Académique Documents

Professionnel Documents

Culture Documents

3.AH Performance

Transféré par

dreamboy870 évaluation0% ont trouvé ce document utile (0 vote)

17 vues20 pagesAH

Copyright

© © All Rights Reserved

Formats disponibles

PPT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentAH

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

17 vues20 pages3.AH Performance

Transféré par

dreamboy87AH

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 20

AIR HEATER PERFORMANCE

• GAS OUTLET • GAS OUTLET

TEMPERATURE TEMPERATURE

LOWER THAN HIGHER THAN

OPTIMUM OPTIMUM

– LEADS TO COLD – MORE DRY GAS LOSS

END CORROSION – RISE OF 220C ABOVE

• LOSS OF HEAT OPTIMUM REDUCE

TRANSFER BOILER EFFICIENCY

ELEMENTS

BY 1%

– 20C RISE ABOVE

OPTIMUM RESULTS

LOSS OF 600Kcal HEAT

IN 1 TONNE OF F.G.

FACTORS AFFECTING A.H. GAS

OUTLET TEMPERATURE

• LOWER THAN • HIGHER THAN OPTIMUM

OPTIMUM – QTY. OF AIR PASSING THROUGH

– LIGHTING AND A.H.

FIRING COLD • TEMPERING AIR

• SETTING INFILTRATION

BOILER

• BYPASS DAMPERS PASSING

• USE SCAPH

– TEMP.OF GAS ENTERING A.H

– AIR LEAKAGE

• DEPOSITS ON BOILER HEAT TRANSFER

• SEALS CONDITON AREAS

• DIFF. PR. • DELAYED/SY.COMBUSTION

BETWEEN AIR AND

• FEED WATER TEMP

F.G

– FOULED / CORRODED ELEMENTS

– DEFECTIVE BAFFLES

– QTY.OFGAS PASSING THROUGH

A.H.

AIR HEATER PERFORMANCE TESTS

• REQUIREMENTS

– CHECKING ACTUAL PERFORMANCE

AGAINST MANUFACTURER’S GUARANTEE

– COMPARISON WITH A STANDARD OF

OPERATION

– COMPARING PERFORMANCE WHEN FIRING

DIFFERENT FUELS

– DETERMINING THE EFFECTS OF CHANGES

TO EQUIPMENT

– DETERMINING CORRECTIONS TO A.H.

EXITGAS TEMP. CAUSED BY VARIATIONS IN

INLET TEMP. IN AN EFFICIENCY TEST OF A

BOILER

AIR HEATER PERFORMANCE

TESTS

• PERFORMANCE ITEMS DETERMINED

– GAS SIDE EFFICIENCY

– AIR LEAKAGE

– X-RATIO

– GAS AND AIR TEMPERATURE

CORRECTIONS

– GAS AND AIR PRESSURE LOSS

DATA REQUIRED FOR A.H.

PERFORMANCE TESTS

• TEMP.OF AIR ENTERING

• TEMP.OF AIR LEAVING

• TEMP.OF GAS ENTERING

• TEMP.OF GAS LEAVING

• QTY. OF AIR ENTERING

• QTY. OF HEATED AIR LEAVING

• AIR SIDE INLET AND OUTLET STATIC PRESSURE

• AIR SIDE INLET AND OUTLET VELOCITY PRESSURE

• GAS SIDE INLET AND OUTLET STATIC PRESSURE

• GAS SIDE INLET AND OUTLET VELOCITY PRESSURE

• GAS ANALYSIS OF F.G.ENTERING AND LEAVING A.H

• HUMIDITY OF INLET AIR

DATA REQUIRED FOR A.H.

PERFORMANCE TESTS

• QTY. OF GAS ENTERING A.H.

• QTY. OF GAS LEAVING A.H.

• QTY. OF FUEL MEASURED OR COMPUTED

• ULTIMATE ANALYSIS OF COAL

• QTY. OF ATOMISING STEAM IF BURNING OIL

AIR HEATER CALCULATIONS

GAS SIDE EFFICIENCY

G = {(tG14-tG15(NL))/(tG14-tA8)}*100

WHERE tG14 - MEASURED GAS TEMP. ENTERING A.H.

tA8 - MEASURED AIR TEMP. ENTERING A.H

tG15(NL) - CALCULATED GAS TEMP LEAVING

A.H. CORRECTED FOR NO AIR

LEAKAGE

HEAT BALANCE FOR LEAKING AIR IN

AIR HEATER

HEAT GAINED BY LEAKING AIR=HEAT LOST BY F.G

HEAT GAINED BY LEAKING AIR=HEAT REQUIRED TO

RISE TEMP. OF

LEAKING AIR (tA8)

TO GAS OUTLET

TEMP.( tG15)

=A (L)*CpA*(tG15- tA8)

WHERE A (L) - % AIR LEAKING

CpA - Sp.HEAT OF AIR

HEAT BALANCE FOR LEAKING AIR IN

AIR HEATER

HEAT LOST BY F.G =HEAT LOST TO BRING

DOWN THE GAS TEMP.

