Académique Documents

Professionnel Documents

Culture Documents

Automated Seed Sowing Machine

Transféré par

Ashutosh Dongarwar0 évaluation0% ont trouvé ce document utile (0 vote)

271 vues12 pagesMy work

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMy work

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

271 vues12 pagesAutomated Seed Sowing Machine

Transféré par

Ashutosh DongarwarMy work

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 12

“Presentation Inspiration and Motivation have always played a key role

in the success of any venture”

In the accomplishment of this course project successfully, many people

have bestowed upon us their blessings and the heart pledged support.

We are taking this opportunity to thank all the people who have been

concerned with this course project.

We are highly in indebted to Prof. Virendra R. Bhokse whose valuable

guidance has been the ones that helped us patch this project and

make it full proof success. His valuable instructions regarding this project

and kind supervision have played a major role in completion of our

course project successfully.

We would like to extend our gratitude to the Director Prof.(Dr.)

RAJESH M. JALNEKAR and to the HOD of DESH Department Prof.(Dr.)

C.M. MAHAJAN for providing us with all the facility that was required

during this project.

Last but not the least we would like to thank our parents who have

helped us with their valuable suggestion in various phase of this project.

The model has been proposed with the aim to establish

a 12kg per hour capacity seed processing plant. As is

evident from the financial analysis that the project is

sound and estimated results are encouraging and

hence the model may be considered for financing

under the scheme of GOI for boosting seed production

in private sector. The assembly is developed for

cultivating ploughed land automatically i.e. less power is

required. The blocking of seed problem is eliminated

with the help of water pressure. So this model increases

the efficiency and accuracy. The project consists of two

different mechanisms. The first mechanism contains

making an assembly of vehicle and its motion, whereas

second mechanism is preparing a seed bed on

ploughed land .Due to no man power requirement and

high speed of operation, it has scope for further

expansion.

Why the need for automation?

Sowing is the most important process in farming. It is a very tiring

and time consuming process that requires a lot of human effort.

Here we propose the design and fabrication of a fully automatic

seed sowing robot that automates this task. The proposed robot

uses four motors for running it in desired directions. We use a

small bracket for pouring seeds. The robot consists of a funnel like

arrangement in order to pour seeds into a lower container. There

we use a shaft with gear like bucket teeth to pick up limited

quantity of seeds and pour them on the ground in a steady

manner in proper quantity. The front of the robot consists of a

bent plate that drags on the soil to make a slot ahead of the

machine before seeds are poured in it. The back portion of the

robot consists of a tail like bent rod that is again used to pour soil

on seeds sowed thus covering them with soil. Thus the system

completely automated the seed sowing process using a smartly

designed mechanical robotic system.

D.C. motor (2V and 100rpm)

Shaft

Rectangular Container

Funnel(Diameter 10 cm)

Wheels

Mounts

Supporting Frame(Wooden)

Joints & Fixtures

Screws

The working principle of our model will start by engine power

transmission through chain and sprocket arrangement mechanism.

Here engine power shaft is connected to rear axle of the wheel

where it produces the torque produces movement of the vehicle and

we can control the speed of the machine by controlling the throttle

provided in the machine. Simultaneously another sprocket of same

size in rear axle is used to maintain the same speed to provide the

rotational effect to the another shaft which is below the seed sowing

machine equipment the shaft rotates at the same speed as that of

rear axle rotates. Here another larger teeth sprocket is used to provide

rotational effect to seed sowing machine shaft. As this shaft consists of

two circular plates and made a slot at specified distance to easily

pick the seeds from the hopper as the rear axle wheels turns due to

power transmission of engine the seed are dropped by the circular

plate. The circular plates are turned in clockwise direction as the

rotational effects provided by shaft and seed are dropped into

ground. We are maintaining the speed of the machine very low so it

produces maximum amount of torque. Hence the model can be run

smoothly on agricultural land.

What should be used for chassis development?

=The iron metal chassis would be more heavy and more difficult

to fabricate, so we decided to use timber wood instead of iron.

Also ,to reduce the cost of the equipment.

What type of wheel should be used?

