Académique Documents

Professionnel Documents

Culture Documents

Slide Srevisi 0

Transféré par

citraDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Slide Srevisi 0

Transféré par

citraDroits d'auteur :

Formats disponibles

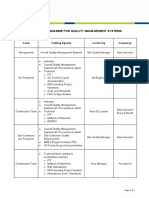

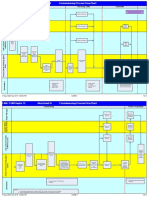

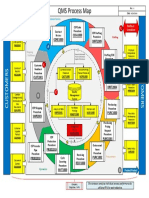

MANUFACTURE LOGISTIC PPIC QC

LV Relocation Relocation Future Logistic MES Central QC World class test central

Januari 2018. Kapasitas dari 600 menjadi Building Construction Done (70%) : ALC, MK, NA

800, dan naik kembali menjadi 1200 km MV, LV, FO.

On Progress (30%) :

Increase Drawing Capacity Reduce area 15% Develop Dashboard

Production ALC Voksel QC Test Centre with

R&D Facility

Total Output MTB 1 & 2 sebesar 16

Ton/hari. Setelah di ganti satu mesin euro QC will have QC Center

alpha, output menjadi 22 Ton/hari. Increse whose building will be

joined by HV Building

2016 sebesar 6 Ton/hari.

Increase storage capacity 3x which is under

construction, currently lay

HV Production out for Testing machine is

NA being arranged

Building Construction

Logistic flow in out 30 minutes

Pencapaian flow in out Logistik saat ini rata -rata jan-july 2018 = 23

menit. (Mulai masuk Logistic s/d serah terima Surat Jalan) .

In - Out Security = Target 100 Minutes (KPI) 2018 sekarang rata- rata Jan-

July 2018 = 94 Minutes

Yang sudah dilakukan : Share Informasi dari setiap ekspedisi by email &

WA mengenai rencana kedatangan kendaraan dengan melengkapi No Pol,

No PE, jml Kend dll. Sehingga mempermudahadmin dalam membuat

draft surat jalan dan persiapan barang di area transit oleh team lapangan

dan diberi tanda khusus jika ada beberapa customer.

Setiap saat kepala group aktif melihat Papan Informasi pengiriman dan

berkoordinasi dengan admin setiap mobil masuk dan keluar memakai

sistem pass car. Koordinasi antara Logistik dan security GA

MANUFACTURE LOGISTIC PPIC QC

HV Cable Project In process quality --> Less inspections

and more in-process control Average

Cable assessment for process one-time pass ratio 98%

1000 mm2

Actual 96,88 %

FO business expanding

Skills improvement --> On job training

Survey lokasi di Kendal, Jawa Tengah. Specific skills: Compliance rate 90%

Product (submarine optic cable and fiber Multi-skill: Compliance rate 50% for 2 skills and above

drawing and confession cable)

New Skill Mapping and Training Needs Analysis on

Enhance the existing business

2017 of our subsidiaries

progress

Scrap/waste control --> Reduce waste: 30%

Relayout MK to profide more capacity:

Reduced WIP:50%

1. Power Cable

2. Building Cable

3. Control Cable Rata Rata Pencapaian Waste 2017 :

4. Instrument Cable 3,6%,Tahun 2018 : 2,4%. Increase sebesar

33% (Tercapai).

Machine/process outputs --> Less

Provide system solutions

machines less room: 1/3 off Less

headcounts for machines: 1/3 off

Bigger outputs: 1.5-2.0times NA

Energy and telecom.-related products

Some machine are deactivated , and

and services

remove headcounts to other department

( ALC to LV and MV , HV)

NA

Vous aimerez peut-être aussi

- ISMARTVN - RMX ExpressEnhanceBatchresult To CQC v1Document3 pagesISMARTVN - RMX ExpressEnhanceBatchresult To CQC v1Quoc AnPas encore d'évaluation

- KRA Sheet EMR FY23Document15 pagesKRA Sheet EMR FY23BHUVANESH MPas encore d'évaluation

- Home Connection ExperienceDocument26 pagesHome Connection ExperienceKomang WahyuPas encore d'évaluation

- FTC Solar - Actis Preso Rough BaselineDocument20 pagesFTC Solar - Actis Preso Rough BaselineHernan ArrigonePas encore d'évaluation

- FY2015 Q1 - Operation Team Quarter Closure Performance Report V0.3Document20 pagesFY2015 Q1 - Operation Team Quarter Closure Performance Report V0.3Messi WorkuPas encore d'évaluation

