Académique Documents

Professionnel Documents

Culture Documents

Euronorm en 10025

Transféré par

paulapanaitCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Euronorm en 10025

Transféré par

paulapanaitDroits d'auteur :

Formats disponibles

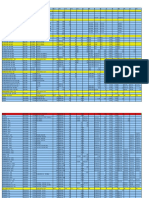

EN 10025 (Euronorm 10025) Steel Norms

Designation

Method of deoxidation

Sub

group

C in % max. for nominal product

thickness in mm

Mn %

max.

Si %

max.

P%

max.

S%

max.

N%

max.

According EN 10027-1 and

ECISS IC 10

According EN

10027-2

S 185

1.0035

opt.

BS

S235 JR

1.0037

opt

BS

0,17

0,20

--

1,40

0,045

0,045

0,009

S235 JRG1

1.0036

FU

BS

0,17

0,20

--

1,40

0,045

0,045

0,007

S235 JRG2

1.0038

FN

BS

0,17

0,17

0,20

1,40

0,045

0,045

0,009

S235 JO

1.0114

FN

QS

0,17

0,17

0,17

1,40

0,040

0,040

0,009

S235J2G3

1.0116

FF

QS

0,17

0,17

0,17

1,40

0,035

0,035

S235J2G4

1.0117

FF

QS

0,17

0,17

0,17

1,40

0,035

0,035

S275 JR

1.0044

FN

BS

0,21

0,21

0,22

1,50

0,045

0,045

0,009

> or = 16

< 16, > or = 40 < 40

S275 JO

1.0143

FN

QS

0,18

0,18

0,18

1,50

0,040

0,040

0,009

S275 J2G3

1.0144

FF

QS

0,18

0,18

0,18

1,50

0,035

0,035

S275 J2G4

1.0145

FF

QS

0,18

0,18

0,18

1,50

0,035

0,035

S355JR

1.0045

FN

BS

0,24

0,24

0,24

1,60

0,55

0,045

0,045

0,009

S355JO

1.0553

FN

QS

0,20

0,20

0,22

1,60

0,55

0,040

0,040

0,009

S355J2G3

1.0570

FF

QS

0,20

0,20

0,22

1,60

0,55

0,035

0,035

355J2G4

1.0577

FF

QS

0,20

0,20

0,22

1,60

0,55

0,035

0,035

S355K2G3

1.0595

FF

QS

0,20

0,20

0,22

1,60

0,55

0,035

0,035

S355K2G4

1.0596

FF

QS

0,20

0,20

0,22

1,60

0,55

0,035

0,035

E295

1.0050

FN

BS

--

---

0,045

0,045

0,009

E335

1.0060

FN

BS

--

0,045

0,045

0,009

E360

1.0070

FN

BS

--

0,045

0,045

0,009

Upper Limits applicable for product analysis, based on previous table.

Designation

Method of deoxidation

Sub

group

1.0035

opt.

S235 JR

1.0037

S235 JRG1

According EN 10027-1 and

ECISS IC 10

According EN

10027-2

S 185

C in % max. for nominal product

thickness in mm

Mn %

max.

Si %

max.

P%

max.

S%

max.

N%

max.

