Académique Documents

Professionnel Documents

Culture Documents

Distillation Column: - Distillation - Types of Distillation Columns

Transféré par

Mutawara BaigDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Distillation Column: - Distillation - Types of Distillation Columns

Transféré par

Mutawara BaigDroits d'auteur :

Formats disponibles

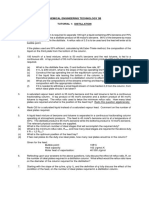

DISTILLATION COLUMN

Distillation

Types of distillation columns

Batch columns

Continuous columns

Selection

Choice Between Plate and Packed Column

Plate column are designed to handle wide range of liquid flow rates without

flooding.

If a system contains solid contents; it will be handled in plate column, because solid

will accumulate in the voids, coating the packing materials and making it

ineffective.

Dispersion difficulties are handled in plate column when flow rate of liquid are low

as compared to gases.

For large column heights, weight of the packed column is more than plate column.

If periodic cleaning is required, man holes will be provided for cleaning. In packed

columns packing must be removed before cleaning.

For non-foaming systems the plate column is preferred.

Design information for plate column is more readily available and more reliable

than that for packed column.

Inter stage cooling can be provided to remove heat of reaction or solution in plate

column.

When temperature change is involved, packing may be damaged.

Design

Design Steps

Calculation of minimum reflux ratio.

Calculation of optimum reflux ratio.

Calculation of theoretical no. of stages.

Calculation of actual no. of stages.

Calculation of diameter.

Calculation of height.

Calculation of no. of holes.

Calculation of weeping and flooding.

Calculation of pressure drop.

49814.10037 kg

Top Product = 6850.67kg

Bottom = 42963.42kg

Continue . . .

Nature of feed

Pressure of feed = P=1100kpa

At, Temperature=103.7

o

C

Light Key (lk) =n-Butane

Heavy Key (hk) =n-Pentane

Top temperature =62

o

C

Bottom temperature=163

o

C

Feed is entering as liquid , so q=1.477

Continue . . .

Calculation of Minimun Reflux Ratio

Using Underwood Equation;

By iterations we find

R

min

= 1.334

Calculation of Optimum Reflux Ratio

R=(1,2 1.5) R

min

=2

q

x

n

i

i

F i

i

=

=

1

1

u o

o

1

min

1

+ =

=

R

x

n

i

i

D i

i

u o

o

Continue . . .

Calcualtion of Minimum No. of Plates

Using Fenske relation;

N

min

= 22

Using Gililand-Eduljee Relation

N = 22

Efficiency of the Plate

E

o

= 74 %

Actual No. of Stages

N=29

( )

avg HK LK

B

LK

HK

D

HK

LK

x

x

x

x

N

/

min

ln

ln

o

|

|

.

|

\

|

|

|

.

|

\

|

=

(

(

|

.

|

\

|

+

=

+

566 . 0

min min

1

1 75 . 0

1 R

R R

N

N N

Continue . . .

Location of Feed Plate:

Using Kirkbride relation;

We get

Actual N

D

= 11

Actual N

B

= 18

( )

( )

)

|

|

.

|

\

|

|

.

|

\

|

=

2

log 206 . 0 log

D HK

B LK

F

LK

HK

B

D

x

x

x

x

D

B

N

N

621 . 0 =

B

D

N

N

Continue

Top Condition Bottom Conditions

L

n

= 204 kmol/hr

V

n

= 344Kgmol/hr

M aver. = 47.04Kg/Kgmol

T = 62

o

C

Liq density = d

L

= 520.8 Kg/m

3

Vap density = d

V

= 1.875Kg/m

3

L

m

= 292.172 Kmol/hr

V

m

= 175.25 Kmol/hr

M aver=117.75 Kg/Kgmol

T = 163

o

C

Liquid density = d

L

= 543 Kg/m

3

Vapor density = d

V

= 4.55 Kg/cm

3

Continue . . .

Flooding Velocity in Stripping Section

F

LV

= 0.44

Taking Plate Spacing = 0.8 m

From Graph

K

1

= 0.07

Now putting values in the following relation

Uf = 0.25 m/sec

L

V

m

m

LV

V

L

F

=

V

V L

f

K U

=

1

Continue . . .

