Académique Documents

Professionnel Documents

Culture Documents

Development of Sustainable Medical Devices

Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Development of Sustainable Medical Devices

Droits d'auteur :

Formats disponibles

DEVELOPMENT OF SUSTAINABLE MEDICAL DEVICES

SHANTESH HEDE* Supervisors: Luis Alexandre Rocha, Paula Ferreira and Manuel Nunes

* shanteshhede@gmail.com

University of Minho School of Engineering <Department of Production and Systems Engineering>

I. INTRODUCTION

Medical Devices consume significant non-renewable resources, throughout its Life Cycle. Thus affecting social, economic and environmental sustainability. Therefore, it necessitates the inclusion of Sustainability in the Design and Development Phase.

II. AIM and MOTIVATION: To Devise a Multifaceted Product Development Framework:

To illustrate the correlation between the Design & Development Phase and Sustainability throughout the Product Life Cycle. To present and apply a priority based decision model incorporating appropriate criteria for developing medical devices.

III. MULTIFACETED FRAMEWORK

A) PRIORITY BASED DECISION MAKING MODEL USING ANALYTICAL HIERARCHY PROCESS

Market Competitiveness, Profitability, Safety and Regulatory Compliance (Functionality and Sustainability) TIER 1 (Mandatory and Non Negotiable).

Fig.1: Conflict resolution, during Product Development (Refer Section C) and inclusion of other 2 Tiers only in accordance with Tier 1 (Non Negotiable).

End-of Life Opportunities, Growth in Market Share and Employment Community Development and Corporate Expansion.

TIER 2 (Negotiable).

TIER 3 (Negotiable).

B) Design Structure Matrix (DSM) & Value Engineering Analysis

A. B. C.

Parts A B C D E A x x B x x C x D x E

A B E

INPUTS (COST) -Knowledge -Human Resources -Services & Resources PROCESS

E.

D.

C D Process Plan Sequence

Example: Dialysis Cartridge designed by Hanson and Hitchcock, 2009

OUTPUT (VALUE) -Profit: Economic & Social Goals -Knowledge Growth. -Emissions and Waste. -Safety and Regulatory Compliance. -Product Functionality

Fig. 2: Medical Devices are a result of multiple interdependent processes and decisions. DSM (Source: DSMWeb.org) can illustrate the interdependencies (& conflicts) of the Value of each Process(s) from the Scale of 1 to 9, in order to accommodate the Dynamically changing Business and Regulatory scenarios.

Fig. 3:Value Engineering Analysis (Source: SAVE International). The Value pertains to Business Performance, Regulatory Compliance and Sustainability. The said approach minimizes negative consequences at the downstream phase.

C) Comprehensive Sustainable Product Development Framework-A Life Cycle Approach

Idea Generation End-Of Life Options: Recycling Remanufacturing Market and Portfolio Planning Concept Definition Proof of Principle & Product Layout Iterate using AHP Requirements Specifications Conceptual Design PDR Design CDR Cancel Production Sales and Distribution Use Maintenance End-Of-Life

Transportation Resources Extraction Disposal

Fig. 4: 1. Preliminary Design Review (PDR):Clinical Studies, Prototyping, Design Validation of Sub-systems. 2. Critical Design Review (CDR) of Production Tool Development, Integration, Assembly and Testing.

IV. CONCLUSION The Framework, accounts for the interdependencies between the various developmental processes, pertinent to the 3 Value Dimensions. The

decision making tool, assists in conflict resolution between various product requirements, at every developmental stage, by focusing on the essential criteria and limitations of the accessible resources. .

V. ACKNOWLEDGEMENTS

The author acknowledges the contribution of MIT Portugal Program, University of Minho and Foundation Of Science and Technology, Portugal.

