Académique Documents

Professionnel Documents

Culture Documents

PVT Properties

Transféré par

Joseph Yepez0 évaluation0% ont trouvé ce document utile (0 vote)

251 vues20 pagesPropiedades PVT

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPropiedades PVT

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

251 vues20 pagesPVT Properties

Transféré par

Joseph YepezPropiedades PVT

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 20

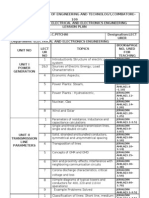

RESERVOIR ROCK AND FLUID

CHARACTERIZATION

PVT PROPERTIES OF RESERVOIR FLUIDS

LABORATORY TEST

• Characterize the phase behavior and properties of reservoir fluids at

simulated reservoir conditions.

• Reservoir fluid studies are conducted in the absence of water.

• Almost all reservoir fluid studies are conducted in the absence of a

porous medium.

• The laboratory tests are mostly depletion experiments, increasing the

fluid volume.

• Differential liberation (DL) - all the gas expelled in the test

• Constant volume depletion (CVD) - only some gas expelled in

test.

• The reduction of pressure results in the formation of a second phase

and various physical properties are measured

PVT EQUIPMENT

• Specialized equipment capable of handling high-pressure and high-

temperature conditions.

• PVT cell - the most essential component of it

• Cylindrical, special grade stainless steel or titanium

• Equipped with a mechanism to increase or decrease the cell volume

by altering the pressure.

• Housed in a thermostatic enclosure or an air bath.

• The volume of the PVT cell, ranging from 50 to about 5000 cc.

• It can be gas condensate PVT, black oil PVT, multipurpose or dual

cell PVT equipment.

PVT EQUIPMENT

CONSTANT COMPOSITION

EXPANSION (CCE) TEST

The most common test type, performed for all fluids type, also called:

• flash vaporization,

• flash liberation,

• flash expansion,

• PV relation.

CONSTANT COMPOSITION

EXPANSION (CCE) TEST

CONSTANT COMPOSITION EXPANSION

(CCE) TEST - PROCESS

1. The loaded sample is pressurized to a value equal to or greater than

the initial reservoir pressure, and the air-bath temperature is set at

reservoir temperature.

2. After the pressure and temperature conditions are stabilized, a

pressure depletion experiment is carried out by increasing the

volume in increments. The cell contents are agitated regularly to aid

the equilibration process.

3. The total and phase volumes of the hydrocarbon system are

recorded at each pressure step.

CONSTANT COMPOSITION EXPANSION

(CCE) TEST - PROCESS

4. The depletion process continues in this fashion until a

predetermined low pressure or the capacity of the cell is reached.

5. In case of windowed PVT cells, saturation pressures can also be

determined by visual observation of cell contents.

6. After completion of the test, the PV data are plotted.

CONSTANT COMPOSITION

EXPANSION (CCE) TEST

CONSTANT COMPOSITION

EXPANSION (CCE) TEST

Additionally, some properties can be measured below the saturation

pressure.

• densities,

• compositions,

• volumes,

• viscosities of the equilibrated phases,

• surface tensions

The equilibrium phase data are valuable in the calibration or tuning of

equations of state models.

CONSTANT COMPOSITION

EXPANSION (CCE) TEST

• CCE is the only main PVT test carried out for dry and wet gases.

• In case of wet gases, separate additional tests are necessary to

determine the amount and properties of produced fluids at the

surface conditions.

• In case of dry gases, the measured PV data are used to calculate the

Z factor and the gas formation volume factor. The coefficient of

isothermal compressibility factor can be calculated using the PV

relationship or from Z factor values.

• A combination of produced fluid data and the PV relationship can be

used to determine the required properties of wet gases.

DIFFERENTIAL LIBERATION (DL)

TEST

• The classical depletion experiment carried out on reservoir oils at

reservoir temperature to evaluate the volumetric and compositional

changes that take place in the oils during the primary production

process (pressure depletion).

