Académique Documents

Professionnel Documents

Culture Documents

Horizontal Drilling

Transféré par

ayanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Horizontal Drilling

Transféré par

ayanDroits d'auteur :

Formats disponibles

Horizontal Drilling

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 1 of 36

Lesson 14 - Horizontal Drilling

Why Drill Horizontal Wells?

Relative Production Rates

Relative Costs

Types of Horizontal Wells

Drilling Problems & Solutions

How Popular is Horizontal Drilling?

Examples

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 2 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 3 of 36

Why Drill Horizontal Wells?

Increase Reserves

Increase Production Rates

Control Water Production

Control Gas Production

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 4 of 36

Why Drill Horizontal Wells?

Control Sand Production

Produce From Thin Reservoirs

Connect Vertical Fractures

Produce Methane from Coal Seams

Increase Injectivity

- (steam, water, polymers, etc.)

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 5 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 6 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 7 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 8 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 9 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 10 of 36

Production Rates

Oryx - Austin Chalk

Vertical Horizontal Horizontal/Vertical

Well Well Production Ratio

B/D B/D

12 507 42

15 215 14

5 107 21

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 11 of 36

Production Rates

Drilled 7 wells from 1986 to 1989.

Drilled ~ 85 wells in 1990

Vertical Well Drilling Cost: 235 $/ft

Horizontal Well Drilling Cost: 520-282 $/ft

Cost Ratio: 2.2-1.2

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 12 of 36

Drilling Costs

Austin Chalk (1993)

Vertical well ~ $500,000

Recompletion as Horizontal Well ~ $375,000

New Horizontal Well ~

$1,000,000-2,000,000

~ $100+/ft to

$150/ft

{these numbers are rough estimates only}

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 13 of 36

Rospo Mare - Italy

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 14 of 36

Prudhoe Bay

Vertical Well: 3,000 – 4,000 B/D

Horizontal Well: 10,000 - 12,000 B/D

Production Ratio: 3-4

Vertical Well: 235 $/ft

Horizontal Well: 520 - 282 $/ft

Cost Ratio: 2.2-1.2

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 15 of 36

Long Radius (~1,000-3,000 ft) {~2-6 deg/100 ft}

Medium Radius (140~700 ft) {~8-40 deg/100 ft}

Short Radius (~20-40 ft)

{~1.5-3 deg/ft}

<1,000 ft ~5,000 ft ~8,000 ft

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 16 of 36

New Drilling Technology

Measurement While Drilling (MWD)

Directional Surverying and Control

Indentification of Markers (identify zones)

Top Drive

Drill with 90-ft stands instead of 30-ft joints

Circulate while pulling drillpipe out of hole

Rotate drillpipe while pulling out of hole

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 17 of 36

New Drilling Technology

Mud Motors

Drill without rotating pipe

Change hole direction while

drilling

Steerable systems

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 18 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 19 of 36

Potential Problems in Horizontal

Drilling

• Running equipment in and out of hole

• drillstring, casing, cables

• Preventing/Remedying differential

sticking

• Excessive torque

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 20 of 36

Potential Problems in Horizontal

Drilling

• Cleaning the hole and preventing cuttings

from settling along the hole bottom

• Controlling weight on bit to achieve and

maintain directional control

• Cementing casing or liner

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 21 of 36

Summary

• Horizontal wells may produce at 3-5 times the

rate of vertical wells in the same area

(… as much as 20 times higher in special

cases).

• Horizontal wells typically cost 1.5-3 times as

much as vertical wells in the same area.

• Horizontal wells are often very attractive in

formations with extensive vertical fractures.

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 22 of 36

Summary

• The use of horizontal wells is growing -

worldwide.

• Horizontal wells has increased our

recoverable reserves.

• In the U.S. one rig in ten is drilling

horizontal wells. (1994) (1998)

~ 7% in Oct. 2001

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 23 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 24 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 25 of 36

Long - Radius Wells

• Used for achieving large horizontal

displacements from platforms or drilling pads

• Used for achieving very long horizontal sections

(to 6,000 ft +)

Build Rate: ~ 2-6 degrees/100 ft

Build Radius: ~ 1,000-3,000 ft

Length of Horiz. Section: 1,000 - 8,000 ft (1995)

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 26 of 36

Method:

• Use conventional directional drilling

technology

• Use rigid bottom hole assemblies,

motors & bent subs, stabilizers

• or Use Navigation drilling systems with

“steerable” drilling motors

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 27 of 36

Medium - Radius Wells

Build Rate: ~ 8 - 20 degrees/100 ft

(up to 40 deg/100 ft in some

cases)

Build Radius: ~ 300 - 700 ft

Length of Horiz. Section: 1,000-6,000 ft

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 28 of 36

Method:

• Use modified long-radius drilling technology

• Use different motors for Angle Build and

Angle Hold sections.