> or = 16

< 16, > or = 40

< 40

BS

opt

BS

0,21

0,25

--

1,50

0,055

0,055

0,011

1.0036

FU

BS

0,21

0,25

--

1,50

0,055

0,055

0,009

S235 JRG2

1.0038

FN

BS

0,19

0,19

0,23

1,50

0,055

0,055

0,011

S235 JO

1.0114

FN

QS

0,19

0,19

0,19

1,50

0,050

0,050

0,011

S235J2G3

1.0116

FF

QS

0,19

0,19

0,19

1,50

0,045

0,045

S235J2G4

1.0117

FF

QS

0,19

0,19

0,19

1,50

0,045

0,045

S275 JR

1.0044

FN

BS

0,24

0,24

0,25

1,60

0,055

0,055

0,011

S275 JO

1.0143

FN

QS

0,21

0,21

0,21

1,60

0,050

0,050

0,011

S275 J2G3

1.0144

FF

QS

0,21

0,21

0,21

1,60

0,045

0,045

S275 J2G4

1.0145

FF

QS

0,21

0,21

0,21

1,60

0,045

0,045

S355JR

1.0045

FN

BS

0,27

0,27

0,27

1,70

0,60

0,055

0,055

0,011

S355JO

1.0553

FN

QS

0,23

0,23

0,24

1,70

0,60

0,050

0,050

0,011

S355J2G3

1.0570

FF

QS

0,23

0,23

0,24

1,70

0,60

0,045

0,045

355J2G4

1.0577

FF

QS

0,23

0,23

0,24

1,70

0,60

0,045

0,045

S355K2G3

1.0595

FF

QS

0,23

0,23

0,24

1,70

0,60

0,045

0,045

S355K2G4

1.0596

FF

QS

0,23

0,23

0,24

1,70

0,60

0,045

0,045

E295

1.0050

FN

BS

--

---

0,055

0,055

0,011

E335

1.0060

FN

BS

--

0,055

0,055

0,011

E360

1.0070

FN

BS

--

0,055

0,055

0,011

Maximum CEV based on the ladle analysis, if agreed at the time of the enquiry and order.

Designation

According EN 10027-1 and ECISS IC 10 According EN 10027-2

Method of de-oxidation Sub group

Maximum CEV for nominal product thickness in mm

> or = 40

< 40, > or = 150

> 150, > or = 250

S235 JR

1.0037

opt

BS

0,35

--

--

S235 JRG1

1.0036

FU

BS

0,35

--

--

S235 JRG2

1.0038

FN

BS

0,35

0,38

0,40

S235 JO

1.0114

FN

QS

0,35

0,38

0,40

S235J2G3

1.0116

FF

QS

0,35

0,38

0,40

S235J2G4

1.0117

FF

QS

0,35

0,38

0,40

S275 JR

1.0044

FN

BS

0,40

0,42

0,44

S275 JO

1.0143

FN

QS

0,40

0,42

0,44

S275 J2G3

1.0144

FF

QS

0,40

0,42

0,44

S275 J2G4

1.0145

FF

QS

0,40

0,42

0,44

S355JR

1.0045

FN

BS

0,45

0,47

0,49

S355JO

1.0553

FN

QS

0,45

0,47

0,49

S355J2G3

1.0570

FF

QS

0,45

0,47

0,49

355J2G4

1.0577

FF

QS

0,45

0,47

0,49

S355K2G3

1.0595

FF

QS

0,45

0,47

0,49

S355K2G4

1.0596

FF

QS

0,45

0,47

0,49

Mechanical properties for flat and long products.

C in % max. for nominal product thickness in mm

Tensile strength Rm in N/mm2

Nominal thickness in mm

Nominal thickness in mm

Designation

According EN

10027-1 and

ECISS IC 10

According EN

10027-2

Method of

Sub

de- oxidation group

> 16, > 40,

> 80,<

> or = 3, > or =

<or =

> 63, <

> 100, < > 150, < > 200, <

>or =150,

< or = < or =

or =

< 3. < or = 100, <or

16

or = 80

or = 150 or = 200 or = 250

<or = 250

40

63

100

100.

= 150

S 185

1.0035

opt.