Column Cross sectional Area in Stripping Section:

Taking Actual Operating Velocity to be 85% of the maximum

flooding velocity we get

Operating Velocity = 0.21 m/sec

Net Area = 2.2 m

2

Taking Down-comer Area as 12% of total cross sectional area we get

Total Column cross sectional Area = Net Area/0.88

A

c

= 2.5 m

2

Column Diameter

D

C

= 1.78 m (5.82 ft)

Velocity

rate Flow vol.

Operating

Vapor

Area Net =

Continue . . .

Flooding Velocity in Rectifying Section

F

LV

= 0.112

K

1

= 0.11

U

f

= 0.48 m/sec

Actual Operating Velocity = 0.41 m/sec

Net Area = 1.11 m

2

A

c

= 1.25 m

2

D

C

= 1.26 m

Nearest Standard available for Rectifying section = 1.37 m (4.5 ft)

Continue . . .

Tray Design for Stripping Section

Down-Comer Area = 0.12(A

c

)

A

D

= 0.316

Active Area = A

c

2A

D

A

a

= 2 m

2

Hole Area = 0.07(A

a

)

Take weir height = 38 mm

Plate Thickness = 3mm

Plate Spacing = 0.8m

Material of Construction = Stainless Steel

Continue . . .

Weir Length:

From Fig.

L

w

= 1.39 m

Weir Liquid Crest:

Using relation,

h

ow

= 66 mm

12 100 =

c

d

A

A

76 . 0 =

c

w

D

L

3 / 2

750

|

|

.

|

\

|

=

w L

m

ow

L

L

h

Continue . . .

For minimum Crest use 70% of maximum flow

h

ow(min)

= 52 mm

Min. Liquid Crest = h

w

+ h

ow

= 90 mm

Weeping Check:

From Fig. K

2

= 30.9

U

min

= 2.1 m/sec

Actual minimum Vapor velocity through holes;

V

act(min)

= 2.4 m/sec

( )

( )

2 / 1

2

min

4 . 25 9 . 0

v

h

d K

U

=

7 . 0

Area Hole

.

(min)

=

rate flow vol Vapor

V

act

Continue . . .

Pressure Drop for Stripping Section:

There are three main sources of pressure drop

(a) Flow through holes

(b) Static head of liquid on plate

(c) Residual pressure drop

Dry Plate Pressure Drop:

Plate thickness / hole diameter = 0.94

From Fig. C

o

= 0.82

Hence,h

d

= 38.3 mm-liquid

l

v

o

h

d

C

u

h

2

51

|

|

.

|

\

|

=

8 100 =

Ap

Ah

Continue . . .

Residual Head:

hr = 23 mm-liq.

Total Pressure Drop:

Total head loss per plate = h

d

+ h

r

+ h

w

+ h

ow

h

t

= 165 mm-liq.

Pressure drop per plate = 9.8110

-3

(h

t

) (

L

)

P = 883 Pa

Total Pressure drop in Stripping section;

P

s

= No. of plates in Stripping Section P

p

= 16 Kpa

L

r

h

3

10 5 . 12

=

Continue . . .

Down comer Backup:

Assuming that down comer is 6 mm below the weir level;

Then height of aperture thus formed is

h

ap

= h

w

- 6

=32mm

Flow Channel at bottom of down comer;

A

ap

=h

ap

L

w

= 0.05m

2

h

dc

=87.8

2

] [ 166

m l

wd

dc

A

L

h

=

Continue . . .

= 354mm

Residence Time:

=3.1

Height of Stripping Section:

H

s

= No of plates in Stripping section Plate Spacing

+ Vapor Disengagement section

H

s

= 16.3 m

Residence Time:

t

r

= 6 sec

Height of Rectifying Section:

H

s

= 9.7 m

d t ow w b h h h h h + + + =

m

L bc d

r

L

h A

t

=

Continue . . .

Tray Design for Rectifying Section:

A

D

= 0.1769

A

a

= 1.12 m

2

Hole Area = 0.112 m

2

Take weir height = 38 mm

L

w

= 1.12m

Weir Liquid Crest:

h

ow-min

= 17 mm

Min. Liquid Crest = h

w

+ h

ow

= 55 mm

Weeping Check:

From Graph K

2

= 30.2

U

min

= 2.36 m/sec

V

act(min)

= 2.9 m/sec

Continue . . .