• Use a “Tangent Section” between the two

build sections

• Use compressive service drillpipe through

the curve if Build Rate > 15 deg./100 ft.

(CS drillpipe has integral wear knots

every ~ 10 ft)

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 29 of 36

Short-Radius Wells

Build Rate: ~ 1 - 3 degrees/ft

Build Radius: ~ 20 - 40 ft

Length of Horiz. Section: 200 - 1,000 ft

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 30 of 36

Method:

Two downhole motor designs are available

Drill vertical “rathole” to identify horizon

Build angle with special curve-drilling

assembly with a non-rotating shell that

gives curvature to the tool

After building angle to horizontal, use a

special angle-hold assembly: this

consists of two undergauge stabilizers

behind the bit, and flexible drillpipe.

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 31 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 32 of 36

Horizontal Well Pair

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 33 of 36

Horizontal Well Pair

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 34 of 36

Vertical Injection Wells and

Horizontal Production Well

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 35 of 36

14. Horizontal Drilling PETE 661 - Drilling Engineering Slide 36 of 36

Vous aimerez peut-être aussi

- Directional Drilling MathDocument18 pagesDirectional Drilling MathSazzadul HossainPas encore d'évaluation

- Drilling Fluids For Drilling of Geothermal Wells - Hagen HoleDocument8 pagesDrilling Fluids For Drilling of Geothermal Wells - Hagen HoleAdil AytekinPas encore d'évaluation

- DD Ops Guidelines 1 - IPMDocument8 pagesDD Ops Guidelines 1 - IPMEmre Cengiz100% (1)

- Directional DrillingDocument92 pagesDirectional Drillingreborn2100% (6)

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsDocument6 pagesFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalPas encore d'évaluation

- ENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageDocument8 pagesENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageHamid Reza BabaeiPas encore d'évaluation

- Training Report Down HoleDocument36 pagesTraining Report Down HolePulkit GururaniPas encore d'évaluation

- Modelling of Torque PDFDocument102 pagesModelling of Torque PDFMahmoud Ahmed Ali Abdelrazik100% (1)

- Khanna's Objective Questions in Petroleum EngineeringDocument396 pagesKhanna's Objective Questions in Petroleum EngineeringTouhid Islam92% (13)

- Directional Drilling Project Advisor Dr. BiltayibDocument140 pagesDirectional Drilling Project Advisor Dr. BiltayibFarshad BaserehPas encore d'évaluation

- Wellbore Sidetracking GuidelinesDocument5 pagesWellbore Sidetracking Guidelinesmadonnite3781Pas encore d'évaluation

- Chapter 8Document29 pagesChapter 8Mahrouz Mado100% (1)

- Completion Fluid ProgramDocument8 pagesCompletion Fluid ProgramMessaoud Amr100% (1)

- 2012 10 PetroJet PresentationDocument30 pages2012 10 PetroJet PresentationNorfolkingPas encore d'évaluation

- Well InterventionDocument83 pagesWell InterventionJosue FishPas encore d'évaluation

- 4) +DGA Pre-Read DirectionalDocument19 pages4) +DGA Pre-Read DirectionalyuriiPas encore d'évaluation

- SPE 167647 Challenges in Testing and Completion of Highly Sour HPHT Reservoir in The State of KuwaitDocument8 pagesSPE 167647 Challenges in Testing and Completion of Highly Sour HPHT Reservoir in The State of KuwaitTheNourEldenPas encore d'évaluation

- Rilling Ngineering Course (2 Ed.)Document43 pagesRilling Ngineering Course (2 Ed.)MarcoPas encore d'évaluation

- Perforation of Perforation of Oil and OiDocument27 pagesPerforation of Perforation of Oil and OiAiham AltayehPas encore d'évaluation

- 33 05 23.13 - Horizontal Directional DrillingDocument17 pages33 05 23.13 - Horizontal Directional DrillingThomas Bennett100% (1)

- 6.1a Introduction To CementingDocument102 pages6.1a Introduction To CementingSamuel Okezie100% (1)

- Horizontal Well Completion and Stimulation Techniques: A Project Report OnDocument48 pagesHorizontal Well Completion and Stimulation Techniques: A Project Report OnTripoli ManoPas encore d'évaluation

- Horizontal WellsDocument55 pagesHorizontal WellsYassir HindiPas encore d'évaluation

- Formation Pressure For Well DesignDocument20 pagesFormation Pressure For Well DesignadeniyiPas encore d'évaluation