Uma Escola a Reinventar o Futuro Semana da Escola de Engenharia - 3 a 8 de Outubro de 2011

Vous aimerez peut-être aussi

- 1-S2.0-S2212827114007756-Main 2Document6 pages1-S2.0-S2212827114007756-Main 2J.C.VPas encore d'évaluation

- KA-Healthcare Systems EngineeringDocument26 pagesKA-Healthcare Systems EngineeringMaykel Kristopher BautistaPas encore d'évaluation

- DOP024Document2 pagesDOP024Fahmi FareaPas encore d'évaluation

- Hygienic Design of Food Industry EquipmentDocument10 pagesHygienic Design of Food Industry EquipmentBồ Công AnhPas encore d'évaluation

- Chapter 2 Designing-Product-Services-And-PrcessesDocument31 pagesChapter 2 Designing-Product-Services-And-PrcessesRomeo De Guzman Jr.Pas encore d'évaluation

- Product Driven Supply ChainDocument15 pagesProduct Driven Supply ChainwuryaningPas encore d'évaluation

- Sciencedirect: Manufacturing System Flexibility: Product Flexibility AssessmentDocument6 pagesSciencedirect: Manufacturing System Flexibility: Product Flexibility AssessmentitzgayaPas encore d'évaluation

- Product Lifecycle Management Notes (Mechanical Engineering)Document16 pagesProduct Lifecycle Management Notes (Mechanical Engineering)ususama78Pas encore d'évaluation

- Maintenance and Operational Reliability: 24 Essential Building BlocksD'EverandMaintenance and Operational Reliability: 24 Essential Building BlocksPas encore d'évaluation

- E (OTDA: O T D A) : Valuation of An Operating Theatre Design by A Software Program Perating Heatre Esign NalyzerDocument8 pagesE (OTDA: O T D A) : Valuation of An Operating Theatre Design by A Software Program Perating Heatre Esign NalyzerOlim AriyaPas encore d'évaluation

- Artículo 3Document6 pagesArtículo 3JuanCamiloPas encore d'évaluation

- Literature Review On Concurrent Engineering and Its ImplementationDocument7 pagesLiterature Review On Concurrent Engineering and Its Implementationpp3986Pas encore d'évaluation

- Product Platforms and Production - Current State and Future Research Directions Targeting Producibility and Production PreparationDocument10 pagesProduct Platforms and Production - Current State and Future Research Directions Targeting Producibility and Production PreparationJosip StjepandicPas encore d'évaluation

- Sustainability Assessment of Products A Comparative Study of Sustainability Assessment ToolsDocument10 pagesSustainability Assessment of Products A Comparative Study of Sustainability Assessment ToolsGabriel Lopez BarajasPas encore d'évaluation

- Preprints201807 0517 v1Document17 pagesPreprints201807 0517 v1tantibaPas encore d'évaluation

- Robust ProductDocument10 pagesRobust Productkshatriyamanoj521Pas encore d'évaluation

- A Framework For Product DevelopmentDocument15 pagesA Framework For Product DevelopmentWayn CahiligPas encore d'évaluation

- Taguchi on Robust Technology Development: Bringing Quality Engineering UpstreamD'EverandTaguchi on Robust Technology Development: Bringing Quality Engineering UpstreamÉvaluation : 1 sur 5 étoiles1/5 (1)

- A Case For Assisting Product Family' Manufacturing System DesignersDocument6 pagesA Case For Assisting Product Family' Manufacturing System DesignersNur SutrakasihPas encore d'évaluation

- 266 Arun NambiarDocument6 pages266 Arun NambiarJen S. GallanoPas encore d'évaluation

- Guidelines for the Management of Change for Process SafetyD'EverandGuidelines for the Management of Change for Process SafetyPas encore d'évaluation

- Managing Product Life Cycle For Effective Supply Chain Strategies - Case of Pharmaceutical Industry in MoroccoDocument11 pagesManaging Product Life Cycle For Effective Supply Chain Strategies - Case of Pharmaceutical Industry in MoroccoMostafa AfifyPas encore d'évaluation

- 1.1 Product Life Cycle Costing in The Changing Industrial ScenarioDocument10 pages1.1 Product Life Cycle Costing in The Changing Industrial ScenarioVishal MalikPas encore d'évaluation

