Académique Documents

Professionnel Documents

Culture Documents

Viscosity: Introduction and Application in Paint Flow & Pigment Dispersion

Transféré par

Nur KhadijahDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Viscosity: Introduction and Application in Paint Flow & Pigment Dispersion

Transféré par

Nur KhadijahDroits d'auteur :

Formats disponibles

Viscosity

Introduction and Application in

Paint Flow & Pigment

Dispersion

1

2

Background

Viscosity is a measure of a fluids

resistance to flow. Think of viscosity as a

coefficient that relates the stress applied to

a fluid and the fluids response. For

example:

where t is the stress (Pa), is the

resulting velocity gradient in the fluid, and

q is the viscosity (sometimes referred to as

shear viscosity in this context).

This basaltic lava flow emanating

from a very small vent on Mt. Etna is

about as viscous as a thick salsa.

Photo by L. Connor

What is viscosity?

t q =

du

dx

1

2

du

dx

1

2

3

Background

Consider a fluid trapped between

two plates. When a stress is

applied to the upper plate while the

lower plate is held still, a vertical

velocity gradient is created in the

fluid. This velocity gradient is

equivalent to a strain rate. Since

the units of viscosity are Pascal

seconds (Pa s).

In order to explain shear rate, first there are a few items that need

to be discussed:

Reynolds Number

Turbulent and Laminar Flow

Newtonian and non-Newtonian fluids

Fountain Flow.

What are the units of viscosity?

t q =

du

dx

1

2

Figure from Mader, 2006, Volcanic processes as a source

of statistical data, In: Mader et al., (eds) Statistics in

Volcanology, Geological Society of London, 1-14.

4

The units of Viscosity are:

Pascal.second [Pa.s] in SI, Poise in CGS

1 poise = 100 centipoise (cps)

1 poise = 0.1 Pasec

1 poise = 0.0671969 lb/(ftsec)

1 poise = 4.031814 lb/(ftmin)

Pa = Pascal = Nm pressure, stress

stoke = (poise)/(g/cm)

Viscosity Units

Reynolds Number

When discussing fluid flow, there are two distinct

types of flow:

Turbulent and Laminar (there is also transitional

flow which occurs between the two distinct

types)

Turbulent flow is very random and there is a lot

of mixing that takes place within the molecules.

Laminar flow is very ordered, the molecules

move in layers.

The Reynolds number is a dimensionless

number that is used to describe the type of flow

that is occurring.

Reynolds Number

The Reynolds Number (Re) of a fluid moving

through a round channel is equal to;

Re = density x velocity x diameter = .v . d

viscosity

If a fluid has a Re of:

2300 > Laminar Flow

2300-4000 Transitional Flow

> 4000 Turbulent Flow

Turbulent flow provides a higher degree of mixing and a more consistent temperature across the flow

channel than laminar flow.

In applications where we use water flow to cool tooling, we want turbulent flow in order to get better heat

transfer.

Faster Flow less drag

Frictional Drag

Frictional Drag

Laminar Flow

While Turbulent flow is very chaotic an there is a

lot of mixing that takes place, Laminar flow is

much smoother and there is a difference in

velocity across the flow channel.

The molecules at the channel wall are flowing

more slowly than the molecules in the middle

due to frictional drag.

Laminar flow is sometimes envisioned as a

series of plates or layers that flow across each

other.

The shear rate is determined by the velocity

divided by the thickness of the laminate or:

= v/h

7

Types of viscosity

Newton's law of

viscosity, is a

constitutive equation

(like Hooke's law,

Fick's law, Ohm's

law).

It is not a

fundamental law of

nature but an

approximation that

holds in some

materials and fails in

others.

8

Non-Newtonian fluids exhibit a more complicated relationship between

shear stress and velocity gradient than simple linearity. Thus there exist a

number of forms of viscosity:

Newtonian: fluids, such as water and most gases which have a constant

viscosity.

Shear thickening: viscosity increases with the rate of shear.

