Académique Documents

Professionnel Documents

Culture Documents

Ansi Asme b163 PDF

Ansi Asme b163 PDF

Transféré par

ilhangulumser0 évaluation0% ont trouvé ce document utile (0 vote)

30 vues30 pagesTitre original

ansi-asme-b163.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

30 vues30 pagesAnsi Asme b163 PDF

Ansi Asme b163 PDF

Transféré par

ilhangulumserDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 30

a EE

AN AMERICAN NATIONAL STANDARD

FF

Malleable Iron

Threaded Fittings

ASME B16.3-1992

Ce The American Society of

‘Mechanical Engineers

345 East 47th Street, New York, N.Y. 10017 —

Date of Issuance: January 29, 1993,

‘The 1992 edition of this Standard is being issued with an automatic addenda

subscription service. The use of an addenda allows revisions made in response

to public review comments or committee actions to be published as necessary;

revisions published in addenda will become effective 6 months after the Date

of Issuance of the addenda. The next edition of this Standard is scheduled for

publication in 1997.

ASME issues written replies to inquiries conceming interpretations of technical

aspects of this Standard. The interpretations will be included with the above

addenda service. Interpretations are not part of the Standard or addenda to the

‘Standard.

ASME isthe registered trademark of The American Sociaty of Mechanical Engineers.

‘This code or standard was developed under procedures accredited as meeting the criteria for

‘American National Standarde. The Consensus Committee that approved the code or standard was

‘bolancad to assure that individuals from competent and concemed interests have had an opportunity

10 participate, The proposed code or standard was made avaiable for pubic review end comment

‘which provides an opportunity for additional public input from industry, academia, regulatory agen-

ies, and the public-atlange.

"ASME does not “epprove.” “rate,” or “endorse” any item, construction, propristary device, or

activity.

"ASME does not take any postion with respect to the validity of sny patent rights asserted in

connection with any items mentioned inthis document, and doos not undertake to insure anyone

utlizing a standard against Kbiity for infringement of any applicable Letters Patent, nor assume

‘any such liabllty. Users ofa code or standard ae expressly advised that deterrination of the validity

‘of any such patent rights, and the ik of infingement of such fights is entely their own responsibilty.

Participation by federal agency representatives) or person(s) aflited with industry isnot to be

Interpreted as goverment or industry endorsement ofthis code or standard.

'ASME accepts responsibilty for only those interpretations issued in accordance with govering

[ASME procedures and policies which preclde the issuance of interpretations by individual

volunteers

[No part ofthis document may be reproduced in ay form,

in an electronic retvieval system or otherwise,

‘without the prior written permission ofthe publisher.

© 1993 by

‘THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

‘Al Rights Reserved

Printed in USA.

FOREWORD

(This Foreword is not a pst of ASME B16.3-1982)

In 1921 the American Engineering Standards Committee, later the American Standards

‘Association (ASA), now the American National Standards Institute (ANSI), authorized

the organization of a Sectional Committee on the Standardization of Pipe Flanges and

Flanged Fittings, with the following organizations as joint sponsors: Heating, Piping,

and Air Conditioning Contractors National Association (later the Mechanical Contractors

‘Association of America, MCAA), Manufacturers Standardization Society of the Valves,

and Fittings Industry (MSS), and The American Society of Mechanical Engineers.

‘Threaded fittings were also included in the scope of the B16 Committee, and Subcom-

mittee No. 2 (now Subcommittee B) was made responsible for threaded fittings other

than steel. The first edition of a standard covering malleable iron fittings, 150 Ib, was

approved as American Tentative Standard by ASA in December 1927. In 1936 a revision

was undertaken to add hydraulic service ratings, material specifications, alignment tol-

‘erances, and dimensions for additional sizes. It was approved with the designation Amer-

ican Standard B16c-1939.

Pipe plugs, bushings, and locknuts, included in the first editions, are now covered in

a separate standard, B16.14.

‘revision begun in 1947 amplified the sections on threading, inspection, and tolerances,

and added dimensions for additional sizes of elbows, reducing crosses, reducing tees,

straight and reducing couplings, caps, and return bends. It was approved as ASA BI6.3-—

1951.

‘Meanwhile, MSS, in cooperation with the Association of American Railroads (AAR),

developed the first standard for 300 Ib malleable iron threaded fittings, published as MSS.

SP-31 of 1932. The 1950 edition of SP-31, which agreed with AAR Purchase Specification

'M-404, was submitted to ASA Sectional Committee B16 and assigned to Subcommittee

No. 2. After balloting, it was approved as a separated standard, ASA BI6.19-1951.

In 1961 work was begun to combine the two standards (for 150 Ib and 300 Ib) in a

single document. The resulting Standard was approved as ASA B16.3-1963.

‘Subsequent reviews of the Standard, leading to revisions approved as ANSI BI6.3-

1971 and ANSI B16.3-1977, involved updating of referenced standards and the intro-

duction of metric (SI) dimensions and ratings. In the 1977 Edition, 150 Ib and 300 Ib

were redesignated as Class 150 and Class 300.

In 1982, American National Standards Committee B16 became the ASME B16 Standards

‘Committee, operating with the same scope under ASME procedures accredited by ANSI.

‘A further revision of the standard, approved and published as ANSI/ASME B16.3-1985,

provided for electrodeposition as an alternative to hot dipping when zinc coating was

required.

‘This 1992 edition of B16.3 omits metric units, establishing U.S. customary units as the

standard. Clarifying and editorial revisions were made in order to improve the text.