- Gestión de No Conformidad (2QN) - Diagramas de ProcesoDocument2 pagesGestión de No Conformidad (2QN) - Diagramas de ProcesoDiego CincottaPas encore d'évaluation

- CTQ of SR Manager Electrical Maintenance CopyDocument4 pagesCTQ of SR Manager Electrical Maintenance CopymdkhandavePas encore d'évaluation

- 00 Training ProgrammeDocument1 page00 Training ProgrammeMehaboob BashaPas encore d'évaluation

- Yes Securities Cummins India LTD Initiating Coverage Q3FY22Document10 pagesYes Securities Cummins India LTD Initiating Coverage Q3FY22eichermguptaPas encore d'évaluation

- CEPLDocument18 pagesCEPLSudhanshu BaranwalPas encore d'évaluation

- Chapter15 R1 AttADocument2 pagesChapter15 R1 AttAJazielPas encore d'évaluation

- HTTP 139.165.65.75 Projets Biblio Upload Compit06 335capraceetal AnAnalyticalCostAssessmentModulefortheDetailedDesignStageDocument11 pagesHTTP 139.165.65.75 Projets Biblio Upload Compit06 335capraceetal AnAnalyticalCostAssessmentModulefortheDetailedDesignStageval-ovidiu iordachePas encore d'évaluation

- CHAPTER 2 PROCESS COSTING - Situation 1 & 2Document30 pagesCHAPTER 2 PROCESS COSTING - Situation 1 & 2Noranis NajwaPas encore d'évaluation

- Ganesh Kumar: Career Snapshot SkillsDocument1 pageGanesh Kumar: Career Snapshot SkillsAnkush ChoudharyPas encore d'évaluation

- Business Highlight's Inputs of Hod'sDocument4 pagesBusiness Highlight's Inputs of Hod'sVansh1 TharejaPas encore d'évaluation

- Kaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Document7 pagesKaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Jonas PadillaPas encore d'évaluation

- Estidama Level 1 InductionDocument61 pagesEstidama Level 1 InductionVijayakumarVageesanPas encore d'évaluation

- Scope of ActivityDocument9 pagesScope of ActivityBangkit SamosirPas encore d'évaluation

- 2 Use of Construction Productivity and Capability Fund (CPCF) To Enhance Productivity 12jan17Document83 pages2 Use of Construction Productivity and Capability Fund (CPCF) To Enhance Productivity 12jan17Jan Kristoffer Aguilar UmaliPas encore d'évaluation

- WCM ConfigDocument11 pagesWCM ConfigvrkattulaPas encore d'évaluation

- Устройство для пересадки персоналаDocument28 pagesУстройство для пересадки персоналаRustem IakhinPas encore d'évaluation

- Good Sample IKWDocument23 pagesGood Sample IKWTs-Radzif OmarPas encore d'évaluation

- WCM 2010-2014 PlanDocument24 pagesWCM 2010-2014 PlanFatur PratamaPas encore d'évaluation

- q3 Presentation 221028Document13 pagesq3 Presentation 221028jesperandersson.09Pas encore d'évaluation

- TOTAL Calculation SheetDocument22 pagesTOTAL Calculation SheetMd. Abdulla Al MamunPas encore d'évaluation

- Homag VentureDocument16 pagesHomag VentureWilliam Orozco LópezPas encore d'évaluation

- QM Process Map PDFDocument1 pageQM Process Map PDFghafoorian_khoshgovar148850% (2)

- Muhammad Shahid - Head of ProductionDocument4 pagesMuhammad Shahid - Head of ProductionTechnoPas encore d'évaluation

- QC Sites KcicDocument2 pagesQC Sites Kcicurza_081Pas encore d'évaluation

- Controlsoft Engineering ProfileDocument37 pagesControlsoft Engineering ProfileDuraisamy PanchatcharamPas encore d'évaluation

- 1 s2.0 S0959652621002390 MainDocument15 pages1 s2.0 S0959652621002390 Mainroi.ho2706Pas encore d'évaluation

- Quay Container Crane Productivity Effectiveness Analysis Case Study PT Jakarta International Container TerminalDocument9 pagesQuay Container Crane Productivity Effectiveness Analysis Case Study PT Jakarta International Container TerminalInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- August QA - QC Report of Yabello Bypass Road ProjectDocument8 pagesAugust QA - QC Report of Yabello Bypass Road ProjectKEMAL SHANBELPas encore d'évaluation

- Safety: First MustDocument13 pagesSafety: First MustJose FrancisPas encore d'évaluation

