Académique Documents

Professionnel Documents

Culture Documents

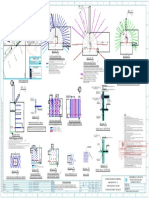

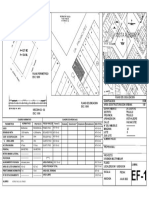

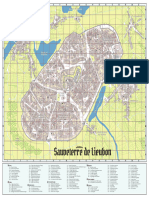

Manufacturing Notes - U.S.O.: SCALE 1: 7.5 Scale 1: 5

Transféré par

SergioTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manufacturing Notes - U.S.O.: SCALE 1: 7.5 Scale 1: 5

Transféré par

SergioDroits d'auteur :

Formats disponibles

1 2 3 4 5 6 7 8 9 10 11 12

A A

4150

26 16

2588

6.3

1960

240

8 4

425 130 1031 1031 130

20 8 11 16 7 16 19 6

10 TYP.

Q A 20 THK.

167

R1

5 J TYP. 4 PLS.

11 50 7

R4

0

140

37

100

18 TYP.

94.5

6 PLS.

275

R2

50

50

5

0

J 350 x 250 x 8

2

37 37 n140

90

885

18

176 n165.2 32 80

164.8

373.5

9 127 127

6)

E 160

6.

n300

(1

B T B

R3

174

33 0

11

J 400 x 200 x 12

14 DETAIL 'P' TYP. 6 PLS. DETAIL 'T'

350 350

A Y J SCALE 1 : 7.5 SCALE 1 : 5

RHS RHS

11 12 15 36

E 1021 1021

360 275 500 500 500 275 725 500 275 2042 (125)

(125) 2292

775 1000 1000 775

2542 36

1190 2000 960 8 3x M16x2 - 6H

35

R70

0

EQUI SPACED ON PCD 138 0

17

0

23

10

0

n110

30°

C C

(32)

28

n60

4320 2288

30

)

(33°

SISPENSION SISPENSION

345

n138 PCD

29 17 6 19 11 36 16 390 16 11 17 n180

6.3

H G n139.7 173 127 14

5 TYP.

195

131

19 50

800 50

6.3

3

35 35

8

DETAIL 'Y' TYP. 6 PLS.

28 SECTION F-F

85

31 28 SCALE 1 : 5

20 THK.

170

140

0

200

F R2 24 24 SCALE 1 : 10

194

173

P

97

J 250 x 150 x 6

741.0

740.0

80 127 123

30 11

50°

50°

205

D 8 D

F

405

K. 14

(5

CHS 139.7 OD x 6.3 WT

715

500

°)

TH

4°

33

(54

)

20 12 13

270 270

55 TYP

30 THK.

30 x45°

20 14

240

TYP.

20 5

480 220 5

545.5

C 36 34

2 36

J 250 x 150 x 8

34

345

1

80°

100°

2280

690

800

100

n350 SECTION A-A

2402

1091

2458

°

SCALE 1 : 15

CHS 139.7 OD x 6.3 WT

40° 0

C

R 20

P.

TY LS

P

4

545.5

J 400 x 200 x 10

E E

Ø139.7

480 50

192 150

65 180 203 (30)

J 400 x 200 x 10

J 400 x 200 x 12

90 145

33 10 680

5

TH

K. R50

60

1000

405

14 40 22

114

n25

30 0

R5

(118)

300

120

110

R50

240

30°

J 250 x 150 x 6 R1

55

400

00

12

126

131

°

10°

180 16xM12x1.75

n140

B 155

8 THK.

8 THK.

B 29

BOTH ENDS

BOTH ENDS

Ø125 n125 ISOMETRIC VIEW

60 1

10 TYP.

10 TYP.

F F

120 REF.

TYP. 4 PLS. DETAIL 'X' DETAIL 'Q'

H

X G SCALE 1 : 10 SCALE 1 : 10

29 6 37 19 11 16 7 26 16 11 19

NOTE: - ALL WELDS IN ACCORDANCE WITH BS 5135

G - FABRICATION TO BE SQUARE AND TRUE TO CENTRE LINES. G

- ALL WELDS 6 mm CONTINUOUS FILLET OR PART PENETRATION U.S.O

MANUFACTURING NOTES - U.S.O. COPYRIGHT AND DESIGN RIGHT JOHN M. HENDERSON MACHINES LTD.