Following approval by the Standards Committee and ASME, approval as an American

National Standard was given on December 2, 1992, with the designation ASME B16.3-

1992.

Requests for interpretation and suggestions for revision should be sent to the Secretary,

B16 Committee, The American Society of Mechanical Engincers, United Engineering

Center, 345 East 47th Street, New York, NY 10017.

ASME B16 COMMITTEE

‘Standardization of Valves, Flanges, Fittings, Gaskets, and Valve Actuators

(The folowing is the roster ofthe Committee a the time of approval ofthis Standard)

OFFICERS:

W.N. McLean, Chatman

RA Scheid, Vice Chairman

‘4. Yarrmush, Sacrotary

COMMITTEE PERSONNEL

|W. Balls, Coumbie Gas Distribution Co. Columbus, Ohio

14. E.Batay, Union Carbide Corp. South Charleston, West Virginia

KC M. Bell, Underwriters Laboratories, Inc, Northbrook, tinois

M.L_Blaic, US Coast Guard, Washington, D.C.

LA. Brodin, Fischer Controls Intemational, Inc, Mershatown, lows

W. G. Canham, J, Consutant, Brentwood, Missourt

W.M. Stephan, Flextalic, Inc, Pennsauken, New Jersey

1. F, Stroud, Ductile Iron Pipe Research Association, Birmingham, Alsbema

LE White, Repairs, Inc, South Bond, Indiana

A Wiliam, Souther Company Services, Birningham, Alabama

4 Yaemush, Secretary, ASME, New York, New York

PERSONNEL OF SUBCOMMITTEE B—THREADED FITTINGS (EXCEPT STEEL)

W.C. Farrel. Je, Chaiman, Stockham Valves and Fittings, In, Birmingham, Alebama

‘A.M Nickles, Secretary, ASME, New York, New York

‘A. Cohen, Copper Development Association, Greenwich, Connecticut

A. Garrett, Nibco, Inc, Stuarts Draft, Virgina

M.D. Goodson, U Brand Corp, Ashland, Ohio

1. Kennedy, Jr, Consultant, Eastiand, Texas

FLL Larkin, American Daring Valve, Birningham, Alabama

‘J. Longaere, Nibco, In. Elkhart, Inciona

» L MeGrath, J US. Pipe and Foundry Co. Birmingham, Alabome

W.N. MeLeen, Newco Valves, Palos Park, iinois

PERSONNEL OF SUBCOMMITTEE C—STEEL FLANGES AND FLANGED FITTING

LR Fritken, Chairman, Monsanto Co. St. Lous, Missouri

<3 Yarmush, Secretary, ASME, New York, New York

V.C. Bhesin, Westinghouse Electric Corp. Pittsburgh, Penneyivania

M. Blair, US. Coast Guard, Washington, D.C.

GD, Conles, Nooter Corp, St.Louis, Missouri

W.C. Ferrel Jr. Stockham Valves and Fittings, Ine. Biminghem, Alsboms,

13.5. Jol, J Square Engineering Co. Houston, Texss

FL Koester, The Willer Powell Co, Cincinnst, Ohio

WN MeLean, Newco Valves, Palos Park. tins

4. E Price, Amoco Oil Co, Chicago, Minois

Reid, Navel Sea Systems Command, Washington, D.C

Fi Rood, MW Kellogg, Houston, Texas?

BLA Schmidt, Ladiah Co, Russolvile, Arkansas

LL Shire, Taylor Forge intemationa, In. Memphis, Tennessee

PERSONNEL OF SUBCOMMITTEE F—STEEL THREADED AND WELDING FITTINGS

GA Jolly, Charman, Honey Vogt Machine Co. Louinvil, Kentucky

M.A Weinstock, Secrotary, ASME, New York, New York

P.R. Benavides, Bonney Forge Corp. Allentown, Pennsytvenis

DLR Frkken, Monsanto Co, St. Louis, Missourl

RC. Lafferty, Penna Mechine Works, Inc, Chester, Penneyivaris

1D_H. Monroe, Stockham Valves and Fittings, Birmingham, Alabama

.W. Muir, Carl Limited, Simcoe, Ontario, Canada

BLA Schmid, Laieh Co., Russie, Arkansas

(CH. Schmitt, Capitol Monufecturing Co, Columbus, Ohio

HLA Sesnin, Pipe Engineering and Design, Jenkintown, Penneyivania

€. A Williams, Department of Navy, Washington, 0.C.

PERSONNEL OF SUBCOMMITTEE G—GASKETS FOR FLANGED JOINTS:

W.M. Stephen, Charman, Fexialic, Inc. Pennsauken, New Jersey

‘1 Yermush, Secretary, ASME, New York, New York

1CA Benton, Furon Metalic Gasket Division, Houston, Texas

LP. Burgess, Standoo Industries, Houston, Texas

'D. Comber, Richard Klinger Inc. Sidney, Ohio

1. Frikken, Monsanto Co. St Louis, Missouri

R.A. Howard, Ucar Carbon Co. Cleveland, Ohio

G.R. McKillop, John Crane-Houdale, inc, Morton Grove, Minas

‘A.M. Smith South Carolina Ol Tool, Cudahy, California

LW. Schmitt, Capitol Manufectuing Co, Columbus, tio

L Stanford, Lamions Gaskets Co, Houston, Texas

FL L Whittaker, Garlock Inc, Palmyra, New York

PERSONNEL OF SUBCOMMITTEE J—COPPER AND COPPER ALLOY FLANGES

4. Longaere, Chairman, Nibeo, In. Elkher.indiona

TAM Nickles, Socreary, ASME, New York, New York

‘D Blankinehip, Lee Brass Co, Houston, Texas

[A Cohen, Copper Development Assocation, Inc. Greenwich, Connecticut

1G Fitton, Amecast Industrial Corp. Stowe, Penneyivnia

1D.R Frikken, Monsanto Co, St. Louis, Missour

GA Garett, Nibco, Inc, Stuarts Draft, Virginia

LC. Heenke, Musler Brass Co, Port Huron, Michigan

M. E. Holmgren, Elhart Products Comp. Elkhart Indiana

DLW. Smith, Armcast Industrial Corp, Elkhart Indians

PERSONNEL OF SUBCOMMITTEE L—GAS SHUTOFF AND VALVES:

