Académique Documents

Professionnel Documents

Culture Documents

Supply Chain Management

Transféré par

Amit LohiaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Supply Chain Management

Transféré par

Amit LohiaDroits d'auteur :

Formats disponibles

Presented by : Mahesh Kr.

Singh (089) Nitin Choudhary (095) Gautam Saini (096) Rohit Lohia (99) Rahul Dubey (108)

Also referred to as the logistics network Suppliers, manufacturers, warehouses, distribution centers and retail outlets facilities

Suppliers Manufacturers

Warehouses & Customers Distribution Centers

and the

Raw materials Work-in-process (WIP) inventory Finished products

Material Costs

Transportation Costs

Transportation Costs Transportation Manufacturing Costs Inventory Costs Costs

that flow between the facilities

2

Suppliers

Manufacturers

Warehouses & Distribution Centers

Customers

Material Costs

Transportation Costs

Transportation Costs

Manufacturing Costs

Transportation Costs Inventory Costs

3

Plan

Source

Make

Deliver

Buy

Suppliers

Manufacturers

Warehouses & Distribution Centers

Customers

Transportation Transportation Costs Transportation Costs Material Costs Manufacturing Costs Inventory CostsCosts

4

Plan

Source

Make

Deliver

Buy

A set of approaches used to efficiently integrate

Suppliers Manufacturers Warehouses Distribution centers In the right quantities To the right locations And at the right time

So that the product is produced and distributed

System-wide costs are minimized and Service level requirements are satisfied

1. PlanThis is the strategic portion of SCM. Companies need a strategy for managing all the resources that go toward meeting customer demand for their product or service. 2. SourceNext, companies must choose suppliers to deliver the goods and services they need to create their product. Therefore, supply chain managers must develop a set of pricing, delivery and payment processes with suppliers and create metrics for monitoring and improving the relationships. And then, SCM managers can put together processes for managing their goods and services inventory, including receiving and verifying shipments, transferring them to the manufacturing facilities and authorizing supplier payments. 3. MakeThis is the manufacturing step. Supply chain managers schedule the activities necessary for production, testing, packaging and preparation for delivery. This is the most metric-intensive portion of the supply chainone where companies are able to measure quality levels, production output and worker productivity. 4. DeliverThis is the part that many SCM insiders refer to as logistics, where companies coordinate the receipt of orders from customers, develop a network of warehouses, pick carriers to get products to customers and set up an invoicing system to receive payments. 5. ReturnThis can be a problematic part of the supply chain for many companies. Supply chain planners have to create a responsive and flexible network for receiving defective and excess products back from their customers and supporting customers who have problems with delivered products.

1960s - Inventory Management Focus, Cost Control 1970s - MRP & BOM - Operations Planning 1980s - MRPII, JIT - Materials Management, Logistics 1990s - SCM - ERP - Integrated Purchasing, Financials, Manufacturing, Order Entry 2000s - Optimized Value Network with Real-Time Decision Support; Synchronized & Collaborative Extended Network

Strategic Advantage It Can Drive Strategy

* Manufacturing is becoming more efficient * SCM offers opportunity for differentiation (Dell) or cost reduction (Wal-Mart or Big Bazaar)

Globalization It Covers The World * Requires greater coordination of production and

distribution * Increased risk of supply chain interruption * Increases need for robust and flexible supply chains

At the company level, supply chain management impacts

* COST For many products, 20% to 40% of total product costs are controllable logistics costs. * SERVICE For many products, performance factors such as inventory availability and speed of delivery are critical to customer satisfaction.

Reduced inventory Reduced distribution costs Reduced time to market Reduced market risks through effective co-ordination and communication Improved quality of product/service Improved inventory management Increased ability to implement just-in-time delivery Increase in on-time deliveries Increased factory responsiveness Order cycle time reduced Increased revenue Increased visibility of processes Increased customer service Create competitive advantage

Plan

Source

Make

Deliver

Buy

Uncertainty is inherent to every supply chain

Travel times Breakdowns of machines and vehicles Weather, natural catastrophe, war Local politics, labor conditions, border issues

The complexity of the problem to globally optimize a supply chain is significant

Minimize internal costs Minimize uncertainty Deal with remaining uncertainty

11

Distortion of information about the demand for a product as it passes from one entity to the next across the supply chain. More accuracy from the Supply chain management system can help in overcoming the bullwhip effect. With Perfect information about demand and production , a firm can implement an effective just-in time(a japanese concept), delivering goods in the right amount and at the right time as they are needed.