- Sop Consolidated (Revision 2019)Document456 pagesSop Consolidated (Revision 2019)Siddhartha ChakradharPas encore d'évaluation

- Well PlanningDocument43 pagesWell PlanningAbrar Ahmed Khan100% (1)

- Types of Well Completion: 1. Open Hole CompletionsDocument6 pagesTypes of Well Completion: 1. Open Hole CompletionsHidayatHandariantoPas encore d'évaluation

- PE-12 Well Stimulation and Clean UpDocument14 pagesPE-12 Well Stimulation and Clean Upeng20072007Pas encore d'évaluation

- Well Control EquipmentDocument58 pagesWell Control Equipmentdriller22100% (3)

- Directional DrillingDocument25 pagesDirectional Drillingsuhrab samiPas encore d'évaluation

- 2-New Completion Technology4Document7 pages2-New Completion Technology4klibiPas encore d'évaluation

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsD'EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsPas encore d'évaluation

- IDPT - 08 - Intro To IPM Process and SystemsDocument15 pagesIDPT - 08 - Intro To IPM Process and Systemsnurwinanto01Pas encore d'évaluation

- Horizontal Directional Drilling XCMG Xz450 45 TonDocument2 pagesHorizontal Directional Drilling XCMG Xz450 45 TonY.EbadiPas encore d'évaluation

- Cementing ActivityDocument42 pagesCementing ActivityHiral jainPas encore d'évaluation

- Mud Engineer User ManualDocument48 pagesMud Engineer User ManualstevebeardsleyPas encore d'évaluation

- Mud Losses PDFDocument67 pagesMud Losses PDFMohamed KouchachePas encore d'évaluation

- Cutting Transport 1999Document5 pagesCutting Transport 1999Dicky PratamaPas encore d'évaluation

- Spe 106346 MSDocument0 pageSpe 106346 MSManthan MarvaniyaPas encore d'évaluation

- Yasir Ahmad, 00657735, 1644-Rewaq Ousha Educational Institute. (IG-2)Document18 pagesYasir Ahmad, 00657735, 1644-Rewaq Ousha Educational Institute. (IG-2)ayanPas encore d'évaluation

- Drilling With Casing Promises Major BenefitsDocument12 pagesDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaPas encore d'évaluation

- Wellbore Completion ConceptsDocument20 pagesWellbore Completion ConceptsAngel NgoPas encore d'évaluation

- Monitoring Drilling Bit Parameters Parameters Allows Optimization of Drilling RatesDocument16 pagesMonitoring Drilling Bit Parameters Parameters Allows Optimization of Drilling RatesAnmol JassalPas encore d'évaluation

- S2 2015 336441 Chapter1Document15 pagesS2 2015 336441 Chapter1arispriyatmonoPas encore d'évaluation

- Cost Model For Geothermal Wells: Carolyn KipsangDocument12 pagesCost Model For Geothermal Wells: Carolyn Kipsangdimastaha100% (1)

- TAMU - Pemex Offshore Drilling: Lesson 20 Horizontal WellsDocument54 pagesTAMU - Pemex Offshore Drilling: Lesson 20 Horizontal Wellsdriller22100% (1)

- Drilling Engineering Lecture 2Document63 pagesDrilling Engineering Lecture 2shanecarl100% (1)

- Drilling and Completion Egy Petroleum Engineer PDFDocument208 pagesDrilling and Completion Egy Petroleum Engineer PDFRahma MejriPas encore d'évaluation

- Drilling Fluids: Islamic Azad University Science and Research Branch Drilling DepartmentDocument26 pagesDrilling Fluids: Islamic Azad University Science and Research Branch Drilling Departmentali nahiPas encore d'évaluation

- Advanced Drilling Practices - Casing DesignDocument92 pagesAdvanced Drilling Practices - Casing DesignGFarizPas encore d'évaluation

- 09 Icruise Best Practice v2Document45 pages09 Icruise Best Practice v2Nelson RamirezPas encore d'évaluation

- Acid TunnelingDocument3 pagesAcid TunnelingFisher YohannesPas encore d'évaluation

- Measurement While Drilling: Signal Analysis, Optimization and DesignD'EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignPas encore d'évaluation

- Cap 17 Well Costing - Libro Well Engineering and ConsDocument32 pagesCap 17 Well Costing - Libro Well Engineering and Conscapl9300% (1)

- Fundamentals and Applications of Bionic Drilling FluidsD'EverandFundamentals and Applications of Bionic Drilling FluidsPas encore d'évaluation