- X Development Overview of Sustainable Manufacturing MetricsDocument5 pagesX Development Overview of Sustainable Manufacturing MetricsHelton SantanaPas encore d'évaluation

- Guide To Agile Design and Development For Medical Devices-AMDD-Greenlight-GuruDocument40 pagesGuide To Agile Design and Development For Medical Devices-AMDD-Greenlight-Gururemliw101Pas encore d'évaluation

- System Concurrent Engineering For The Development of An Aeronautical Navigation SystemDocument16 pagesSystem Concurrent Engineering For The Development of An Aeronautical Navigation SystemnicolasPas encore d'évaluation

- Operations MGMT Lecture Note (Chapter 3) MLTDocument42 pagesOperations MGMT Lecture Note (Chapter 3) MLTnatiPas encore d'évaluation

- 3.review Article (RA) Comparison of The Product Life Cycle Cost System With The Traditional Cost System... Serdar KUZUDocument24 pages3.review Article (RA) Comparison of The Product Life Cycle Cost System With The Traditional Cost System... Serdar KUZUAinYazidPas encore d'évaluation

- Product Design and DevelopmentDocument27 pagesProduct Design and DevelopmentGur- FeatPas encore d'évaluation

- An Investigation of Sustainable Maintenance Performance Indicators Identification Expert Validation and Portfolio of Future ResearchDocument18 pagesAn Investigation of Sustainable Maintenance Performance Indicators Identification Expert Validation and Portfolio of Future ResearchMelinda IbrahimPas encore d'évaluation

- Project Sustainable Design ManagementDocument24 pagesProject Sustainable Design ManagementNhan DoPas encore d'évaluation

- Ingeniero de ProductoDocument27 pagesIngeniero de ProductoJuan Diego Arroyave SernaPas encore d'évaluation

- Chapter 5 Design of Goods and ServicesDocument5 pagesChapter 5 Design of Goods and ServicesShiela MayPas encore d'évaluation

- Usability of Software Architecture Design Pattern in Medical Process Re-Engineering ModelDocument10 pagesUsability of Software Architecture Design Pattern in Medical Process Re-Engineering ModeleditorijaiemPas encore d'évaluation

- Performance Measurement of R&D Projects in A Multi Project Concurrent Engineering EnvironmentDocument13 pagesPerformance Measurement of R&D Projects in A Multi Project Concurrent Engineering EnvironmentpapplionPas encore d'évaluation

- Costing Life CycleDocument8 pagesCosting Life CycleDxtr MedinaPas encore d'évaluation

- Cirp Annals - Manufacturing TechnologyDocument24 pagesCirp Annals - Manufacturing TechnologyBosco BeloPas encore d'évaluation

- Operations and Supply Chain Management Week 3Document6 pagesOperations and Supply Chain Management Week 3Rhyn RutherfordPas encore d'évaluation

- Systems Engineering: Systems Engineering Is An Interdisciplinary Field of Engineering That Focuses On HowDocument14 pagesSystems Engineering: Systems Engineering Is An Interdisciplinary Field of Engineering That Focuses On HowBraylynBarracaPas encore d'évaluation

- Thrust Area PPT - PLM REV-01Document39 pagesThrust Area PPT - PLM REV-01Raghvendra Pratap SinghPas encore d'évaluation

- Informs: INFORMS Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Operations ResearchDocument13 pagesInforms: INFORMS Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Operations ResearchValentin CorbeaPas encore d'évaluation

- Machining WasteDocument6 pagesMachining Wastegunawan refiadiPas encore d'évaluation

- Selection of Design Concept: A Case Study: S.S.Kalashetty, Dr.G.K.Purohit and Dr.S.S.HebbalDocument6 pagesSelection of Design Concept: A Case Study: S.S.Kalashetty, Dr.G.K.Purohit and Dr.S.S.HebbalIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalPas encore d'évaluation