Pressure Drop

h

d

= 35 mm-liquid

h

r

= 24 mm-liq.

h

t

= 123.4 mm-liq.

P

t

= 640 Pa

P

R

=7.1 Kpa

Down comer Backup:

h

ap

=32 mm

A

ap

= 0.05 m

2

h

dc

=4 mm-liq.

h

b

= 182 mm-liq

Continue . . .

Total Pressure drop in column

Total P

T

= P

s

+ P

R

=23KPa

Total Column Height:

H

c

= H

s

+ H

R

= 26 m

Vous aimerez peut-être aussi

- Distillation ColumnDocument58 pagesDistillation Columnphoenix0467% (3)

- Distillation Column - Stripping SectionDocument8 pagesDistillation Column - Stripping SectionKvspavan KumarPas encore d'évaluation

- Design of Distillation ColumnDocument21 pagesDesign of Distillation Columnusmanafzal246100% (1)

- Plate Design ProcedureDocument8 pagesPlate Design ProcedureDaniel Andres Canro CalderónPas encore d'évaluation

- DISTILLATION 2bDocument24 pagesDISTILLATION 2bhusseinPas encore d'évaluation

- Designing an Acetone-Water Distillation ColumnDocument23 pagesDesigning an Acetone-Water Distillation ColumnamandaPas encore d'évaluation

- Distillation Column1Document49 pagesDistillation Column1prafulla1983100% (1)

- Distillation Column DesignDocument49 pagesDistillation Column DesignHardik SampatPas encore d'évaluation

- Distillation ColumnDocument49 pagesDistillation ColumngenergiaPas encore d'évaluation

- Distillation Column1Document49 pagesDistillation Column1Nagwa MansyPas encore d'évaluation

- Stripper Column DesignDocument17 pagesStripper Column DesignLafyumemlePas encore d'évaluation

- Silo DesignDocument12 pagesSilo Designraju_420034520Pas encore d'évaluation

- 07 - Convective Heat TransferDocument75 pages07 - Convective Heat TransferMerazka FaroukPas encore d'évaluation

- Design Stripper Column ProcessDocument10 pagesDesign Stripper Column ProcessAhmed HassanPas encore d'évaluation

- Combined Footing DesgnDocument14 pagesCombined Footing DesgnKhalid RehmanPas encore d'évaluation

- Shell & Tube Heat Exchanger: - DesigningDocument18 pagesShell & Tube Heat Exchanger: - DesigningKusmakar100% (1)

- Radiator Fan Moterating CalculationDocument20 pagesRadiator Fan Moterating Calculationmyungkwan haPas encore d'évaluation

- Performance Test On Gear (Oil) Pump: Experiment 5Document4 pagesPerformance Test On Gear (Oil) Pump: Experiment 5DevXPas encore d'évaluation

- Monoethanolamine Design 2520of 2520equipmentsDocument54 pagesMonoethanolamine Design 2520of 2520equipmentsbhaskar5377Pas encore d'évaluation

- Design Calculations of Distillation ColuDocument25 pagesDesign Calculations of Distillation ColuDHEERESH KUMARPas encore d'évaluation

- Bell Delaware Math Cad ExampleDocument8 pagesBell Delaware Math Cad ExampleMohammed A IsaPas encore d'évaluation

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MPas encore d'évaluation

- Chemical Engineering DepartmentDocument18 pagesChemical Engineering Departmentiffat100% (1)

- OSD Calculation 09238Document10 pagesOSD Calculation 09238Anonymous O404LiV4CPas encore d'évaluation

- Design of Distillation Column EquipmentDocument41 pagesDesign of Distillation Column EquipmentHardik Gandhi100% (1)

- Dryer Silo NewdesignDocument3 pagesDryer Silo Newdesignmgokten77Pas encore d'évaluation

- ilide.info-exercise-c2-and-c3-group-1-pr_460b39743ded9744b4e45c894f64bb0bDocument20 pagesilide.info-exercise-c2-and-c3-group-1-pr_460b39743ded9744b4e45c894f64bb0bAdrija ChakrabortyPas encore d'évaluation