THIS DRAWING IS THE PROPERTY OF JOHN M. HENDERSON MACHINES LTD.

Station Works, North Street

AND MUST NOT BE COPIED WITHOUT WRITTEN PERMISSION. Forfar, Scotland

REMOVE ALL SHARP EDGES ITS CONTENTS ARE CONFIDENTIAL AND MUST NOT BE DISCLOSED DD8 3BN

MACHINING TOLERANCES:- TO ANYONE WITHOUT WRITTEN PERMISSION,

+44(0)1307 474030

DIMENSIONS `0.25mm AND ARE TO BE USED ONLY FOR PURPOSE

FOR WHICH THE DRAWING IS SUPPLIED www.johnmhenderson.com

ANGULAR `0.25~

INTERNAL CORNERS 1.0mm RADIUS 26/06/18 TITLE:

EXTERNAL CORNERS 1.5mm CHAMFER

DRAWN G.F. DATE TERNIUM - SIDERAR

FABRICATION TOLERANCES:- CHECKED M.B. DATE 01/01/01

QUENCH CAR

DIMENSIONS 0-2000 `2mm BOGIES

124 26/06/18 G.F. ORIGINAL M.B. M.B.

DIMENSIONS 2000-4000 `3mm APPROVED M.B. DATE 01/01/01 BOGIE UNIT FRAME

H DIMENSIONS ABOVE 4000 `4mm H

No. DATE QTY. DESCRIPTION No. DATE DRAWN DESCRIPTION CKD APPD ANGULAR ±1~ PROJECTION SCALE SIZE DRAWING No. SHEET No. REV.

SCREW THREAD TOLERANCE TO BS3643 MEDIUM FIT (6H/6g)

PROJECT REVISION PRECISION BOLTS TO BS3692 ISO METRIC GR.8.8 - NUTS GR.8 1 : 15 A1 124-QBG-1000 1 of 2 0

1 2 3 4 5 6 7 8 9 10 11 12

Vous aimerez peut-être aussi

- 2ma084c2 1-6Document1 page2ma084c2 1-6Daoud ElkoursiPas encore d'évaluation

- Im8 92591 0Document1 pageIm8 92591 0juan soteloPas encore d'évaluation

- 2ma084c2 1-4Document1 page2ma084c2 1-4Daoud ElkoursiPas encore d'évaluation

- Not Isolated Isolated: California Institute of Telecommunication and Information Technology (Calit 2)Document1 pageNot Isolated Isolated: California Institute of Telecommunication and Information Technology (Calit 2)Admir BašićPas encore d'évaluation

- MEGA2560 Rev3e SCHDocument1 pageMEGA2560 Rev3e SCHАндрей ВидинPas encore d'évaluation

- Sección: Vicepresidencia de Proyectos Mina Chuquicamata Subterránea Ingeniería de DetalleDocument1 pageSección: Vicepresidencia de Proyectos Mina Chuquicamata Subterránea Ingeniería de DetalleCarlos FitPas encore d'évaluation

- Abba Gold - TubaDocument5 pagesAbba Gold - TubaEdipo Luan OstroskiPas encore d'évaluation

- Schéma Électrique MoteurDocument1 pageSchéma Électrique MoteurramiPas encore d'évaluation

- 2ma084c2 1-3Document1 page2ma084c2 1-3Daoud ElkoursiPas encore d'évaluation

- Brilho Celeste - Piano para InicianteDocument1 pageBrilho Celeste - Piano para InicianteSarah RibeiroPas encore d'évaluation

- FondationDocument1 pageFondationElghoul RamziPas encore d'évaluation

- Estrutura R 17 - 21 R00Document1 pageEstrutura R 17 - 21 R00Robinson DanzaPas encore d'évaluation

- Corneta em SibDocument1 pageCorneta em SibEscola Modelo de MutáPas encore d'évaluation

- Vendavais - 4 Sax Tenor BBDocument1 pageVendavais - 4 Sax Tenor BBSidionir FalchetePas encore d'évaluation

