Académique Documents

Professionnel Documents

Culture Documents

Mgks 15 A

Transféré par

Alain DefoeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mgks 15 A

Transféré par

Alain DefoeDroits d'auteur :

Formats disponibles

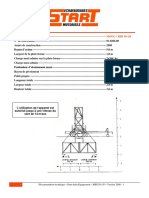

OPERATION AND MAINTENANCE INSTRUCTIONS

Hydrauliprässi Workshop presses

KSG-15 A / KMG-15 A / KMG-30 A

MELCHOR GABILONDO, S.A.

Polígono Industrial Eitua,6 / 48240 Bérriz (Vizcaya) ESPAÑA / Tel.94 622 50 90 / Intl: 34-94 622 50 90

Telefax: 94 622 52 78 / Intl.: 34-94 622 52 78 / Teléfono Ventas: 94 622 50 30

Telefax Ventas: 94 682 73 50 / E -MAIL: interior@mega-sa.com / export@mega-sa.com

KMG-30A

57

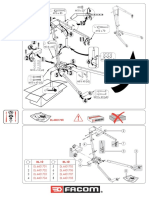

Nº NOMBRE/DESCRIPTION KSG-15A KMG-15A KMG-30A Nº NOMBRE/DESCRIPTION KSG-15A KMG-15A KMG-30A

DESIGNATION 15 t 15 t 30 t DESIGNATION 15 t 15 t 30 t

1 Tornillo/Screw/Vis GN-20/1934 GN-20/1934 YMK-15/1408 31 Columna/Upright/Colonne KSMM-15/1296 KMM-15/1296 KMM-30/1296

2 Cabeza/Piston head/Tête MGK-15/1108 MGK-15/1108 CK-50/1108 32 Bastidor/Frame/Châssis KMM-15/1237 KMM-15/1237 KMM-30/1237

3 Anillo/Ring/Bague MG -15/1361 MG-15/1361 MG-30/1361 33 Eje/Axle/Axe KMM-15/1197 KMM-15/1197 KMM-30/1197

4 Aro/Ring/Bague MG -15/1102 MG-15/1102 MG-30/1102 34 Arandela/Washer/Rondelle MB-22-B/1295 MB-22-B/1295 KMM-30/2149

MGK-30/1371

5 O-Ring MG -15/1131 MG-15/1131 35 Tuerca/Nut/Ecrou TJM-2/1397 TJM -2/1397 TJM-2/1540

MGK-30/1131

5.2 O-Ring - - MGK-30/2119 36 Circlip ME-1002/1179 ME-1002/1179 MB-32-B/1377

6 Pistón/Main piston/Piston MGK-15/C14 MGK-15/C14 MGK-30/C14 37 Eje/Axle/Axe KMM-15/1376 KMM-15/1376 KMM-30/1376

7 O-Ring MG -15/1134 MG-15/1134 MG-30/1134 38 Casquillo/Bushing/Douille KMM-15/1370 KMM-15/1370 KMM-30/1370

8 Aro/Ring/Bague MG -15/1164 MG-15/1164 MG-30/1164 39 Mesa/Table/Table KMM-15/1334 KMM-15/1334 KMM-30/1334

9 Botella/Hy.Unit./Ens.Hydr. MGK-15/C25 MGK-15/C25 MGK-30/C25 40 Eje/Axle/Axe KMM-15/1670 KMM-15/1670 KMM-30/1670

10 Tapón/Plug/Bouchon ME-12001/1139 ME-12001/1139 ME-12001/1139 41 Tuerca/Nut/Ecrou MB-22-B/1405 MB-22-B/1405 MB-22-B/1405

11 Tornillo/Screw/Vis KC -15/1309 KC-15/1309 KC-15/1309 42 Casquillo/Bushing/Douille KMM-15/2206 KMM-15/2206 KMM-30/2206

12 Tuerca/Nut/Ecrou EF -1,5/1318 EF-1,5/1318 EF -1,5/1318 43 Eje/Axle/Axe - KMM-15/1264 KMM-30/1264

13 Bola/Ball/Bille ME-1501/1149 ME-1501/1149 ME-1501/1149 44 Arandela/Washer/Rondelle - AP-100/1553 AP-100/1553

14 Muelle/Spring/Ressort MG -2/1161 MG-2/1161 MG-2/1161 45 Tirante/Cross section /Tirant KMM-15/1333 KMM-15/1333 KMM-30/1333