- Assignment Help (+1) 346-375-7878Document30 pagesAssignment Help (+1) 346-375-7878Muhammad Sheharyar MohsinPas encore d'évaluation

- Introduction To Logistics: EctureDocument22 pagesIntroduction To Logistics: EcturemawandePas encore d'évaluation

- Risk Based Maintanance PDFDocument9 pagesRisk Based Maintanance PDFRafaelPachecoPas encore d'évaluation

- Different Approaches To Concurrent EngineeringDocument21 pagesDifferent Approaches To Concurrent EngineeringNiket KawalePas encore d'évaluation

- Realistic - Constraints and Design - MethodsDocument6 pagesRealistic - Constraints and Design - MethodsAmr SamyPas encore d'évaluation

- Dillinger CPSL2022Document10 pagesDillinger CPSL2022Peter ParkerPas encore d'évaluation

- P19 Vol3 Issue-2 July2015 ijstmLEANMANUFACTURINGAREVIEWDocument6 pagesP19 Vol3 Issue-2 July2015 ijstmLEANMANUFACTURINGAREVIEWjabir sulaimanPas encore d'évaluation

- Pdve Paper Soultion 2011Document19 pagesPdve Paper Soultion 2011AMIT SOLANKIPas encore d'évaluation

- Application of QFDDocument10 pagesApplication of QFDSehr KhanPas encore d'évaluation

- MCQ and Short Answers For Week 4Document18 pagesMCQ and Short Answers For Week 4Usama TahirPas encore d'évaluation

- Certifiable Software Applications 2: Support ProcessesD'EverandCertifiable Software Applications 2: Support ProcessesPas encore d'évaluation

- Lean Manufacturing: A Review: January 2015Document6 pagesLean Manufacturing: A Review: January 2015AkshayPas encore d'évaluation

- Design For Quality and Product Excellence: NotesDocument11 pagesDesign For Quality and Product Excellence: NotesadnilsallyPas encore d'évaluation

- COMMERCIAL SPECIFICATIONS OpensystDocument33 pagesCOMMERCIAL SPECIFICATIONS OpensystmalinksPas encore d'évaluation

