Académique Documents

Professionnel Documents

Culture Documents

Drive Systems

Transféré par

Arun ManiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Drive Systems

Transféré par

Arun ManiDroits d'auteur :

Formats disponibles

North Bay Electric Auto Association Summer 2009 Technical Series

Electric Vehicle Drive Systems

www.nbeaa.org

Presented June 13, 2009 Corrected June 15, 2009 This presentation is posted at: http://www.nbeaa.org/presentations/drive_systems.pdf

NBEAA Summer Technical Series

TODAY>>

1. EV Drive Systems 2. EV Batteries and Management Systems

3. EV Charging Systems

4. EV Donor Vehicles

Agenda

What is an EV Drive System?

EV Drive System History

EV Drive System Requirements Types of EV Drive Systems

EV Drive System Cooling

EV Drive System Management EV Drive System Comparison Future EV Drive Systems EV Drive System Testimonials, Show and Tells and Test Drives

What is an EV Drive System?

From Battery From Driver

To Wheel

Motor controller

CV Joint Half Shaft CV Joint

Motor

FlyMotor wheel Adapter and Clutch

Transmission

U Joint

Drive Shaft

U Joint

Differential CV Joint Half Shaft

All or a subset of the components between the batteries and the wheels shown above.

CV Joint To Wheel

What is an EV Drive System?

Demonstration of electric motor principles: Two permanent magnets attracting and repelling each other An electromagnet attracting and repelling a permanent magnet with a DC source, reversed with polarity A small brushed permanent magnet DC motor, speed increased with varying voltage through variable resistor, and reversed with polarity

EV Drive System History

First electric motor, for demonstration only First DC motor that could turn machinery First electric carriage, 4 MPH with nonrechargeable batteries First DC motor that was commercially successful First AC motor First mass produced electric vehicle, with variable resistor DC motor control First high efficiency small air gap motors First SCR controllers First MOSFET PWM controllers First IGBT PWM controllers First digital configuration PWM controllers First digital control PWM controllers 1821 1832 1839 1873 1888 1914 1950s 1960s 1970s 1980s 1990s 2000s England England Scotland Belgium US US US US US US US US Michael Faraday William Sturgeon Robert Anderson Zenobe Gramme Nikola Tesla Thomas Edison and Henry Ford

EV Drive System Requirements

Safe High Power

High Efficiency

Durable

EV Drive System Requirements: Safe

Examples of EV drive system safety issues:

Short Circuit common DC motor controller failure mode, exacerbated by high currents and hence high heat probability reduced with improved efficiency response enhanced with a clutch, circuit breaker and automatic contactor controller Low power some more efficient or lower cost setups with low power could expose vehicle to oncoming traffic overheating undersized or poorly controlled systems could induce thermal cutback that can exacerbate this

EV Drive System Requirements: High Power

Power = Watts = Volts x Amps Power out = power in x efficiency of portion of system being evaluated at the output shaft or at the brake pads 1 Horsepower = 746 Watts Motor controller efficiency = >90%

Motor efficiency = 85-95%

Rest of drive train efficiency = 85-90% Overall efficiency 65-75% 25-35% lost due to heat

EV Drive System Requirements: High Power

Example

Accelerating or driving up a short steep hill Peak Motor Shaft Power = ~50 HP or ~37,000 W Peak Motor Current ~500A for 144V nominal pack with DC drive ~200A RMS for 288V nominal pack with AC drive

Driving steady state on flat ground at high speed Continuous Motor Shaft Power = ~20 HP or ~15,000 W Continuous Motor Current ~200A for 144V nominal pack with DC drive ~75A RMS for 288V nominal pack with AC drive

Regenerative Braking Depends on battery type Example: 3C max charge Thunder Sky LFP series LiFePO4 180A for 60 Ah cells 270A for 90 Ah cells

EV Drive System Requirements: High Efficiency

Power losses due to heat cause power and range reduction. Switching Transistor, freewheel diode heat Motor controller Copper, bearing heat Bearing heat FlyMotor wheel Adapter and Clutch Transmission Bearing heat U Joint Bearing heat U Joint

Bearing heat x5 CV Joint Half Shaft CV Joint Differential CV Joint Half Shaft CV Joint

Motor

Drive Shaft

The more current, the more load, and hence the more heat is lost throughout.

EV Drive System Requirements: Durable

Wide range of driving requirements combined with downwards pressure on size and weight for performance and cost reasons can put excess stress on drive system components Harsh automotive environment much worse than indoor environment: temperature: -40C to 50C humidity: 5% to condensing shock: potholes vibration: gravel roads

Make sure to use a motor for and EV that was intended for on-road use.

