

- 545WKS 2 Building and Construction Provision of Facilities and SafetyDocument68 pages545WKS 2 Building and Construction Provision of Facilities and SafetyAlexPas encore d'évaluation

- Sci NB Mod 2 LSN 3Document4 pagesSci NB Mod 2 LSN 3Ramses octavio Rodriguez ocanasPas encore d'évaluation

- Breaking The Ice: De-Icing Power Transmission Lines With High-Frequency, High-Voltage ExcitationDocument7 pagesBreaking The Ice: De-Icing Power Transmission Lines With High-Frequency, High-Voltage Excitationkunchamspandana_4871Pas encore d'évaluation

- Vibration Analysis Report Of: Ongc Petro Addition LTDDocument6 pagesVibration Analysis Report Of: Ongc Petro Addition LTDVinod RushinathPas encore d'évaluation

- Basic Knowledge of Bolts & NutsDocument15 pagesBasic Knowledge of Bolts & NutsnixneonPas encore d'évaluation

- Bar Grating Anchoring & FastnersDocument2 pagesBar Grating Anchoring & Fastnersseccion3dPas encore d'évaluation

- Walter GropiusDocument23 pagesWalter GropiusKaunda Lembalemba100% (1)

- EQ Cheat Sheet v1Document1 pageEQ Cheat Sheet v1notbuggedPas encore d'évaluation

- 11 TH STD PracticalDocument21 pages11 TH STD PracticalRudra PatelPas encore d'évaluation

- Analysis Done in LPILE Plus v5.0Document9 pagesAnalysis Done in LPILE Plus v5.0Afzal WaseemPas encore d'évaluation

- BEAM1224 Data SheetDocument2 pagesBEAM1224 Data SheetWilliam DiasPas encore d'évaluation