FROM IF THERE IS NO

LEAK (tG15(NL)) TO

ACTUAL GAS TEMP. ( tG15)

=100*CpG*( tG15(NL) - tG15 )

WHERE CpG - Sp.HEAT OF F.G.

100*CpG*( tG15(NL) - tG15 ) = A (L)*CpA*(tG15- tA8)

tG15(NL) = [{A (L)*CpA*(tG15- tA8)}/ 100*CPg ] + tG15

AIR HEATER LEAKAGE

A(L) =[WET AIR LEAKAGE/WET GAS ENTERING A.H]*100

=[{WG15-WG14}/WG14]*100

BY EMPRICAL APPROXIMATION

A(L) =90*{%CO2 ENTERING A.H.-%CO2 LEAVING A.H.}/

%CO2 LEAVING A.H.

A(L) =91*{%O2 LEAVING A.H.-% O2 ENTERING A.H.}/

(21- %O2 LEAVING A.H.)

EFFECT OF VARIOUS

PARAMETERS ON A.H. GAS SIDE

EFFICIENCY

• AIR INLET TEMP.IN ALL CASES 300C

GAS GAS

INLET OUTLET LEAKAGE EFFICIENCY

CASE

TEMP. TEMP. % %

0 0

C C

IDEAL 400 140 13 66.5

1 400 155 13 62.2

2 400 140 20 64.6

3 400 155 20 59.7

4 430 165 20 59.8

EFFECT OF COMPONENT ON DRY GAS

LOSS / EFFICIENCY

Gcv Gross calorific value Kcal/kg 3689.10 3689.10 3689.10

of fuel

C Carbon in fuel % 36.92 36.92 36.92

S Sulphur in fuel % 0.28 0.28 0.28

U Unburnt carbon/kg Kg 0.0066 0.0066 0.0066

fuel

CO2 Carbon di oxide in % 13 12 13

flue gas

Wd Dry gas wt. Per kg Kgmol/kg 0.2331 0.2525 0.2331

of fuel

Sp.ht Specific heat Kcal/kgmol 7.31 7.31 7.31

/0c

0

Tg Gas temperature C 155 155 165

leaving boiler

0

Ta Ambient C 35 35 35

temperature

0

DT Tg-Ta C 120 120 130

L1 Dry gas loss % 5.54 6.00 6.00

Change in loss for

1% CO2 % -0.46

100C -0.46

EFFECTS OF TRAMP AIR

TO BOILER

• NOT CONTRIBUTING TO

COMBUSTION

• OFTEN IT IS COLD

• INCREASE GAS VELOCITY

THROUGH E.S.P

• BYPASSING A.H. INCREASED GAS

OUTLET TEMPERATURE

SOURCES OF AIR INGRESS

• ASH HOPPER SEALS

• ASH HOPPER DOOR LEFT OPEN

• DEFECTIVE EXPANSION JOINTS

• DUCT OPENINGS UNCOVERED

• BOILER ROOF SEALS DEFECTIVE

• ATTEMPERATING AIR DAMPERS

PASSING

• A.H.AIR BYPASSING DAMPERS PASSING

• SUCTION MILLING PLANT

• WORN SHAFT SEAL ON EXHAUSTERS

X RATIO

HEAT CAPACITY OF AIR PASSING THROUGH A.H.

X RATIO = --------------------------------------------------------------------------

HEAT CAPACITY OF GAS PASSING THROUGH A.H.

WA9*CpA*(tA9 - tA8) = WG14*CpG*(tG14 - tG15(NL))

WA9*CpA (tG14 - tG15(NL))

X RATIO = ------------- = ------------------

W G14*CpG (tA9 - tA8)

CpA / CpG = 0.95

INDICATION OF AIR BY PASSING A.H

EFFECT OF BYPASSING AIR ON F.G. TEMP.

LEAVING A.H

EFFECT OF AIR BYPASSING AH ON X RATIO AND GAS TEMP.

Qg Gas quantity entering T/hr 700 700 700

A.H.