- Sensing Complex Environments With Localization RequirementsDocument1 pageSensing Complex Environments With Localization RequirementsSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Water Scarcity and Drought in Sôrdo River BasinDocument1 pageWater Scarcity and Drought in Sôrdo River BasinSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Advanced Production Scheduling Applied To Diferent Levels of Mass Customization Industrial EnvironmentsDocument1 pageAdvanced Production Scheduling Applied To Diferent Levels of Mass Customization Industrial EnvironmentsSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Cooling System Optimization in Polymer Injection MouldingDocument1 pageCooling System Optimization in Polymer Injection MouldingSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Resource Complementarity in Activity NetworksDocument1 pageResource Complementarity in Activity NetworksSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Model of Integrated Management of Public Procurement: Guidance For The Development of Electronic Public Procurement Oriented To Public ValueDocument1 pageModel of Integrated Management of Public Procurement: Guidance For The Development of Electronic Public Procurement Oriented To Public ValueSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Automatic Detection and Segmentation of Cortical Lesions in Multiple SclerosisDocument1 pageAutomatic Detection and Segmentation of Cortical Lesions in Multiple SclerosisSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Rodrigo Lameiras Joaquim Barros, Miguel Azenha and Isabel ValenteDocument1 pageRodrigo Lameiras Joaquim Barros, Miguel Azenha and Isabel ValenteSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Users' Perceptions Regarding The Use of Biometric Authentication Technologies in The Access To Health ServicesDocument1 pageUsers' Perceptions Regarding The Use of Biometric Authentication Technologies in The Access To Health ServicesSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Performance's Evaluation of Building's Envelope To EarthquakesDocument1 pagePerformance's Evaluation of Building's Envelope To EarthquakesSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Critical Knowledge Monitor System ModelDocument1 pageCritical Knowledge Monitor System ModelSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Experimental Characterization of Commercially Available Grouts For Use in Masonry StructuresDocument1 pageExperimental Characterization of Commercially Available Grouts For Use in Masonry StructuresSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Decision Support System For The Intensive Care UnitDocument1 pageDecision Support System For The Intensive Care UnitSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Archetype Based Intelligent System For Healthcare InteroperabilityDocument1 pageArchetype Based Intelligent System For Healthcare InteroperabilitySemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Product and Process Traceability at Manufacturing Organizations: An Ontological Unification in Information SystemsDocument1 pageProduct and Process Traceability at Manufacturing Organizations: An Ontological Unification in Information SystemsSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Business Intelligence Supporting Higher Education Institutions: The Case of Student Relationship ManagementDocument1 pageBusiness Intelligence Supporting Higher Education Institutions: The Case of Student Relationship ManagementSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Formalizing A Modeling Business Organization Methodology (Mlearn)Document1 pageFormalizing A Modeling Business Organization Methodology (Mlearn)Semana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Design Software Systems From Business Process ModelingDocument1 pageDesign Software Systems From Business Process ModelingSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- UV Protection of Polyamide Fabrics With Polymeric NanocompositesDocument1 pageUV Protection of Polyamide Fabrics With Polymeric NanocompositesSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Hybridization of A Genetic Algorithm With A Pattern Search Augmented Lagrangian MethodDocument1 pageHybridization of A Genetic Algorithm With A Pattern Search Augmented Lagrangian MethodSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Semantic Interoperability and Health RecordsDocument1 pageSemantic Interoperability and Health RecordsSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Improving Quality of Information in Health Records With Medical OnthologiesDocument1 pageImproving Quality of Information in Health Records With Medical OnthologiesSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Social Signals Processing in Human-Computer InteractionDocument1 pageSocial Signals Processing in Human-Computer InteractionSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- INFLUENCE OF THE LOOP TYPE ON THE ENERGY ABSORPTION PERFORMANCE OF WEFT-KNITTED FABRICS PRODUCED WITH NiTi WIRESDocument1 pageINFLUENCE OF THE LOOP TYPE ON THE ENERGY ABSORPTION PERFORMANCE OF WEFT-KNITTED FABRICS PRODUCED WITH NiTi WIRESSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Sheet Metal Processing Equipment and Markets Under Uncertain Future Environments: A Framework To Assist Technology Strategy DecisionsDocument1 pageSheet Metal Processing Equipment and Markets Under Uncertain Future Environments: A Framework To Assist Technology Strategy DecisionsSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Articulation Between Information Systems and Quality Management SystemsDocument1 pageArticulation Between Information Systems and Quality Management SystemsSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Risk Characterization in Wood CompaniesDocument1 pageRisk Characterization in Wood CompaniesSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Soils Contaminated With Hexavalent Chromium - Sorption, Migration and RemediationDocument1 pageSoils Contaminated With Hexavalent Chromium - Sorption, Migration and RemediationSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Application of Functional Textiles in The Healthcare AreaDocument1 pageApplication of Functional Textiles in The Healthcare AreaSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Assessing The Performance of Neonatology UnitsDocument1 pageAssessing The Performance of Neonatology UnitsSemana da Escola de Engenharia da Universidade do MinhoPas encore d'évaluation

- Vanguard 44 - Anti Tank Helicopters PDFDocument48 pagesVanguard 44 - Anti Tank Helicopters PDFsoljenitsin250% (2)

- HR Practices in Public Sector Organisations: (A Study On APDDCF LTD.)Document28 pagesHR Practices in Public Sector Organisations: (A Study On APDDCF LTD.)praffulPas encore d'évaluation

- Tec066 6700 PDFDocument2 pagesTec066 6700 PDFExclusivo VIPPas encore d'évaluation

- Scoring Rucric Lecture Eassess2.docx NewDocument6 pagesScoring Rucric Lecture Eassess2.docx NewMaica Ann Joy SimbulanPas encore d'évaluation