- 00123-MECF-GEN-LAY-001 - Plan de Masse - RévgDocument1 page00123-MECF-GEN-LAY-001 - Plan de Masse - Révgbennete1969Pas encore d'évaluation

- Il - Etait - Une - Fois - Nous - Deux PianoDocument3 pagesIl - Etait - Une - Fois - Nous - Deux PianoggodetPas encore d'évaluation

- FORTIFICACION D1 - T18M404-06832-205GE-00001 - 1 (IM8-80708) Rev. 1Document1 pageFORTIFICACION D1 - T18M404-06832-205GE-00001 - 1 (IM8-80708) Rev. 1ronaldfredesPas encore d'évaluation

- Lenght of StreetsDocument1 pageLenght of StreetsGyandeep JaiswalPas encore d'évaluation

- Rencana Exhaust FanDocument2 pagesRencana Exhaust Fanabduh81Pas encore d'évaluation

- EXE DTEI GOE AKN R+1 COF 0300 - Ind A0 - Plancher Haut R+1 - CoffrageDocument1 pageEXE DTEI GOE AKN R+1 COF 0300 - Ind A0 - Plancher Haut R+1 - CoffrageRAFANOMEZANTSOA solohery mamyPas encore d'évaluation

- Berceuse SchumannDocument4 pagesBerceuse SchumannluciefcPas encore d'évaluation

- (Superpartituras Com BR) - Corisco PDFDocument1 page(Superpartituras Com BR) - Corisco PDFA Ema GemeuPas encore d'évaluation

- G+1 AR 1-MergedDocument4 pagesG+1 AR 1-MergedአንዋርጀማልPas encore d'évaluation

- G+1 MergedDocument4 pagesG+1 MergedአንዋርጀማልPas encore d'évaluation

- 140 - E - 611 - 05 RSF - Toit TerrasseDocument1 page140 - E - 611 - 05 RSF - Toit TerrasseERIOLA mendelPas encore d'évaluation

- Simple Man - TrompeteDocument2 pagesSimple Man - TrompeteRafael PanceriPas encore d'évaluation

- Gnossssiennne - 2 Avec 68-PianoDocument2 pagesGnossssiennne - 2 Avec 68-PianoJacques JibPas encore d'évaluation

- 16 V1 RDCDocument1 page16 V1 RDCAEMa CCCPas encore d'évaluation

- Planos Catastrales Perez de CuellarDocument1 pagePlanos Catastrales Perez de CuellarHuayanay coronel taylor juniorPas encore d'évaluation

- Duettissimo BB PDFDocument5 pagesDuettissimo BB PDFNikosPas encore d'évaluation

- Res Moc Arq Ex 0000 - 103 Plan R02Document1 pageRes Moc Arq Ex 0000 - 103 Plan R02fehrnandalessaPas encore d'évaluation

- PianoDocument4 pagesPianoemerson soaresPas encore d'évaluation

- Que Sorte A Nossa Violino 1Document1 pageQue Sorte A Nossa Violino 1Rafael FontinelePas encore d'évaluation

- Takie Tango - 1st Tenorhorn - 2008-05-27 2108Document1 pageTakie Tango - 1st Tenorhorn - 2008-05-27 2108Krzysiek WołowiecPas encore d'évaluation

- 05 Requiem t1Document1 page05 Requiem t1Alvaro Lazaro BruzonPas encore d'évaluation

- Staaloverzicht 3 TWDocument1 pageStaaloverzicht 3 TWCristi CapetisPas encore d'évaluation

- Alma Bogotana (Carlos Rozo Manrique) PDFDocument2 pagesAlma Bogotana (Carlos Rozo Manrique) PDFLorena MendigañoPas encore d'évaluation

- Alma Bogotana (Carlos Rozo Manrique)Document2 pagesAlma Bogotana (Carlos Rozo Manrique)Alex NocturnoPas encore d'évaluation

- $RQFI2EVDocument1 page$RQFI2EVMiluskaPas encore d'évaluation

- Adoniran Barbosa - Samba Do ArnestoDocument1 pageAdoniran Barbosa - Samba Do ArnestoJesse AlvesPas encore d'évaluation