Types of EV Drive Systems: Which Type is Best?

AC vs. DC AC is more efficient, less maintenance and more robust DC is less expensive, but mainly due to higher volume fork lift industry trend is moving from DC to AC late model OEM EVs have mostly been AC; conversions mostly DC

Transmission or fixed gear Transmission is more efficient Fixed gear is lighter and less complex

Clutch or no clutch Clutch is more efficient No clutch is lighter and less complex

The debate rages on, but the highest performance is AC with transmission and clutch.

Types of EV Drive Systems: Motor Terminology

Rotor: Stator: rotating part of motor stationary part of motor

Field:

produces magnetic field to be acted upon by armature; can be electromagnet or permanent magnet

carries current normal to field to generate torque

Armature:

Rotor or stator can be either field or armature.

Types of EV Drive Systems: Motor Comparison

type DC Series brushes Yes Stator Field windings Rotor Armature windings, commutated through brushes and split rings, in series with field Armature windings, commutated through brushes, separately excited from field Armature windings, commutated through brushes Field permanent magnet Field windings, DC energized through brushes and slip rings Opposing magnetic field induced via eddy currents caused by slip between stator and rotor in copper or aluminum squirrel cage frame

DC Shunt

Yes

Field windings

DC Brushed Permanent Magnet DC Brushless Permanent Magnet AC Synchronous

Yes No Yes

Field permanent magnet Armature windings, PWMd via rotor position sensor Armature windings, PWMd via rotor position sensor Armature windings, PWMd via rotor position sensor

AC Induction

No

Types of EV Drive Systems

Categ ory DC Type Series Example Motors Advanced DC Kostov2 Netgain Example Controllers Alltrax Auburn3 Caf Electric1 Curtis Raptor1 Alltrax Sevcon

Shunt

D&D

Brushed Permanent Magnet

Brushless Permanent Magnet AC Synchronous Induction

Perm PMG Et-R, RT

Mars Toyota RAV4 EV3 Siemens2 AC Propulsion Azure Dynamics Brusa Curtis MES Siemens2

Alltrax

Sevcon Toyota RAV4 EV3 Siemens2 AC Propulsion Azure Dynamics Brusa Curtis MES Siemens2

Notes: 1 Requires special order, 2 are no longer readily available in the US, 3 are obsolete.

Types of EV Drive Systems: Drivelines

Shaft Type Fit for flywheel and clutch? Picture

Smooth Keyed

Yes

Splined

No

Involuted Spline

Heck No

Types of EV Drive Systems: Motor Control via Pulse Width Modulation

100% duty cycle

75%

50%

25%

0%

Types of EV Drive Systems: Switch Mode Power Supply Buck Regulator

Motor Armature (and field for DC series; separate circuit for DC shunt and AC synchronous)

Filter capacitors From batteries

Freewheel diodes From PWM control circuit

Power switching transistors (MOSFETs or IGBTs)

When power is applied to input, capacitors are charged up. When transistors are switched on, current flows from the batteries and capacitors to the motor. When the transistors are off, the capacitors are recharged by the batteries while current flows from the motor to the freewheel diodes while the motors magnetic field collapses to keep from increasing the voltage across the transistor to the point of failure.

Types of EV Drive Systems: 3 Phase AC Configurations

delta A B A wye

C Coil voltage = line voltage RPM varies with voltage Used at lower voltages to maximize speed

C Coil current = line current Torque varies with current Used at higher voltages to maximize torque

Types of EV Drive Systems: PWM control circuit types

Analog Digital configuration Digital control

Types of EV Drive Systems: Cooling Systems

Type Sealed, no fan Motor Center may overheat Motor Controller Needs large area heat sink; can be flat plate Takes up a single large fixed volume

Sealed, external fan on heat sink

Sealed, liquid

Internal fan, open

Requires small cooling system Requires small cooling system

Needs debris and splash shield; low slung motor can not be submerged Takes up more volume; Needs debris and splash shield; low slung motor can not be submerged May corrode due to humidity, or overheat due to dust accumulation

External fan, open

Types of EV Drive Systems: Management Systems

Voltage (speed) or current (torque) regulation vs. pedal (potbox or hall effect) input Motor current limiting Battery current limiting Low pack voltage cutoff Low cell voltage cutoff Motor controller thermal cutback Motor thermal cutback Battery thermal cutback