Foren, Chaiman, Mueler Co, Decatur, tinois

[A.M Nickles, Secretary, ASME, Now York, New York

{W.{ Balls, Cohumbla Gas Distribution Co, Columbus, Ofio

aie. Bararduech Kerotest MFG Corp. Pittsburgh, Pennsylvania

13 W. Crawford, Amican Gas Association Lab, Cleveland, Ohio

4.0. Eckel A'Y McDonald, Dubuque, lowe

'3.M. Horvath, Nordstrom Valves, Inc, Suiphur Springs, Texas

‘J. note, Central Pastic Co, Shawnee, Oklahoma

J.B. MeGowan, Jr, Umse, Inc, Exton, Pennsyivanio

‘A.M Pietramate, Eclipse, inc, Rockford, Minos

‘3 L Rumple, Division of Eclipse, Inc, Rockford, tinois

1.6. Smith, Dresser Manufacturing Division, Bradford, Pennsyivenia

G.R Stevens, National Meter Co, Birmingham, Alabema.

RC. Stewart, Consultant, Palm City, Florida

EL Tenhangel Conbreco Industies, Inc, Matthews, North Carling

FR. Volgstadt, Perfection Corp, Research and Engineering. Madison, Ovo

AG. Yooper, Je, New Orleans Public Service Inc, New Oreans, Louisiana

PERSONNEL OF SUBCOMMITTEE N—STEEL VALVES, FACE-TO-FACE AND END-TO-END

W.N. McLean, Chairman, Newco Valves, Palos Park, iinois

Koester, ce Chatman, The Wiliom Powell Co, Cincinnati, Ohio

(M. Weinstock, Secretary, ASME, New York, New York

EA Bake, Edward Valve, inc, Raleigh, North Cortine

WM. Blais, US. Coast Guard, Washington, D.C.

1. R.Fritken, Monsanto Co, St.Louis, Missouri

LA Handschumecher, Hendechumacher Association, Seunderstown, Abode ilond

G.R eenogle, Fisher Controls Internationa, Ine, Marshaltown, lowe.

4S, John, J Square Engineering Co., Houston, Texas

GA sally, Henry Vogt Mach Co, Louiavile, Kentucky

R.J. Kissel, US. NAC, Washington, D.C.

WG. Knecht, AnchorDaring Valve Co, Wilismsport, Pennyiveria

F.R.OPBrien Pace Valves, Long Beach, California

J. Paptzun, Yerway Corp, Blue Bel, Pennsyivania

F.C. Rosch Jr, Technicon Enterprises, ine, Oley, Penneyivenio

{1.6 Thompaon, E | Dupont De Nemours and Company, Ine, Newer, Delaware

F.C. Teno, Department of Navy, Weshington, D.C.

M.P. 2yne, Consutant, Birmingham, Aleboma

Identification of Reducing Fietings.

2. Gaging of Chamfered Internal Threads.

Tables

Pressure-Temperature Ratings...

Inspection Tolerances...

Class 150—Dimensions of 90 deg. Elbows, Tees, Crosses, and 45 deg.

Elbows (Straight Sizes)...

(Class 150—Dimensions of 90 deg. Elbows and Crosses (Reducing Sizes)

Class 150—Dimensions of Tees (Reducing Sizes)

(Class 150—Dimensions of 45 deg. Y-Branches (Straight Sizes)

(Class 150—Dimensions of Street Tees and 90 deg. and 45 deg.

Street Elbows. es

Class 150—Dimensions of Complings (Straight and Reducing Sizes).

(Class 150—Dimensions OF Caps .escessectsses

10 Class 150—Dimensions of Closed, Medium, and Open Pattern

Return Bends =

11 Class 300—Dimensions of 90 deg. Elbows, Tees, Crosses, and 45 deg.

Elbows (Straight Sizes) .

ee

Class 300—Center-to-End Dimensions of 90 deg. Elbows

(Reducing Sizes).

ass 300--Center-to-End Dimensions of Tees (Reducing Size).

Class 300—Dimensions of Couplings.

‘Class 300—Dimensions of Reducing Couplings

Class 300—Dimensions of Caps

‘Class 300—Dimensions of 90 deg. and 45 deg. Street Elbows

Class 300—Dimensions of Return Bends.

|

1 SCOPE

‘This Standard for malleable iron threaded fittings,

‘Class 150 and 300 covers:

(a) pressure-temperature ratings;

(b) size and method of designating openings of

reducing fittings;

(ce) marking;

(d) material;

(@) dimensions and tolerances;

) threading;

(8) coatings.

2 PRESSURE-TEMPERATURE RATINGS

(a) Pressure-temperature ratings for these fittings

are shown in Table 1. Ratings are independent of the

contained fluid and are the maximum nonshock pres-

sures atthe tabulated temperatures. Intermediate rat-

ings may be obtained by linear interpolation between

the temperatures shown.