Qa Air quantity leaving A.H. T/hr 500 475 525

Xr X ratio Qa*95/Qg 0.68 0.64 0.71

0

Tgi Gas temp. entering A.H. C 330 330 330

0

Tai Air temp. entering A.H. C 35 35 35

0

Tao Air temp. leaving A.H. C 310 311 309

0

Tgo Gas temp. leaving A.H. C 143.39 152.08 134.78

without leakage

Tgi-[ Xr*( Tao- Tai )]

VARIATION 8.69 - 8.62

Aef A.H.Efficiency % 63 60 66

CALCULATING AIR INGRESS %

Qg Gas quantity at A.H.inlet T/hr 700

Qaf Air quantity based on T/hr 650

excess air at A.H.inlet

Xr A.H.Xratio 0.7

Qa Air quantity leaving A.H. T/hr 515.79

Xr*Qg/0.95

Qat Tempering air quantity T/hr 100

from mill heat balance

Qi Air ingress quantity T/hr 34.21

Qaf-Qat-Qa

% Air ingress 5.26

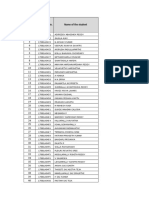

Vous aimerez peut-être aussi

- Water Treatment Plant Process Flow & Description: by Chemical Department Vendor: Doshion Veolia Water SolutionsDocument8 pagesWater Treatment Plant Process Flow & Description: by Chemical Department Vendor: Doshion Veolia Water Solutionsdreamboy87Pas encore d'évaluation

- Train Schedule Booklet SettingDocument24 pagesTrain Schedule Booklet Settingdreamboy87100% (1)

- Energy Conservation at Macro LevelDocument53 pagesEnergy Conservation at Macro Leveldreamboy87Pas encore d'évaluation

- 8 SP Oil, Cap RednDocument8 pages8 SP Oil, Cap Redndreamboy87Pas encore d'évaluation

- Methods and Effects of Manpower TrainingDocument17 pagesMethods and Effects of Manpower Trainingdreamboy87Pas encore d'évaluation

- 4.mill PerfDocument30 pages4.mill PerfRAJESH KUMARPas encore d'évaluation

- SelfDeclarationForm TN 620190926329Document1 pageSelfDeclarationForm TN 620190926329dreamboy87Pas encore d'évaluation

- Status Basic EngineeringDocument19 pagesStatus Basic Engineeringdreamboy87Pas encore d'évaluation

- Chapter - VII Infrastructure Water SupplyDocument25 pagesChapter - VII Infrastructure Water Supplydreamboy87Pas encore d'évaluation

- Turbine Oil System: P & I Check List.: Required ConditionsDocument4 pagesTurbine Oil System: P & I Check List.: Required Conditionsdreamboy87100% (1)

- Work at Height InventoryDocument1 pageWork at Height Inventorydreamboy87Pas encore d'évaluation

- Construction Contractor Safety Guidelines-EditDocument5 pagesConstruction Contractor Safety Guidelines-Editdreamboy87Pas encore d'évaluation

- Formula Study GuideDocument8 pagesFormula Study Guidemusharat_shafiquePas encore d'évaluation

- Ref: Work Permit No:: Honeywell International ME-HBS - Dubai Site-JBR-CCTV Upgrade Special Work PermitDocument6 pagesRef: Work Permit No:: Honeywell International ME-HBS - Dubai Site-JBR-CCTV Upgrade Special Work Permitdreamboy87Pas encore d'évaluation

- PTW 1Document8 pagesPTW 1dreamboy87Pas encore d'évaluation

- Tur ProtnsDocument2 pagesTur Protnsdreamboy87Pas encore d'évaluation

- Inspection Checklist AugustDocument3 pagesInspection Checklist Augustdreamboy87Pas encore d'évaluation

- Construction Safety Manual-EditDocument65 pagesConstruction Safety Manual-Editdreamboy87100% (2)

- Emergency Response Plan For Construction Site-EditDocument11 pagesEmergency Response Plan For Construction Site-Editdreamboy87100% (4)

- Silt Content TestDocument3 pagesSilt Content Testdreamboy87100% (2)

- Concept Note For HSD Storage / HandlingDocument3 pagesConcept Note For HSD Storage / Handlingdreamboy87Pas encore d'évaluation

- SHE Manual For Construction Contractors-EditDocument79 pagesSHE Manual For Construction Contractors-Editdreamboy87100% (1)

- 3393 - Supervision of Concrete Construction Volume 2Document271 pages3393 - Supervision of Concrete Construction Volume 2Oum ChhayNoy100% (11)

- Commissioning ScheduleDocument1 pageCommissioning Scheduledreamboy87Pas encore d'évaluation

- A 2 Z India 01-2019Document24 pagesA 2 Z India 01-2019dreamboy87Pas encore d'évaluation

- Checklist For RMCDocument23 pagesChecklist For RMCAjinPas encore d'évaluation

- Ballclay Sale 201601Document2 pagesBallclay Sale 201601dreamboy87Pas encore d'évaluation