EV Drive System Comparison

Type DC Series DC Shunt DC Brushed PM DC Brushless PM AC Synchronous AC Induction

Safety ~ ~ ~ + + +

Efficiency ~ ~ ~ + + +

Torque + ~ ~ ~ ~ ~

Regen ~ ~ ~ + + +

EV Drive System Comparison

Controller

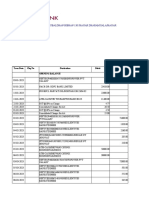

Motor Peak HP at 144V Continuous HP Peak Torque at 144V, ft-lb Regenerative Braking Efficiency Output Shaft Sealed Controller? Brushes? Cooling adjustable battery minimum voltage (and maximum if regen) independent main contactor safety control accelerator modulation Motor and Controller Weight, lbs System Price Curtis 1231C8601 Advanced DC 9" FB1-4001 72 28 110 no 75% smooth keyed yes yes air no no speed 170 $3,000 Raptor 600 Advanced DC 9" FB1-4001 86 28 132 no 75% smooth keyed no Cafe Electric Zilla 1K-LV Advanced DC 9" FB1-4001 144 28 220 no 75% smooth keyed yes yes water, controller only yes yes torque 170 $3,500 Raptor 1200 Advanced DC 9" FB1-4001 172 28 264 no 75% smooth keyed no Cafe Electric Zilla 2K-LV Advanced DC 9" FB1-4001 288 28 440 no 75% smooth keyed yes yes water, controller only yes yes torque 190 $4,000 Solectria DMOC445 Solectria AC24 w/smooth keyed output shaft 58 24 55 yes 85% smooth keyed yes no air yes yes torque 117 $6,500 MES-DEA TIM600 MES 200-150 73 19 118 yes 85% involuted spline, but 8.64:1 Carraro gearbox with differential available yes no water, motor and controller yes yes torque 121 $12,000

Example to be updated

yes air with internal fan ? ? ? 170 $3,000 yes air with internal fan ? ? ? 190 $3,500

Other Drive Systems Not Considered: - Solectria AC55: too heavy at 234 lbs, aand splined shaft with no matching gearbox, requiring custom differential gear machining or non-standard flywheel coupling. - MES 200-175 28 HP: exceeds rating of Carraro gearbox, leaving an involuted spline, not good for a flywheel. - Siemens AC: also splined shafts only with no matching gearbox. And they are surplus, so they might be hard to get support for, but they do carry a 10 year warranty. - Brusa AC: also splined shaft with no matching gearbox. - AC Propulsion: cost prohibitive at $25KK for 150 kW system (although it includes high power charging). - Kostov series wound DC motors: not readily available. - Auburn series DC controllers: company no longer in business. - Curtis 1244 Sep-Ex shunt DC regen controller: complex with marginal performance. - Zapi Sep-Ex shunt DC regen controller: same as above. - Customized series wound DC motor with variable mechanical brush timing to improve forward and regen efficiency: too many parts - Dual DC with no transmission: too inefficient. 60% efficiency estimated. The following AC drive systems are under development or are currently not available to hobbyists: Enova, UQM, TM4, Reliance, AC Electric Vehicles

EV Drive System Comparison

EV Drive System Comparison Advanced DC 9 Series DC at 120V

EV Drive System Comparison D&D Shunt SepEx DC at 72V

EV Drive System Comparison D&D Shunt SepEx DC at 72V

EV Drive System Comparison PMG 132 Brushed Permanent Magnet DC at 72V

EV Drive System Comparison Et-RT Brushed Permanent Magnet DC at 48V

EV Drive System Comparison Azure Dynamics AC24LS/DMOC445 delta at 156V

EV Drive System Comparison Azure Dynamics AC24LS/DMOC445 delta at 156V

EV Drive System Comparison Azure Dynamics AC24LS/DMOC445 wye at 312V

EV Drive System Comparison Azure Dynamics AC24LS/DMOC445 wye at 312V

Future EV Drive Systems

Even more efficient motors and motor controllers? 4 wheel hub motors? 4 inboard wheel motors? Fully integrated braking systems? Nano-capacitor driven motor controllers? Optical pedal input?

