Académique Documents

Professionnel Documents

Culture Documents

Updates Session Welder Phwe Installer

Transféré par

INSTECH ConsultingCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Updates Session Welder Phwe Installer

Transféré par

INSTECH ConsultingDroits d'auteur :

Formats disponibles

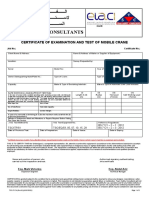

WELDER CERTIFICATION

ISO 9606-1

Qualification Testing of Welders - Fusion Welding

Part 1 : Steels

PROFESSIONAL INDUSTRIAL WELDER CERTIFICATION

ALL RIGHTS RESERVED

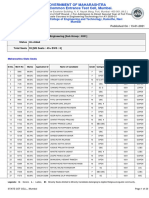

CERTIFICATION vs QUALIFICATION

Description ISO 9606 (Certification) ASME (Qualification)

Certification Body Independent Certification Body Fabricator or Contractor

Testing Body Independent Testing Laboratory

Standard / Code ISO 9606 ASME IX, AWS etc

Accreditation Structured in accordance with ISO -

17024

Written Job Knowledge Recommended but not mandatory Not Mentioned

Examination

Surveillance Every 6 month (Certification Body) Every 6 month (fabricator or

contractor)

Re-Certification 3 Years (Certification Body) When a welder has not welded with a

process during a period of 6 months

or more

Re-Validation for Re- Carry out by Certification Body Under supervision and control of the

Certification Retesting or monitoring qualifying contractor that will extend

qualification another 6 months.

ALL RIGHTS RESERVED

WELDER CERTIFICATION

QUESTION:

What is the main reason for certifying (qualifying) a

welder?

ANSWER:

To show that the welder has the skill to be able to make

production welds that are free from defects

Note: when welding in accordance with a Qualified WPS

ALL RIGHTS RESERVED

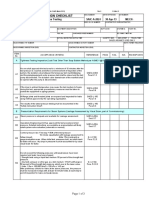

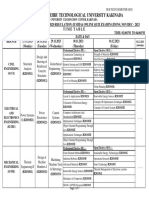

TEST METHODS

NOTE : If the weld is accepted by visual testing, the remaining test(s) according to

Table above shall be carried out

ALL RIGHTS RESERVED

ACCEPTANCE REQUIREMENTS FOR TEST PIECES

Slag and spatters are removed

No grinding on the root and the face side of the weld

Stop and restart in the root run and in the capping run are

identified

Bend-test specimens shall not reveal any discrete discontinuity

≥ 3 mm in any direction.

The sum of the greatest discontinuities exceeding 1 mm but

less than 3 mm in any one bend specimen shall not exceed 10

mm.

If the imperfections in the welder's test piece exceed the

permitted maximum specified, then the welder fails the test.

ALL RIGHTS RESERVED

PRESSURISED HOT WORK ENCLOSURE (PHWE)

INSTALLER CERTIFICATION

Pressurized Hot Work Enclosure (PHWE) offers a practical

engineering solution in managing and controlling the risks

associated for carrying out hot work and use of other sources of

ignition in classified hazardous areas (explosive environment).

ALL RIGHTS RESERVED

PHWE INSTALLER PRE REQUISITES

Installer should have certain level of knowledge in ;

Hazardous Area Ex protection type

OHS requirements in hazardous area,

Ex equipment inspection and handling

PHWE installation and dismantling requirements

ALL RIGHTS RESERVED

Pressurized Hot Work

PHWE INSTALLER Enclosure

ASSESSMENT

KNOWLEDGE ASSESSMENT

Written Examination

PRACTICAL ASSESSMENT

Pre-Assembly

Assembly (Thermography : Heat Leaks)

Dismantling

3 years validity

ALL RIGHTS RESERVED

Vous aimerez peut-être aussi

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1D'EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Évaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Welder Qualification and Certification: What Is Certification? "Certification"Document22 pagesWelder Qualification and Certification: What Is Certification? "Certification"Pawan PatilPas encore d'évaluation

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&AD'EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&APas encore d'évaluation

- Welding Procedure: Job KnowledgeDocument4 pagesWelding Procedure: Job KnowledgeMuhammed SulfeekPas encore d'évaluation