BS

185

175

310290-510

540

S235 JR

1.0037

opt

BS

235

225

360340-470

510

S235 JRG1

1.0036

FU

BS

235

225

360340-470

510

S235 JRG2

1.0038

FN

BS

235

225

215

215

215

195

185

175

360340-470 340-470

510

320-470

S235 JO

1.0114

FN

QS

235

225

215

215

215

195

185

175

360340-470 340-470

510

320-470

S235J2G3

1.0116

FF

QS

235

225

215

215

215

195

185

175

360340-470 340-470

510

320-470

S235J2G4

1.0117

FF

QS

235

225

215

215

215

195

185

175

360340-470 340-470

510

320-470

S275 JR

1.0044

FN

BS

S275 JO

1.0143

FN

QS

S275 J2G3

1.0144

FF

QS

275

265

255

245

235

225

215

205

430410-560 400-540

510

380-540

S275 J2G4

1.0145

FF

QS

S355JR

1.0045

FN

BS

S355JO

1.0553

FN

QS

S355J2G3

1.0570

FF

QS

355J2G4

1.0577

FF

QS

355

345

335

325

315

295

285

275

510490-630 470-630

680

450-630

S355K2G3

1.0595

FF

QS

S355K2G4

1.0596

FF

QS

E295

1.0050

FN

BS

295

285

275

265

255

245

235

225

490470-610 450-610

660

440-610

E335

1.0060

FN

BS

335

325

315

305

295

275

265

255

590570-710 550-710

770

540-710

E360

1.0070

FN

BS

360

355

345

335

325

305

295

285

690670-830 650-830

900

640-830

Mechanical properties for flat and long products. (continued)

Minimum percentage elongation 1)

Designation

Method of de- Sub

oxidation

group

L0=80 mm

L0= 5.65 VS0

Nominal thickness

Nominal thickness

Position of

test pieces

1

According EN 10027- According EN

1 and ECISS IC 10

10027-2

<or

=1

> 1,

> 2,

> 1.5,

<or =

<or =

<or = 2

1,5

2,5

> 2,5 > 3,

<or = <or =

3

40

> 40,

<or =

63

> 63,

<or =

100

> 100,

<or =

150.

> or equal to

150, <or =

250.

10

11

12

13

14

18

10

11

12

16

17

18

19

20

21

26

25

24

22

21

QS

15

16

17

18

19

24

23

22

22

21

FN

BS

14

15

16

17

18

22

21

20

18

17

1.0143

FN

QS

S275 J2G3

1.0144

FF

QS

S275 J2G4

1.0145

FF

QS

12

13

14

15

16

20

19

18

18

17

14

15

16

17

18

22

21

20

18

17

S 185 2)

1.0035

opt.

BS

1.0037

opt

BS

1.0036

FU

BS

S235 JRG2

1.0038

FN

BS

S235 JO

1.0114

FN

QS

S235J2G3

1.0116

FF

QS

S235J2G4

1.0117

FF

S275 JR

1.0044

S275 JO

S235 JR

S235 JRG1

)

2

S355JR

1.0045

FN

BS

S355JO

1.0553

FN

QS

S355J2G3

1.0570

FF

QS

355J2G4

1.0577

FF

QS

S355K2G3

1.0595

FF

QS

S355K2G4

1.0596

FF

QS

E295

1.0050

FN

BS

E335

1.0060

FN

BS

E360

1.0070

FN

BS

12

13

14

15

16

20

19

18

18

17

12

13

14

15

16

20

19

18

16

15

10

11

12

13

14

18

17

16

15

14

10

11

12

16

15

14

12

11

10

14

13

12

11

10

11

10

10

1) The Value in the table apply to longitudinal test pieces (1) for the tensile test. For plate, strip and wide flats with width > 600mm transverse test pieces (t) are

applicable

2) Only available in nominal thickness < 25mm.

Mechanical properties --- impact strength KV longitudinal for flat and long products.

Designation

Temperature Minimum energy (J) Nominal thickness in mm

Method of de- oxidation Sub group

According EN 10027-1 and ECISS IC

10

According EN 10027-2

S 185

1.0035

opt.

BS

S235 JR

1.0037

opt

S235 JRG1

1.0036

S235 JRG2

> 10, <or = 150

> 150, <or = 250

BS

20

27

FU

BS

20

27

1.0038

FN

BS

20

27

23

S235 JO

1.0114

FN

QS

27

23

S235J2G3

1.0116

FF

QS

- 20

27

23

S235J2G4

1.0117

FF

QS

- 20

27

23

S275 JR

1.0044

FN

BS

20

27

23

S275 JO

1.0143

FN

QS

27

23

S275 J2G3

1.0144

FF

QS

- 20

27

23

S275 J2G4

1.0145

FF

QS

- 20

27

23

S355JR

1.0045

FN

BS

20

27

23

S355JO

1.0553

FN

QS

27

23

S355J2G3

1.0570

FF

QS

- 20

27

23

355J2G4

1.0577

FF

QS

- 20

27

23

S355K2G3

1.0595

FF

QS

- 20

40

33

S355K2G4

1.0596

FF

QS

- 20

40

33

E295

1.0050

FN

BS

E335

1.0060

FN

BS

E360

1.0070

FN

BS

List of National European Steel Standards Corresponding To EURONORM

MEsteel.com - Linking steel buyers and sellers in the Middle East. info@mesteel.com