15 Collarín/Seal/Coupelle MG -2/1133 MG-2/1133 MG-2/1133 46 Asiento en V/ V block/V centrage KMG-15A/C15 KMG-15A/C15 KCK-30A/C15

Portapalanca/Handle MGK-15/C7 MGK-15/C7 MGK-15/C7 KP-30/1948-A KP-30/1948-A KP-30/1948-A

16 47 Tornillo/Screw/Vis

socket/Chape porte-levier

17 Palanca/Handle/Levier BM-3/1113 BM-3/1113 BM-3/1113 48 Base/Foot/Semelle KSMM-15/1330 KMM-15/1330 KMM-30/1330

18 Descarga/Release/Descente BM-04/C11 BM-04/C11 BM-04/C11 49 Eje/Axle/Axe KMM-15/1365 KMM-15/1365 KMM-30/1365

19 O-Ring MG -2/1130 MG-2/1130 MG-2/1130 50 Tope/Clip/Clip KMM-15/1366 KMM-15/1366 KMM-15/1366

20 Bola/Ball/Bille ME-1501/1212 ME-1501/1212 ME-1501/1212 51 Eje/Axle/Axe KY-15/1383 KY-15/1383 KY-30/1383

21 Bola/Ball/Bille ME-1501/1149 ME-1501/1149 ME-1501/1149 52 Placa/ Spring plate/ Platine ressort KMM-15/1463 KMM-15/1463 KMM-30/1463

22 - - - - 53 Muelle/Spring/Ressort MK-15/1240 MK-15/1240 MK-30/1240

23 O-Ring MB-22-A/1130 MB-22-A/1130 MB-22-A/1130 54 Tornillo/Screw/Vis EF -1,5/1315 EF -1,5/1315 EF-1,5/1315

- - -

Soporte de unidad hid./ Hyd. unit KMM-15/1464 KMM-15/1464 KMM-30/1464

24 - 55

support./Support unité hydaulique

25 Tornillo/Screw/Vis MGK-15/1485 MGK-15/1485 MGK-15/1485 56 Tuerca/Nut/Ecrou ME-1002/1114 ME-1002/1114 ME-1002/1114

57 J.reparación / Repair kit/ Kit rép. RMGK-15A

3-5-7-8-10-15-19

RMGK -15A

3-5-7-8-10-15-19

RMGK-30A

3-5-5.2-7-8-10-15-19

Manómetro/ Press gauge / A-5121 A-5121 A-5121 BKN-07/1475 BKN-07/1475 BKN-07/1475

26 58 Casquillo/Bushing/Douille

Manomètre

Cto.Hidráulico/ Hy.Unit./Ens.Hydr MGK-15 MGK-15 MGK-30

3

30 Casquillo/Bushing/Douille KMM -15/2133 KMM- 15/2133 KMM- 30/2133 cm V.aceite/Oil-Huile volume 500 500 980

GB

1 SAFETY INSTRUCTIONS

1.1 Do not exceed the rated capacity of the press.

1.2 Do not exceed the stroke indicated on the label.

1.3 Keep hands and body clear of the work table when operating the press.

1.4 Always wear suitable eye and face protection.

1.5 Ensure the workpiece is correctly secured before operating.

1.6 If these basic rules are not followed, injury to the user, the press or the workpiece may result.

2 USE AND OPERATION

2.1 Attach the press securely to a flat, firm surface.

2.2 Place the table at the correct height firmly onto the table pins. Very important on presses fitted with winch .

2.3 Position the head of the hydraulic unit on the centre of the workpiece using the extension screw.

2.4 Before operating the press, you must purge its hydraulic unit to eliminate any possible air in the system.

To purge the system, open the release valve part n.º 18 by turning it anti-clockwise.Then, with the aid of the lever, operate the pump several

times.

2.5 Close the release valve part n.º 18 in a clockwise direction until it is fully closed.The hydraulic unit is ready for use.