- Routes To Welding Procedure ApprovalDocument6 pagesRoutes To Welding Procedure ApprovalJose Marie Rmgrocks BatoPas encore d'évaluation

- Welders QualificationDocument22 pagesWelders QualificationSreedhar Patnaik.M100% (2)

- Welder Qualification and CertificationDocument5 pagesWelder Qualification and CertificationMohamed Ibrahim100% (2)

- Welding Procedure: Job Knowledge 39Document6 pagesWelding Procedure: Job Knowledge 39manimaranPas encore d'évaluation

- TWI - Welding Procedure - Job Knowledge 39Document9 pagesTWI - Welding Procedure - Job Knowledge 39tuanPas encore d'évaluation

- 1.1 Welding Procedure Specification (WPS)Document35 pages1.1 Welding Procedure Specification (WPS)Mohamed WahidPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saep 322Document18 pagesSaep 322brecht1980100% (1)

- Inspection and Test Plan (Itp) For Control ValvesDocument15 pagesInspection and Test Plan (Itp) For Control ValveszakariaPas encore d'évaluation

- Introduction Wps and PQRDocument4 pagesIntroduction Wps and PQRdhasdj100% (1)

- What Is InspectionDocument6 pagesWhat Is InspectionRathnakrajaPas encore d'évaluation

- WPS, PQR, WPQR PDFDocument4 pagesWPS, PQR, WPQR PDFYousef Adel HassanenPas encore d'évaluation

- Itp HeDocument15 pagesItp HeAldeline SungahidPas encore d'évaluation

- 5.AIA PresentationDocument22 pages5.AIA PresentationudomPas encore d'évaluation

- Wps PQR GuideDocument40 pagesWps PQR GuideBalakumar100% (10)

- Yasar Arafath Habibullah: Personal ProfileDocument7 pagesYasar Arafath Habibullah: Personal ProfileMohamed AdelPas encore d'évaluation

- Part A - CWI - Fundamental Orignal 2017Document588 pagesPart A - CWI - Fundamental Orignal 2017Husseinallawi banderPas encore d'évaluation

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiPas encore d'évaluation

- Inspection and Test Plan For Pressure Reliving Devices 1707841397Document16 pagesInspection and Test Plan For Pressure Reliving Devices 1707841397BernathTurnipPas encore d'évaluation

- Approval Standard For Explosionproof Electrical Equipment General RequirementsDocument33 pagesApproval Standard For Explosionproof Electrical Equipment General RequirementsEduardo_77Pas encore d'évaluation

- 000-API 510 Pressure Vessel Iinspector Preparation Course BROCHUREDocument9 pages000-API 510 Pressure Vessel Iinspector Preparation Course BROCHUREInstech Premier Sdn BhdPas encore d'évaluation

- 11kv 3 Unit 350MVA Kiosk With 2700kVA TransformerDocument35 pages11kv 3 Unit 350MVA Kiosk With 2700kVA Transformer10derPas encore d'évaluation

- Job Description Shutdown Oil&gasDocument2 pagesJob Description Shutdown Oil&gasAbdul QuddoosPas encore d'évaluation

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Sudhakar KarnanPas encore d'évaluation

- 1 Typical Duties of Welding InspectorsDocument7 pages1 Typical Duties of Welding InspectorspandimrPas encore d'évaluation

- Section 1 Typical Duties of Welding InspectorsDocument13 pagesSection 1 Typical Duties of Welding InspectorsMohd Farid OsmanPas encore d'évaluation

- Saic A 2004Document8 pagesSaic A 2004karthi51289Pas encore d'évaluation

- CSWIP-WI-6-92 14th Edition April 2017Document17 pagesCSWIP-WI-6-92 14th Edition April 2017mullanjiPas encore d'évaluation

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishPas encore d'évaluation

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsPas encore d'évaluation

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- The Certification Scheme of Persons (Welders) : Form AK VO-7-0Document4 pagesThe Certification Scheme of Persons (Welders) : Form AK VO-7-0imupathanPas encore d'évaluation

- En Scheme of Welder Certification ENGDocument4 pagesEn Scheme of Welder Certification ENGHoque Anamul100% (1)