• The process is also called:

• differential vaporization,

• differential depletion,

• differential expansion.

• As opposed to the CCE test the solution gas that is liberated from an

oil sample during a decline in pressure is continuously removed

from contact with the oil.

DIFFERENTIAL LIBERATION (DL)

TEST

DIFFERENTIAL LIBERATION (DL)

TEST - PROCESS

1. Pressure is reduced by increasing the cell volume at a pressure less

than the bubble-point pressure.

2. After achieving stabilization of pressure and temperature conditions

and the equilibrated volumes of the gas and the liquid phases, all the

evolved gas is expelled isobarically by reducing the cell volume.

3. The procedure is repeated in 10–15 pressure stages down to the

atmospheric pressure. At each pressure stage, the remaining oil

volume, the expelled gas volume at the cell conditions and standard

conditions, and the gas specific gravity are measured.

4. In the final step, cell temperature is reduced to 60°F, and the volume

of remaining liquid is measured. This volume of oil is called the

residual oil volume by DL.

DIFFERENTIAL LIBERATION (DL)

TEST

• The properties determined from DL experiments:

• gas deviation factor Z,

• formation volume factor BoD,

• total formation volume factor BtD,

• the solution GOR, RsD as a function of pressure.

(D denotes determined based on DL test)

CONSTANT VOLUME DEPLETION

(CVD) TEST

• CVD test is a classical test performed gas condensate fluids.

• The CVD test is performed to simulate the pressure depletion of the

actual reservoir, under the assumption that the retrograde liquid

appearing during production remains immobile in the reservoir.

• The test consists of a series of expansion or pressure reduction steps

in which some excess gas is expelled at constant pressure but in such

a way that the cell volume remains constant at the end of each step.

• The CVD test differs from the DL test in that not all the equilibrium

gas is removed at each pressure stage!

CONSTANT VOLUME DEPLETION

(CVD) TEST

CONSTANT VOLUME DEPLETION

(CVD) TEST - PROCESS

1. The experiment starts with a single-phase reservoir fluid sample of

known volume and composition at reservoir temperature and

pressure.

2. The pressure is reduced stepwise resulting in an expanded volume

for the fluid at each stage. At some point during the pressure

reduction, the fluid passes through the dew point. The volume at the

dew point is called the saturation volume and is considered as the

reference (constant) volume in this test.

3. At later stages, the cell pressure is reduced further below the dew-

point pressure and the excess gas is removed from the top of the cell

at constant pressure to return to the reference volume, hence the

name CVD.

CONSTANT VOLUME DEPLETION

(CVD) TEST - PROCESS

5. The gas phase removed at each stage is flashed to near-standard

conditions and analyzed to determine the composition, volume, and

compressibility factor.

6. The condensate volume in the cell is also measured at each pressure

step below the dew point. The entire CVD process is accomplished

in 5–10 pressure reduction steps down to atmospheric.

7. On termination of the test, the liquid remaining in the cell is

analyzed.

Properties of the condensate accumulated in the cell during CVD are not

measured, except in the last stage when the condensate is also expelled

from the cell. However, the condensate compositions at various pressure

stages of the CVD test can be determined from a material balance

approach.

CONSTANT VOLUME DEPLETION

(CVD) TEST

Vous aimerez peut-être aussi

- EG502A (FINAL) Well Test - Analysis and DesignDocument5 pagesEG502A (FINAL) Well Test - Analysis and DesignMohamed-DeqSabriyePas encore d'évaluation

- Five Types of Reservoir FluidsDocument24 pagesFive Types of Reservoir Fluidspriyrnjn100% (1)

- PVT Analysis Principles and ApplicationDocument2 pagesPVT Analysis Principles and ApplicationMukhtarov PgPas encore d'évaluation

- Lecture 1 Reservoir DeliverabilityDocument36 pagesLecture 1 Reservoir DeliverabilitySInowrita100% (2)

