Académique Documents

Professionnel Documents

Culture Documents

Flow Calibration

Transféré par

Abilash100%(1)100% ont trouvé ce document utile (1 vote)

121 vues26 pagesCalibration of flow

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentCalibration of flow

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

121 vues26 pagesFlow Calibration

Transféré par

AbilashCalibration of flow

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 26

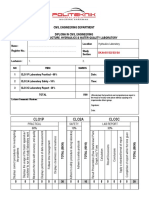

FLOW CALIBRATION

Calibration and Standards

Flow rate calibration depends on standards of volume(length) and

time or mass and time.

Classified into two: (a) Primary calibration & (b) Secondary calibration

Primary calibration based on the establishment of steady flow

through the flowmeter to be calibrated and subsequently

measurement of volume or mass of flowing fluid that passes through

in a accurately timed interval.

Any stable and precise flow meter calibrated by such primary

methods becomes a secondary flow rate standard against which less

accurate flow meters may be calibrated conveniently.

Calibration and Standards Continued…

Significant deviations of the conditions of use from those at

calibration will invalidate the calibration

Possible sources of error in flow meters include variation in

(a) fluid properties - density, viscocity and temperature

(b) orientation of meter

(c) pressure level

(d)flow disturbances-elbows,tees,valves etc,upstream and to a lesser

extend down stream etc

Calibration of Flow meters

Flow meters are classified into gas flow meters , liquid flow meters

and solid flow meters

Avoided the solid flow meter calibration in this presentation

Focusing on gas flow meter and liquid flow meter

Both gas flow meter and liquid flow meter can either be

volumetric(volumetric flow) or gravimetric (mass flow)

Calibration of Flow meters Contd...

Difference between liquid and gas is that liquid can be collected and

measured easily.

For eg. A bucket can be used to collect the water and weigh it before

and after collecting the certain volume of water which has flown

through the system.

By collecting and measuring the volume or mass of the liquid which

has flown through the flow meter for a certain period of time, we can

find volumetric rate or mass flow rate

Gas Flow Calibration Contd

We have a meter on test eg. Rotameter and have gas supply which

flows through a vertical burette as shown in the figure.

At some particular time, allow a soap film/soap bubble to enter the

burette.

Gas flow is going to carry film across the burette.

Using the photocell along with timing device we can find out the

amount of time taken in sweeping a certain volume of burette.

By dividing volume sweeped by period of time ,actual volume flow

rate can be obtained.

By comparing the measured and actual value, we can calibrate the

flow meter.

Liquid Flow Meter Calibration Contd

Using pump the liquid is circulated across testmeter and either to

sump or weighing tank(as per diverter/control valve action)

We start measuring process by allowing it to come to weighing tank

and after a certain length of time, divert it to sump.

Either weigh or measure volume of liquid which is collected.

Volume or mass divided by time will give actual volume rate or mass

rate.

Using the actual value and measured value from meter, we can plot

calibration curve.

Flow Calibration(Calibration Curve) contd.

Flow Calibration(Calibration Curve) contd.

From Calibration curve we can see the variation between actual value

and measured value.

We can use the variations as calibration information and can apply

correction factor.

Examples of Commercial Flow rate

Calibrators

Calibrators using dynamic weighing scheme(using liquid)

Ballistic flow prover(using liquid)

Gas flow calibrator(piston driven by motor)

Liquid Flow rate Calibration using dynamic

weighing scheme

Liquid Flow rate Calibration using dynamic

weighing scheme Contd…

Available in models to cover the range 0.5 to 150,000 lbm/h and have

overall accuracy of +/-0.1 %

Procedure for carrying out dynamic weighing test are:

a) Running operation before test-

• Fluid contained in the reservoir is pumped through a closed hydraulic

circuit

• First, it enters the filter and heat exchange equipment,which controls

temperature within +/- 1Degree Fahrenheit.

• It then passes through control valves, meter undertest,backpressure

valves, weigh tank,then back into reservoir

Liquid Flow rate Calibration using dynamic

weighing scheme Contd…

b)Start of preliminary fill (Tare Time)

• When control valves have been adjusted for desired flow,a tare weight

is placed on the weigh pan.