- Sagar Resume1Document3 pagesSagar Resume1Sagar DeodharPas encore d'évaluation

- Criteria For Sustainable Development and Indicators Table PDFDocument5 pagesCriteria For Sustainable Development and Indicators Table PDFkhabiranPas encore d'évaluation

- Case Study KFW PDFDocument4 pagesCase Study KFW PDFborisg3Pas encore d'évaluation

- Ali Ahmad CVDocument4 pagesAli Ahmad CVali ahmadPas encore d'évaluation

- Insulation WorksDocument8 pagesInsulation WorksBangkit SamosirPas encore d'évaluation

- Workstation Optimization by Applying Lean Manufacturing Technique-A Production Case StudyDocument10 pagesWorkstation Optimization by Applying Lean Manufacturing Technique-A Production Case StudyInternational journal of Engineering Science and FPas encore d'évaluation

- Will Quantum Computing Drive The Automotive Future FinalDocument8 pagesWill Quantum Computing Drive The Automotive Future FinalAmaratpal KaurPas encore d'évaluation

- Lifting PlanDocument12 pagesLifting Plangeriaxavier2022Pas encore d'évaluation

- Techniques in Managerial Decision MakingDocument58 pagesTechniques in Managerial Decision MakingPranit GhangalePas encore d'évaluation

- World Class ManufacturingDocument32 pagesWorld Class ManufacturingUng Kok Aik100% (1)

- PerusahaanDocument3 pagesPerusahaanFaza InsanPas encore d'évaluation

- Analysis of Kanban Warehouses-Flextronics Doumen CampusDocument21 pagesAnalysis of Kanban Warehouses-Flextronics Doumen CampusJonahPas encore d'évaluation

- Mitsubishi M80ADocument17 pagesMitsubishi M80Aluh.kikooPas encore d'évaluation

- Difference Between QCI - NABET Scheme For Accreditation of GWCO - Version 1.2 - 23rd Nov 2020 Vs Version 1.0 of Jan-2020 - Google SearchDocument3 pagesDifference Between QCI - NABET Scheme For Accreditation of GWCO - Version 1.2 - 23rd Nov 2020 Vs Version 1.0 of Jan-2020 - Google Searchneeraj sharmaPas encore d'évaluation

- SPMF AssignmentDocument2 pagesSPMF AssignmentGururaja Hebbur SatyanarayanaPas encore d'évaluation

- @agilesensei: Claudio PerroneDocument88 pages@agilesensei: Claudio PerroneabringasPas encore d'évaluation

- Resume IpoelDocument2 pagesResume IpoelEka maulanaPas encore d'évaluation

- Coupling The ILS Optimisation Algorithm and A Simulation Process To Solve The Travelling Quay-Crane Worker Assignment and Balancing ProblemDocument18 pagesCoupling The ILS Optimisation Algorithm and A Simulation Process To Solve The Travelling Quay-Crane Worker Assignment and Balancing ProblemImane TorbiPas encore d'évaluation

- David BirchDocument27 pagesDavid BirchShubham JainPas encore d'évaluation

- Design of Performance Management System For Underground Mining Construction Using Integrated Performance Management SystemDocument10 pagesDesign of Performance Management System For Underground Mining Construction Using Integrated Performance Management SystemsdfkjgskfPas encore d'évaluation

- Bosch PackagingDocument3 pagesBosch PackagingNagendiran RavichandranPas encore d'évaluation

- Daily Report - Site Quality Maintenance Work 1Document2 pagesDaily Report - Site Quality Maintenance Work 1shahrilzainul77Pas encore d'évaluation

- WCM - 02Document5 pagesWCM - 02wagqualidadePas encore d'évaluation

- Akram CV Final 2Document5 pagesAkram CV Final 2akram husseinPas encore d'évaluation

- Competency Matrix - Coil TubingDocument7 pagesCompetency Matrix - Coil TubingSomto NwachukwuPas encore d'évaluation

- Credit NoteDocument1 pageCredit NotesprabhathPas encore d'évaluation

- Blanks WordDocument1 pageBlanks WordcitraPas encore d'évaluation

- Junk ExcelDocument4 pagesJunk ExcelcitraPas encore d'évaluation

- Fivem Service Agreement 1Document3 pagesFivem Service Agreement 1Ilham PrasetyoPas encore d'évaluation

- Ceklist Event KNS 2017Document2 pagesCeklist Event KNS 2017citraPas encore d'évaluation

- Lunch Consumption 2018Document10 pagesLunch Consumption 2018citraPas encore d'évaluation