- Ubicomp PracticalDocument27 pagesUbicomp Practicalvikrant sharmaPas encore d'évaluation

- Optical Transport Network SwitchingDocument16 pagesOptical Transport Network SwitchingNdambuki DicksonPas encore d'évaluation

- Learning Competency PDFDocument1 pageLearning Competency PDFLEOMAR PEUGALPas encore d'évaluation

- Data Science ProjectsDocument3 pagesData Science ProjectsHanane GríssettePas encore d'évaluation

- Wordbank 15 Coffee1Document2 pagesWordbank 15 Coffee1akbal13Pas encore d'évaluation

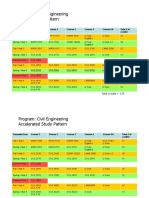

- HKUST 4Y Curriculum Diagram CIVLDocument4 pagesHKUST 4Y Curriculum Diagram CIVLfrevPas encore d'évaluation

- Guidelines For Doing Business in Grenada & OECSDocument14 pagesGuidelines For Doing Business in Grenada & OECSCharcoals Caribbean GrillPas encore d'évaluation

- The One With The ThumbDocument4 pagesThe One With The Thumbnoelia20_09Pas encore d'évaluation

- 5 Ways To Foster A Global Mindset in Your CompanyDocument5 pages5 Ways To Foster A Global Mindset in Your CompanyGurmeet Singh KapoorPas encore d'évaluation

- Vendor Registration FormDocument4 pagesVendor Registration FormhiringPas encore d'évaluation

- Norman, K. R., Pali Philology & The Study of BuddhismDocument13 pagesNorman, K. R., Pali Philology & The Study of BuddhismkhrinizPas encore d'évaluation

- 4039-Texto Del Artículo-12948-3-10-20211123Document14 pages4039-Texto Del Artículo-12948-3-10-20211123Ricardo ApazaPas encore d'évaluation

- Flight Data Recorder Rule ChangeDocument7 pagesFlight Data Recorder Rule ChangeIgnacio ZupaPas encore d'évaluation

- Aharonov-Bohm Effect WebDocument5 pagesAharonov-Bohm Effect Webatactoulis1308Pas encore d'évaluation

- Population Second TermDocument2 pagesPopulation Second Termlubna imranPas encore d'évaluation

- Pepsico SDM ProjectDocument6 pagesPepsico SDM ProjectJemini GanatraPas encore d'évaluation

- Subeeka Akbar Advance NutritionDocument11 pagesSubeeka Akbar Advance NutritionSubeeka AkbarPas encore d'évaluation

- E Voting PPT - 1Document11 pagesE Voting PPT - 1madhu100% (2)

- Final - Anarchy One-Sheet Sell SheetDocument2 pagesFinal - Anarchy One-Sheet Sell SheetMaddanie WijayaPas encore d'évaluation

- 2022 AMR Dashboard Funding Opportunity Announcement 11.18.2022Document16 pages2022 AMR Dashboard Funding Opportunity Announcement 11.18.2022Tuhin DeyPas encore d'évaluation

- Bichelle HarrisonDocument2 pagesBichelle HarrisonShahbaz KhanPas encore d'évaluation

- Dynamic Study of Parabolic Cylindrical Shell A Parametric StudyDocument4 pagesDynamic Study of Parabolic Cylindrical Shell A Parametric StudyEditor IJTSRDPas encore d'évaluation

- Coke Drum Repair Welch Aquilex WSI DCU Calgary 2009Document37 pagesCoke Drum Repair Welch Aquilex WSI DCU Calgary 2009Oscar DorantesPas encore d'évaluation

- Clinical Skills TrainingDocument12 pagesClinical Skills TrainingSri Wahyuni SahirPas encore d'évaluation

- Corelink Mmu600ae TRM 101412 0100 00 enDocument194 pagesCorelink Mmu600ae TRM 101412 0100 00 enLv DanielPas encore d'évaluation

- Catalogo PukangDocument41 pagesCatalogo PukangClarita Muller LeiguePas encore d'évaluation