• Then the cycle start button is pushed, resetting the timer, closing the

dumb valve which starts the filling of the weigh tank.

c)End of prefill,start of weighing cycle

• As the weigh tank fills, the weigh pan rises, tripping the timer actuator,

and the electronic timer begins counting in millisecond, starting the

actual weighing cycle

Liquid Flow rate Calibration using dynamic

weighing scheme Contd…

• The preliminary fill, balanced out by the tare weight before actual weighing

begins, permits a net measurement of the new fluid added after

preliminary fill.

• The preliminary fill method permits measurement of only a portion of the

cycle,eliminating the mechanical errors in the start and stop portions and

allowing dynamic errors to be cancelling.

d)Weighing cycle in operation

• The weighing cycle is continued as the precision weight is placed on the

weigh pan,again deflecting the beam

• The cone shape deflector at the inlet of weigh tank permits the even

distribution of the metered fluid

Liquid Flow rate Calibration using dynamic

weighing scheme Contd…

e)End of weighing cycle

• As the tank fills, the weigh pan rises, until it again trips the timer actuator,

stopping the timer and indicating the time within a thousandth of a

second.

• By combining the precision test weight with the timed interval, the actual

flow rate in pounds/hour is easily accurately determined.From these basic

mass units, other flow units can be accurately calculated.

f) Emptying for recycling

• After the beam movement trips the timer, weigh tank automatically

empties in less than 25 seconds,even at maximum flow.

• The calibrator is now ready for next flow setting.This cuts total calibrating

time as much as 50%.

Ballistic flow prover calibator

• Useful for fast-response, high resolution flowmeters such as turbine,

positive displacement,vortex shedding etc, types, where steady state

can be achieved quickly and the integration of the flow rate to get

total flow is accomplished accurately by accumulating the meter

pulse rate output in a counter.

• The Integration gives accurate total flow even if the flow rate is not

perfectly steady.

• One such calibrator uses Teflon sealed air driven free piston travelling

down a precision honed tube to dispense a precise volume of

calibration fluid through the attached flowmeter to be calibrated.

Ballistic flow prover calibrator Contd…

• Precise time and displacement measurements on moving piston are

utilised in a microprocessor data reduction system to achieve a

claimed flow rate accuracy of +/- 0.02%

• The small flow volume(above 5 gal for a 700 gal/min full scale unit)

involved in checking a single flow rate allows rapid calibration, 20

repeats of a single point typically being achieved in 8 minutes for a

300 gal/min flow rate.

• Units are available with maximum flow rates of 100 to 6000 gal/min.

• A similar type of gas flow calibrator is shown in next slide (except that

the piston is driven by electric motor is available for gas flow)

Gas flow Calibrator

(piston driven by electric motor)

Important Points

• The calibration of flow meters to be used with gases often can be

carried out with liquids as long as the pertinent similarity

relations(Reynold no.) are maintained and theoretical density and

expansion corrections are applied.

• If this procedure is felt to be insufficient accuracy, a direct calibration

with actual gas to be employed can be carried out by means of the

gasometer system as shown in next slide.

• Here the gas flowing through the flowmeter during a time interval is

trapped in the gasometer bell and its volume is measured.

Gas-flow Calibration

Important Points Contd..

• Temperature and pressure measurements allow calculation of mass

and conversion of volume to any desired standard condition.

• By filling the bell with gas, raising it to the top and adding appropriate

weights, such a system may be used as a gas supply to drive gas

through a flow meter as the bell gradually drops at a measured rate.

• By using a precision analytical balance to measure the mass

accumulated in a storage essel overtime, accuracies of 0.02% were

obtained for flow rates up to 9 Kg /s (20 lbm/s)

• The size of the equipment makes it more economical for flow rate;

however accuracy is less(+/- 0.08%)

Important Points Contd..

• When the above primary methods cannot be justified,comparison

with secondary standard flowmeter connected in series with the

meter to be calibrated may be sufficiently accurate.

• Turbine flowmeters and their associated digital counting equipment

have been found particularly suitable for such secondary standards.

• With attention to details of such standards can closely approach the

accuracy of primary standards.

