Académique Documents

Professionnel Documents

Culture Documents

Aseptic Techniques: Preventing Contamination in Sterile Environments

Transféré par

Shashidhar Shashi0 évaluation0% ont trouvé ce document utile (0 vote)

77 vues26 pagesAseptic techniques refer to procedures performed under sterile conditions to prevent microbial contamination, especially in medical and laboratory settings. Key aspects of aseptic technique include the design of aseptic areas with features like laminar airflow systems, strict environmental controls to limit particles and microbes, and preventive measures for sources of contamination from air, fluids, and personnel. The goal is to provide sterilized protection against infections by maintaining minimal levels of pathogens.

Description originale:

Titre original

ASEPTIC TECHNIQUES.pptx

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentAseptic techniques refer to procedures performed under sterile conditions to prevent microbial contamination, especially in medical and laboratory settings. Key aspects of aseptic technique include the design of aseptic areas with features like laminar airflow systems, strict environmental controls to limit particles and microbes, and preventive measures for sources of contamination from air, fluids, and personnel. The goal is to provide sterilized protection against infections by maintaining minimal levels of pathogens.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

77 vues26 pagesAseptic Techniques: Preventing Contamination in Sterile Environments

Transféré par

Shashidhar ShashiAseptic techniques refer to procedures performed under sterile conditions to prevent microbial contamination, especially in medical and laboratory settings. Key aspects of aseptic technique include the design of aseptic areas with features like laminar airflow systems, strict environmental controls to limit particles and microbes, and preventive measures for sources of contamination from air, fluids, and personnel. The goal is to provide sterilized protection against infections by maintaining minimal levels of pathogens.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 26

ASEPTIC TECHNIQUES

• Aseptic technique refers to a procedure that is performed

under sterile conditions.

This includes medical and laboratory techniques which deal

with cultures and human cells and tissue for transplantation.

• What is the Aim of Aseptic Technique?

• To prevent the access of micro-organisms during the

preparation and testing.

Requirements for design of aseptic

area

• Aseptic techniques are defined as a set of procedures

carried out to obtain an environment with minimal

contamination from pathogenic microorganisms.

• These procedures are carried out under controlled

conditions.

• The main goal of aseptic technique is to provide

protection against infections.

• 1.Site of premises

Aseptic area should be designed at a site away from stairs, lift

shafts , corridors and general manufacturing area as these areas

are capable of providing routes by which microorganisms may

travel.

Each stage of the production should be carried out in separate

rooms of aseptic area.

Store rooms should be adjacent to aseptic area where all sterile

equipments and products can be stored.

2.Size of premises

Aseptic area should be constructed in such a manner that

maximum number of personnels can work at a time.

The rooms should be large and spacious by which overall effect of

microorganisms can be reduced which ultimately results in

minimal contamination.

3.Windows

• Large windows with transparent glass are suitable for aseptic area.

• These windows should remain closed and ventilation should be provided

artificially by air filtration system.

• These type of windows are used to prevent heat loss from glass material.

4.Doors

Entrance should have double doors with an air-lock system.

In this way, air entering from outside into the aseptic area can be prevented .

Even sliding and swing doors can be used.

5.Floors, walls and bench tops

The floor, walls and bench tops should be, 1. Easy to clean 2. Smooth with no

cracks and pores 3. Impervious to cleaning agents like disinfectants etc 4.

Chemically resistant to solvents, dyes, strong acids or alkalis.

Floor It should be made up of the following materials, a) Terrazzo b) Linoleum

c) plastics

• Walls and ceiling

• They should have surfaces made up of,

a) Tiles – they are smooth, non-absorbent in nature and tend to

crack on prolonged usage. They can be easily cleaned.

b) Glass paint – this type of paint is applied on smooth plaster.

These plaster walls get easily damaged.

c) Plastic laminate – this type of material I used to cover the walls

and ceiling of an aseptic room. However, it is expensive.

Tops of working bench

The tops of the working benches should be made up either of the

following materials.

a) Stainless steel – the screws used in benches should be located

under the surface of the bench to avoid accumulation of the

dust.

b) Plastic laminates – they are available in various bright colors.

Types of laminar flow systems

• laminar air flow systems are generally of three

types.

1. Vertical flow system

2. Horizontal flow system

3. Wall to floor flow system

• This system consists of false floor & ceiling

• The air is filtered through pre-filters, electroststic filters

and HEPA filters in sequence

• These 3 filters are placed in false ceiling

• From the false floor, a small portion of filtered air is

recirculated in to false ceiling through a recirculation

duct

Advantages:

• The operating area is provided with exhaust filters

which remove the remaining portion of the air.