- Multilateral Well (Mohsin)Document10 pagesMultilateral Well (Mohsin)Mohsin ZiaPas encore d'évaluation

- SPE-203872-MS - Multistage FracutringDocument24 pagesSPE-203872-MS - Multistage Fracutringzach100% (1)

- Production Logging - Theoretical and Interpretive Elements Second EditionDocument20 pagesProduction Logging - Theoretical and Interpretive Elements Second Editionahmed abdallah100% (1)

- Spe 187025 MSDocument12 pagesSpe 187025 MSKd FaPas encore d'évaluation

- Cementing Engineering Design: Calculations Made EasyDocument15 pagesCementing Engineering Design: Calculations Made EasyPegasus Vertex, Inc.Pas encore d'évaluation

- Well Control by HelbrtonDocument23 pagesWell Control by Helbrtonاحمد عبد الحسين جولانPas encore d'évaluation

- Section02 Drilling ApparatusDocument31 pagesSection02 Drilling ApparatusMohamed ElshoraPas encore d'évaluation

- SPE-192670-MS Preserving Great Discoveries by Using Non-Damaging Killing Fluid During The Temporary Abandonment of HPHT Exploratory WellsDocument9 pagesSPE-192670-MS Preserving Great Discoveries by Using Non-Damaging Killing Fluid During The Temporary Abandonment of HPHT Exploratory WellsAli mohammadPas encore d'évaluation

- Horizontal DrillingDocument3 pagesHorizontal Drillingallen_renzi100% (2)

- SPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyDocument14 pagesSPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyErika Daniela ReyesPas encore d'évaluation

- Artificial LiftDocument7 pagesArtificial LiftShakerMahmoodPas encore d'évaluation

- Group 4 - Expandable TubularDocument20 pagesGroup 4 - Expandable TubularAzka Roby AntariPas encore d'évaluation

- 5 - Formation DamageDocument39 pages5 - Formation DamageRaed fouadPas encore d'évaluation

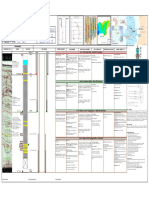

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaPas encore d'évaluation

- Sickwellanalysis 2013Document28 pagesSickwellanalysis 2013mts1234Pas encore d'évaluation

- Well Basis of Design DocumentDocument6 pagesWell Basis of Design DocumentSamuel ArevaloPas encore d'évaluation

- Basics Downhole ConfigurationsDocument13 pagesBasics Downhole ConfigurationsAthaurrohman Alfaina ShidiqPas encore d'évaluation

- Petani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)Document30 pagesPetani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)handokoPas encore d'évaluation

- Microbial Enhancement of Oil Recovery - Recent AdvancesD'EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesPas encore d'évaluation

- SohailDocument1 pageSohailayanPas encore d'évaluation

- 4th Ethics in EngineeringDocument59 pages4th Ethics in EngineeringayanPas encore d'évaluation

- Universities in ChinaDocument3 pagesUniversities in ChinaayanPas encore d'évaluation

- PG Unies in ChinaDocument8 pagesPG Unies in ChinaayanPas encore d'évaluation

- 5th Engineers Responsibility and SafetyDocument49 pages5th Engineers Responsibility and SafetyayanPas encore d'évaluation

- Drilling MSQSDocument7 pagesDrilling MSQSayanPas encore d'évaluation

- FYP ThesisDocument34 pagesFYP ThesisayanPas encore d'évaluation

- ChinaDocument2 pagesChinaayanPas encore d'évaluation

- Petroleum Universities Under CSCDocument1 pagePetroleum Universities Under CSCayanPas encore d'évaluation

- I Am A Fresh Petroleum Engineering GraduateDocument1 pageI Am A Fresh Petroleum Engineering GraduateayanPas encore d'évaluation

- Question No. 7Document2 pagesQuestion No. 7Asjad MachingalPas encore d'évaluation

- Q Num 5Document1 pageQ Num 5ayanPas encore d'évaluation

- Certificate of School AttadenceDocument1 pageCertificate of School AttadenceayanPas encore d'évaluation

- Q1 FinalDocument2 pagesQ1 FinalayanPas encore d'évaluation

- Miscible FloodingDocument52 pagesMiscible FloodingayanPas encore d'évaluation

- Science, 34 (1-3), 131-150Document2 pagesScience, 34 (1-3), 131-150ayanPas encore d'évaluation

- Q2. Part (C) (5) Important To Practice of ERP: and Injuries.,the Resumption of Normal OperationsDocument1 pageQ2. Part (C) (5) Important To Practice of ERP: and Injuries.,the Resumption of Normal OperationsayanPas encore d'évaluation