THANK YOU

Vous aimerez peut-être aussi

- Flow Meter CalibrationDocument2 pagesFlow Meter CalibrationavandetqPas encore d'évaluation

- Gas Meter CalibrationDocument13 pagesGas Meter CalibrationMimi Hashim100% (1)

- DKD R 6 2 t5 e PDFDocument9 pagesDKD R 6 2 t5 e PDFDragan IlicPas encore d'évaluation

- How To Calibrate An IR Thermometer - Frank Liebmann 2017-06-21Document35 pagesHow To Calibrate An IR Thermometer - Frank Liebmann 2017-06-21CALIBRATION TRACKING100% (1)

- 11 Loadcell Accuracy PDFDocument8 pages11 Loadcell Accuracy PDFCecep AtmegaPas encore d'évaluation

- Theoretical Uncertainty of Orifice Flow Measurement 172KBDocument7 pagesTheoretical Uncertainty of Orifice Flow Measurement 172KBSatya Sai Babu YeletiPas encore d'évaluation

- Verification Coriolis Flow Meter Calibration 2015 0164Document12 pagesVerification Coriolis Flow Meter Calibration 2015 0164tetioPas encore d'évaluation

- Calibration of AnemometerDocument4 pagesCalibration of AnemometerAhmet ŞenPas encore d'évaluation

- Accreditation No: LAB 131Document9 pagesAccreditation No: LAB 131Doulat RamPas encore d'évaluation

- Gas Meter CalibrationDocument5 pagesGas Meter CalibrationDanial AzimPas encore d'évaluation

- Chris Mills 2020Document17 pagesChris Mills 2020AminPas encore d'évaluation

- Tank+Calibration OP 0113 WebsiteDocument2 pagesTank+Calibration OP 0113 WebsiteMohamed FouadPas encore d'évaluation

- Flow Calibration Procedure PDFDocument32 pagesFlow Calibration Procedure PDFkfathi55100% (1)

- Homework 1 ME 531 2018 WebDocument4 pagesHomework 1 ME 531 2018 WebEhab WilsonPas encore d'évaluation

- EURAMET Cg-19 V 2.0 Guidelines in Uncertainty Volume 01Document20 pagesEURAMET Cg-19 V 2.0 Guidelines in Uncertainty Volume 01fabfalcioniPas encore d'évaluation

- As 3778.6.3-1992 Measurement of Water Flow in Open Channels Measuring Devices Instruments and Equipment - CalDocument7 pagesAs 3778.6.3-1992 Measurement of Water Flow in Open Channels Measuring Devices Instruments and Equipment - CalSAI Global - APACPas encore d'évaluation

- Astm E145 1994 OVENDocument4 pagesAstm E145 1994 OVENNinit MiyuPas encore d'évaluation

- SOP-Procedure Calibration of Metal TapesDocument12 pagesSOP-Procedure Calibration of Metal Tapeshaharamesh100% (1)

- PC-EI-MS-05 Instrument Calibration PDFDocument11 pagesPC-EI-MS-05 Instrument Calibration PDFahmed011Pas encore d'évaluation

- EGP Measurement ManualDocument57 pagesEGP Measurement ManualMohd HassanudinPas encore d'évaluation

- CP No.601-Hydraulic Type (Pressure) - RevDocument18 pagesCP No.601-Hydraulic Type (Pressure) - Revamelchan_tiquePas encore d'évaluation

- Measurement Uncertainty and Analytical Decision in AASDocument33 pagesMeasurement Uncertainty and Analytical Decision in AASmilossmilePas encore d'évaluation

- DKD R 6 2 t1 E.pdf VacuometrosDocument6 pagesDKD R 6 2 t1 E.pdf VacuometrosAldrin HernandezPas encore d'évaluation

- Method Statement For Conductivity MeterDocument2 pagesMethod Statement For Conductivity MeterMuhamed RasheedPas encore d'évaluation

- Calibration Procedure KrissDocument12 pagesCalibration Procedure KrissALP69Pas encore d'évaluation

- T16 Liquid Density PDFDocument26 pagesT16 Liquid Density PDFVictor Enrique Rosales ParadaPas encore d'évaluation

- EA 10 17 Manometer CalibrationDocument35 pagesEA 10 17 Manometer CalibrationMohammed S.GoudaPas encore d'évaluation

- EMM Unit I - 1.7.19Document91 pagesEMM Unit I - 1.7.19Udhaya KumarPas encore d'évaluation

- Verifying Flowmeter AccuracyDocument8 pagesVerifying Flowmeter AccuracynokarajuPas encore d'évaluation

- MeterRunDesign BestPracticesDocument8 pagesMeterRunDesign BestPracticesjohnzrwPas encore d'évaluation

- Mep365 Deadweight Tester Exp04Document4 pagesMep365 Deadweight Tester Exp04rituneshmPas encore d'évaluation