(b) The temperatures shown for the correspond-

ing pressure rating shall be the material temperature

of the pressure retaining structure. It may be assumed

that the material temperature isthe same as the fuid

temperature. Use of a pressure rating at a material

temperature other than that of the contained fluid is

the responsibility of the user and subject to the re-

quirements of any applicable code.

(c) Class 300 street elbows are not recommended

for gage pressures above 600 psi.

The use of the word “nominal” as a modifier ofa dimension or

sizes intended to ident thatthe stated dimension or sie bs wed

{or purposes of designation.

ASME 8163-1952

MALLEABLE IRON THREADED FITTINGS, CLASSES 150 AND 300

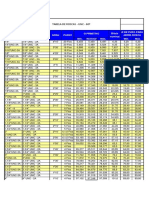

‘TABLE 1 PRESSURE-TEMPERATURE RATINGS

(Gass 300, pela

case 150, | Sizes | Sime | Sine

Temperature, °F | peg | et | 1¥e-2 | 2ve-3

=20% 150 | 300 | 2000 | 1500 | 1000

200 265 | 1785 | 1350 | s10

250 225 | 1875 | 1200 | 925

300 105, | 1360 | 1050 | 735

350 150' | 1160 | 900 | 650

400 ce. | 935 | 750 | 560

450 725 | 600 | 475

500 ‘i 510 | 450 | 395

550 1 _|_ 300 | 300 | 300

NOTE:

(1) Permissible for service temperature up to 366°F, reflecting

‘the tompereture of saturated steam at 150 psig.

‘The size of the fittings scheduled in the following,

tables is identified by the corresponding nominal’ pipe

size (NPS).

For reducing tees, crosses, and Y-branches (later-

als), the size of the largest run opening shall be given

first, followed by the size of the opening at the op-

posite end of the run. Where the fitting is a tee or Y-

branch (lateral), the size of the outlet is given last.

Where the fitting is a cross, the largest side-outlet

‘opening is the third dimension given, followed by the

‘opening opposite. The straight line sketches of Fig.

1 illustrate how the reducing fittings are read.

4 MARKING

4.1 Class 150 Fittings

Each Class 150 fitting shall be marked for identi-

fication with the manufacturer's name or trademark.

‘ASME BI63-1982

4

3

2 2

4 4

AXAK2 Tee | 4K 3X2 TOO

1 3

2 2

4 4

axax2 4x3x2

Branch Branch

4 4 7

4 4 4

Axax2X2 AKAXIKZ 4KIRBK TT

Crom Crom Crom

FIG. 1 IDENTIFICATION OF REDUCING

FITTINGS:

42 Class 300 Fittings

ach Class 300 fitting shall be marked for identi-

fication with:

(a) the manufacturer's name or trademark;

(b) the numerals **300"

(c) the letters “MI” to designate malleable irot

(a) the size;

(e) other markings as permitted by MSS SP-25,

Standard Practice Marking System for Valves, Fit-

tings, Flanges, and Unions.

5 MATERIAL

5.1 Malleable Iron

‘The chemical and physical properties of the castings

shall be in accordance with ASTM A 197, Specifi-

‘cation for Cupola Malleable Iron, The manufacturer

shall be prepared to certify that the product has been

so produced.

MALLEABLE IRON THREADED FITTINGS

52 Steel

Class 150 couplings and caps in NPS ¥, ¥4, and

‘Ye may be made from steel rod or bar with a minimum.

yield strength of 30 ksi at the manufacturer's option.

6 DIMENSIONS AND TOLERANCES

6.1 General

‘Tables 3 through 18 of center-to-end dimensions

are given for both straight and reducing fittings.

62 Reducing Fittings

‘The dimensions in Tables 3 through 18 of reducing,

fittings are for use only when making patterns for the

specific reducing fitting in question and do not apply

‘when a larger size pattern is bushed to make the re-

ducing fitting wanted.

63 Tolerances

It is recognized that some variations are absolutely

unavoidable in the making of patterns and castings.

‘The following tolerances shall be permitted.

(a) Metal Thickness Tolerances. Metal thickness

‘at no point in the castings shall be less than 90% of

the value given in the tables.

(b) Center-To-End Tolerances. Permitted toler-

ances on the center-to-end dimensions of the fit

are shown in Table 2. Tolerances for end-to-end di-

mensions and lengths of couplings and reducers shall

betwice those given. The largest opening in a reducing

fitting governs the tolerances to be applied to all open-

ings. These tolerances do not apply to return bends

and caps.

7 THREADING

7A Types of Threads

‘All fittings shall be threaded with ANSI/ASME

'B1.20.1 Pipe Threads, General Purpose (Inch) and

shall have taper threads except wrought couplings

(Table 8), and wrought caps (Table 9) in NPS 4, M4,

‘and % which may have straight threads.

MA EABLE RON THREADED FITTINGS

72 Tolerances

Variations in taper threading shall be limited to 1

turn large or 1 turn small from the gaging face on

ringyand gaging notch on plug, when using working

‘The variations in straight threading shall be

Tingeed to 1¥e turns large or small from the gaging

notch on plug, when using a aper pipe thread working

gage:'The reference point for gaging internal fittings

thredds depends upon the chamfer diameter. When

thinternal chamfer diameter exceeds the major di

ameter of the internal thread, the reference point is

the last thread scratch on the chamfer cone. When

‘the internat chamfer diameter does not exceed the

‘major diameter of the internal thread, the reference

ppoint is the end of the fitting (see Fig. 2).

