Académique Documents

Professionnel Documents

Culture Documents

Abaque Tac Els Cara

Transféré par

GEORGES0 évaluation0% ont trouvé ce document utile (0 vote)

7 vues1 pageCopyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

7 vues1 pageAbaque Tac Els Cara

Transféré par

GEORGESDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

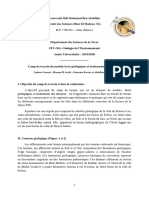

Abaque de frottement en t/ml par situation et type de pieu (hors résistance de pointe)

MODE DE SOLLICITATION TYPE DE PIEUX Catégorie Mise en œuvre Ø de référence Comportement

Foré tarière creuse simple Pieux non ancrés dans la

ELS CARA rotation, ou double rotation

6

craie

0.5 Compression

Type de sol Argile % CaCO3 < 30% Limon Sols intermédiaires Marne et Calcaire- Roche altérée ou

Craie

PL* Sols intermédiaires Sable Grave Marneux fragmentée

qs max kPa 90.00 90.00 170.00 200.00 200.00

0.1 1.724 t 1.199 t 1.748 t 3.236 t 3.244 t

0.2 2.961 t 2.300 t 3.315 t 5.689 t 5.717 t

0.3 3.852 t 3.311 t 4.722 t 7.556 t 7.611 t

0.4 4.497 t 4.241 t 5.987 t 8.984 t 9.071 t

0.5 4.967 t 5.098 t 7.125 t 10.084 t 10.204 t

0.6 5.314 t 5.889 t 8.150 t 10.938 t 11.093 t

0.7 5.573 t 6.619 t 9.076 t 11.608 t 11.798 t

0.8 5.769 t 7.295 t 9.913 t 12.140 t 12.365 t

0.9 5.921 t 7.922 t 10.672 t 12.569 t 12.829 t

1 6.041 t 8.504 t 11.361 t 12.921 t 13.215 t

1.1 6.139 t 8.692 t 11.988 t 13.216 t 13.543 t

1.2 6.222 t 8.692 t 12.560 t 13.467 t 13.828 t

1.3 6.293 t 8.692 t 13.083 t 13.686 t 14.080 t

1.4 6.356 t 8.692 t 13.562 t 13.882 t 14.308 t

1.5 6.413 t 8.692 t 14.004 t 14.059 t 14.517 t

1.6 6.466 t 8.692 t 14.411 t 14.222 t 14.713 t

1.7 6.517 t 8.692 t 14.789 t 14.376 t 14.898 t

1.8 6.565 t 8.692 t 15.139 t 14.521 t 15.075 t

1.9 6.612 t 8.692 t 15.466 t 14.662 t 15.247 t

2 6.658 t 8.692 t 15.771 t 14.798 t 15.414 t

2.1 6.703 t 8.692 t 16.058 t 14.931 t 15.579 t

2.2 6.748 t 8.692 t 16.329 t 15.061 t 15.740 t

2.3 6.792 t 8.692 t 16.419 t 15.190 t 15.900 t

2.4 6.836 t 8.692 t 16.419 t 15.318 t 16.059 t

2.5 6.880 t 8.692 t 16.419 t 15.444 t 16.216 t

2.6 6.924 t 8.692 t 16.419 t 15.570 t 16.373 t

2.7 6.968 t 8.692 t 16.419 t 15.695 t 16.529 t

2.8 7.011 t 8.692 t 16.419 t 15.820 t 16.685 t

2.9 7.055 t 8.692 t 16.419 t 15.945 t 16.841 t

3 7.098 t 8.692 t 16.419 t 16.069 t 16.996 t

3.1 7.142 t 8.692 t 16.419 t 16.193 t 17.151 t

3.2 7.185 t 8.692 t 16.419 t 16.317 t 17.306 t

3.3 7.229 t 8.692 t 16.419 t 16.441 t 17.461 t

3.4 7.272 t 8.692 t 16.419 t 16.565 t 17.615 t

3.5 7.316 t 8.692 t 16.419 t 16.688 t 17.770 t

3.6 7.359 t 8.692 t 16.419 t 16.812 t 17.925 t

3.7 7.403 t 8.692 t 16.419 t 16.936 t 18.079 t

3.8 7.446 t 8.692 t 16.419 t 17.060 t 18.234 t

3.9 7.490 t 8.692 t 16.419 t 17.183 t 18.389 t

4 7.533 t 8.692 t 16.419 t 17.307 t 18.543 t

4.1 7.577 t 8.692 t 16.419 t 17.431 t 18.698 t

4.2 7.620 t 8.692 t 16.419 t 17.554 t 18.852 t

4.3 7.664 t 8.692 t 16.419 t 17.678 t 19.007 t

4.4 7.707 t 8.692 t 16.419 t 17.801 t 19.161 t

4.5 7.751 t 8.692 t 16.419 t 17.925 t 19.316 t

4.6 7.794 t 8.692 t 16.419 t 18.049 t 19.316 t

4.7 7.837 t 8.692 t 16.419 t 18.172 t 19.316 t

4.8 7.881 t 8.692 t 16.419 t 18.296 t 19.316 t

4.9 7.924 t 8.692 t 16.419 t 18.420 t 19.316 t

5 7.968 t 8.692 t 16.419 t 18.543 t 19.316 t

FACTEURS PARTIELS ET COEFFICIENTS MODELES

compression traction ELU ELU fondamental ELU accidentel

γR;d1= 1.15 1.40 Compression : γb = 1.10 1.00

γR;d2= 1.10 1.10 γs = 1.10 1.00

Traction : γs;t = 1.15 1.05

ELS ELS caractéristique ELS quasi-permanent

Compression : γcr = 0.90 1.10

Traction : γs;cr = 1.10 1.50

Vous aimerez peut-être aussi

- Levées Géologiques Et Traitement Des Données S6 Filière STU - 1 PDFDocument13 pagesLevées Géologiques Et Traitement Des Données S6 Filière STU - 1 PDFmohammed LautfiPas encore d'évaluation