- Tuv Rheinland Iso 3834 Certification enDocument2 pagesTuv Rheinland Iso 3834 Certification enAdrewhassTechnicaPas encore d'évaluation

- 1 Typical Duties of Welding InspectorsDocument7 pages1 Typical Duties of Welding InspectorsSamerPas encore d'évaluation

- 1a. Crawler CraneDocument2 pages1a. Crawler CraneSHARAFUDHEEN TKPas encore d'évaluation

- Saep 324Document8 pagesSaep 324brecht1980100% (3)

- Aws D1.1 D1.1M-2010 VTDocument7 pagesAws D1.1 D1.1M-2010 VTCristian Alejandro Huerta HernandezPas encore d'évaluation

- SAIC-A-2024 Rev 6 Leakness Tightness TestDocument3 pagesSAIC-A-2024 Rev 6 Leakness Tightness Testpookkoya thangalPas encore d'évaluation

- R S Radhakrishnan: Address: No.1/35 KumilangulamDocument3 pagesR S Radhakrishnan: Address: No.1/35 KumilangulamUdayan JadavPas encore d'évaluation

- ASME Conformity AssessmentDocument31 pagesASME Conformity AssessmentGTpianomanPas encore d'évaluation

- Att. 6.1 General Inspection and TestingDocument15 pagesAtt. 6.1 General Inspection and TestingbayuPas encore d'évaluation

- Inspection Test Procedure ModelDocument8 pagesInspection Test Procedure ModelMahesh SuthaPas encore d'évaluation

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroPas encore d'évaluation

- 510 DuitiesDocument2 pages510 DuitiesMohammad Aamir PerwaizPas encore d'évaluation

- Saif Ullah Updated AramcoDocument4 pagesSaif Ullah Updated AramcoHaleem Ur Rashid BangashPas encore d'évaluation

- Saep 323Document8 pagesSaep 323brecht1980100% (1)

- Shortcut To A WPSDocument18 pagesShortcut To A WPSCepi Sindang Kamulan100% (1)

- Cherry Picker MTCDocument2 pagesCherry Picker MTCeldhoPas encore d'évaluation

- Uic-qp-Ins-011 PSV Rev11Document12 pagesUic-qp-Ins-011 PSV Rev11Iksan Adityo MulyoPas encore d'évaluation

- Pile Welding Quality Control Plan: SpecificationsDocument8 pagesPile Welding Quality Control Plan: Specificationsvelmurug_balaPas encore d'évaluation

- Pneumatic Test ProcedureDocument5 pagesPneumatic Test ProcedureBharat BhoirPas encore d'évaluation

- 5welding BasicsDocument70 pages5welding BasicssreePas encore d'évaluation

- Welding Procedure Qualificartion SpetsDocument25 pagesWelding Procedure Qualificartion SpetstonytrujilloPas encore d'évaluation

- Mobile CraneDocument2 pagesMobile CraneSHARAFUDHEEN TKPas encore d'évaluation

- Seminar Pemerkasaan Perundangan, Pelesenan Dan Keselamatan Gas 26 Sept 2018Document54 pagesSeminar Pemerkasaan Perundangan, Pelesenan Dan Keselamatan Gas 26 Sept 2018INSTECH Consulting100% (1)

- ZanussiDocument2 pagesZanussiINSTECH ConsultingPas encore d'évaluation

- ASME GDTP Pricing Structure FY18Document1 pageASME GDTP Pricing Structure FY18Ravi Kiran MeesalaPas encore d'évaluation

- Guide On Piped Gas Safety Management Plan and Programmed1 PDFDocument24 pagesGuide On Piped Gas Safety Management Plan and Programmed1 PDFINSTECH ConsultingPas encore d'évaluation

- 05 Amir Luqman February 2018 Confirmation Iso 17020 Instech PremierDocument1 page05 Amir Luqman February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- 01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierDocument1 page01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- Offshore Containers PosterDocument1 pageOffshore Containers PosterINSTECH ConsultingPas encore d'évaluation