TABLE 2 INSPECTION TOLERANCES

‘Norainal Pipe Size Plus or Minos,

e 0.03

Me 0.08

* 0.05,

Ye 0.08

i 0.07

14,2 0.08

2.3.38 0.10

45 oz

8 ota

Tolerance

Face of fitting:

chamfer:

Point of last thread scratch

‘on chamfer cone

Plane of gaging notch

NOTE: Plane of gaging notch should

intersect crest of thread on gage

Enlarged view showing chamfered

nal thread of basic size with

fer exceeding the major diameter

‘ASME B163-1992

73 Countersink or Chamfer

Al internal threads shall be countersunk a distance

of not less than one half the pitch of the thread at

‘an angle of approximately 45 deg. with the axis of

the thread, and all external threads shall be chamfered

at an angle of 30 deg. to 45 deg. with the axis, both

for the purpose of easier entrance in making a joint

and for protection of the thread. Countersinking and

‘chamfering shall be concentric with the threads.

74 Thread Length

‘The length of threads specified in all tables shall

‘be measured to include the countersink or chamfer.

7.5 Alignment

‘The maximum allowable variation in the alignment

of threads of all openings of threaded fittings shall

be 0.06 in./ft (0.5%).

8 RIBS

8.1 General

‘The addition of ribs or lugsis permitted on threaded

fittings. Where ribs are used, it is recommended that

their thickness shall be the same as specified for metal

“The chamfer illustrated is at 45 deg. angle and is

‘spproximately 38 pitch in depth. However

these details are not requirements and are

‘given only for informati

shown,

FIG. 2 GAGING OF CHAMFERED INTERNAL THREADS

3

‘ASME B163-1992

thickness of the fitting. Right-hand couplings shall

hhave not more than 2 ribs.

82 Special Couplings

Right- and left-hand couplings shall have four or

more ribs unless the left-hand opening is clearly

‘marked “‘L”” in which case the use of ribs is optional

with the manufacturer.

9 PLUGS, BUSHINGS, AND LOCKNUTS

For dimensions of plugs, bushings, and locknuts

to be used in connection with Classes 150 and 300

malleable iron threaded fittings, see ASME B16.14

Ferrous Pipe Plugs, Bushings, and Locknuts With

Pipe Threads.

10 FACE BEVEL,

‘A bevel not exceeding 5 deg. is permitted on the

faces of fitting openings. Center-to-end, end-to-end,

and width of band dimensions may include or exclude

the bevel.

[MALLEABLE IRON THREADED FITTINGS

11 COATINGS

11.1 Malleable Iron Fittings

‘When malleable iron fittings are zine coated, they

shall be hot dipped in accordance with ASTM A 153

or have an electrodeposited zine coating conforming

to ASTM B 633 Type I, Service Condition 4. Hot

dipped coatings shall be 0.0034 in. minimum thickness

and applied prior to threading. Electrodeposited zinc

shall be 0.001 in. minimum thickness and applied

following threading.

112 Steel Fittings

Couplings and caps made from steel rod or bar may

have electrodeposited zinc coatings conforming to

ASTM B 633, Type 1, Service Coating 4, or cadmium

coatings conforming to ASTM B 766, Type NS. The

electrodeposited coatings shall be applied after

threading.

11.3 Other Coatings

Other coatings specified by the purchaser shall be

furnished meeting the agreed requirements.

(MALLEABLE IRON THREADED FITTINGS ‘ASME B163-1992

CLASS 150

45 don. Cow

‘TABLE 3 DIMENSIONS OF 90 deg. ELBOWS, TEES, CROSSES, AND

‘45 deg. ELBOWS (STRAIGHT SIZES)

Canter

totnd, | Comer Oveside

hows, | twEnd, | Length | width Inside Diameter Diameter

Nominst | Tees,and | 45 deg. of ot of iting F Metal of

foe | Cronos’ | eowe | tamaad | Band Tetness | tend

in a c Bie. | EM, Min, | Max. o cs

‘e Das O75 0.20 040 | 04a ‘o08 069

% ‘oat a7 0.32 0.21 ose | ose 0.08 0.84

* 0.95 0.80, 0.36 0.23 os7 | 072 2.10 1.01

% 112 O88 043. 0.28, oss | 090 10 1.20

% 131 0.98, 0.50 027 vos | oat oz 148,

1 1.50 1412, 0.58. 0.30 ast | 138 oa wn

% 175 129 os7 034 166 | 173 one 218

Ws 196 143 0.70 037 uso | 197 ons 243

2 225 168, 075 oz 237 | 246 017 296

2 270 1.98 0.92 048 2a7 | 297 0.21 389

3 3.08 207 0.98 oss aso | 360 0.23 428

3% 3.42 239 1.03 0.60 400 | 410 0.25 404

4 3.79 261 1.08, 0.66 450 | 460 0.26 540

5 4.50 3.05, 118 0.78 sso | 565 0.30 658

6 5.13 3.48 128 0.90 esz_ | 6.72 0.36 17

(GENERAL NOTE: Dimensions aren inches.

Nore:

(1) Dimensions for reducing elbows and reducing cross

‘are given in Table 4 and dimensions fr reducing tes in Table 8.

ASME 8163-1992 MALLEABLE IRON THREADED FITTINGS

TABLE 4 DIMENSIONS OF 90 deg. ELBOWS AND CROSSES (REDUCING SIZES)

Bows (Grosses

Conr-toend Conterto-End (Conter-to-End

‘Nominal Pipe Nominal Pipe Nominal Pipe

Size x|z Slee male ‘Size x lz

x ov | ove | tmxd 75 | 100 | wenn y20 | 122

ra oes | ogo | exw | 152 | 175 | rxtx mee a37 | 145.