• This provides protection to the operator.

• It is more preferable when compared to horizontal flow

systems.

Disadvantages: It is an expensive system as it requires

double installation of HEPA filters.

• The air is filtered through prefilters, HEPA filters

which are placed in lateral walls.

• Air is recirculated through punched plate wall

or recirculation duct.

• Achievement of complete sterile conditions is

not possible because the airflow is not focused

on working area

• Disadvantage: During the handling of materials

like antineoplastic drugs, this system fails to

provide protection to the operator.

• The filtered air enters from the lateral wall

with an inclined flow towards the floor.

• This system offers high aseptic conditions.

Advantage:

• The system is portable.

Disadvantage:

It is expensive.

Sources of contamination and

methods of prevention

Contamination, in broad sense, is the presence of minor

unwanted particulate matter called contaminants in

atmosphere, physical body, work station etc.

Right from production to packaging almost every

sector of pharmaceutical industry comes across

contamination. The most common sources of

contamination fall into the following three main

categories:

Atmospheric contamination

Fluid contamination

Transfer contaminants.

1.Atmospheric contamination

Atmospheric conditions during manufacturing as well as during

storage affects the quality of final preparation.

Atmosphere in and around the industrial area contains

potential contaminants like dust, silica etc and gases like

Co2 , water vapor etc.

Besides the above mentioned contaminants, microorganisms

like P.aeruginosa, A.niger etc.

These contaminants may get incorporated into the end

product either during the process of manufacturing or

during purification.

• Prevention:

Prior to its entry into the working area, the air should be

initially passed through a suitable prefilter then treated with

an electrostatic precipitator and finally through HEPA filters.

Periodic removal of air-borne dust settled on walls, floors

and ceilings is essential.

Fluid contamination

• Besides serving as the most common solvent in pharmaceutical

industry, water also serves as the greatest solvent in pharmaceutical

industry.

• Although, it is deprived of most of the contaminants yet it contains

pyrogens and traces of sulphates, chlorides and carbonates of Ca, Mg

and Na.

• Therefore, usage of water for washing the machineries and working

areas may leave traces of these contaminants.

Prevention:

• Almost all of the pharmaceutical operations should be carried out using

purified water obtained upon deionization, distillation, ion- exchange,

reverse osmosis, filtration or other similar processes.

• For the preparation of parenterals, water for injection, sterile water for

injection or bacteriostatic water for injection must be employed.

• 3.Transfer contaminants

Transfer contaminants refer to the contaminants

sourced from personnel and wheels of trolleys

used for transport of goods.

Personnel working in aseptic areas, if suffering

from cold, allergies, dermatological conditions or

any similar illness carry multiple microorganisms

which upon expulsion into atmosphere via

sneezing, coughing, talking etc., can lead to

contamination.

For example, atmospheric dust particles may get

entangled with the fibres of the clothes which can

get dislodged due to body movements and lead to

contamination.

• Prevention:

Personnel should be well trained and periodically evaluated in the

principles of aseptic processing and techniques to be employed

before participating in the preparation of sterile products.

Apart from gown, the personnel area also required to put on face

mask, head cap, gloves, foot covers and even goggle to ensure

complete coverage of all skin areas.

The entrance of most of the working areas is equipped with air

blowers that aid in removing any loose dirt, lint from uniform of the

operators.

Those mechanical pars of the equipments that come in contact with

the parenteral products should be demountable which enables

their easy cleaning and sterilization.

All the apparatus and their carriers being carried to the aseptic

areas should be sterilized by suitable methods.

Environmental control

• The environmental control maintained is different

for different areas.

• Stringent environmental control is required

before and during the processing of parenterals

to assure an area free from contamination and

where there is no accumulation of dust particles,

lint, viable microorganisms etc.

• Production environment is constantly monitored

and evaluated to assure that the required aseptic

conditions are maintained.

• Various evaluation tests are available to

evaluate the environmental control.

1. Particle count

2. Slit to agar (STA) sampler

3. Rodac plates

• Particle count

• The number of particles in a volume of air sample

is measured by particle measuring systems which

not only count the particles but also provide size

distribution details based on the magnitude of

light scattered by the particles

• This instrument although detects all forms of

particulate matter but fails to differentiate

between viable and non-viable forms.

• 2.Slit to Agar (STA) Sampler

• This device consists of a rotating agar plate

comprising of a slit through which measured

amount of air is accumulated by applying

vacuum.