Shear thinning: viscosity decreases with the rate of shear. Shear thinning

liquids are very commonly, but misleadingly, described as thixotropic.

Thixotropic: materials which become less viscous over time when shaken,

agitated, or otherwise stressed.

Rheopectic: materials which become more viscous over time when

shaken, agitated, or otherwise stressed.

A Bingham plastic is a material that behaves as a solid at low stresses

but flows as a viscous fluid at high stresses.

A magnetorheological fluid is a type of "smart fluid" which, when

subjected to a magnetic field, greatly increases its apparent viscosity, to the

point of becoming a viscoelastic solid.

Forms of Viscosity

9

Viscosity Coefficients

Dynamic viscosity, also absolute viscosity, the more usual one (typical units

Pas, Poise, P);

Kinematic viscosity is the dynamic viscosity divided by the density (typical

units cm

2

/s, Stokes, St).

Viscosity is a tensorial quantity that can be decomposed in different ways into

two independent components. The most usual decomposition yields the

following viscosity coefficients:

Shear viscosity, the most important one, often referred to as simply viscosity,

describing the reaction to applied shear stress; simply put, it is the ratio

between the pressure exerted on the surface of a fluid, in the lateral or

horizontal direction, to the change in velocity of the fluid as you move down in

the fluid (this is what is referred to as a velocity gradient).

Volume viscosity (also called bulk viscosity or second viscosity) becomes

important only for such effects where fluid compressibility is essential.

Examples would include shock waves and sound propagation. It appears in the

Stokes' law (sound attenuation) that describes propagation of sound in

Newtonian liquid.

Alternatively,

Extensional viscosity, a linear combination of shear and bulk viscosity,

describes the reaction to elongation, widely used for characterizing polymers.

10

Newtons Law of Viscous Flow

Examples of nonNewtonian fluids are:

polymer solutions and melts

slurries of ore, sand, coal

cement, asphalt

paint, ketchup, peanut butter

blood, saliva

Newtonian and non-Newtonian Fluids

If is constant the fluid is called Newtonian. If is not constant

and depends on the gradient then the fluid is non-Newtonian.

Water is a Newtonian fluid.

11

Background

Any fluid, including the solvent

in paint industry is considered

Newtonian if there is a linear

relationship between stress and

strain. That is, if:

Newtonian and non-Newtonian viscosity

In a non-Newtonian fluid, the above linear relationship does not hold true. For

example, in a Bingham fluid:

where t

o

is a yield stress (also called yield strength) required to get the fluid

moving. Although still linear, a new term is added to the linear equation.

high slope, high viscosity

low slope, low viscosity

t q =

du

dx

1

2

t t q = +

o

du

dx

1

2

12

Background

Viscosity is highly dependent on

temperature. Think of a pool of molten

glass. As the temperature drops, it will

take more and more applied stress to

make the glass flow.

Temperature and Viscosity

An Arrhenian model of viscosity is one in

which viscosity is exponentially

dependent on temperature:

where q

o

is viscosity under standard

temperature conditions, E is the

activation energy, R is the universal gas

constant, and T is temperature.

q q ( ) exp T

E

RT

o

=

(

This glass is an alkaline silicate melt

with low viscosity at 1000 C and very

workable into shapes at about 800 to

900 C. At about 700 C, the viscosity

is high enough for the shape to not

deform under its own weight.

Learn More about the

Arrhenian model

13

More about the Arrhenian Model

The Arrhenian model is named for Svante Arrhenius, who

developed a method of predicting the increased speed of a

chemical reaction with increased temperature. His equation has

the form:

Arrhenian models are also common in statistics and used to predict the higher

rate of failure of just about anything at higher temperatures. For more about

the statistical application of the model, see:

k A

E

RT

=

(

exp

where k is the rate coefficient that describes how much faster the reaction will

proceed, A is the Arrhenius coefficient, which varies with the specific chemical

reaction, E is the activation energy, R is the gas constant, and T is temperature.