- RRC International Study Textbook, Ig1, Management of Health & SAFETY Element 3Document1 pageRRC International Study Textbook, Ig1, Management of Health & SAFETY Element 3ayanPas encore d'évaluation

- References RRC INTERNATIONAL STUDYT MATERIAL, IG1, Management of Health & SafetyDocument1 pageReferences RRC INTERNATIONAL STUDYT MATERIAL, IG1, Management of Health & SafetyayanPas encore d'évaluation

- Development of A Mathematical Correlation To Predict Onset of Sand ProductionDocument16 pagesDevelopment of A Mathematical Correlation To Predict Onset of Sand ProductionayanPas encore d'évaluation

- EOR BY Khalid WaheedDocument83 pagesEOR BY Khalid WaheedayanPas encore d'évaluation

- MethodologyDocument6 pagesMethodologyayanPas encore d'évaluation

- FypDocument13 pagesFypayanPas encore d'évaluation

- Assigment 2 .. (Unconventional Gas Resources in Pakistan)Document19 pagesAssigment 2 .. (Unconventional Gas Resources in Pakistan)ayanPas encore d'évaluation

- Assignment 1 (EOR)Document4 pagesAssignment 1 (EOR)ayanPas encore d'évaluation

- Result: Data GatheringDocument4 pagesResult: Data GatheringayanPas encore d'évaluation

- Development of A Mathematical Correlation To Predict Onset of Sand ProductionDocument7 pagesDevelopment of A Mathematical Correlation To Predict Onset of Sand ProductionayanPas encore d'évaluation

- Yasir CVDocument1 pageYasir CVayanPas encore d'évaluation

- 17 PG 24Document6 pages17 PG 24ayanPas encore d'évaluation

- (2016) A Review of The Evaluation, Control and Application Technologies For Drillstring S&V in O&G WellDocument35 pages(2016) A Review of The Evaluation, Control and Application Technologies For Drillstring S&V in O&G WellRoger GuevaraPas encore d'évaluation

- North Sea Chalk Reservoirs - An Appealing Target For Horizontal WellsDocument14 pagesNorth Sea Chalk Reservoirs - An Appealing Target For Horizontal WellsJessePas encore d'évaluation

- Underbalanced Drilling (UBD) : Lesson 1Document39 pagesUnderbalanced Drilling (UBD) : Lesson 1HunterPas encore d'évaluation

- Chapter 1 - Directional DrillingDocument89 pagesChapter 1 - Directional DrillingNaufal Syafiq Mohd IsaPas encore d'évaluation

- Directional Drilling Survey Calculations: Least AccurateDocument7 pagesDirectional Drilling Survey Calculations: Least AccurateCHAN NYEINPas encore d'évaluation

- Logging Through The Bit: James Aivalis Tony Meszaros Robert Porter Rick Reischman Robin Ridley Peter WellsDocument10 pagesLogging Through The Bit: James Aivalis Tony Meszaros Robert Porter Rick Reischman Robin Ridley Peter WellspendexxPas encore d'évaluation

- The Important of Horizontal Directional Drilling SDocument19 pagesThe Important of Horizontal Directional Drilling SBubu Keke CacaPas encore d'évaluation

- Fundamentals of Drilling OperationsDocument93 pagesFundamentals of Drilling OperationsSAKPas encore d'évaluation

- At Well X Field Y: Drillstring Design For Directional DrillingDocument11 pagesAt Well X Field Y: Drillstring Design For Directional DrillingMuhammad Khatami RafsanjaniPas encore d'évaluation

- 13 - Attivita' Di PerforazioneDocument8 pages13 - Attivita' Di PerforazioneROBERSON ROMERÒPas encore d'évaluation

- Evaluation LibreDocument12 pagesEvaluation LibrePeng TerPas encore d'évaluation

- Directional Drillingjuly08Document23 pagesDirectional Drillingjuly08ANISAHPas encore d'évaluation

- Directional DrillingDocument26 pagesDirectional Drillingroaa ahmed100% (1)

- Introduction To Directional Drilling IntDocument52 pagesIntroduction To Directional Drilling IntJamel SlimaniPas encore d'évaluation

- Vol 1 3drillingDocument12 pagesVol 1 3drillingVamshiPas encore d'évaluation

- Technology Advances Increase Drilling EfficiencyDocument5 pagesTechnology Advances Increase Drilling EfficiencyPradipta NaskarPas encore d'évaluation

- Directional Drilling: University of Baghdad College of Engineering Department of PetroleumDocument16 pagesDirectional Drilling: University of Baghdad College of Engineering Department of PetroleumAhmed Abdulameer AbdulwahidPas encore d'évaluation