- Water Drive Oil ReservoirDocument2 pagesWater Drive Oil ReservoirJoseph YepezPas encore d'évaluation

- 4d - Reservoir Fluid Sampling and PVT Analysis and Rs CorrelationsDocument23 pages4d - Reservoir Fluid Sampling and PVT Analysis and Rs CorrelationsTHE TERMINATORPas encore d'évaluation

- SC Re Chap14 - PVTDocument109 pagesSC Re Chap14 - PVTweldsvPas encore d'évaluation

- Reservior Drive Mechanism.: Okoh Oluchi IdamDocument22 pagesReservior Drive Mechanism.: Okoh Oluchi IdamOko Id100% (1)

- Sampling TechniquesDocument7 pagesSampling Techniquesmhuf89Pas encore d'évaluation

- Reservoir Drive MechanismDocument4 pagesReservoir Drive Mechanismronak pandyaPas encore d'évaluation

- Reservoir EngineeringDocument164 pagesReservoir EngineeringPhong NguyenPas encore d'évaluation

- Reservoir Modeling For Simulation PurposesDocument7 pagesReservoir Modeling For Simulation PurposesPradityan Febri YudhistiraPas encore d'évaluation

- Res Eng PP Ch2 Reservoir PressuresDocument28 pagesRes Eng PP Ch2 Reservoir PressuresMohamed AoudiPas encore d'évaluation

- CHAPTER-16 EOR Methods PDFDocument6 pagesCHAPTER-16 EOR Methods PDFPradeep EapenPas encore d'évaluation

- Advanced Reservoir EngineeringDocument75 pagesAdvanced Reservoir Engineeringedwin mpouho100% (1)

- EOR of VNDocument26 pagesEOR of VNVann Torng BmcPas encore d'évaluation

- 4 Reservoir-Fluid-PropDocument68 pages4 Reservoir-Fluid-PropPalash Ravi Srivastava50% (2)

- Phase Behavior (Compatibility Mode)Document30 pagesPhase Behavior (Compatibility Mode)Ali RostamiPas encore d'évaluation

- Geophysic and Res ManagementDocument33 pagesGeophysic and Res Managementdina mutia sariPas encore d'évaluation

- Schedule 03Document70 pagesSchedule 03Tarek HassanPas encore d'évaluation

- Water Flooding M.techDocument65 pagesWater Flooding M.techHameed Bin AhmadPas encore d'évaluation

- Thermal Recovery: Steam DisplacementDocument46 pagesThermal Recovery: Steam DisplacementFranklyn FrankPas encore d'évaluation

- Preview of Applied MultiphaseDocument20 pagesPreview of Applied MultiphaseAngel Ngo33% (3)

- 7-Gullfaks IOR ScreeningDocument31 pages7-Gullfaks IOR ScreeningShakerMahmood100% (2)

- Chap15 - MBalDocument38 pagesChap15 - MBalSlim.BPas encore d'évaluation

- EOR Case StudiesDocument3 pagesEOR Case StudiessagarPas encore d'évaluation

- Chapter 2 - Intro To Petroleum Production (Reservoir Drive Mechanism)Document25 pagesChapter 2 - Intro To Petroleum Production (Reservoir Drive Mechanism)PrincessFaraBPPas encore d'évaluation

- Reservoir Simulation: Chapter 1: IntroductionDocument52 pagesReservoir Simulation: Chapter 1: IntroductionShakerMahmoodPas encore d'évaluation

- PTRT2323 Chapter 3-6Document52 pagesPTRT2323 Chapter 3-6Sig BahaPas encore d'évaluation

- PVT Analysis For Oil EnglishDocument4 pagesPVT Analysis For Oil EnglishPaolo RTPas encore d'évaluation

- Reservoir SimulationDocument487 pagesReservoir SimulationAbhinav Shahi100% (2)