• This air comes in contact with the surface of the

agar plate.

• Viable microorganisms stick to the surface of the

agar plate and start growing in the form of

colonies that are counted as colony forming units

(CFUs).

3.Rodac plates These plates

consists of nutrient agar with

a convex surface which is

rolled on the surface to be

tested. Microorganisms

stick to the surface of agar

following which the plates are

incubated.

Vous aimerez peut-être aussi

- Cleanroom Technology: Fundamentals of Design, Testing and OperationD'EverandCleanroom Technology: Fundamentals of Design, Testing and OperationPas encore d'évaluation

- Aseptic Processing of Parenteral ProductsDocument50 pagesAseptic Processing of Parenteral ProductsHanuma KanthetiPas encore d'évaluation

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryD'EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryPas encore d'évaluation

- Designing Aseptic Areas to Prevent ContaminationDocument26 pagesDesigning Aseptic Areas to Prevent ContaminationSmk Mahmud KoliPas encore d'évaluation

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsD'EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsPas encore d'évaluation

- Production Facilities: Aseptic Area: This Area Is The Heart of Sterile Product OperationDocument18 pagesProduction Facilities: Aseptic Area: This Area Is The Heart of Sterile Product Operationmonoj5859100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Design of Aseptic Area-KDBDocument21 pagesDesign of Aseptic Area-KDBKiran0% (1)

- Air Sanitation SystemsDocument29 pagesAir Sanitation SystemsmanmithPas encore d'évaluation

- Aseptic Area:: DefinitionDocument4 pagesAseptic Area:: DefinitionNon.d AlmalkiPas encore d'évaluation

- Design of aseptic areaDocument5 pagesDesign of aseptic areaSayyeda SumaiyahPas encore d'évaluation

- Basic Requirements For Clean RoomDocument6 pagesBasic Requirements For Clean Roomsamuel debebePas encore d'évaluation

- TEORI DAN PRINSIP DASAR TEKNIK ASEPTIKDocument43 pagesTEORI DAN PRINSIP DASAR TEKNIK ASEPTIKPraditya 00Pas encore d'évaluation

- ??????? WPS OfficeDocument15 pages??????? WPS Officeஎன்றும் அன்புடன் செல்லமுத்து சுரேந்தர்Pas encore d'évaluation

- Effective Contamination Control, Cleanroom Protocols, & Lab SafetyDocument60 pagesEffective Contamination Control, Cleanroom Protocols, & Lab SafetyFauzan BakriPas encore d'évaluation

- The Importance of HVAC Systems in Hospitals: KeyterDocument9 pagesThe Importance of HVAC Systems in Hospitals: KeyterAnonymous yniiLtiPas encore d'évaluation

- VentilationDocument34 pagesVentilationmohammed hussienPas encore d'évaluation

- Media and Bioreactor Sterilization Techniques: Manam Walait Lecturer FLS, UCP LahoreDocument12 pagesMedia and Bioreactor Sterilization Techniques: Manam Walait Lecturer FLS, UCP LahoreJawadPas encore d'évaluation

- AIRCONDITIONING BASICS GUIDEDocument61 pagesAIRCONDITIONING BASICS GUIDESaba ArifPas encore d'évaluation

- Pharmaceutical Clean RoomDocument32 pagesPharmaceutical Clean RoomMustafizur Rahman AviPas encore d'évaluation

- Laminar Air Flow FinalDocument7 pagesLaminar Air Flow FinalSafa KhurramPas encore d'évaluation

- Duct Cleaning PDFDocument4 pagesDuct Cleaning PDFMaazARazaPas encore d'évaluation

- Aseptic Techniques MFG IIDocument84 pagesAseptic Techniques MFG IIapi-197854430% (1)

- 09 SterilizationDocument34 pages09 Sterilizationitung2350% (2)

- Production AreasDocument8 pagesProduction AreasAmruta PusuluriPas encore d'évaluation

- 6 ParenteralDocument36 pages6 ParenteralVipin Valappil100% (1)

- 2021 Lecture 2 Laboratory Layout and ContaminationDocument58 pages2021 Lecture 2 Laboratory Layout and ContaminationNur RazinahPas encore d'évaluation

- Guidance On Designing Aseptic Area For GMP ManufacturingDocument39 pagesGuidance On Designing Aseptic Area For GMP ManufacturingLeilPas encore d'évaluation