Me oat | oss | 2x1 2o2 | 216 | iia 126 | 1:36

hom soa | 1.03 | 21% 490 | 210 | iextuextd vse | 1.67

Theme os7 | ose | 2x1 473 | 202 | ex WM vas | 1.62

Yoo r20 | 122 | 2% reo | 197 | vexiexrmexim | 192 | 188

x vaz | ata | 2x2 239 | 260 | wx thei xt 165 | 1-80

x vos | 108 | 2axim | 216 | 251 | vax them us2 | 1.78

x xar | ves | 32% 203 | 209 | 2x2x 1x1 202 | 216

x 126 | 136 | 3x2 2s2 | 209 | 2x20 1% 1H 1.90 | 2:10

1% vie |azr | axa aso | 360 | 2x2«1%1 1.73 | 202

Med use} 1.67 2x2 YM veo | 1.97

ait | as | 162 Dh x 2x 2x2 239 | 260

axe | 13a | 153 Bx ax2%2 252 | 289

Yh x a2 | 188

GENERAL NOTES:

(a) Dimensions arin inches.

(0) For dimensions not given, dee Table 3.

{c} Reducing sivee of tings for which dimensions are not given in tables may be produced from regulr patterns frksted sizes by sand

bushing

MALLEABLE IRON THREADED FITTINGS. ‘ASME 8163-1992

CLASS 150

ral

qT]

404

TABLES DIMENSIONS OF TEES (REDUCING SIZES)

Conter-to-End Conter-t0-End Conter-to-End

Nominal Nominal Nominal

Posie | x | y | z Pipe Size x|{yrife2 Pipe Size x|riz

Wax exe 0.76 rmxix1 | 1.88 | 1.50 2x%xe 2.25

Ya x Ye x a 0.76 Yivextxa | 1.48 | 1137 2x hx? 2.25

x xe 0.90 flimxixy | 1.38] 126 Wh x 1% x2 202

a 3h x he 0.85 | tv xe x 1M | 1.78 | 1.62 We x Mle x 2 1.90

ax Mex te 0.95 xxx | 1.58 | 1.45 Tete? 1.73

ax lex he Mex Mex Xe | 1.48 | 1.31 | 1.62 ff 2m x 24 x2 2.60

Ya Ya x Me Wa x Ye x Ae | 4.75 | 1.83 | 1.78 |] 22 x 2m x Tv 251

Yeh eM Weer | 188] 1.98 | 1.67 |] 2% x 2M x 1% 245

Ya x Mh x Ye Vx tx Me 87 | 1.67 | 1.58 |] 22 x 2x1 237

Ya xa xe Hex He Me | 1.62 | 1.62 | 1.45 fav x 21h x 2.32

axe x He 1.03 ff 1¥2 x 1% x 1%] 1.82 | 1.82 | 1.88 fav x2x2% | 2.70 | 2.60 | 2.70

Ya x Ya x Me 112 Pex hx 1 | 1.65 | 1.65 | 1.80 ]amx2x2 | 2.39 | 2.25 | 260

hh xe 9.04 | 1% x Ye 2M | 4.52 | 1.82 | 1.75 | ave x 1 x 2% | 2.70 | 2°81 | 2.70

Yee he 4.22 1% x 1% xe | 1.41 | 1.41 | 1.68 av x 1% x2 | 2.99 | 2:16 | 260

He Hee 1.13 | 1h x 1M x 1¥e | 1.96 | 1.88 | 1.94 ]2x2~2% | 2.60 | 2.60 | 2.39

Ye xe 1.08 ff 1¥ x 1% x 14%] 1.82 | 1.75 | 1.98 [3 xax2% | 2.93 | 2.03 | 2.99

Ye xh xe 1.31] 1% x11 | 1.65 | 1:58 | 1.80 13x32 252 | 282 | 289

Yo Va Ne 4.22 | 1% x 1x % | 1.52] 145] 1.75 ]3x3x1% | 2.29 | 2.29 | 2.80

Hex he 1.43 | va x tex te | rar | 1.94 | 1.66 3x ax1% | 247 | 207 | 2.74

Hh 1.31 | th xii | 1.94] 1.80 | 1.94 fa «3x0 2.00 | 2.00 | 2.66

Ya xe x He 1.43 te xt cam | 1.82 | 1.67 | 1.88 3x ae% 1.87 | 1.87

Ye hex he 131] Maxtx1 [165] 1.50] 1.80 ]3x2%x3 | 3.08 | 2.99

Ya x Yh x Ye 1.20 1% x Mec 1% | 1.94] 1.75 | 1.94 ]}3x 2% x 2% | 2.63 | 2.70

Vt Wax x th | 1.94] 1.66] 1.94 }3x2%%2 | 262 | 239

Txt Ve Mex 1 | 1.88 | 1 3x2x3 3.08 | 2.69

1x1 1.27 Jaxreim | 1.80 Bx2x2 282 | 2.25

Vt 122 }2x2«1% | 202 Bhxahx3 | 299

Teed 1.80 ]2x2x1%m | 1.90 3th xh x 2% | 2.93

Teh 1.45 2x 2%1 1.73 Axax3 3.30

Tho he 1.36 [2 «2% 1.60, ax4x2h | 305

Txt 1.50 }2x 2x 1.49 | 1.49 | 1.88 4x 4x2 274 | 2.74] 3.41

1x aH 148 2xtex2 [2.25] 216] 228 Jaxaxime | 261] 281 | 332

1x Vax th 1.96 }2 1x 1m | 202] 1.94] 216 | axa x4 3.79 | 3.60 | 3.79

et 1.37 2x 1x 1% | 1.90] 1.82 | 210 ]3x3%4 3.60 | 3.60 | 3.30

Vax ext 1.26 f2xiex1 | 1.73] 1.65 | 202 ]5x5x3 ast | ast | 4.22

Wax Wexd | 1.58 | 1.58] 1.67 faximx2 | 2.25] 210] 2.25 Jexexa 4.13 | 4.13 | 4.94

We x Mex we | 1.48 | 1.48 | 1.62 [21% x 1% | 202 | 1188 | 216 lexexs 3.64 | 3.64 | 4.75