=Normal wheels can’t be used in fields .To overcome this

situation we used wheels with spikes which provides better grip

with the soil and enables the model to perform the seed sowing

operation.

1.When seed is small in size we need manual effort

for setting.

2. It is operated on battery supply, if any failure

occurs whole system will not function.

3.This machine cannot be operated in uneven land.

4.Cannot work on swampy or wet lands.

5.After a couple of hours the battery should be

charged regularly for a smooth application.

To meet future food demands the farmers have

to implement new techniques which will not

affect the soil texture but will the crop production.

In the farming process often used conventional

seeding operation takes more time and more labour.

The seed feeding is also more and total cost is

increased due to labour. All the above mentioned

problems can be reduced considerably with the

help of the automatic seed sowing machine.

Fundamentals Of Agronomy

Economics Of Farm Production And

Management.

Wikipedia

http://nevonprojects.com/automatic-

seed-sowing-robot/

http://www.internationaljournalssrg.org/I

JECE/2017/Special-Issues

Vous aimerez peut-être aussi

- Design and Fabrication of A Automated Seed Sowing Machine Powered by Solar PowerDocument5 pagesDesign and Fabrication of A Automated Seed Sowing Machine Powered by Solar PowerMark Andrew CabalePas encore d'évaluation

- Fabrication and Automation of Seed Sowing Machine Using IotDocument10 pagesFabrication and Automation of Seed Sowing Machine Using IotMani KarthikeyanPas encore d'évaluation

- Design of Semi-Automated Solar Powered Seed Sowing MachineDocument51 pagesDesign of Semi-Automated Solar Powered Seed Sowing MachineSamuel Gashura100% (1)

- Automatedseedsowing MachineDocument15 pagesAutomatedseedsowing MachinePrimoJr CarilloPas encore d'évaluation

- 2-ROW GROUNDNUT PLANTING MACHINE THRESHES, SOWS & SPRAYSDocument8 pages2-ROW GROUNDNUT PLANTING MACHINE THRESHES, SOWS & SPRAYSrock starPas encore d'évaluation

- Automated Seed Sowing MachineDocument40 pagesAutomated Seed Sowing MachineRaja Mane67% (3)

- Multi Purpose Seed Sowing Machine SeminarDocument17 pagesMulti Purpose Seed Sowing Machine SeminarJose JojoPas encore d'évaluation

- Seed Sowing MachineDocument117 pagesSeed Sowing Machinekalidass92% (13)

- Campus Radio StationDocument15 pagesCampus Radio StationAberhamPas encore d'évaluation

- Design and Analysis of Manually Operated Seed Sowing MachineDocument12 pagesDesign and Analysis of Manually Operated Seed Sowing MachinePiyush Narkhede0% (1)

- JennylynreductocleofeDocument4 pagesJennylynreductocleofeLia Estrelle CleofePas encore d'évaluation

- Mongan, Katrina L. Excess Lot Batuhan Dasmariñas City, CaviteDocument1 pageMongan, Katrina L. Excess Lot Batuhan Dasmariñas City, Cavitema.chrislyn viloriaPas encore d'évaluation

- PeraDocument4 pagesPeraSofia Linelle P EdecerPas encore d'évaluation

- Sa20230107 PDFDocument4 pagesSa20230107 PDFLea EspejoPas encore d'évaluation

- Inbound 1410519762906399569Document4 pagesInbound 1410519762906399569Mickhail PeñaPas encore d'évaluation

- Multi Agri Cutter - AbstractDocument4 pagesMulti Agri Cutter - AbstractShankar G75% (4)

- Rapid Application Development Model Iterative ProcessDocument2 pagesRapid Application Development Model Iterative ProcesstamiratPas encore d'évaluation

- Certificate of Service Completion for Training ConsultantDocument1 pageCertificate of Service Completion for Training ConsultantAloha GeveraPas encore d'évaluation

- Miranda, BenignoDocument1 pageMiranda, BenignoErron Perlas MirandaPas encore d'évaluation

- PERT and CPM Project Planning TechniquesDocument28 pagesPERT and CPM Project Planning TechniquesJayson PagalPas encore d'évaluation