Occurs when slight demand variability is magnified as information moves back upstream

10-13

Four critical methods for reducing the Bullwhip effect:

Reduce uncertainty in the supply chain

Reduce variability in the supply chain

Centralize demand information Keep each stage of the supply chain provided with up-todate customer demand information More frequent planning (continuous real-time planning the goal) Every-day-low-price strategies for stable demand patterns Use cross-docking to reduce order lead times Use EDI techniques to reduce information lead times

Reduce lead times

Eliminate the bullwhip through strategic partnerships

Vendor-managed inventory (VMI) Collaborative planning, forecasting and replenishment (CPFR)

14

Forecasts are never right

Very unlikely that actual demand will exactly equal forecast demand

The longer the forecast horizon, the worse the forecast

A forecast for a year from now will never be as accurate as a forecast for 3 months from now

Aggregate forecasts are more accurate

A demand forecast for all CV therapeutics will be more accurate than a forecast for a specific CV-related product

Nevertheless, forecasts (or plans, if you prefer) are important management tools when some methods are applied to reduce uncertainty

15

Overcoming functional silos with conflicting goals

Manufacturing Distribution Low inventories Low transportatio n DELIVER Customer Service/ Sales

High inventories High service levels Regional stocks

Purchasing

Low purchase price Multipl e vendors SOURCE

Few changeovers

Stable schedules

Long run lengths MAKE

SELL

16

ISSUE Network Planning

CONSIDERATIONS

Warehouse locations and capacities Plant locations and production levels Transportation flows between facilities to minimize cost and time How should inventory be managed? Why does inventory fluctuate and what strategies minimize this? Impact of volume discount and revenue sharing Pricing strategies to reduce order-shipment variability Selection of distribution strategies (e.g., direct ship vs. cross-docking) How many cross-dock points are needed? Cost/Benefits of different strategies How can integration with partners be achieved? What level of integration is best? What information and processes can be shared? What partnerships should be implemented and in which situations?

Inventory Control Supply Contracts Distribution Strategies

Integration and Strategic Partnering

Outsourcing & Procurement Strategies Product Design

What are our core supply chain capabilities and which are not? Does our product design mandate different outsourcing approaches? Risk management How are inventory holding and transportation costs affected by product design? How does product design enable mass customization?

17

STRATEGY Make to Stock

WHEN TO CHOOSE

standardized products, relatively predictable demand customized products, many variations many variations on finished product; infrequent demand

BENEFITS

Low manufacturing costs; meet customer demands quickly Customization; reduced inventory; improved service levels Low inventory levels; wide range of product offerings; simplified planning Enables response to specific customer requirements

Make to Order Configure to Order

Engineer to Order

complex products, unique customer specifications

18

demand-driven focus to manage demand more efficiently. helps a company create a more customerfocused mindset, without sacrificing operational efficiency help overall costs and customer service efforts

business landscape is rapidly becoming more global. improvements in communications, globalization is dramatically impacting the way business is managed and transacted Manufacturing, distribution, sourcing of materials, invoicing and returns have all been significantly impacted by the increased integration of a global customer and supplier base

ways to reduce cost and are creating a more efficient value chain to remain cost competitive. provide value-added services to meet the demands of sophisticated customers. Cost improvements through : Sales and operations planning Transportation/distribution management Improved product lifecycle management

significant economic benefits optimally outsourced supply chain , relies heavily on: (1) Superior supply chain network design (2) Inclusion of that outsource partner in the information chain (3) Establishment of control mechanisms to proactively monitor the various components of the supply chain (4) Information systems to connect and coordinate the supply chain as seamlessly as possible

pressure to develop innovative products need more efficient product lifecycle management Processes managing new product introduction , product discontinuation, design for manufacturability and leveraging across their entire product and infrastructure characteristics.

increase visibility throughout the value chain decrease value chain costs collaboration provides key people throughout the value chain with the information needed to make business-critical decisions with the best available information.

The Kaira District Co-operative Milk Producers Union Limited, popularly known as Amul Dairy is a US $ 500 million turnover institution Network of over 10000 Village Co-operative Societies and 500,000 plus members. Formed in the year 1946 , Amul is the leading food brand in India and today 70,000 villages and 200 districts in India are part of it. markets its products through 50 sales offices throughout India and distribution is done through a network of 4,000 stockiest who in turn supply 500,000 retail outlets.

Amul is the largest food brand in India with an annual turnover of US $1068 million.

Currently Amul has 3.11 million producer members with milk collection average of 6.04 million litres/day. Amul is the largest producer of milk and milk products in the world.

large decentralized network of suppliers and producers, simultaneous development of markets and suppliers, lean and efficient supply chain , and breakthrough leadership.

Every day Amul collects 447,000 litres of milk from 2.12 million farmers , converts the milk into branded, packaged products, and delivers goods worth Rs 6 crore (Rs 60 million) to over 500,000 retail outlets across the country.

GCMMF is directly responsible only for a small part of the chain, with a number of third party players (distributors, retailers and logistics support providers) playing large roles.

Amul products are available in over 500,000 retail outlets across India through its network of over 3,500 distributors. There are 47 depots with dry and cold warehouses to buffer inventory of the entire range of products.

GCMMF transacts on an advance demand draft basis from its wholesale dealers instead of the cheque system adopted by other major FMCG companies. Wholesale dealers carry inventory that is just adequate to take care of the transit time from the branch warehouse to their premises. This just-in-time inventory strategy improves dealers' return on investment (ROI). All GCMMF branches engage in route scheduling and have dedicated vehicle operations.

E-SCM is planning and controlling the flow of materials from suppliers to the end users using internet technologies.

E-SCM refers to the complex network of relationship that organizations maintain with trading partner to source, manufacture and deliver the products.