- Thermometer CalibrationDocument8 pagesThermometer CalibrationGeroldo 'Rollie' L. Querijero100% (1)

- Flow Measurement Uncertainty and Data Reconciliation-EssenceDocument29 pagesFlow Measurement Uncertainty and Data Reconciliation-EssenceWen Wu100% (1)

- Mitutoyo Bore Gauge PDFDocument12 pagesMitutoyo Bore Gauge PDFAnonymous 8rb48tZSPas encore d'évaluation

- Calibration and Measurement Capability of Gas AnalysisDocument15 pagesCalibration and Measurement Capability of Gas AnalysisTrịnh Đức HạnhPas encore d'évaluation

- Euramet PDFDocument23 pagesEuramet PDFIgor GrujićPas encore d'évaluation

- Manual TP Prover Vessel PDFDocument7 pagesManual TP Prover Vessel PDFWilfredo MolinaPas encore d'évaluation

- THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFDocument7 pagesTHERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFGustavo SánchezPas encore d'évaluation

- The Calibration of Flow Meters PDFDocument35 pagesThe Calibration of Flow Meters PDFRené Mora-CasalPas encore d'évaluation

- Calibration 161217162207Document36 pagesCalibration 161217162207Oula HatahetPas encore d'évaluation

- EURAMET-cg-08 V 2.1 ChangesDocument18 pagesEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoPas encore d'évaluation

- Gas Measurement Fundamentals & EFMDocument4 pagesGas Measurement Fundamentals & EFMAtiqah OmarPas encore d'évaluation

- EG 15-14-1.2 Instrument Calibration: ScopeDocument21 pagesEG 15-14-1.2 Instrument Calibration: ScopeaminPas encore d'évaluation

- MMM Lab ManualDocument13 pagesMMM Lab ManualSangam PatilPas encore d'évaluation

- 01 Pressure Gauge CalibrationDocument3 pages01 Pressure Gauge CalibrationSantosh Odiyar0% (1)

- DP Transmitter CalibrationDocument2 pagesDP Transmitter CalibrationsupercontrollerPas encore d'évaluation

- How To Calibrate A Flow MeterDocument4 pagesHow To Calibrate A Flow Meterابوالحروف العربي ابوالحروفPas encore d'évaluation

- Lab3 Temperature and Calibration - FINALrrDocument6 pagesLab3 Temperature and Calibration - FINALrrDerrick SheePas encore d'évaluation

- Insulation Tester 1 CI 02 I2Document13 pagesInsulation Tester 1 CI 02 I2ebbasinghPas encore d'évaluation

- Dead Weight CalibratorDocument7 pagesDead Weight CalibratorNatashah AshrafPas encore d'évaluation

- T205 - Uncertainty Analysis For Hydrometer Calibration at NMISADocument22 pagesT205 - Uncertainty Analysis For Hydrometer Calibration at NMISApanjang snsuPas encore d'évaluation

- SOP For Calibration of Temperature GaugesDocument3 pagesSOP For Calibration of Temperature Gaugesget_engineer0550% (2)

- "Prover-By-Prover" CALIBRATION OF PROVERS USING COMPACT PROVER AS MASTER METERDocument8 pages"Prover-By-Prover" CALIBRATION OF PROVERS USING COMPACT PROVER AS MASTER METERابوالحروف العربي ابوالحروفPas encore d'évaluation

- Method Statement For PH MeterDocument2 pagesMethod Statement For PH MeterMuhamed RasheedPas encore d'évaluation

- U 5753 Centrifuge 17300Document1 pageU 5753 Centrifuge 17300NENO BHUBANESWAR100% (1)

- Weights and Measures BSTI RulesDocument8 pagesWeights and Measures BSTI RuleskafilussPas encore d'évaluation

- Flow - and - Pressure Measurement by ManometerDocument23 pagesFlow - and - Pressure Measurement by ManometerDhanraj Patil100% (1)

- Microsoft WordghfghDocument67 pagesMicrosoft WordghfghMilosPas encore d'évaluation

- CalibrationDocument7 pagesCalibrationstolen mechieducPas encore d'évaluation

- Calibration and Standards in Flow MeasurementDocument5 pagesCalibration and Standards in Flow MeasurementEvelina DonisanPas encore d'évaluation

- 06-Water Hammer ProtectionDocument9 pages06-Water Hammer Protectionjdsa123Pas encore d'évaluation