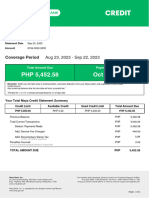

- MayaCredit SoA 2023SEPDocument3 pagesMayaCredit SoA 2023SEPNancy DiplomaPas encore d'évaluation

- Rosalyncsarino: Page1of3 Bopalma 1 0 6 9 - 2 1 8 2 - 3 3 Victorias 6 1 1 9Document4 pagesRosalyncsarino: Page1of3 Bopalma 1 0 6 9 - 2 1 8 2 - 3 3 Victorias 6 1 1 9Stacey Zain SarinoPas encore d'évaluation

- Machinery TextDocument25 pagesMachinery TextMd Firoz Alam Khan100% (1)

- Nerissasjimena : 30dinarststmichaelsubd Meycauyanbulacan 3 0 2 0Document6 pagesNerissasjimena : 30dinarststmichaelsubd Meycauyanbulacan 3 0 2 0Nerda Jimena- CarabioPas encore d'évaluation

- Implement Types and Field CapacityDocument37 pagesImplement Types and Field CapacityLiam LagartoPas encore d'évaluation

- Prime Movers in The Agricultural and Bio Production SystemsDocument37 pagesPrime Movers in The Agricultural and Bio Production SystemsMyla Jane CalabioPas encore d'évaluation

- Tuning into University Campus Radio & Campus TV in BangladeshDocument2 pagesTuning into University Campus Radio & Campus TV in BangladeshJahangirAhmadJahanPas encore d'évaluation

- Be 20230629Document4 pagesBe 20230629Emman GalangPas encore d'évaluation

- Makati WayDocument2 pagesMakati WayBangtan Law FirmPas encore d'évaluation

- Phportalserverservicesrestv 2 Esoadownloadreport Id 29 e 3984 D 8 CC 3 Be 1 D 8Document4 pagesPhportalserverservicesrestv 2 Esoadownloadreport Id 29 e 3984 D 8 CC 3 Be 1 D 8Margarita Michelle Puntil ElamparoPas encore d'évaluation

- (Group 5) Engineering ManagementDocument31 pages(Group 5) Engineering ManagementairaPas encore d'évaluation

- Storm Water Drainage Design CalculationsDocument17 pagesStorm Water Drainage Design Calculationskarthi100% (1)

- Design and fabrication of multi-purpose sieving machineDocument6 pagesDesign and fabrication of multi-purpose sieving machineMICHEL RAJ MechPas encore d'évaluation

- Document 2Document84 pagesDocument 2Noor IslamPas encore d'évaluation

- Evaluating opportunities and differentiating strategies for Carrefour's expansionDocument1 pageEvaluating opportunities and differentiating strategies for Carrefour's expansionmaryPas encore d'évaluation

- Advanced Pepper Separator Machine: A Project ReportDocument42 pagesAdvanced Pepper Separator Machine: A Project ReportSports GalleryPas encore d'évaluation

- Design & Fabrication of Multipurpose Agricultural VehicleDocument3 pagesDesign & Fabrication of Multipurpose Agricultural VehicleSIDDPPA.SATAYMANAVAR Sataymanavar100% (1)

- MayaCredit - SoA - 2023AUG 2Document3 pagesMayaCredit - SoA - 2023AUG 2Mae RemulloPas encore d'évaluation

- Motorized Screw JackDocument3 pagesMotorized Screw JackJeya KumarPas encore d'évaluation

- Machinery Machinery Selection and Selection and Management ManagementDocument28 pagesMachinery Machinery Selection and Selection and Management ManagementJohn Pierre NuncioPas encore d'évaluation

- 4.journal of Arecanut Tree ClimberDocument3 pages4.journal of Arecanut Tree ClimberPranith K VPas encore d'évaluation

- ME Board - Machine DesignDocument5 pagesME Board - Machine Designrhchri100% (1)

- Design of A Bladeless Wind TurbineDocument5 pagesDesign of A Bladeless Wind TurbineJosafatPas encore d'évaluation

- RATIO ANALYSIS JaypeeDocument60 pagesRATIO ANALYSIS Jaypeevickram jainPas encore d'évaluation