Mex Werth | 1.34 | 1.94 | 1.83 2x 1%1% | 1.90] 1.75 | 210 flexex2% | 3.99 | 3.39 | 4.66

Whe x rex ae | 1:26 | 1.26 | 1.44 12 x1 x2 6x6x2 3.08 | 3.08 | 4.56

Vex vere [1.78 | 1.67 | 1.75 2x1 x 1%

Vous aimerez peut-être aussi

- Comme Il Faut - AmDocument2 pagesComme Il Faut - AmDarry GuiltterPas encore d'évaluation

- Tablas de Torque - Ast PDFDocument2 pagesTablas de Torque - Ast PDFJOSE LOPEZPas encore d'évaluation

- Tabla Pandeo OmegaDocument1 pageTabla Pandeo OmegaAngel VegaPas encore d'évaluation

- Tabla de Perfiles Gerdau PDFDocument3 pagesTabla de Perfiles Gerdau PDFmevice63Pas encore d'évaluation

- Reducción Concéntrica: Normas de Diseño: Material: CédulaDocument2 pagesReducción Concéntrica: Normas de Diseño: Material: Cédulazulema guevaraPas encore d'évaluation

- Tee Acero SoldableDocument1 pageTee Acero Soldablebrady floresPas encore d'évaluation

- Thesis Yi ZHU 2004Document257 pagesThesis Yi ZHU 2004Djerboua OuahibaPas encore d'évaluation

- Manual IchaDocument58 pagesManual IchaPatricio Rodriguez ZuñigaPas encore d'évaluation

- EST P 002 - Rev - B Tensionado de PernosDocument9 pagesEST P 002 - Rev - B Tensionado de PernosPolita PolaPas encore d'évaluation

- Catalogue Ponts Roulants PDFDocument38 pagesCatalogue Ponts Roulants PDFBen TailleurPas encore d'évaluation

- Perfiles WDocument18 pagesPerfiles WJhon Alexander Buitrago DiazPas encore d'évaluation

- Maquina MK30 Mk40Document2 pagesMaquina MK30 Mk40MeniouraPas encore d'évaluation

- CodoDocument1 pageCodoMarco DiazPas encore d'évaluation

- En 12165 (Pages 1-26, 28-36) PDFDocument36 pagesEn 12165 (Pages 1-26, 28-36) PDFManpreet Singh100% (1)

- Aranceles Amdroc, 2021Document46 pagesAranceles Amdroc, 2021perfecto cigarroa salvadorPas encore d'évaluation

- Prontuario Arcelor MittalDocument44 pagesProntuario Arcelor MittalCamiloRestrepoAguilarPas encore d'évaluation

- Docshare - Tips - Tabela de Rosca Unc PDFDocument1 pageDocshare - Tips - Tabela de Rosca Unc PDFMarcos JuniorPas encore d'évaluation

- Asme B16.9Document46 pagesAsme B16.9frank.marcondes2416Pas encore d'évaluation

- Chavetas ANSI B17 1Document1 pageChavetas ANSI B17 1Elcio MarcioPas encore d'évaluation

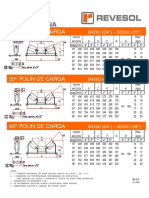

- Polines RevesolDocument52 pagesPolines Revesolrom100% (1)

- 1 Feipl Aiims Acad CHW Schematic Layout 29-09-2021 Hvac SchematicDocument1 page1 Feipl Aiims Acad CHW Schematic Layout 29-09-2021 Hvac Schematicngoc tanPas encore d'évaluation

- Course Pack For PoetryDocument37 pagesCourse Pack For PoetryLady MarupokPas encore d'évaluation

- Antosha Haimovich - Arpeggio For Jazz Saxophone PDFDocument9 pagesAntosha Haimovich - Arpeggio For Jazz Saxophone PDFRandy MarmerPas encore d'évaluation

- Ana MiléDocument2 pagesAna MiléCAMILO HERNANDEZ ARISTIZABALPas encore d'évaluation

- Imaniyath PDFDocument50 pagesImaniyath PDFMD.T.R. RehmanPas encore d'évaluation

- (Arreglos) - Mix Frankie Ruiz #2Document20 pages(Arreglos) - Mix Frankie Ruiz #2José Gabriel Siza AguilarPas encore d'évaluation

- ProbailityDocument42 pagesProbailityYassine Er-rabbanyPas encore d'évaluation

- El Liston Detu Pelo - Trompeta BB 2Document1 pageEl Liston Detu Pelo - Trompeta BB 2Felipe ChipanaPas encore d'évaluation

- Anexo - C1 - Trabajos en AlturaDocument1 pageAnexo - C1 - Trabajos en AlturaujeidohjahaotydhkfPas encore d'évaluation