- LAB MANUAL. EXPERIMENT 1. Viscosity of Fluids (Ball Drop Method)Document6 pagesLAB MANUAL. EXPERIMENT 1. Viscosity of Fluids (Ball Drop Method)james Principe0% (2)

- Ervice AND Arts AnualDocument76 pagesErvice AND Arts AnualMelanie Gerdes100% (1)

- CH7 1Document25 pagesCH7 1Nikola TrnavacPas encore d'évaluation

- Behavior of A Pneumatic Pressure Regulator Valve Under Leakage CircumstancesDocument7 pagesBehavior of A Pneumatic Pressure Regulator Valve Under Leakage CircumstancesbadaboyPas encore d'évaluation

- Lab Sheet 2 Bernoulli's EquationDocument5 pagesLab Sheet 2 Bernoulli's EquationEmmanuel EasterPas encore d'évaluation

- 20C1001 Pick ListDocument15 pages20C1001 Pick ListLeavithPas encore d'évaluation

- Flow and Pressure Control ValvesDocument9 pagesFlow and Pressure Control ValvesMaryland SalcedoPas encore d'évaluation

- AE 301 - Aerodynamics I - Spring 2015 Problem Set 2: Assigned: Friday, January 23, 2015 Due: Friday, January 30, 2015Document2 pagesAE 301 - Aerodynamics I - Spring 2015 Problem Set 2: Assigned: Friday, January 23, 2015 Due: Friday, January 30, 2015TheTannedFishPas encore d'évaluation

- How To Troubleshoot A FCS300-ES Atomized Spray PatternDocument5 pagesHow To Troubleshoot A FCS300-ES Atomized Spray PatternPatel TejasPas encore d'évaluation

- 2.venturimeter Theory PDFDocument9 pages2.venturimeter Theory PDFSWETHAPas encore d'évaluation

- Chapter 21. Hydraulics: by Brian BomanDocument10 pagesChapter 21. Hydraulics: by Brian BomanLao ZhuPas encore d'évaluation

- Pumping For WaterDocument17 pagesPumping For WaterJeffrey CaparasPas encore d'évaluation

- Chapter 5: Incompressible Flow Over Finite WingsDocument54 pagesChapter 5: Incompressible Flow Over Finite WingsveeraraghavanPas encore d'évaluation

- Pressure Drop CalculationDocument1 pagePressure Drop CalculationCak NhassPas encore d'évaluation

- Control ValveDocument24 pagesControl ValveTarit Mahata100% (2)

- Hydraulic System of DozerDocument5 pagesHydraulic System of DozerYe' Naing0% (1)

- Daily Welding Record LPDocument27 pagesDaily Welding Record LProbby monePas encore d'évaluation

- SEVO 1230 CylindersDocument2 pagesSEVO 1230 Cylindersjohnattan SaldañaPas encore d'évaluation

- Hyd Schematic 2658487205 - 005Document3 pagesHyd Schematic 2658487205 - 005Angelo Solorzano100% (2)

- DPAR AgitationDocument41 pagesDPAR AgitationFritz FestejoPas encore d'évaluation

- THE OF: Hydraulics Stepped Chutes and Spill W A YsDocument3 pagesTHE OF: Hydraulics Stepped Chutes and Spill W A YsChandeshwor ShahPas encore d'évaluation

- Sequence TestDocument2 pagesSequence Testmaswil99Pas encore d'évaluation

- Reynolds-Averaged Navier-Stokes Equations For Turbulence ModelingDocument20 pagesReynolds-Averaged Navier-Stokes Equations For Turbulence ModelingAlfa RidziPas encore d'évaluation

- Ebara GS Ibb April 2022 - 220404 - 200628Document4 pagesEbara GS Ibb April 2022 - 220404 - 200628chandra atmaPas encore d'évaluation

- Pump Basics PDFDocument43 pagesPump Basics PDFtsrinivasan5083Pas encore d'évaluation

- TurbimachinesDocument2 pagesTurbimachinesArun BeniwalPas encore d'évaluation

- CIV2263 - Water Systems - S1 2021: My UnitsDocument9 pagesCIV2263 - Water Systems - S1 2021: My UnitsEngr.Towhidul IslamPas encore d'évaluation

- 1800 CurvesDocument12 pages1800 Curvesdjs_fericelliPas encore d'évaluation