- Design & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostDocument8 pagesDesign & Fabrication of Portable Organic Waste Chopping Machine To Obtain CompostIJIRSTPas encore d'évaluation

- Materials and Processing in Agricultural and Biosystems Engineering ABE 221Document46 pagesMaterials and Processing in Agricultural and Biosystems Engineering ABE 221Mary Dawn MadrioPas encore d'évaluation

- ResearchDocument25 pagesResearchLarry ErbitePas encore d'évaluation

- Design and Peformance Test of Coconut Skin Testa Peeling MachineDocument5 pagesDesign and Peformance Test of Coconut Skin Testa Peeling MachineInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- 1 Controlling What Is Controlling?Document16 pages1 Controlling What Is Controlling?John Lester SalongaPas encore d'évaluation

- Design and Fabrication of Floor Cleaning Machine - A ReviewDocument4 pagesDesign and Fabrication of Floor Cleaning Machine - A ReviewIJIERT-International Journal of Innovations in Engineering Research and Technology100% (1)

- Design of Machine Elements ReviewDocument2 pagesDesign of Machine Elements ReviewSuraj WodeyarPas encore d'évaluation

- Broadcast SpreaderDocument14 pagesBroadcast SpreaderEilegnaPas encore d'évaluation

- Chapter-1: 1.2 Why To Use Solar Tracking SystemDocument46 pagesChapter-1: 1.2 Why To Use Solar Tracking Systemmgitecetech100% (1)

- Design of An Innovative Coconut Grating Machine Using TinkercadDocument5 pagesDesign of An Innovative Coconut Grating Machine Using TinkercadChristopher Ysit100% (1)

- Design Rice Transplanter Local Farmers North CotabatoDocument5 pagesDesign Rice Transplanter Local Farmers North CotabatoJosafat BaylosisPas encore d'évaluation

- Seed Sowing Machine Project ReportDocument14 pagesSeed Sowing Machine Project ReportMantha BalajiPas encore d'évaluation

- Design and Fabrication of Hand Operated Seed Sowing MachineDocument25 pagesDesign and Fabrication of Hand Operated Seed Sowing MachineSergio PugazhPas encore d'évaluation

- Pre-Evaluation Report Sample (2Document6 pagesPre-Evaluation Report Sample (2Qazi QaziPas encore d'évaluation

- Pre-Evaluation Report Sample (2Document6 pagesPre-Evaluation Report Sample (2Qazi QaziPas encore d'évaluation

- Literature Review on Automatic Seed FeederDocument4 pagesLiterature Review on Automatic Seed FeederMani KarthikeyanPas encore d'évaluation

- Effect of Hydraulic Accumulator On The System Parameters of An Open Loop Transmission SystemDocument5 pagesEffect of Hydraulic Accumulator On The System Parameters of An Open Loop Transmission SystemAshutosh DongarwarPas encore d'évaluation

- Design of 15 Meter Head Hydraulic Ram Pump: Y Y M, Z M HDocument5 pagesDesign of 15 Meter Head Hydraulic Ram Pump: Y Y M, Z M HAshutosh DongarwarPas encore d'évaluation

- Design Methodology For Hydraulic Ram Pump: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument9 pagesDesign Methodology For Hydraulic Ram Pump: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyAshutosh DongarwarPas encore d'évaluation

- Untitled Presentation-2Document1 pageUntitled Presentation-2Ashutosh DongarwarPas encore d'évaluation

- Untitled Presentation-1Document1 pageUntitled Presentation-1Ashutosh DongarwarPas encore d'évaluation

- Academic Calendar 19-20 SemIIDocument1 pageAcademic Calendar 19-20 SemIIAshutosh DongarwarPas encore d'évaluation

- Untitled Presentation-1Document1 pageUntitled Presentation-1Ashutosh DongarwarPas encore d'évaluation

- Engineering Drawing by N.D BhattDocument738 pagesEngineering Drawing by N.D BhattJagadish90% (48)

- SOLAR2013 0091 Final-PaperDocument7 pagesSOLAR2013 0091 Final-PaperCrazy VideosPas encore d'évaluation