Note that this is the exact form of the Arrhenian viscosity model, with A replaced

by the viscosity of the fluid at some standard temperature condition.

More about E,R,T

14

Pseudoplastic and Dilatant Flow

Pseudoplastic and Dilatant

Coating that decrease in viscosity with

increase of shear stress (shear-thinning).

Coating that increase in velocity with

increase of shear stress is called dilatant.

If h decreases as the shear force on the

fluid increases then the fluid is called

thixotropic.

paint, tomato ketchup, toothpaste, peanut

butter

This is the more common behaviour

because the shear force destroys the weak

secondary (van der Waals) forces which

hold the molecules together.

15

Why is Rheology Important for Paint

Industries

Mixing

Pigment Dispersion

Pumping

Storage

Settling

Application

Spray

Dip

Flow coat

Roller coat

Brush

Film formation

Flow and levelling

Coalescence

16

Paint Application

Brush Application

Shear thinning-easy brushing

low resistance

Flow and Leveling - recovery

Sagging - high low shear

viscosity

Open time - lapping

Settling - thixotropic

What Effects Spray Performance

Paint Viscosity (Elongational)

Surface tension

Shear thinning

Thixotropy

Pseudo plastic flow

Solvent evaporation

Thixotropy

Sagging

Flow and Leveling

17

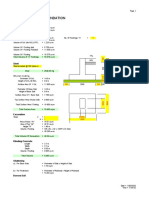

Common Viscosity Measurement

Vous aimerez peut-être aussi

- Viscosity ReportDocument12 pagesViscosity ReportBF3nobelPas encore d'évaluation

- Viscosity-1 Viscometer-2 Relation Between Viscosity &temperature-3 Vogel Equation-4 Programming ofDocument71 pagesViscosity-1 Viscometer-2 Relation Between Viscosity &temperature-3 Vogel Equation-4 Programming ofDr_M_SolimanPas encore d'évaluation

- ViscosityDocument5 pagesViscositydwarika2006Pas encore d'évaluation

- Viscosity ReportDocument11 pagesViscosity ReportMuhammad Farooq100% (1)

- Newtonian and Non-Newtonian Fluids: Velocity Profiles, Viscosity Data, and Laminar Flow Friction Factor Equations For Flow in A Circular DuctDocument9 pagesNewtonian and Non-Newtonian Fluids: Velocity Profiles, Viscosity Data, and Laminar Flow Friction Factor Equations For Flow in A Circular DuctAmedeo Franco BonattiPas encore d'évaluation

- Archimedes' Principle: Density of WaterDocument2 pagesArchimedes' Principle: Density of WaterNg Mei EngPas encore d'évaluation

- Capillary Viscometer Calculation NotesDocument2 pagesCapillary Viscometer Calculation NotesRichard NokyPas encore d'évaluation

- Vinaza ViscosidadDocument8 pagesVinaza ViscosidadPatricia J ÁngelesPas encore d'évaluation

- High Temperature High Shear Rate Viscometers: TheoryDocument4 pagesHigh Temperature High Shear Rate Viscometers: TheoryChamuditha BenaragamaPas encore d'évaluation

- Viscosity of Fluids Lab Ball Drop MethodDocument4 pagesViscosity of Fluids Lab Ball Drop MethodNOKIAPas encore d'évaluation

- 1.explain The Following Types of Distribution Systems : (A) Dead EndDocument15 pages1.explain The Following Types of Distribution Systems : (A) Dead EndMichael LangatPas encore d'évaluation

- Alcohols and EthersDocument51 pagesAlcohols and EthersnanaPas encore d'évaluation

- Collection and Distribution of Water 4.1 Types of IntakeDocument71 pagesCollection and Distribution of Water 4.1 Types of IntakenimcanPas encore d'évaluation

- The Chemical Oxygen Demand (Cod)Document7 pagesThe Chemical Oxygen Demand (Cod)arif hilimiPas encore d'évaluation