- ME4102 MedTech - Week 3 LecDocument32 pagesME4102 MedTech - Week 3 LecLeonelPas encore d'évaluation

- Operating RoomDocument23 pagesOperating RoomTheresa Bread83% (6)

- Lecture 3 PharmaceuticalDocument13 pagesLecture 3 PharmaceuticalNIMRAHPas encore d'évaluation

- Manufacturing Pollutants Microbes Aerosol: Clean RoomsDocument11 pagesManufacturing Pollutants Microbes Aerosol: Clean RoomsPrasanth H UPas encore d'évaluation

- STERILISATION METHODSDocument44 pagesSTERILISATION METHODSRanganathan IyerPas encore d'évaluation

- Aseptic TechniquesDocument12 pagesAseptic TechniquesTanu nathnaiPas encore d'évaluation

- Bio Safety in Operation Theaters in O TDocument47 pagesBio Safety in Operation Theaters in O Ttummalapalli venkateswara raoPas encore d'évaluation

- QC Qa NotesDocument66 pagesQC Qa Noteskavya nainitaPas encore d'évaluation

- Air Pollution Control TechnologiesDocument16 pagesAir Pollution Control Technologiesdhanya100% (1)

- Clean Room - PPT 1Document30 pagesClean Room - PPT 1Jaswant Singh100% (1)

- GMP Element 1 (MS1514 - 2009), The Confusion Among Consultants.Document47 pagesGMP Element 1 (MS1514 - 2009), The Confusion Among Consultants.0132571489Pas encore d'évaluation

- Sterilization of AirDocument5 pagesSterilization of AirBeena KakranPas encore d'évaluation

- 2 - Principles of Sterilization.Document76 pages2 - Principles of Sterilization.Mitchelle Sauramba0% (1)

- CGMP Regulations of Sterile ProductsDocument33 pagesCGMP Regulations of Sterile ProductsSukesh Potla75% (4)

- Integrated circuit packaging and clean room classificationDocument7 pagesIntegrated circuit packaging and clean room classificationDramq XkingxPas encore d'évaluation

- Laminar Flow Hoods & Biological Safety CabinetsDocument2 pagesLaminar Flow Hoods & Biological Safety CabinetsShaezarah MohamudallyPas encore d'évaluation

- 09 Sterilization PDFDocument34 pages09 Sterilization PDFDian NurdianaPas encore d'évaluation

- Clean Room TextilesDocument21 pagesClean Room TextilesaniketPas encore d'évaluation

- DETERMINING MICROBIOLOGICAL CONTAMINATION USING MFDocument2 pagesDETERMINING MICROBIOLOGICAL CONTAMINATION USING MFMUHAMMAD SOHAIBPas encore d'évaluation

- Prevention of Cross - Contamination by HVAC in Pharmaceuticals - Pharmaceutical GuidelinesDocument2 pagesPrevention of Cross - Contamination by HVAC in Pharmaceuticals - Pharmaceutical GuidelinesShoaib BiradarPas encore d'évaluation

- Isolators Vs Biological Safety Cabinets: Learning ObjectivesDocument10 pagesIsolators Vs Biological Safety Cabinets: Learning Objectivesแทฮัน ออมม่าPas encore d'évaluation

- Animal Cell and Tissue Culture: Lab Practice RequirementsDocument26 pagesAnimal Cell and Tissue Culture: Lab Practice RequirementsN. Beauregard이진기Pas encore d'évaluation

- Snails Containment GuidelinesDocument11 pagesSnails Containment GuidelinesVladut BratfaleanPas encore d'évaluation

- Operating Room 2Document66 pagesOperating Room 2Ogy Ayop Mummy UddinPas encore d'évaluation

- Infection Control in Surgical PracticeDocument41 pagesInfection Control in Surgical PracticeMuhammad Azeem KhanPas encore d'évaluation

- ASEPTIC FILL CLEANING VALIDATIONDocument9 pagesASEPTIC FILL CLEANING VALIDATIONangel vencesPas encore d'évaluation

- Clean RoomDocument20 pagesClean RoomSuchitK100% (1)

- Pharmaceutical Sterile Praperation 1682157653Document8 pagesPharmaceutical Sterile Praperation 1682157653Nour MohamedPas encore d'évaluation

- VrateshDocument14 pagesVrateshvaippapatelPas encore d'évaluation

- Annex 5 MANUFACTURE OF IMMUNOLOGICAL VETERINARYDocument8 pagesAnnex 5 MANUFACTURE OF IMMUNOLOGICAL VETERINARYTrường Tuấn Anh ĐỗPas encore d'évaluation