- Reservoir Engineering-: Primary Recovery MechanismsDocument16 pagesReservoir Engineering-: Primary Recovery Mechanismsعلي حسين جميل100% (1)

- Ex2 PDFDocument1 pageEx2 PDFMusab UsmanPas encore d'évaluation

- 1 - Water and Gas Coning-AHEDocument78 pages1 - Water and Gas Coning-AHEAdel Ahmed AlkhaligyPas encore d'évaluation

- Water & Gas Coning in Horizontal & Vertical WellDocument21 pagesWater & Gas Coning in Horizontal & Vertical WellNoraeen EleanorPas encore d'évaluation

- Eclipse Tutorial 1 (3D 2-Phase) ADocument5 pagesEclipse Tutorial 1 (3D 2-Phase) AAzwar KhanPas encore d'évaluation

- Lecture - 5 - Gas in Place B MBE of Dry and Wet Gas Reservoirs (Compatibility Mode)Document47 pagesLecture - 5 - Gas in Place B MBE of Dry and Wet Gas Reservoirs (Compatibility Mode)Ibrahim_Kocabas100% (1)

- Reservoir Fluid Sampling (Lulav Saeed)Document15 pagesReservoir Fluid Sampling (Lulav Saeed)Lulav BarwaryPas encore d'évaluation

- Water Influx 1Document43 pagesWater Influx 1ChoiriahAgustinaSaritikaPutrianiPas encore d'évaluation

- Tips On Converting Prosper-PipesimDocument3 pagesTips On Converting Prosper-PipesimAkin Muhammad0% (1)

- Enhanced Oil Recovery - EOR-1Document16 pagesEnhanced Oil Recovery - EOR-1seb359Pas encore d'évaluation

- 3.3 Capillary PressureDocument78 pages3.3 Capillary PressureHind Lionne100% (1)

- Introduction To Reservoir SimulationDocument25 pagesIntroduction To Reservoir SimulationWenKhai LimPas encore d'évaluation

- Horner PlotDocument10 pagesHorner PlotUriel AlavezPas encore d'évaluation

- Water Alternating Gas (WAG)Document2 pagesWater Alternating Gas (WAG)ranjit.martisPas encore d'évaluation

- PVT ModellingDocument6 pagesPVT ModellingFan JackPas encore d'évaluation

- Assignment 1 - ProsperDocument9 pagesAssignment 1 - ProsperMuhammad Amirullah SanadiPas encore d'évaluation

- The General Material Balance Equation (GMBE)Document25 pagesThe General Material Balance Equation (GMBE)Homam MohammadPas encore d'évaluation

- Immiscible and Miscible Gases Injection To Improve Oil Recovery in Oil ReservoirsDocument12 pagesImmiscible and Miscible Gases Injection To Improve Oil Recovery in Oil ReservoirsAli MahmoudPas encore d'évaluation

- EOR Sim - MZA4Document16 pagesEOR Sim - MZA4Tpegteam TrainingPas encore d'évaluation

- Prosper® Tutorial 08: Modelling A Gas Well With Connected PipelineDocument9 pagesProsper® Tutorial 08: Modelling A Gas Well With Connected PipelinePedro MarquezPas encore d'évaluation

- MSC (PET) 02reservoir Production Concept-6 SlidesDocument11 pagesMSC (PET) 02reservoir Production Concept-6 SlidesUsman HasanPas encore d'évaluation

- Composition & PVT (Fluid Properties As A Function of Pressure, Volume and Temperature)Document31 pagesComposition & PVT (Fluid Properties As A Function of Pressure, Volume and Temperature)Aamir LokhandwalaPas encore d'évaluation

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsD'EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsPas encore d'évaluation

- Thermal Properties and Temperature-Related Behavior of Rock/Fluid SystemsD'EverandThermal Properties and Temperature-Related Behavior of Rock/Fluid SystemsPas encore d'évaluation