- Class - 12/chemistry-2 - Reactions of AlcoholsDocument60 pagesClass - 12/chemistry-2 - Reactions of AlcoholsAISHA AHAMMEDPas encore d'évaluation

- Viscousity Unit EngineeringDocument22 pagesViscousity Unit EngineeringMachineryengPas encore d'évaluation

- Viscosity PDFDocument8 pagesViscosity PDFsoran najebPas encore d'évaluation

- Rotational ViscometerDocument17 pagesRotational ViscometerShivam PrajapatiPas encore d'évaluation

- Mechanical PropertiesDocument57 pagesMechanical PropertiesElmedin Gluhic100% (1)

- Lab #10: Dissolved Oxygen Levels in Natural Waters: Date: Name: Student Id: Co-WorkerDocument5 pagesLab #10: Dissolved Oxygen Levels in Natural Waters: Date: Name: Student Id: Co-WorkerCuong NguyenPas encore d'évaluation

- Three-Point Flexural TestDocument3 pagesThree-Point Flexural TestBassey Okon100% (1)

- Faculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetDocument18 pagesFaculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetPanadol PanadolPas encore d'évaluation

- Work ReportDocument6 pagesWork ReportAmit Karmakar100% (1)

- AER507 Lab ManualDocument39 pagesAER507 Lab Manualarmon_domingoPas encore d'évaluation

- Exp 4result Discussion For FaDocument4 pagesExp 4result Discussion For FanasuhaPas encore d'évaluation

- Engr. Miriam B. VillanuevaDocument10 pagesEngr. Miriam B. VillanuevaJane Carnisel PasionPas encore d'évaluation

- Hydrologic CycleDocument4 pagesHydrologic CycleDEXTUREPas encore d'évaluation

- Viscosity Lee Eakin Gonzales PG 55Document140 pagesViscosity Lee Eakin Gonzales PG 55Paul Renzo Miranda ZuritaPas encore d'évaluation

- 04-01 Water ResourcesDocument74 pages04-01 Water ResourcesAindrila Ganguly100% (1)

- Final Report - 2008 - 10 - 27Document81 pagesFinal Report - 2008 - 10 - 27jarrydPas encore d'évaluation

- Oxygen Demand SlidesDocument8 pagesOxygen Demand SlidesShakir MohyuddinPas encore d'évaluation

- Fluid and Fluid PropertiesDocument42 pagesFluid and Fluid PropertiesCIPETIPT Tool RoomPas encore d'évaluation

- Experiment 6: Fluid Friction Apparatus This Is A Sample Report, It Is The Perfect FormatDocument15 pagesExperiment 6: Fluid Friction Apparatus This Is A Sample Report, It Is The Perfect FormatBryan Pashian ManaluPas encore d'évaluation

- Semnar ReportDocument32 pagesSemnar ReportRishabh Parihar0% (1)

- The Properties of Resins Used For Varnishing and Retouching of Paintings Part3Document12 pagesThe Properties of Resins Used For Varnishing and Retouching of Paintings Part3Jose E BatistaPas encore d'évaluation

- Expt 4b.flexure TestDocument5 pagesExpt 4b.flexure TestVishwasVerma100% (1)

- Envisci Lesson 8water Use and ManagementDocument30 pagesEnvisci Lesson 8water Use and ManagementMaria100% (1)

- Strip Teas' - Solubility Data For The Removal (And Application) Picture VarnishesDocument9 pagesStrip Teas' - Solubility Data For The Removal (And Application) Picture Varnishesmp77Pas encore d'évaluation

- DriersDocument5 pagesDriersAnimesh BhowmikPas encore d'évaluation

- Project RepresentionDocument13 pagesProject RepresentionDeema sultanPas encore d'évaluation

- Organic Soils: BY Roaa Monam FadhilDocument18 pagesOrganic Soils: BY Roaa Monam FadhilroaaPas encore d'évaluation