- (Piano) Brigitte - Sauver Ma PeauDocument8 pages(Piano) Brigitte - Sauver Ma PeauPierre GauthierPas encore d'évaluation

- Paul Desmond - Samba Cantina PDFDocument4 pagesPaul Desmond - Samba Cantina PDFPeter PeukerPas encore d'évaluation

- Attention Mesdames Et Messieurs - GuitareDocument3 pagesAttention Mesdames Et Messieurs - GuitareNicolas SchiffPas encore d'évaluation

- I Got Rhythm - Trumpet in BB 4Document2 pagesI Got Rhythm - Trumpet in BB 4Adriano SilvaPas encore d'évaluation

- Finale 2009 - (100 Anos EL CONDOR PASA - Drum SetDocument2 pagesFinale 2009 - (100 Anos EL CONDOR PASA - Drum SetFactor David Esquivel ChavezPas encore d'évaluation

- Asi Fue B PDFDocument30 pagesAsi Fue B PDFJuanca ChugchilanPas encore d'évaluation

- Al Que Es Digno - Venció - Trompeta II - Mus PDFDocument2 pagesAl Que Es Digno - Venció - Trompeta II - Mus PDFMarvin RubenPas encore d'évaluation

- BOE-AUTORIZACION - Formulario - FrancaisDocument2 pagesBOE-AUTORIZACION - Formulario - FrancaisAnas BouraydaPas encore d'évaluation

- Flor Palida - TromboneDocument3 pagesFlor Palida - TromboneJhonny MorenoPas encore d'évaluation

- Calendarul Minerveiu Pe Anul 1909, Mica Enciclopedie Populara A Vietii Practice, 11, 1909Document356 pagesCalendarul Minerveiu Pe Anul 1909, Mica Enciclopedie Populara A Vietii Practice, 11, 1909Ciprian LupuPas encore d'évaluation

- Menu TigrisDocument28 pagesMenu Tigrisandani cakti prasetyaPas encore d'évaluation

- Peromira TrompasDocument1 pagePeromira TrompasLuis José ColomaPas encore d'évaluation

- Al Que Es Digno - Venció - Trompeta I.mus PDFDocument2 pagesAl Que Es Digno - Venció - Trompeta I.mus PDFRogelioPas encore d'évaluation

- 364-004923-1023-Edificio Mon Amour - Soporte de Losa - Piso 18Document1 page364-004923-1023-Edificio Mon Amour - Soporte de Losa - Piso 18melanie.1608.floPas encore d'évaluation

- Mix Antaño 2Document44 pagesMix Antaño 2Jhonatan Castro TorrealvaPas encore d'évaluation

- Finale 2005 - (CALLE LUNA CALLE SOL - 004G Piano)Document7 pagesFinale 2005 - (CALLE LUNA CALLE SOL - 004G Piano)josePas encore d'évaluation

- Got To Be RealDocument3 pagesGot To Be RealAlessandroPas encore d'évaluation

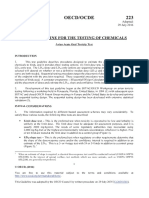

- OECD 223 Avian Acute Oral Toxicity Test 29072016Document28 pagesOECD 223 Avian Acute Oral Toxicity Test 29072016Ellóra Diniz GomesPas encore d'évaluation

- Decreto #37.2022 - Nomeia A Comissao Organizadora - Conferencia Municipal de EducacaoDocument1 pageDecreto #37.2022 - Nomeia A Comissao Organizadora - Conferencia Municipal de EducacaoNadia ReginaPas encore d'évaluation

- 2 - Opera Mercadorias 1Document20 pages2 - Opera Mercadorias 1DANIEL ALVES DA SILVAPas encore d'évaluation

- 1420 - 3e ÉTAGE+valves - 2022-07-22Document1 page1420 - 3e ÉTAGE+valves - 2022-07-22SébastienPas encore d'évaluation

- Una Aventura - Trompeta 1Document2 pagesUna Aventura - Trompeta 1OsvaldoUrzuaValdebenitoPas encore d'évaluation

- Finale 2005 - (MANTECA - 002G Piano)Document5 pagesFinale 2005 - (MANTECA - 002G Piano)josePas encore d'évaluation

- Plano Nuevo Codigo Urbano Añelo DefinitivoDocument1 pagePlano Nuevo Codigo Urbano Añelo Definitivojosedevp30Pas encore d'évaluation

- Casi Te Envidio - Trombon 1Document2 pagesCasi Te Envidio - Trombon 1Oscar Raul Clares QuispePas encore d'évaluation

- SALVE SALVE - Trumpet in BB 1Document1 pageSALVE SALVE - Trumpet in BB 1Edy Layme RiosPas encore d'évaluation

- Grupo 8918 Revision SistematicaDocument1 pageGrupo 8918 Revision SistematicaMARIANO SERGIO FABRICIO DE LA CRUZ RAMOSPas encore d'évaluation

- 24-Mambo No. 5 - Bass Tuba BB - MusDocument2 pages24-Mambo No. 5 - Bass Tuba BB - MusSTUDIO R.K.RPas encore d'évaluation

- Manual Eaton 9px 5-6kva PTDocument44 pagesManual Eaton 9px 5-6kva PTLeopoldo LopesPas encore d'évaluation

- PROPUESTA DRENAJE AGUAS LLUVIAS-Presentación1Document1 pagePROPUESTA DRENAJE AGUAS LLUVIAS-Presentación1via sitionuevofonsecaPas encore d'évaluation

- NF en Iso 3834-1Document17 pagesNF en Iso 3834-1VandebruggePas encore d'évaluation