2.6 Always keep the piston, extension screw and pump piston retracted after use.

3 MAINTENANCE

3.1 Lubricate all moving parts at regular intervals.

3.2 Always keep the press clean and protected from aggressive conditions.

3.3 If you have to replace the oil of the pump, the correct volume is indicated in the parts list. Make sure the piston is fully retracted.

IMPORTANT: An excess of oil will render the press inoperative.

3.4 Use only hydraulic oil, type HL or HM, with an ISO grade cinematic viscosity of 30 cSt at 40º C or an Engler viscosity of 3 at 50º C.

VERY IMPORTANT: Never use brake fluid.

3.5 When ordering spare parts, please make note of the part reference as shown in the parts list. A repair kit is available containing all the common

spare parts.

4 REPAIR

Both maintenance and repair must only be carried out by qualified and approved personnel.

Vous aimerez peut-être aussi

- MBI50 StartDocument1 pageMBI50 StartAlain DefoePas encore d'évaluation

- Effer 150 Spare PartDocument104 pagesEffer 150 Spare PartAlain DefoePas encore d'évaluation

- MBI180 StartDocument1 pageMBI180 StartAlain DefoePas encore d'évaluation

- Geda 500Z-ZPDocument58 pagesGeda 500Z-ZPAlain DefoePas encore d'évaluation

- 619Document9 pages619Alain DefoePas encore d'évaluation

- Bob Cat 463 PDFDocument302 pagesBob Cat 463 PDFBernardo Orozco Larios100% (1)

- MGTJC 02 ADocument3 pagesMGTJC 02 AAlain DefoePas encore d'évaluation

- Catmrol FRDocument17 pagesCatmrol FRAlain DefoePas encore d'évaluation

- DL.150HL 0707Document20 pagesDL.150HL 0707Alain DefoePas encore d'évaluation

- MGKPD 50 ADocument4 pagesMGKPD 50 AAlain DefoePas encore d'évaluation

- GC GC GC GC: FrançaiDocument2 pagesGC GC GC GC: FrançaiAlain DefoePas encore d'évaluation

- MGCVT 03Document4 pagesMGCVT 03Alain DefoePas encore d'évaluation

- MGFMGT 1200 ADocument2 pagesMGFMGT 1200 AAlain DefoePas encore d'évaluation

- DLS.300 0406Document8 pagesDLS.300 0406Alain DefoePas encore d'évaluation

- Oh 4309Document7 pagesOh 4309Alain DefoePas encore d'évaluation

- DL - PLHP1035 1008Document20 pagesDL - PLHP1035 1008Alain DefoePas encore d'évaluation

- DL - PLHP1035 1008Document20 pagesDL - PLHP1035 1008Alain DefoePas encore d'évaluation

- DL.700 0709Document16 pagesDL.700 0709Alain DefoePas encore d'évaluation

- DL.1200 0709Document16 pagesDL.1200 0709Alain DefoePas encore d'évaluation

- DL.10 Montage0106Document1 pageDL.10 Montage0106Alain DefoePas encore d'évaluation

- DL.150HL 0707Document20 pagesDL.150HL 0707Alain DefoePas encore d'évaluation

- DL.150HL 0707Document20 pagesDL.150HL 0707Alain DefoePas encore d'évaluation

- DL.150HL 0707Document20 pagesDL.150HL 0707Alain DefoePas encore d'évaluation

- dumarent-manUSM BW213 - FR PDFDocument158 pagesdumarent-manUSM BW213 - FR PDFBrahim MidounePas encore d'évaluation

- Krane / Cranes / Grues / Grúa: Ladekran AK 96.3Document6 pagesKrane / Cranes / Grues / Grúa: Ladekran AK 96.3Alain DefoePas encore d'évaluation

- DL.5 1008Document20 pagesDL.5 1008Alain DefoePas encore d'évaluation

- Codes & Annotations + Dico D'accordsDocument6 pagesCodes & Annotations + Dico D'accordsSalsaPas encore d'évaluation

- Github Git Cheat SheetDocument2 pagesGithub Git Cheat SheetWise guyPas encore d'évaluation

- Les Relations Lexicales Sans Reì VisionDocument92 pagesLes Relations Lexicales Sans Reì VisionprivetPas encore d'évaluation

- Automatisation Des Tâches D'administration Système: M2 SicsDocument4 pagesAutomatisation Des Tâches D'administration Système: M2 SicsMANAL BENNOUFPas encore d'évaluation