EV Drive System Testimonials, Show and Tells and Test Drives

Peter Oliver: Azure Dynamics AC24 motor and DMOC445 controller in Porsche Speedster conversion (http://www.evalbum.com/1683) ; AC 55 motor

Brian Hall: Curtis 96V AC drive system in 72V Geo Metro conversion; 72V Et-RT permanent magnet brushed DC motor

Chris Jones: 9 Advanced DC motor and Curtis 1231C motor controller in Ford Mustang conversion (http://www.evalbum.com/733)

Things to add in future: 0-60 MPH comparison DC, AC, gasoline Diagrams and graphs for each motor and controller type Movies for each motor and controller type Update table comparing all parameters of all drive systems Overlays of motor curves Written descriptions of how to read motor curves More detailed written descriptions of how motors and motor controllers work References

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lab 1Document51 pagesLab 1aliPas encore d'évaluation

- UserProvisioningLabKit 200330 093526Document10 pagesUserProvisioningLabKit 200330 093526Vivian BiryomumaishoPas encore d'évaluation

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDocument64 pagesUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091Pas encore d'évaluation

- P6 - TT2 - Revision Test 2021-2022 Page 1 of 11Document11 pagesP6 - TT2 - Revision Test 2021-2022 Page 1 of 11Nilkanth DesaiPas encore d'évaluation

- Jy992d66901 CDocument6 pagesJy992d66901 CMaitry ShahPas encore d'évaluation

- XXXX96 01 01 2023to28 08 2023Document18 pagesXXXX96 01 01 2023to28 08 2023dabu choudharyPas encore d'évaluation

- RS-All Digital PET 2022 FlyerDocument25 pagesRS-All Digital PET 2022 FlyerromanPas encore d'évaluation

- Rare Watches (Christie's) 16. 05. 2016.Document236 pagesRare Watches (Christie's) 16. 05. 2016.Simon LászlóPas encore d'évaluation

- ProjectDocument32 pagesProjectroshan jaiswalPas encore d'évaluation

- Lecture BouffonDocument1 pageLecture BouffonCarlos Enrique GuerraPas encore d'évaluation

- Circuit Construction: Assignment 3Document45 pagesCircuit Construction: Assignment 3ali morisyPas encore d'évaluation

- WCDMA Radio Access OverviewDocument8 pagesWCDMA Radio Access OverviewDocMasterPas encore d'évaluation

- 2396510-14-8EN - r1 - Service Information and Procedures Class MDocument2 072 pages2396510-14-8EN - r1 - Service Information and Procedures Class MJuan Bautista PradoPas encore d'évaluation

- MCC333E - Film Review - Myat Thu - 32813747Document8 pagesMCC333E - Film Review - Myat Thu - 32813747Myat ThuPas encore d'évaluation

- Baby DedicationDocument3 pagesBaby DedicationLouriel Nopal100% (3)

- On The Wings of EcstasyDocument79 pagesOn The Wings of Ecstasygaya3mageshPas encore d'évaluation

- Catalogue - Central Battery SystemDocument12 pagesCatalogue - Central Battery SystemarifzakirPas encore d'évaluation

- Democracy or Aristocracy?: Yasir MasoodDocument4 pagesDemocracy or Aristocracy?: Yasir MasoodAjmal KhanPas encore d'évaluation

- The Fastest Easiest Way To Secure Your NetworkDocument9 pagesThe Fastest Easiest Way To Secure Your NetworkMark ShenkPas encore d'évaluation

- Introduction To Microelectronic Fabrication PDFDocument332 pagesIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- 1en 02 PDFDocument96 pages1en 02 PDFAndrey100% (2)

- Training Design SprintDocument11 pagesTraining Design Sprintardi wiantoPas encore d'évaluation

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasPas encore d'évaluation

- Gold Loan Application FormDocument7 pagesGold Loan Application FormMahesh PittalaPas encore d'évaluation

- What Is Urban PlanningDocument33 pagesWhat Is Urban PlanningDivine Grace FernandoPas encore d'évaluation

- Batron: 29 5 MM Character Height LCD Modules 29Document1 pageBatron: 29 5 MM Character Height LCD Modules 29Diego OliveiraPas encore d'évaluation

- Product Handbook Arendal 1961 Series SubwoofersDocument44 pagesProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicPas encore d'évaluation

- RS2 Stress Analysis Verification Manual - Part 1Document166 pagesRS2 Stress Analysis Verification Manual - Part 1Jordana Furman100% (1)

- DC Generator - Construction, Working Principle, Types, and Applications PDFDocument1 pageDC Generator - Construction, Working Principle, Types, and Applications PDFGokul GokulPas encore d'évaluation

- BLG311 Cell Biology: Course Outline (Fall 2020)Document11 pagesBLG311 Cell Biology: Course Outline (Fall 2020)Emilija BjelajacPas encore d'évaluation