- Offshore Gas Hydrates: Origins, Development, and ProductionD'EverandOffshore Gas Hydrates: Origins, Development, and ProductionPas encore d'évaluation

- Practical Petroleum Geochemistry for Exploration and ProductionD'EverandPractical Petroleum Geochemistry for Exploration and ProductionPas encore d'évaluation

- Microbial Enhancement of Oil Recovery - Recent AdvancesD'EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesPas encore d'évaluation

- Quantifying Uncertainty in Subsurface SystemsD'EverandQuantifying Uncertainty in Subsurface SystemsCéline ScheidtPas encore d'évaluation

- Retrograde Condensate ReservoirDocument10 pagesRetrograde Condensate ReservoirLuchito Canteen SPas encore d'évaluation

- Consideraciones Geológicas y AnticolisiónDocument15 pagesConsideraciones Geológicas y AnticolisiónJoseph YepezPas encore d'évaluation

- Density Log PDFDocument22 pagesDensity Log PDFJoseph YepezPas encore d'évaluation

- IntroducciónDocument35 pagesIntroducciónJoseph YepezPas encore d'évaluation

- Tarner Method - Oil ReservoirDocument1 pageTarner Method - Oil ReservoirJoseph YepezPas encore d'évaluation

- Open Hole Log 6 PDFDocument14 pagesOpen Hole Log 6 PDFJoseph YepezPas encore d'évaluation

- Oil and Gas Reservoir ProblemsDocument1 pageOil and Gas Reservoir ProblemsJoseph YepezPas encore d'évaluation

- Oil and Gas Reservoir ProblemsDocument1 pageOil and Gas Reservoir ProblemsJoseph YepezPas encore d'évaluation

- Gas Cap Oil ReservoirDocument1 pageGas Cap Oil ReservoirJoseph YepezPas encore d'évaluation

- Gas Cap Oil ReservoirDocument10 pagesGas Cap Oil ReservoirJoseph YepezPas encore d'évaluation

- Deber L: Da Ge6 / EteioDocument4 pagesDeber L: Da Ge6 / EteioJoseph YepezPas encore d'évaluation

- 2.1 Gas Reservoir MBE Method With Water InfluxDocument1 page2.1 Gas Reservoir MBE Method With Water InfluxJoseph YepezPas encore d'évaluation

- Reservoir Engineering I: Oil PropertiesDocument25 pagesReservoir Engineering I: Oil PropertiesJoseph YepezPas encore d'évaluation

- Deber 2 ElectrónicaDocument4 pagesDeber 2 ElectrónicaJoseph YepezPas encore d'évaluation

- Reservoir Engineering Ii: Gas ReservoirsDocument19 pagesReservoir Engineering Ii: Gas ReservoirsJoseph YepezPas encore d'évaluation

- Gas Reservoir Material BalanceDocument9 pagesGas Reservoir Material BalanceJoseph YepezPas encore d'évaluation

- Class 4-Social Studies-Digital Module 1-15-11th June 2020Document10 pagesClass 4-Social Studies-Digital Module 1-15-11th June 2020stephen_george_29Pas encore d'évaluation

- Values of Safe Bearing CapacityDocument2 pagesValues of Safe Bearing CapacityChee Soon LeePas encore d'évaluation

- WeCommunities - BrochureDocument6 pagesWeCommunities - BrochurejayanthfunucationPas encore d'évaluation

- Taxonomy Test Review With ANSDocument4 pagesTaxonomy Test Review With ANSdani abrahaPas encore d'évaluation

- World Energy Council 2013 World Energy Resources: CoalDocument32 pagesWorld Energy Council 2013 World Energy Resources: CoalIswan ArpadiPas encore d'évaluation

- Energy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsDocument6 pagesEnergy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsЈово КруљPas encore d'évaluation

- Ee2303 Newlp ADocument3 pagesEe2303 Newlp ARavi KannappanPas encore d'évaluation