Amul has installed over 3000 automatic milk collection system units (AMCUS) at village societies to capture member information, milk fat content and amount payable to each member. Each member is given plastic card for indentification Computer calculate amount due to the farmer on the basis of the fat content The value of the milk is printed out on the slip and handed over to the farmer , who collects the payment from the adjacent window Thus with the help of it farmer gets the payment within the minutes On the logistic more than 5000 trucks move milk from the villages to 200 dairy processing plants twice a day according to a carefully planned scheduled Every day Amul collects 7 million liters of milk from 2.6 million farmers (many illiterate), converts the milk into branded, packaged products, and delivers goods to over 500,000 retail outlets across the country ERP software named as enterprise wide integrated application system covers a operation like planning advertisement and promotion and distribution network planning. Each Amul office are connected via internet and all of them send daily reports on sales and inventory to the main system at Anand

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ba Core 6 Emodule 11Document4 pagesBa Core 6 Emodule 11Francheska LarozaPas encore d'évaluation

- WAREHOUSING & STORAGE TECHNIQUES - Lecture 2Document31 pagesWAREHOUSING & STORAGE TECHNIQUES - Lecture 2Muhammad AhsanPas encore d'évaluation

- Long Term Planning PDFDocument55 pagesLong Term Planning PDFJorz AuguPas encore d'évaluation

- Logistics & Supply ChainDocument32 pagesLogistics & Supply ChainprashantmiraclePas encore d'évaluation

- Material Requirements Planning (MRP)Document19 pagesMaterial Requirements Planning (MRP)Anaya MalikPas encore d'évaluation

- Job Order CostingDocument25 pagesJob Order CostingNors PataytayPas encore d'évaluation

- AWB Draft 9887MS-URBAN BLISS - AirshipmentDocument1 pageAWB Draft 9887MS-URBAN BLISS - Airshipmentfaisal benisonPas encore d'évaluation

- Project Plant Pals Operations & Training Plan: February 15thDocument3 pagesProject Plant Pals Operations & Training Plan: February 15thCharlie Goyal83% (6)

- 8055 Case StudyDocument5 pages8055 Case Studyphebe varghesePas encore d'évaluation

- SCM Med TecDocument4 pagesSCM Med Tecsitinurzahrah100% (2)

- Research Paper On DHLDocument5 pagesResearch Paper On DHLafnhekkghifrbm100% (1)

- Case Study - Wal-Mart FinalDocument10 pagesCase Study - Wal-Mart FinalMartin Allen ClaudioPas encore d'évaluation

- TAPMI Newsletter August2012Document20 pagesTAPMI Newsletter August2012mitpgandhiPas encore d'évaluation

- Study Material PDFDocument69 pagesStudy Material PDFbalamurugan0% (1)

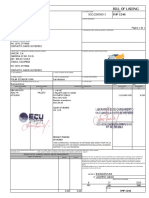

- Bill of Lading Logimpex Cargo S.A.SDocument1 pageBill of Lading Logimpex Cargo S.A.SFrancisco RiascosPas encore d'évaluation

- Inventory MethodsDocument15 pagesInventory MethodsKevin KouamenPas encore d'évaluation

- CIM - A Tool For Continuous ImprovementDocument2 pagesCIM - A Tool For Continuous ImprovementArunPas encore d'évaluation

- Green Coffee FOB, C & F, CIF Contract: (/ - .'. - .. - /J'JJ. (T:::L?!D.Document4 pagesGreen Coffee FOB, C & F, CIF Contract: (/ - .'. - .. - /J'JJ. (T:::L?!D.coffeepathPas encore d'évaluation

- POMDocument64 pagesPOMvignesh. viswanathanPas encore d'évaluation

- Value Stream Mapping at SysIntegDocument16 pagesValue Stream Mapping at SysIntegAsher RamishPas encore d'évaluation

- Amazon and Walmart On Collision CourseDocument27 pagesAmazon and Walmart On Collision Coursekaushal gupta100% (1)

- Individual Assignment - Video ReviewDocument5 pagesIndividual Assignment - Video ReviewNurul Athira Omar SaifuddinPas encore d'évaluation

- Inventory Improvement QuestionnaireDocument6 pagesInventory Improvement QuestionnaireShailesh SoniPas encore d'évaluation

- Cost Accounting CH 17 SolutionsDocument49 pagesCost Accounting CH 17 Solutionsbdameron60% (10)

- Warehouse Manager or SupervisorDocument2 pagesWarehouse Manager or Supervisorapi-76952316Pas encore d'évaluation

- Sap MM Interview QuestiondocxDocument29 pagesSap MM Interview QuestiondocxManjunath a nPas encore d'évaluation

- 20 Principles of Material HandlingDocument3 pages20 Principles of Material HandlingNerz CionPas encore d'évaluation

- Landed Cost Management DemoDocument9 pagesLanded Cost Management DemoManojPas encore d'évaluation

- P5-2 Dan 3Document5 pagesP5-2 Dan 3ramaPas encore d'évaluation

- Code Movement Sub Movement Code Number SourceDocument44 pagesCode Movement Sub Movement Code Number SourceSanath SuvarnaPas encore d'évaluation