- What Is Portland Slag Cement - Properties - Uses: Muhammad Abbas March 11, 2019 2 CommentsDocument3 pagesWhat Is Portland Slag Cement - Properties - Uses: Muhammad Abbas March 11, 2019 2 CommentsRussell Jhegs CuevasPas encore d'évaluation

- TSSDocument3 pagesTSSMusfirah AzrinaPas encore d'évaluation

- Full Report Kinematic ViscosityDocument11 pagesFull Report Kinematic ViscosityKyle Pong100% (1)

- Lab Report 2Document13 pagesLab Report 2Unique GuyPas encore d'évaluation

- Drilling Report JessicaDocument14 pagesDrilling Report JessicaJéssica RamalhoPas encore d'évaluation

- Experimental Mechanics Laboratory ManualDocument76 pagesExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- Unit 3 - Construction Site Selection Criteria Assignment 08-05-20Document7 pagesUnit 3 - Construction Site Selection Criteria Assignment 08-05-20Rob PagePas encore d'évaluation

- CM 4655 Polymer Rheology Lab: For Complex Fluids in Motion, We Want To MeasureDocument6 pagesCM 4655 Polymer Rheology Lab: For Complex Fluids in Motion, We Want To Measurealvaro562003Pas encore d'évaluation

- BOQ-of FoundationDocument8 pagesBOQ-of FoundationJohn Carlo AbalaPas encore d'évaluation

- Water Resources DipitDocument32 pagesWater Resources Dipitvineet_knwr100% (1)

- Water Management1Document22 pagesWater Management1Angelie Lape100% (1)

- Material ReportDocument20 pagesMaterial Reportfirstman31100% (1)

- Rational Method Hydologic Calculations With Excel CourseDocument20 pagesRational Method Hydologic Calculations With Excel Coursesyammc100% (1)

- 14.0 Experiment On Determination of Total Solids in Water: Sl. NoDocument12 pages14.0 Experiment On Determination of Total Solids in Water: Sl. NoLely CasTroPas encore d'évaluation

- Lecture Note of ENG 309 (Fluid Mechanics)Document8 pagesLecture Note of ENG 309 (Fluid Mechanics)Osuizugbe Esom kennethPas encore d'évaluation

- Seminar ReportDocument34 pagesSeminar Reportsainamalik567Pas encore d'évaluation

- ViscosityDocument20 pagesViscosityOnur CelikkanPas encore d'évaluation

- Chapter 9 The Endocrine SystemDocument1 pageChapter 9 The Endocrine SystemacPas encore d'évaluation

- Chemistry Investigatory ProjectDocument19 pagesChemistry Investigatory ProjectDivya Vatsa50% (4)

- Cationic and Anionic Redox in Lithium-Ion Based Batteries PDFDocument18 pagesCationic and Anionic Redox in Lithium-Ion Based Batteries PDFLeilane Natsumi Alves KanbaraPas encore d'évaluation

- ThermistorsDocument3 pagesThermistorsAbraham96Pas encore d'évaluation

- Analytical Profiles of Drug Substances Volume 18 1989Document643 pagesAnalytical Profiles of Drug Substances Volume 18 1989kunalprabhu148100% (3)

- SM3 9Document17 pagesSM3 9Steven TaylorPas encore d'évaluation

- Energetics QuestionsDocument72 pagesEnergetics QuestionsSahaj SinghPas encore d'évaluation

- 2005-Bonalde-Kinetic Analysis of The Iron Oxide Reduction Using Hydrogen-Carbon Monoxide Mixtures As Reducing AgentDocument6 pages2005-Bonalde-Kinetic Analysis of The Iron Oxide Reduction Using Hydrogen-Carbon Monoxide Mixtures As Reducing AgentRubin ZengPas encore d'évaluation

- T5300 Titan Superflex WhiteDocument8 pagesT5300 Titan Superflex WhiteLola TesiePas encore d'évaluation