- 01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierDocument1 page01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- 2018 2019 Schedule API 510 Full Course Flyers Instech Consulting NewDocument1 page2018 2019 Schedule API 510 Full Course Flyers Instech Consulting NewINSTECH ConsultingPas encore d'évaluation

- 01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierDocument1 page01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- 05 Amir Luqman February 2018 Confirmation Iso 17020 Instech PremierDocument1 page05 Amir Luqman February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- 05 Amir Luqman February 2018 Confirmation Iso 17020 Instech PremierDocument1 page05 Amir Luqman February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- 01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierDocument1 page01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- 01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierDocument1 page01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- 04 Ahmad Izzuddin February 2018 Confirmation Iso 17020 Instech PremierDocument1 page04 Ahmad Izzuddin February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- New Portrait-Iso 17020 Flyers-Interactive Workshop-Instech ConsultingDocument1 pageNew Portrait-Iso 17020 Flyers-Interactive Workshop-Instech ConsultingINSTECH ConsultingPas encore d'évaluation

- 01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierDocument1 page01 Nurul Aiza February 2018 Confirmation Iso 17020 Instech PremierINSTECH ConsultingPas encore d'évaluation

- Train The TrainerDocument1 pageTrain The TrainerINSTECH ConsultingPas encore d'évaluation

- Flyer 3.0Document2 pagesFlyer 3.0INSTECH ConsultingPas encore d'évaluation

- NEW PORTRAIT-API 570 Flyers-APRIL 2019-FULL COURSE-INSTECH CONSULTINGDocument1 pageNEW PORTRAIT-API 570 Flyers-APRIL 2019-FULL COURSE-INSTECH CONSULTINGINSTECH ConsultingPas encore d'évaluation

- 2018 2019 Schedule API 510 Full Course Flyers Instech Consulting NewDocument2 pages2018 2019 Schedule API 510 Full Course Flyers Instech Consulting NewINSTECH ConsultingPas encore d'évaluation

- Hazloc Ex000 April 2019Document1 pageHazloc Ex000 April 2019INSTECH ConsultingPas encore d'évaluation

- Api 570-Topics-Modules-Covered PDFDocument1 pageApi 570-Topics-Modules-Covered PDFINSTECH ConsultingPas encore d'évaluation

- API 650 Tank Shell Evaluation Rev 3Document31 pagesAPI 650 Tank Shell Evaluation Rev 3alokbdasPas encore d'évaluation

- .. Iquas Gpgs Painting PCommondefects PDFDocument9 pages.. Iquas Gpgs Painting PCommondefects PDFrohalestatPas encore d'évaluation

- 2019 Api Icp Exam SchedulesDocument1 page2019 Api Icp Exam SchedulesINSTECH ConsultingPas encore d'évaluation

- 2019 API Icp Exam SchedulesDocument1 page2019 API Icp Exam SchedulesINSTECH ConsultingPas encore d'évaluation

- Laws of Malaysia: Technologists and TechniciansDocument34 pagesLaws of Malaysia: Technologists and TechniciansAnonymous 0FIwxrWLaKPas encore d'évaluation

- Laws of Malaysia: Technologists and TechniciansDocument34 pagesLaws of Malaysia: Technologists and TechniciansAnonymous 0FIwxrWLaKPas encore d'évaluation

- ExMC 1321A Inf General Inf IECEx Ops Meetings de 2018Document5 pagesExMC 1321A Inf General Inf IECEx Ops Meetings de 2018INSTECH ConsultingPas encore d'évaluation

- Question Bank: Prist UniversityDocument5 pagesQuestion Bank: Prist Universitykarthik_1977Pas encore d'évaluation

- A Study of Combined Bending and Axial Load in Reinforced Concrete MembersDocument2 pagesA Study of Combined Bending and Axial Load in Reinforced Concrete MembersMbayo David GodfreyPas encore d'évaluation

- Final Atm Abstract 11Document7 pagesFinal Atm Abstract 11yuvaraaj aleti100% (1)

- Jones - Larry.sheet PileDocument19 pagesJones - Larry.sheet PileJessie Radaza Tutor100% (1)

- BS EN 1997 - Geotechnical Design Examples PDFDocument14 pagesBS EN 1997 - Geotechnical Design Examples PDFBolanle OlaawoPas encore d'évaluation