- Exposition Pierres Précieuses, ParisDocument28 pagesExposition Pierres Précieuses, ParisJason WhittakerPas encore d'évaluation

- Évolution Et Transformation Des Industries Lithiques Taillées Et Polies Durant Le Chalcolithique Et L'âge Du Bronze en CorseDocument9 pagesÉvolution Et Transformation Des Industries Lithiques Taillées Et Polies Durant Le Chalcolithique Et L'âge Du Bronze en CorseLuiz RochaPas encore d'évaluation

- Reconstitution Geologique Des Aquiferes Du Continental Terminal Dans La Region de NiameyDocument56 pagesReconstitution Geologique Des Aquiferes Du Continental Terminal Dans La Region de NiameyBou DaifPas encore d'évaluation

- 73 SGN 112 GeoDocument34 pages73 SGN 112 GeoBenjamin LansPas encore d'évaluation

- Chap. 1. GENERALITES SUR LA PETROGRAPHIEDocument132 pagesChap. 1. GENERALITES SUR LA PETROGRAPHIEHilary ParkerPas encore d'évaluation

- TP Sismique RefractionDocument4 pagesTP Sismique RefractionNasraddine HassanePas encore d'évaluation

- Geographie Territoire1Document29 pagesGeographie Territoire1Ben Mabrouk NaceurPas encore d'évaluation

- Forage MinierDocument2 pagesForage MinierMoussaPas encore d'évaluation

- 69 SGN 265 GitDocument39 pages69 SGN 265 GitMassy TraorePas encore d'évaluation

- EIE CARRIERE BriqueterieDocument69 pagesEIE CARRIERE BriqueteriebelkissPas encore d'évaluation

- Introduction Du Concept D'évolution Humaine Buissonnante Dans Les Manuels Scolaires de Sciences de La Vie Et de La Terre de Terminale ScientifiqueDocument8 pagesIntroduction Du Concept D'évolution Humaine Buissonnante Dans Les Manuels Scolaires de Sciences de La Vie Et de La Terre de Terminale ScientifiqueDJIL BENPas encore d'évaluation

- TD N°2: Sondage Electrique Vertical (S.E.V)Document1 pageTD N°2: Sondage Electrique Vertical (S.E.V)Jean Daniel NgohPas encore d'évaluation

- 8-TRAITEMENT DES CAVITES Dans Le Projet Du CarrouselDocument154 pages8-TRAITEMENT DES CAVITES Dans Le Projet Du Carrouselyoussef elbakkouriPas encore d'évaluation

- Hydrog-Ochimie Et Geothermom-Trie Apports L Identification Du R Servoir Thermal Des Sources de Hammam Righa Alg RieDocument13 pagesHydrog-Ochimie Et Geothermom-Trie Apports L Identification Du R Servoir Thermal Des Sources de Hammam Righa Alg RieAbdellatif MarouanePas encore d'évaluation

- SedimentoDocument14 pagesSedimentoKouao Assiè François AristidePas encore d'évaluation

- Gaz de Schiste !!Document6 pagesGaz de Schiste !!Thomas HansenPas encore d'évaluation

- Chapter 5 Evaluation Minière 5.1. Analyse Des Données Par Télédétection 5.1.1 Vue D'ensemble Des Images SatelliteDocument110 pagesChapter 5 Evaluation Minière 5.1. Analyse Des Données Par Télédétection 5.1.1 Vue D'ensemble Des Images SatelliteTARPas encore d'évaluation

- Cours de Géophysique3Document39 pagesCours de Géophysique3Amen Gracia FOUNA GEMELLAIREPas encore d'évaluation

- Cours Petrographie Sedimentaires m2 GbsDocument61 pagesCours Petrographie Sedimentaires m2 GbsNore TiandrazaPas encore d'évaluation

- CORRIGE TYPE SVT 1ère D Devoir Du 17-11Document1 pageCORRIGE TYPE SVT 1ère D Devoir Du 17-11kissaobilPas encore d'évaluation

- CV-Demande de Stage PFEDocument1 pageCV-Demande de Stage PFEIlboudo MoumounePas encore d'évaluation

- Fascicule de TPDocument66 pagesFascicule de TPMazigh NmaxPas encore d'évaluation

- Bibliography. Argos, Aspida, LarisaDocument4 pagesBibliography. Argos, Aspida, LarisapaszafPas encore d'évaluation

- Exposé Géothermie BrouilionDocument7 pagesExposé Géothermie BrouilionLetoile SaraPas encore d'évaluation

- Caractérisation Mécanique D'un MélangeDocument103 pagesCaractérisation Mécanique D'un Mélangesilarealme0Pas encore d'évaluation

- Cours Hydrologie - 21-22 - Chap. 2Document48 pagesCours Hydrologie - 21-22 - Chap. 2Aya ChikerPas encore d'évaluation

- Cours de GéostatistiqueDocument4 pagesCours de GéostatistiqueAziz AbdelkaderPas encore d'évaluation

- Rapport P6 2015 16Document30 pagesRapport P6 2015 16Rahma GhanemPas encore d'évaluation

- Gabbro CorrectionDocument2 pagesGabbro Correctionmama14lecerfPas encore d'évaluation