- API Safety and Fire Protection PublicationDocument6 pagesAPI Safety and Fire Protection PublicationDan PascoPas encore d'évaluation

- Forklift Safety: Osha TrainingDocument28 pagesForklift Safety: Osha Trainingsuraj11122Pas encore d'évaluation

- Avaya Battlecard IP Office Standard Professional Edition R42 2Document2 pagesAvaya Battlecard IP Office Standard Professional Edition R42 2Santiago De La CruzPas encore d'évaluation

- Sbakx 32Document11 pagesSbakx 32rer0427Pas encore d'évaluation

- PSC Girder Before Concreting MIPL CL 32Document2 pagesPSC Girder Before Concreting MIPL CL 32Rayudu VVS100% (1)

- BurneyDocument22 pagesBurneyRidvan YigitPas encore d'évaluation

- English Solar Farm Proposal by TSF Oct 123Document38 pagesEnglish Solar Farm Proposal by TSF Oct 123Atiqah HamzahPas encore d'évaluation

- ConyDocument5 pagesConykripeshdubeyPas encore d'évaluation

- 6593 PDFDocument14 pages6593 PDFBui Hong PhongPas encore d'évaluation

- Wooden Clock 1 PDFDocument21 pagesWooden Clock 1 PDFAntonio Antonio NuñezPas encore d'évaluation

- Tamilnadu Engineering Admissions 2011 - Information About The CollegesDocument288 pagesTamilnadu Engineering Admissions 2011 - Information About The CollegeskayalonthewebPas encore d'évaluation

- Offshore Container (Generator Skid) Design Approval - 1Document14 pagesOffshore Container (Generator Skid) Design Approval - 1Stephen Koko100% (1)

- Vemag eDocument2 pagesVemag eJohn andre MarianoPas encore d'évaluation

- Workshop Manual DC09Document52 pagesWorkshop Manual DC09Henry Huayhua75% (8)

- New sofa collection and 7 home makeoversDocument173 pagesNew sofa collection and 7 home makeoversCarmen Draghia100% (1)

- 7300 CV Quick Start Programming GuideDocument10 pages7300 CV Quick Start Programming Guidenitin hadkePas encore d'évaluation

- Pad Eye ACS 10Document10 pagesPad Eye ACS 10irnaldi yoza wijayaPas encore d'évaluation

- Graffiti Illustrator TutorialDocument3 pagesGraffiti Illustrator TutorialDoreenPas encore d'évaluation

- 330-333 Elx PDFDocument178 pages330-333 Elx PDFNagendra Kumar PatelPas encore d'évaluation

- MCERTS Certified Continuous Emission Monitoring SystemsDocument22 pagesMCERTS Certified Continuous Emission Monitoring SystemsJoshiMBPas encore d'évaluation

- XLERPLATE Steel Size ScheduleDocument12 pagesXLERPLATE Steel Size SchedulePajaroloco CarpinteroPas encore d'évaluation

- Fisa Tehnica k65 Fitinguri Connex BanningerDocument6 pagesFisa Tehnica k65 Fitinguri Connex BanningerGabriel DobrinoiuPas encore d'évaluation

- Bord & PillarDocument25 pagesBord & PillarNikhil AllenkiPas encore d'évaluation

- Brother PT-210e, 220 Parts ManualDocument16 pagesBrother PT-210e, 220 Parts ManualDuplessisPas encore d'évaluation

- PLC Based Car Washing SystemDocument4 pagesPLC Based Car Washing Systemankush belkarPas encore d'évaluation

- Fatigue Test: ObjectiveDocument4 pagesFatigue Test: Objectiveenzo1078Pas encore d'évaluation

- O MM 8060 Series Iveco MotorsDocument79 pagesO MM 8060 Series Iveco Motorsfishhunter18100% (3)

- Gujarat, SMEDocument20 pagesGujarat, SMEDeepak Pareek100% (1)

- Orona and Lasma Reatment: N VerviewDocument25 pagesOrona and Lasma Reatment: N VerviewRaja Pathamuthu.G0% (1)