- NLC Corrigendum For Ball ClayDocument3 pagesNLC Corrigendum For Ball Claydreamboy87Pas encore d'évaluation

- J. Subbiah,: Thermal Power Station-Ii Neyveli Lignite Corporation Limited NeyveliDocument55 pagesJ. Subbiah,: Thermal Power Station-Ii Neyveli Lignite Corporation Limited Neyvelidreamboy87Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- HSB-H2 Manual 2010Document78 pagesHSB-H2 Manual 2010Hasan SarfrazPas encore d'évaluation

- 150.66-RP4 YcalDocument92 pages150.66-RP4 YcalJosé RamosPas encore d'évaluation

- Mandatory Appendix D Specified Minimum Yield Strength For Steel Pipe Commonly Used in Piping SystemsDocument2 pagesMandatory Appendix D Specified Minimum Yield Strength For Steel Pipe Commonly Used in Piping SystemsAmr HeshamPas encore d'évaluation

- Fenner Drive Coupling Tire CouplingDocument5 pagesFenner Drive Coupling Tire Couplinganandha kumara swamyPas encore d'évaluation

- Timetal 834 Timet Data SheetDocument2 pagesTimetal 834 Timet Data SheetBonnie AttardPas encore d'évaluation

- Module 1 MOdern Physics FinalDocument10 pagesModule 1 MOdern Physics FinalMary Joy BernasolPas encore d'évaluation

- Honeywell Damper Selection and SizingDocument20 pagesHoneywell Damper Selection and SizingroadiewebPas encore d'évaluation

- Electrostatic Handbook PDFDocument60 pagesElectrostatic Handbook PDFLê Tuấn MinhPas encore d'évaluation

- What Is Von Mises StressDocument3 pagesWhat Is Von Mises Stressdwarika2006Pas encore d'évaluation

- Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForDocument18 pagesPolyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForPatricio G. ArrienPas encore d'évaluation

- Mechanics of Machines PDFDocument7 pagesMechanics of Machines PDFChamala Daksheeswara Reddy100% (1)

- Tran Nitta: BittyDocument5 pagesTran Nitta: BittyNam TranPas encore d'évaluation

- Hotspot Temperature Monitoring of Fully Insulated Busbar Taped JointDocument13 pagesHotspot Temperature Monitoring of Fully Insulated Busbar Taped JointAkbar SyawaludinPas encore d'évaluation

- C Water Free Die Casting TechnologyDocument8 pagesC Water Free Die Casting TechnologymetmlzmuhPas encore d'évaluation

- ARCHITECTURAL ACOUSTICS-module 2-Part2Document65 pagesARCHITECTURAL ACOUSTICS-module 2-Part2ardra m oPas encore d'évaluation

- 1.introduction of OrificeDocument20 pages1.introduction of OrificeJohn Andre MarianoPas encore d'évaluation

- Mr. Saxena - EP88Document11 pagesMr. Saxena - EP88Umar ShamshiriPas encore d'évaluation

- Bohr Atom ModelDocument46 pagesBohr Atom ModelJoychandra Wahengbam100% (9)

- Kinetic and Potential EnergyDocument3 pagesKinetic and Potential EnergyTAE0% (1)

- How To Inspect A GearboxDocument13 pagesHow To Inspect A Gearboxkamal arabPas encore d'évaluation

- Intropostlab Exp4Document3 pagesIntropostlab Exp4JC NuquiPas encore d'évaluation

- Equilibrium Problem Set 1 PDFDocument2 pagesEquilibrium Problem Set 1 PDFFistia Maulina100% (1)

- Teori Grup Dan Vibrasi-RevisiDocument204 pagesTeori Grup Dan Vibrasi-RevisiDhieka NopiharguPas encore d'évaluation

- APROS Models For Thermal Hydraulic Analyses of Forsmark's NPPS, Kärnteknik 2008Document3 pagesAPROS Models For Thermal Hydraulic Analyses of Forsmark's NPPS, Kärnteknik 2008Otso CronvallPas encore d'évaluation

- Internal Energy and The Ideal GasDocument9 pagesInternal Energy and The Ideal GasfagroupandahmadsonsPas encore d'évaluation

- Strip TheoryDocument16 pagesStrip Theorysuman010101Pas encore d'évaluation

- IcaDocument6 pagesIcasruthiPas encore d'évaluation

- CPT Data: Processing and ReportingDocument2 pagesCPT Data: Processing and ReportingjajayttPas encore d'évaluation

- Compression 1Document33 pagesCompression 1KSHITIJ MODIPas encore d'évaluation

- Geothermal Well CapacityDocument7 pagesGeothermal Well Capacityhendratondang5294Pas encore d'évaluation