Tel: +971-4-8873003 Fax: +971-4-8873002 P. O. Box No. 57040 - Dubai, United Arab Emirates.

About Us | Add Your Company | Advertise | FAQ

Copyright 2002 mesteel.com. All rights reserved. Disclaimer

Vous aimerez peut-être aussi

- WerkstoffdatenDocument21 pagesWerkstoffdatenersinPas encore d'évaluation

- Acier Courant Fiche TechniqueDocument3 pagesAcier Courant Fiche TechniqueENAENA187Pas encore d'évaluation

- ЦСН Целици Упоредно Са ДИНDocument25 pagesЦСН Целици Упоредно Са ДИНFeromont KvalitetPas encore d'évaluation

- Magvant CatalogueDocument54 pagesMagvant CataloguemalsttarPas encore d'évaluation

- 1421135601561968658Document14 pages1421135601561968658ali4299Pas encore d'évaluation

- MaterialsDocument4 pagesMaterialskamiloktay0% (1)

- FT Aciers Courant Car ChimiquesDocument3 pagesFT Aciers Courant Car ChimiquesToavina Fiandrianana RanaivoarisoaPas encore d'évaluation

- Tab TransistorDocument3 pagesTab TransistorEvandro RechPas encore d'évaluation

- VERINS A TIRANTS Ø 25 À 200 MM - Double Effet CNOMO 06-07-02 - AFNOR Avec Amortissement Pneumatique RéglableDocument8 pagesVERINS A TIRANTS Ø 25 À 200 MM - Double Effet CNOMO 06-07-02 - AFNOR Avec Amortissement Pneumatique Réglableyouri594900% (1)

- Flanges ASME B16.5Document22 pagesFlanges ASME B16.5Madhu KarakkadPas encore d'évaluation

- MATERIALSDocument4 pagesMATERIALSraus_danut100% (23)

- Vue Eclatee - PM32Document20 pagesVue Eclatee - PM32Jean ClaracPas encore d'évaluation

- VerifDocument48 pagesVerifmaintenance finissagePas encore d'évaluation

- Catalogue Arcelor A30 - FRDocument14 pagesCatalogue Arcelor A30 - FRFrancoisPas encore d'évaluation

- EXU01Document34 pagesEXU01Dido KingPas encore d'évaluation

- PzicijeDocument146 pagesPzicijeKemalMalovcicPas encore d'évaluation

- Désignation MatériauDocument18 pagesDésignation Matériaumichael.tujague14Pas encore d'évaluation

- 030811-Correspondance Des AciersDocument3 pages030811-Correspondance Des Acierspascal80% (5)

- Plastfit Catalogue 2021Document110 pagesPlastfit Catalogue 2021Ghulam Mustafa KhanPas encore d'évaluation

- 015.tableau Nuance Matière PremièreDocument1 page015.tableau Nuance Matière PremièreAS BaizidiPas encore d'évaluation

- Ruban Fibre VerreDocument74 pagesRuban Fibre Verretmh ciPas encore d'évaluation

- Otel Carbon de SculeDocument1 pageOtel Carbon de SculeSara HeartPas encore d'évaluation

- Structural Grade Material EquivalentsDocument2 pagesStructural Grade Material EquivalentswholenumberPas encore d'évaluation

- Cablofil 2008Document99 pagesCablofil 2008Eduardo Gonzalez Gonzalez RobayoPas encore d'évaluation

- 24 GRP Tag - DuDocument39 pages24 GRP Tag - DuShreyas GaurPas encore d'évaluation