- Comprehensive Chemical Kinetics BamfordDocument633 pagesComprehensive Chemical Kinetics BamfordDiana Montagut50% (2)

- Advances in Vapor Compression Technology For The Production of USP Purified Water and Water For InjectionDocument8 pagesAdvances in Vapor Compression Technology For The Production of USP Purified Water and Water For InjectionTimPas encore d'évaluation

- Protego 2020 - 21Document429 pagesProtego 2020 - 21jleonclau1Pas encore d'évaluation

- Methodology For Petrophysical and Geomechanical Analysis of Shale Plays. Study Case: La Luna and Capacho Formations, Maracaibo Basin. Presentation of Paper SPE-185606-MSDocument24 pagesMethodology For Petrophysical and Geomechanical Analysis of Shale Plays. Study Case: La Luna and Capacho Formations, Maracaibo Basin. Presentation of Paper SPE-185606-MSCarlos LoboPas encore d'évaluation

- Denso Protal 7200 Brush Application SpecDocument2 pagesDenso Protal 7200 Brush Application SpecTino VelázquezPas encore d'évaluation

- ACS Sustainable Chemistry & Engineering - 2020Document9 pagesACS Sustainable Chemistry & Engineering - 2020Eugene YiPas encore d'évaluation

- Solubility ProductDocument6 pagesSolubility Productuniquestar100% (1)

- Chlodnice Oleju CSL CiesseDocument28 pagesChlodnice Oleju CSL CiesseCARLOS RAMIREZPas encore d'évaluation

- Flootank® Catalogue 2022Document21 pagesFlootank® Catalogue 2022Anindra Ahmad FarrasPas encore d'évaluation

- S Start of Lesson E End of Lesson Grading 1-5: Learning Outcomes Progress ArrowDocument30 pagesS Start of Lesson E End of Lesson Grading 1-5: Learning Outcomes Progress ArrowYu Seung KimPas encore d'évaluation

- Chemistry Project - A Comparison of The Solubilities of Carbon Dioxide in Water at Various TemperaturesDocument4 pagesChemistry Project - A Comparison of The Solubilities of Carbon Dioxide in Water at Various Temperatureszaid mansuri100% (3)

- Module 7 LipidsDocument3 pagesModule 7 Lipidsgarciamigueld23Pas encore d'évaluation

- All Aluminium Alloy ConductorsDocument2 pagesAll Aluminium Alloy ConductorsNeeraj AgarwalPas encore d'évaluation

- David Scanu, Natalia P. Yevlampieva and Robert Deschenaux - Polar and Electrooptical Properties of (60) Fullerene-Containing Poly (Benzyl Ether) Dendrimers in SolutionDocument7 pagesDavid Scanu, Natalia P. Yevlampieva and Robert Deschenaux - Polar and Electrooptical Properties of (60) Fullerene-Containing Poly (Benzyl Ether) Dendrimers in SolutionGlade680Pas encore d'évaluation

- Emulsion Fuel Technology in Combustion FurnacesDocument3 pagesEmulsion Fuel Technology in Combustion Furnacesvuongcoi102Pas encore d'évaluation

- SRU UnitDocument33 pagesSRU UnitCenk Yağız ÖzçelikPas encore d'évaluation

- RT (Main)Document16 pagesRT (Main)Keshav Singhal100% (1)

- Amplify Fact SheetDocument2 pagesAmplify Fact SheetGopal ChavanPas encore d'évaluation

- Models of The Atom Through TimeDocument14 pagesModels of The Atom Through Timeveronica lunaPas encore d'évaluation

- Lecture 1 Surface and Interfacial PhenomenaDocument26 pagesLecture 1 Surface and Interfacial Phenomenabattal eduPas encore d'évaluation

- Comprehensive 2022 & Summer Leaflet New 1 PDFDocument14 pagesComprehensive 2022 & Summer Leaflet New 1 PDFAkshay DhotePas encore d'évaluation