- Topic: Methods For Treating Air Discharges From Industry: National University of Science and TechnologyDocument25 pagesTopic: Methods For Treating Air Discharges From Industry: National University of Science and TechnologyTeererai KaguraPas encore d'évaluation

- Biopharmaceutics - BrahmankarDocument414 pagesBiopharmaceutics - Brahmankarmatin586% (57)

- Behavior Classified As Unfair CompetitionDocument8 pagesBehavior Classified As Unfair CompetitionShashidhar ShashiPas encore d'évaluation

- On-Line Classes For GPAT Examination: ProgramDocument3 pagesOn-Line Classes For GPAT Examination: ProgramShashidhar ShashiPas encore d'évaluation

- Sample 20845Document16 pagesSample 20845Shashidhar Shashi0% (1)

- Evaluation of Cardioprotective Activity of Allium Cepa Aerial LeavesDocument4 pagesEvaluation of Cardioprotective Activity of Allium Cepa Aerial LeavesShashidhar ShashiPas encore d'évaluation

- Literature Review: Polyherbal Formulation "Renolith" For Renal Stone and Found PhytochemicalDocument6 pagesLiterature Review: Polyherbal Formulation "Renolith" For Renal Stone and Found PhytochemicalShashidhar ShashiPas encore d'évaluation

- Cardioprotective Effects of The Garlic (Allium Sativum) in Sodium Fluoride-Treated RatsDocument7 pagesCardioprotective Effects of The Garlic (Allium Sativum) in Sodium Fluoride-Treated RatsShashidhar ShashiPas encore d'évaluation

- 2530-Article Text-6819-1-10-20151218 PDFDocument4 pages2530-Article Text-6819-1-10-20151218 PDFShashidhar ShashiPas encore d'évaluation

- 2530-Article Text-6819-1-10-20151218 PDFDocument4 pages2530-Article Text-6819-1-10-20151218 PDFShashidhar ShashiPas encore d'évaluation

- Antiurolithiatic Activity of The Plant Extracts of Solanum Virginianum On Ethylene Glycol Induced Urolithiasis in RatsDocument7 pagesAntiurolithiatic Activity of The Plant Extracts of Solanum Virginianum On Ethylene Glycol Induced Urolithiasis in RatsShashidhar ShashiPas encore d'évaluation

- Share AdsDocument1 pageShare AdsShashidhar ShashiPas encore d'évaluation

- INDONESIANJDocument9 pagesINDONESIANJShashidhar ShashiPas encore d'évaluation

- Elisa LectureDocument20 pagesElisa LectureDesriwanAnggaMedicaPas encore d'évaluation

- GPAT 14 P'cognosyDocument18 pagesGPAT 14 P'cognosyGANESH KUMAR JELLA86% (7)

- ScreeningDocument2 pagesScreeningShashidhar ShashiPas encore d'évaluation

- Pharmacological Screening of Monotheca Buxifolia F PDFDocument8 pagesPharmacological Screening of Monotheca Buxifolia F PDFShashidhar ShashiPas encore d'évaluation

- Colony Counter PDFDocument7 pagesColony Counter PDFasrianiPas encore d'évaluation

- Microbial Limit TestDocument29 pagesMicrobial Limit TestJai MurugeshPas encore d'évaluation

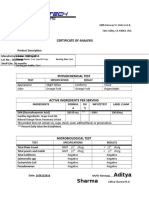

- Certificate of Analysis: CommentsDocument2 pagesCertificate of Analysis: Commentsapi-521865944Pas encore d'évaluation

- Effects of Storage Temperature and Water Activity On TheDocument6 pagesEffects of Storage Temperature and Water Activity On TheAzmier AdibPas encore d'évaluation

- Standard-Setting Quality Without Compromising Your SafetyDocument4 pagesStandard-Setting Quality Without Compromising Your Safetysagor sagorPas encore d'évaluation

- CLEDDocument4 pagesCLEDMongiwethu DungeniPas encore d'évaluation

- Intl Journal of Cancer - 2014 - Lakritz - Beneficial Bacteria Stimulate Host Immune Cells To Counteract Dietary and GeneticDocument12 pagesIntl Journal of Cancer - 2014 - Lakritz - Beneficial Bacteria Stimulate Host Immune Cells To Counteract Dietary and GeneticTrang MốcPas encore d'évaluation