- Equivalencia de NormasDocument1 pageEquivalencia de NormasizzygodswanPas encore d'évaluation

- CablofilDocument84 pagesCablofilEdgar MoyaoPas encore d'évaluation

- NSX 303Document16 pagesNSX 303api-3703813100% (1)

- Transfo 1Document47 pagesTransfo 1Samorai KazaPas encore d'évaluation

- Standardi ČelikaDocument8 pagesStandardi ČelikaZoran HajdukovPas encore d'évaluation

- Generated BoM 2016.05.13Document16 pagesGenerated BoM 2016.05.13Donea ClaudiuPas encore d'évaluation

- Matriculas de Artefactos y AccesoriosDocument25 pagesMatriculas de Artefactos y AccesoriosFernando Sticco67% (3)

- Equivalencias de AcerosDocument1 pageEquivalencias de AcerosCruzmaug Balrog100% (6)

- Bombas Saer 30-30Document1 pageBombas Saer 30-30Natali Arevalo EscalonaPas encore d'évaluation

- OSCNEWDocument3 pagesOSCNEWNguyễn Quang TrânPas encore d'évaluation

- Item Mes FG (FC)Document2 pagesItem Mes FG (FC)Yulius SanjayaPas encore d'évaluation

- MoteursDocument2 pagesMoteursMartinezPas encore d'évaluation

- CorrespondênciasDocument5 pagesCorrespondênciasTTaddictPas encore d'évaluation

- Schedule Table of ASME&SJISDocument3 pagesSchedule Table of ASME&SJISJihwan LeePas encore d'évaluation

- XF221024Document2 pagesXF221024Yair Sánchez blancoPas encore d'évaluation

- SHS 80X80X3 & SHS 120X120X3Document2 pagesSHS 80X80X3 & SHS 120X120X3Özgün BıçakPas encore d'évaluation

- Loi d'AGEC-fiche RecyclableDocument5 pagesLoi d'AGEC-fiche RecyclableDabi YannPas encore d'évaluation

- Test PackageDocument4 752 pagesTest PackagePT Bumi Liputan PusakaPas encore d'évaluation

- Sakura FilterDocument8 pagesSakura Filterandi yusufPas encore d'évaluation

- Plastfit Product CatalogueDocument103 pagesPlastfit Product CatalogueGhulam Mustafa KhanPas encore d'évaluation

- (Inc PPN) Daftar New Price List Maret 2021 Sea YogyaDocument2 pages(Inc PPN) Daftar New Price List Maret 2021 Sea YogyaMuhammad JawadPas encore d'évaluation

- Catalogo Clamps Quilinox 2022Document6 pagesCatalogo Clamps Quilinox 2022imerinoPas encore d'évaluation

- L SPI Resma 2011Document24 pagesL SPI Resma 2011Nacir BoualiPas encore d'évaluation

- Chiffrage Boues Et HydroDocument8 pagesChiffrage Boues Et HydroBilalPas encore d'évaluation

- Aide Mémoire Groupe Matériaux Et Choix Métaux D'apportDocument4 pagesAide Mémoire Groupe Matériaux Et Choix Métaux D'apportmail_younes6592Pas encore d'évaluation

- MaterialsDocument4 pagesMaterialsSameercmorePas encore d'évaluation

- Western Electric MotorDocument2 pagesWestern Electric Motorjemley antzPas encore d'évaluation

- MatériauxDocument144 pagesMatériauxsemvpmPas encore d'évaluation

- H 14Document1 pageH 14CTN2010Pas encore d'évaluation

- 5-51-0301.00 Stücklisten FranzösischDocument32 pages5-51-0301.00 Stücklisten FranzösischHanache MadaniPas encore d'évaluation

- Rsultsep 3Document1 pageRsultsep 3MR.MANOJ SONUNEPas encore d'évaluation

- 07 585 Conversions Nuances Metalliques Et Caracteristiques Pour JointsDocument1 page07 585 Conversions Nuances Metalliques Et Caracteristiques Pour Jointspascal.lebbrechtPas encore d'évaluation