- Napoli b9 Parts PDFDocument29 pagesNapoli b9 Parts PDFJhon Alex Ramirez Idarraga100% (1)

- Exposé Des 7 Âgés de L'égliseDocument56 pagesExposé Des 7 Âgés de L'églisegladstonemutimaPas encore d'évaluation

- Exposé:: La Méthode de La BissectionDocument7 pagesExposé:: La Méthode de La BissectionMennaà Mohamed Fidaa El islam100% (1)

- Les Bonnes Méthodes - Communiquer À L'écrit-0Document22 pagesLes Bonnes Méthodes - Communiquer À L'écrit-0Jimmy ANDRIATSIMIALINA100% (1)

- 9782070357703Document12 pages9782070357703AHMEDPas encore d'évaluation

- CV - RAKOTOHARIMALALA SantatraDocument2 pagesCV - RAKOTOHARIMALALA SantatraSantatra HarimalalaPas encore d'évaluation

- Annexe 1 Fiche Descriptive Formation React NativeDocument3 pagesAnnexe 1 Fiche Descriptive Formation React NativeIrie Konma BI ArsenePas encore d'évaluation

- Uml ClassesDocument25 pagesUml ClassesZozer Mbula LwangaPas encore d'évaluation

- Symfony Cours 3 RoutingDocument35 pagesSymfony Cours 3 RoutingIdris SaddiPas encore d'évaluation

- ProgrammeDocument3 pagesProgrammeJhd AlganPas encore d'évaluation

- A Ele A Gloria - Diante Do Trono - Sax Tenor 1-2Document1 pageA Ele A Gloria - Diante Do Trono - Sax Tenor 1-2Sidionir FalchetePas encore d'évaluation

- La Profession de Foi Des Traditionalistes Musulmans (Al Aquidah At-Tahawiyah)Document254 pagesLa Profession de Foi Des Traditionalistes Musulmans (Al Aquidah At-Tahawiyah)ickodPas encore d'évaluation

- Graine de Mot: FrançaisDocument44 pagesGraine de Mot: FrançaisJo Digital Printing33% (3)

- Cours Theorie de LenonciationDocument6 pagesCours Theorie de LenonciationSïñørítä chøpâcabrà100% (2)

- Fonctions Logarithmiques Exercices Non Corriges 4Document4 pagesFonctions Logarithmiques Exercices Non Corriges 4M'KHEITIRATT AhmdPas encore d'évaluation

- Les Genres Littéraires - Le Roman, La Poésie Et Le Théâtre (Fiche de Révision) : Réussir Le Bac de Français Télécharger, Lire PDFDocument8 pagesLes Genres Littéraires - Le Roman, La Poésie Et Le Théâtre (Fiche de Révision) : Réussir Le Bac de Français Télécharger, Lire PDFmohammed abdouPas encore d'évaluation

- Topchretien La Puissance Insoupconnee de La ReconnaissanceDocument2 pagesTopchretien La Puissance Insoupconnee de La ReconnaissanceMaria GasparPas encore d'évaluation

- (Superpartituras - Com.br) Brejeiro V 6Document2 pages(Superpartituras - Com.br) Brejeiro V 6Jorge Ribeiro0% (1)

- Argumentation 3Document4 pagesArgumentation 3Awatef chammakhiPas encore d'évaluation

- Commande D'un Escenseur Step7-200Document20 pagesCommande D'un Escenseur Step7-200KadriAbderRaouf100% (1)

- PadletDocument5 pagesPadletapi-224553661Pas encore d'évaluation

- Planificare Limba Franceză L2 XIIDocument9 pagesPlanificare Limba Franceză L2 XIIDiana PorțanPas encore d'évaluation

- Second Venue de JesusDocument8 pagesSecond Venue de JesusnizaryPas encore d'évaluation

- Cours AJAX Vers 2008 (JSP)Document38 pagesCours AJAX Vers 2008 (JSP)didataze100% (3)

- Serie Les Fon Ctions 2022Document2 pagesSerie Les Fon Ctions 2022travelfast713Pas encore d'évaluation

- Marguerite DunasDocument16 pagesMarguerite Dunasjoca2008Pas encore d'évaluation