- Eticket YFVNQGDocument2 pagesEticket YFVNQGcitraPas encore d'évaluation

- Kalender 2018 DraftDocument26 pagesKalender 2018 DraftcitraPas encore d'évaluation

- AsakbkhabfdfDocument1 pageAsakbkhabfdfcitraPas encore d'évaluation

- Good Laboratory Practice Bahasa IndonesiaDocument3 pagesGood Laboratory Practice Bahasa IndonesiaMuhammad Thoriqur Rohman Al-KhotamiPas encore d'évaluation

- 353 Version 7thDocument1 page353 Version 7thDuc NguyenPas encore d'évaluation

- Math ExamDocument21 pagesMath ExamedgemarkPas encore d'évaluation

- HG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Document14 pagesHG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Arslan AbbasPas encore d'évaluation

- ISSA2013Ed CabinStores v100 Часть10Document2 pagesISSA2013Ed CabinStores v100 Часть10AlexanderPas encore d'évaluation

- (Kazantzakis Nikos) Freedom or DeathDocument195 pages(Kazantzakis Nikos) Freedom or DeathTarlan FisherPas encore d'évaluation

- 2012 Conference NewsfgfghsfghsfghDocument3 pages2012 Conference NewsfgfghsfghsfghabdPas encore d'évaluation

- GladioDocument28 pagesGladioPedro Navarro SeguraPas encore d'évaluation

- SQLDocument13 pagesSQLRadhakrishnan__7263Pas encore d'évaluation

- Philpost RRDocument6 pagesPhilpost RRGene AbotPas encore d'évaluation

- ITCNASIA23 - Visitor GuideDocument24 pagesITCNASIA23 - Visitor Guideibrahim shabbirPas encore d'évaluation

- ARTS10 Q2 ModuleDocument12 pagesARTS10 Q2 ModuleDen Mark GacumaPas encore d'évaluation

- Preliminary Examination The Contemporary WorldDocument2 pagesPreliminary Examination The Contemporary WorldJane M100% (1)

- Verilog A Model To CadenceDocument56 pagesVerilog A Model To CadenceJamesPas encore d'évaluation

- Adding and Subtracting FractionsDocument4 pagesAdding and Subtracting Fractionsapi-508898016Pas encore d'évaluation

- Mongodb TutorialDocument106 pagesMongodb TutorialRahul VashishthaPas encore d'évaluation

- Model 900 Automated Viscometer: Drilling Fluids EquipmentDocument2 pagesModel 900 Automated Viscometer: Drilling Fluids EquipmentJazminPas encore d'évaluation

- MotorsDocument116 pagesMotorsAmália EirezPas encore d'évaluation

- Evaporative CoolingDocument68 pagesEvaporative Coolingshivas34regal100% (1)

- SMMS7 - Mini7 Product Line-Up OverviewDocument46 pagesSMMS7 - Mini7 Product Line-Up OverviewTín Nguyễn ThànhPas encore d'évaluation

- Measuring and Modeling Vertical Crosshead Vibration in Api-618 Reciprocating CompressorsDocument18 pagesMeasuring and Modeling Vertical Crosshead Vibration in Api-618 Reciprocating CompressorshmshawkiPas encore d'évaluation

- Categories of Cargo and Types of ShipsDocument14 pagesCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviPas encore d'évaluation

- Volcano Lesson PlanDocument5 pagesVolcano Lesson Planapi-294963286Pas encore d'évaluation

- PEA Comp Study - Estate Planning For Private Equity Fund Managers (ITaback, JWaxenberg 10 - 10)Document13 pagesPEA Comp Study - Estate Planning For Private Equity Fund Managers (ITaback, JWaxenberg 10 - 10)lbaker2009Pas encore d'évaluation

- Jar Doc 06 Jjarus Sora Executive SummaryDocument3 pagesJar Doc 06 Jjarus Sora Executive Summaryprasenjitdey786Pas encore d'évaluation

- IGCSE 0408 Unseen Poem QuestionsDocument5 pagesIGCSE 0408 Unseen Poem QuestionsMenon HariPas encore d'évaluation

- SAP HCM Case StudyDocument17 pagesSAP HCM Case StudyRafidaFatimatuzzahraPas encore d'évaluation

- Learning Module - Joints, Taps and SplicesDocument9 pagesLearning Module - Joints, Taps and SplicesCarlo Cartagenas100% (1)

- Catch Up RPHDocument6 pagesCatch Up RPHபிரதீபன் இராதேPas encore d'évaluation

- Project On Mahindra BoleroDocument35 pagesProject On Mahindra BoleroViPul75% (8)