- Exercise C2 and C3 - Group 1Document20 pagesExercise C2 and C3 - Group 1Trung Kỹ PhạmPas encore d'évaluation

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharPas encore d'évaluation

- xylenes_Design-2520of-2520Equipments.docDocument29 pagesxylenes_Design-2520of-2520Equipments.docAditya KumarPas encore d'évaluation

- Open Channel Hunt: BFC 21103 Hydraulics S4 DR Siti Nazahiyah Binti RahmatDocument17 pagesOpen Channel Hunt: BFC 21103 Hydraulics S4 DR Siti Nazahiyah Binti RahmatNur AzreenaPas encore d'évaluation

- Chap 8. CondenserDocument9 pagesChap 8. CondenserAli Ahsan100% (1)

- CH 09Document73 pagesCH 09Vivek Harris88% (8)

- Jacketed VesselsDocument9 pagesJacketed VesselsParikshit Shahane67% (3)

- Anexo Ii: Refuerzo Transversal de Columna T: Ø Øvc VsDocument1 pageAnexo Ii: Refuerzo Transversal de Columna T: Ø Øvc VsJoseph LaurentePas encore d'évaluation

- Presentation 2Document11 pagesPresentation 2Muhazzam KhanPas encore d'évaluation

- NCESQ 2015 Answer KeyDocument10 pagesNCESQ 2015 Answer KeyKenneth Joy SorianoPas encore d'évaluation

- Butyraldehyde Column SpecsDocument27 pagesButyraldehyde Column SpecsfjdmejiaPas encore d'évaluation

- Flat Plate Heat Transfer and Drag Force AnalysisDocument36 pagesFlat Plate Heat Transfer and Drag Force Analysissiva sachaphibulkijPas encore d'évaluation

- Flow Over WeirsDocument12 pagesFlow Over WeirsItemogeng Bernatt Babe100% (1)

- Chlorobenzene Design 2520of 2520equipmentsDocument44 pagesChlorobenzene Design 2520of 2520equipmentsElizabeth Patrick100% (2)

- Dr. Wendy NG Chemical Refining of Crude Soybean OilDocument6 pagesDr. Wendy NG Chemical Refining of Crude Soybean OilDickson ChongPas encore d'évaluation

- Crack Evaluation and Mitigation - CalculationDocument4 pagesCrack Evaluation and Mitigation - CalculationSilvioPas encore d'évaluation

- 6 - Francis Turbine PDFDocument39 pages6 - Francis Turbine PDFMohamed YaserPas encore d'évaluation

- Fliud Mechanics Exxperiment 5Document2 pagesFliud Mechanics Exxperiment 5Nah Sr AdPas encore d'évaluation

- FILTER PRESS OPTIMIZATIONDocument9 pagesFILTER PRESS OPTIMIZATIONEl CoolPas encore d'évaluation

- Secrets of GC Column Dimensions: GC Columns and ConsumablesDocument56 pagesSecrets of GC Column Dimensions: GC Columns and ConsumablesBogdan CioroiuPas encore d'évaluation

- SEO Irrigation Efficiency CalculationsDocument6 pagesSEO Irrigation Efficiency CalculationsBeza Getachew100% (3)

- RectangularDocument6 pagesRectangularhgag selimPas encore d'évaluation

- Distillation Tower - Rectification SectionDocument4 pagesDistillation Tower - Rectification SectionKvspavan KumarPas encore d'évaluation

- Distillation ColumnDocument16 pagesDistillation ColumnSatya Narayan SharmaPas encore d'évaluation

- Solution Manual for an Introduction to Equilibrium ThermodynamicsD'EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsPas encore d'évaluation

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportD'EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportPas encore d'évaluation

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- 7HC - Mt-Ii Oct-98,99 Apr-00Document7 pages7HC - Mt-Ii Oct-98,99 Apr-00Ahmed AliPas encore d'évaluation

- Gel Filteration Principles and MethodsDocument124 pagesGel Filteration Principles and MethodstyahaaPas encore d'évaluation

- Extraction TechniquesDocument18 pagesExtraction TechniquesPushpa RajPas encore d'évaluation