- Essential Oils and Herbal Extracts Show Stronger Antimicrobial Activity than Methylparaben in Cosmetic EmulsionDocument6 pagesEssential Oils and Herbal Extracts Show Stronger Antimicrobial Activity than Methylparaben in Cosmetic EmulsionxiuhtlaltzinPas encore d'évaluation

- Food Microbiology: Peter Kotsoana Montso, Victor Mlambo, Collins Njie AtebaDocument10 pagesFood Microbiology: Peter Kotsoana Montso, Victor Mlambo, Collins Njie AtebaNithin SakthiPas encore d'évaluation

- Hebicsus PDFDocument6 pagesHebicsus PDFJohnPas encore d'évaluation

- Bl-SOP-067 Environmental SOPDocument5 pagesBl-SOP-067 Environmental SOPnishthaPas encore d'évaluation

- 2019 - 23230 Envirocheck Datasheet Contact TVC MRK Final WebDocument2 pages2019 - 23230 Envirocheck Datasheet Contact TVC MRK Final WebNauman Khitran100% (1)

- 2014 - Montei Soleris NFTVC Cocoa Liquor and ButterDocument4 pages2014 - Montei Soleris NFTVC Cocoa Liquor and Butterjasminetsai421Pas encore d'évaluation

- Validation Procedure For Salmonella in Desiccated Coconut Draft - 0814119Document3 pagesValidation Procedure For Salmonella in Desiccated Coconut Draft - 0814119Kathreen Rodriguez DimalibotPas encore d'évaluation

- Recovery of ACB From Inhibitory Fruit JC PDFDocument4 pagesRecovery of ACB From Inhibitory Fruit JC PDFopenid_mRbxHxDCPas encore d'évaluation

- Lab 01 - Streaking For Isolation and Interpreting Primary Culture ResultsDocument18 pagesLab 01 - Streaking For Isolation and Interpreting Primary Culture ResultsVincent ReyesPas encore d'évaluation

- Yuan2012 Article BiodegradationOf2-methylisoborDocument10 pagesYuan2012 Article BiodegradationOf2-methylisoborJOSE ANDRES FERNANDEZ O.Pas encore d'évaluation

- Mic Bro003 HBL 02 00 19 12 2019 EN2Document2 pagesMic Bro003 HBL 02 00 19 12 2019 EN2CARLOS EVELIO CAMARGO HENAOPas encore d'évaluation

- 980.31 Bacillus Cereus en Alimentos - Enumeracion y ConfirmaciònDocument2 pages980.31 Bacillus Cereus en Alimentos - Enumeracion y Confirmaciòndlinareszabaleta100% (2)

- The Microbiology of Drinking Water (2013) - Part 7 - Methods For The Enumeration of Heterotrophic BacteriaDocument29 pagesThe Microbiology of Drinking Water (2013) - Part 7 - Methods For The Enumeration of Heterotrophic BacteriaRoyal BimhahPas encore d'évaluation

- Certificate of Analysis - DHA LiquidDocument1 pageCertificate of Analysis - DHA Liquidwaterwood3388100% (1)

- Kimchi 1Document10 pagesKimchi 1AlfiNurfauziah100% (1)

- Sop For Environmental Monitoring For PersonnelDocument4 pagesSop For Environmental Monitoring For PersonnelMusyoka UrbanusPas encore d'évaluation

- Descrição MPN em RDocument8 pagesDescrição MPN em RNilson BispoPas encore d'évaluation

- Automated Counting of Bacterial Colony Forming UnitsDocument6 pagesAutomated Counting of Bacterial Colony Forming UnitsRicardo Prieto MallquiPas encore d'évaluation

- Microbiological Testing of BeveragesDocument20 pagesMicrobiological Testing of BeveragesSahil Sethi100% (1)

- SFDA GMP Inspectors Workshop on Sterile Medicine ManufacturingDocument37 pagesSFDA GMP Inspectors Workshop on Sterile Medicine ManufacturingNuzul DianperdanaPas encore d'évaluation

- Bacteriological Analysis of Salad Vegetable in Eke Awka Market, Anambra State, NigeriaDocument8 pagesBacteriological Analysis of Salad Vegetable in Eke Awka Market, Anambra State, NigeriaJASH MATHEWPas encore d'évaluation

- MomohDocument4 pagesMomohWilliam GonzalesPas encore d'évaluation

- Caries Detection Diagnosis, Caries Suseptability and Caries Activity TestsDocument144 pagesCaries Detection Diagnosis, Caries Suseptability and Caries Activity TestsrakshaPas encore d'évaluation