- Experiments On Partial Replacement of Coconut Shell As Coarse Aggregate in ConcreteDocument10 pagesExperiments On Partial Replacement of Coconut Shell As Coarse Aggregate in ConcreteIJIRSTPas encore d'évaluation

- SMAW 10 - Q1 - W2 - Mod2Document16 pagesSMAW 10 - Q1 - W2 - Mod2Romeo Dela RosaPas encore d'évaluation

- AC800M Manual, ABBDocument230 pagesAC800M Manual, ABBCristian Tilinschi100% (2)

- DownloadDocument68 pagesDownloadMuhammed A. Mahdi0% (1)

- CSC 437 Course Section AbcdDocument14 pagesCSC 437 Course Section AbcdPost Your FeedbackPas encore d'évaluation

- Resume of Lutfur R. KhandakerDocument2 pagesResume of Lutfur R. KhandakerprobangalPas encore d'évaluation

- 31 R20 IIMid Nov-December 2023Document7 pages31 R20 IIMid Nov-December 2023palivelasrinu12Pas encore d'évaluation

- AaaaDocument1 pageAaaaAkshay MehtaPas encore d'évaluation

- EvacoDocument4 pagesEvacoKem RaiPas encore d'évaluation

- Chapter One - Fundamental of Transport and Highway EngineeringDocument30 pagesChapter One - Fundamental of Transport and Highway Engineeringmollalignm100% (1)

- CE 632 Design of Prestressed ConcreteDocument1 pageCE 632 Design of Prestressed ConcretemuhammadPas encore d'évaluation

- Chapter 6 ControlDocument148 pagesChapter 6 Control.ılı.Govíиð ЯäJ.ılı.Pas encore d'évaluation

- CourseOutline VLSI - 2Document2 pagesCourseOutline VLSI - 2FaHeem KhanPas encore d'évaluation

- How Do You Define Success and How Do You Measure Up To Your Own Definition - HR Interview Questions and AnswersDocument9 pagesHow Do You Define Success and How Do You Measure Up To Your Own Definition - HR Interview Questions and AnswersMohammad AsifPas encore d'évaluation

- Ge6075 - Professional Ethics in Engineering: 2 Marks Questions and AnswersDocument16 pagesGe6075 - Professional Ethics in Engineering: 2 Marks Questions and Answerseee2014.rvsPas encore d'évaluation

- Ecoloair System: Application Features & Benefi TsDocument4 pagesEcoloair System: Application Features & Benefi TsArun Jacob CherianPas encore d'évaluation

- Girder 3 MKD' NO. 1613503-2027: Riyadh Metro Project Package 2 Line 3Document1 pageGirder 3 MKD' NO. 1613503-2027: Riyadh Metro Project Package 2 Line 3GHULAM NABIPas encore d'évaluation

- Faculty of Civil Engineering Technology Universiti Malaysia PerlisDocument11 pagesFaculty of Civil Engineering Technology Universiti Malaysia Perlisadeliene 25Pas encore d'évaluation

- 3175 - M.G.M.'s College of Engineering and Technology, Kamothe, Navi MumbaiDocument20 pages3175 - M.G.M.'s College of Engineering and Technology, Kamothe, Navi MumbaiPrashant ChougulePas encore d'évaluation

- .Power Quality Improvement in Power Distribution System Using D-STATCOMDocument5 pages.Power Quality Improvement in Power Distribution System Using D-STATCOMMuhammad AzisPas encore d'évaluation

- Readme 14 PDFDocument25 pagesReadme 14 PDFVenomKarmaPas encore d'évaluation

- ML-P1-6009-CO-1-060-T-CAL-00006 - Big Arch - Rev01 Span 60mDocument115 pagesML-P1-6009-CO-1-060-T-CAL-00006 - Big Arch - Rev01 Span 60mRavi Teja PolisettiPas encore d'évaluation

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBavikbhaiPas encore d'évaluation

- 3-2 MeDocument28 pages3-2 Mesuvarnalatha devarakondaPas encore d'évaluation

- Tubes and PipesDocument40 pagesTubes and PipesRamazan Erdinç100% (1)