- (CSEC Chemistry) Section A Notes and ESQsDocument191 pages(CSEC Chemistry) Section A Notes and ESQsNathaniel WhytePas encore d'évaluation

- Chemistry: Ogun State School of Nursing Practice Questions For Enterance EXAMS 2022Document103 pagesChemistry: Ogun State School of Nursing Practice Questions For Enterance EXAMS 2022mariamojelade5Pas encore d'évaluation

- Devoll Hydro Power (DHP), AlbaniaDocument122 pagesDevoll Hydro Power (DHP), AlbaniaSai SandeepPas encore d'évaluation

- Hiring of Consultant For DFR of 9MW Ground Mounted Solar ProjectDocument2 pagesHiring of Consultant For DFR of 9MW Ground Mounted Solar ProjectsubudhiprasannaPas encore d'évaluation

- Concept: Subject-General ScienceDocument2 pagesConcept: Subject-General SciencetrevorPas encore d'évaluation

- Steam Circuit Diagram PDFDocument1 pageSteam Circuit Diagram PDFAgeng Firstyan BagaskoroPas encore d'évaluation

- SustainabilityDocument33 pagesSustainabilityConstanza CabreraPas encore d'évaluation

- NLSP I - RubberDocument27 pagesNLSP I - RubberbalachandarPas encore d'évaluation

- Fire Explosion HazardsDocument91 pagesFire Explosion HazardsJoao Santos100% (2)

- EWG LUT 100RE All Sectors Global Report 2019 PDFDocument321 pagesEWG LUT 100RE All Sectors Global Report 2019 PDFPai BuabthongPas encore d'évaluation

- Rocks & Energy Chapter 1 & 2 Environmental Management 0680 Geography GCSE IGCSE O-LevelsDocument108 pagesRocks & Energy Chapter 1 & 2 Environmental Management 0680 Geography GCSE IGCSE O-LevelsIGCSE Physics & Chemistry100% (1)

- Ingeteam Wind Converter Catalogue 2019Document4 pagesIngeteam Wind Converter Catalogue 2019FBPas encore d'évaluation

- Recycling of Waste PlasticDocument41 pagesRecycling of Waste Plasticcreativemadhusr100% (2)

- Student Exploration: Limiting ReactantsDocument2 pagesStudent Exploration: Limiting ReactantsaefPas encore d'évaluation

- Energetic Chemistry TestDocument10 pagesEnergetic Chemistry Testmuhammad naufalPas encore d'évaluation

- Rab 5 KW PAK PURDocument3 pagesRab 5 KW PAK PURilhamPas encore d'évaluation

- A Presentation On: "Multi-Terminal High Voltage Direct Current Transmission"Document22 pagesA Presentation On: "Multi-Terminal High Voltage Direct Current Transmission"Manish Kumar MeenaPas encore d'évaluation

- ModelQuestionsCh16 AKDocument5 pagesModelQuestionsCh16 AKYasmeen ElsawafPas encore d'évaluation

- Anthropo-Saline and Karsto-Saline Lakes From Ocna Şugatag - Maramureş (Romania)Document11 pagesAnthropo-Saline and Karsto-Saline Lakes From Ocna Şugatag - Maramureş (Romania)Andreea StamatePas encore d'évaluation

- Minimum Ignition Energy of A Dust Cloud in Air: Standard Test Method ForDocument8 pagesMinimum Ignition Energy of A Dust Cloud in Air: Standard Test Method ForMahletmelaku100% (1)

- Economic Dispatch For A Microgrid Considering Renewable Energy Cost FunctionsDocument7 pagesEconomic Dispatch For A Microgrid Considering Renewable Energy Cost FunctionsEdwinPas encore d'évaluation

- Cie QDocument17 pagesCie Qinternationalmakkhayar100% (1)

- Physical ScienceDocument5 pagesPhysical ScienceJazz AddPas encore d'évaluation