- Pufal 2000Document4 pagesPufal 2000adolfo olmosPas encore d'évaluation

- Master Complex Columns and Four Assumptions Problems 2020 Set - 5Document7 pagesMaster Complex Columns and Four Assumptions Problems 2020 Set - 5vikyapplePas encore d'évaluation

- Dynamic Mathematical Model For The Ideal Binary Batch Distillation Column Under Constant Reflux RatioDocument18 pagesDynamic Mathematical Model For The Ideal Binary Batch Distillation Column Under Constant Reflux RatioXy kar0% (1)

- Chem r3p0rtDocument5 pagesChem r3p0rtDonghyuck ReyesPas encore d'évaluation

- Chromatography 1 1Document49 pagesChromatography 1 1kelvinPas encore d'évaluation

- 06 Approximate Methods For Multi-Component DistillationDocument61 pages06 Approximate Methods For Multi-Component DistillationNagwa Mansy100% (1)

- Fabricating MWCNT Composite Membrane for Water TreatmentDocument9 pagesFabricating MWCNT Composite Membrane for Water TreatmentSolehah OmarPas encore d'évaluation

- Final Report DistillationDocument8 pagesFinal Report DistillationAlice ToPas encore d'évaluation

- Lazarides 2003Document7 pagesLazarides 2003Sri AmshaPas encore d'évaluation

- Diseño de Equipos de DestilaciónDocument110 pagesDiseño de Equipos de DestilaciónGloria Bailon100% (1)

- Distillation Tutorial 1Document1 pageDistillation Tutorial 1Richardt LootsPas encore d'évaluation

- Date PH Turbidity Conductivity - NTU S/CMDocument29 pagesDate PH Turbidity Conductivity - NTU S/CMmainul qulubiPas encore d'évaluation

- Analytical SeparationsDocument43 pagesAnalytical SeparationsSeagal AsjaliPas encore d'évaluation

- Vacuum Distillation Colume: Mass Transfer Lab AssignmentDocument4 pagesVacuum Distillation Colume: Mass Transfer Lab AssignmentMalik HamidPas encore d'évaluation

- Membrane Separation Processes ExplainedDocument4 pagesMembrane Separation Processes ExplainedShida ShamPas encore d'évaluation

- Distillation-Multicomponent-final UpdatedDocument30 pagesDistillation-Multicomponent-final Updatedwaleed chPas encore d'évaluation

- Mi 123Document12 pagesMi 123Mehran IsgandarliPas encore d'évaluation

- Biology Exercise 3/ex - Transportacrossmembrane/Ymt/Aoghss Name: - 4DDocument2 pagesBiology Exercise 3/ex - Transportacrossmembrane/Ymt/Aoghss Name: - 4DSuki LeungPas encore d'évaluation

- Advanced Analytical Chemistry 1 PDFDocument5 pagesAdvanced Analytical Chemistry 1 PDFHarish TalelePas encore d'évaluation

- Distillation EkstraktifDocument17 pagesDistillation EkstraktifIrlin AfrianingsihPas encore d'évaluation

- High-Performance Liquid Chromatography ExplainedDocument11 pagesHigh-Performance Liquid Chromatography ExplainedThuỳ TrangPas encore d'évaluation

- INTRODUCTIONDocument2 pagesINTRODUCTIONNarsyida Niasara HamdanPas encore d'évaluation

- Batch Distillation Process OverviewDocument19 pagesBatch Distillation Process OverviewMikas PhilipPas encore d'évaluation

- Tugas Kimia Analitik 2Document6 pagesTugas Kimia Analitik 2DiahNurhayatiPas encore d'évaluation

- 016 - Quotation LABIOVAK Uil Water - Membrane by Inge - Part Replacement (Rev.01)Document2 pages016 - Quotation LABIOVAK Uil Water - Membrane by Inge - Part Replacement (Rev.01)Iqbalilah RamdaniPas encore d'évaluation

- Characterization of Proteins Using Ion Exchange Chromatography and Gel Filtration ChromatographyDocument4 pagesCharacterization of Proteins Using Ion Exchange Chromatography and Gel Filtration ChromatographyEricka GalangPas encore d'évaluation

- Chromatography overviewDocument15 pagesChromatography overviewBikas SahaPas encore d'évaluation