- GroundDocument1 pageGroundMaha waelPas encore d'évaluation

- 2024 02 15 - UgDocument1 page2024 02 15 - UgSiswanto ArsitekPas encore d'évaluation

- BKHyrja 16.03.21 Ea Me Parking Dimensionim LorikArifi COLORDocument1 pageBKHyrja 16.03.21 Ea Me Parking Dimensionim LorikArifi COLORburim1979Pas encore d'évaluation

- 20R15g - 04 - 231219 - ZNS - Bloc B1 - Plan ECurent - fr-1800x610 - A1Document1 page20R15g - 04 - 231219 - ZNS - Bloc B1 - Plan ECurent - fr-1800x610 - A1mcmrr69Pas encore d'évaluation

- Szab'Lyoz'Si Terv: Vezeti Betßjel Øs Technikai KD Ptøsi Vezet Jele (A Fogalmak Meghatærozæsa A Hsz-Ben)Document1 pageSzab'Lyoz'Si Terv: Vezeti Betßjel Øs Technikai KD Ptøsi Vezet Jele (A Fogalmak Meghatærozæsa A Hsz-Ben)VivienVargaPas encore d'évaluation

- 001-Planta de Locação Das Estacas-Rv00 PDFDocument1 page001-Planta de Locação Das Estacas-Rv00 PDFEliza SouzaPas encore d'évaluation

- PHASE-01: Typical Sensor Fixing Detail For Open AreaDocument1 pagePHASE-01: Typical Sensor Fixing Detail For Open AreaSenthilmurugan KumaresanPas encore d'évaluation

- Carmen PianoDocument3 pagesCarmen PianoChristine LefebvrePas encore d'évaluation

- Vendavais - 2 Sax Soprano BBDocument1 pageVendavais - 2 Sax Soprano BBSidionir FalchetePas encore d'évaluation

- Nascer de Novo Sax Alto 3Document1 pageNascer de Novo Sax Alto 3Allyson GustavoPas encore d'évaluation

- El DanzónDocument2 pagesEl DanzónMarite MonteroPas encore d'évaluation

- Balada Nerodjenih - Harmonika 4Document2 pagesBalada Nerodjenih - Harmonika 4Predrag RadisavljevicPas encore d'évaluation

- Arq Final Astingitalo LolitiradoDocument1 pageArq Final Astingitalo LolitiradoItalo LoliPas encore d'évaluation

- Los Olores Del Amor - AltoDocument2 pagesLos Olores Del Amor - AltoDiego toroPas encore d'évaluation

- 9 Axesmotion Shield v8 SCHDocument1 page9 Axesmotion Shield v8 SCHRigoberto Hernando Olarte MejiaPas encore d'évaluation

- TES IV Oblivion ThemeDocument2 pagesTES IV Oblivion ThemeToli BovyanskiPas encore d'évaluation

- Jesus O Rei Da Glória (3 TROMPETE) PDFDocument1 pageJesus O Rei Da Glória (3 TROMPETE) PDFAlex MagalhãesPas encore d'évaluation

- Interlude de (24 Petites Pièces, No.9 Op.176)Document2 pagesInterlude de (24 Petites Pièces, No.9 Op.176)Châu Phan Trí NghĩaPas encore d'évaluation

- Chibi-Les Masques de Sauveterre - MapDocument1 pageChibi-Les Masques de Sauveterre - MapPère DelaunayPas encore d'évaluation

- Nuvens Douradas PDFDocument3 pagesNuvens Douradas PDFJuliana SilveiraPas encore d'évaluation

- Book 1Document4 pagesBook 1JanePas encore d'évaluation

- Cello Suite Bach ManuscriptDocument9 pagesCello Suite Bach ManuscriptOlivier RomanielloPas encore d'évaluation

- GuatavitaDocument1 pageGuatavitaS2 ZERO RUSHPas encore d'évaluation

- Aldnoah Zero ED2 - aLIEz PDFDocument3 pagesAldnoah Zero ED2 - aLIEz PDFKratristPas encore d'évaluation

- CL4 Calcul Numérique D'une Expression CORRECTIONDocument3 pagesCL4 Calcul Numérique D'une Expression CORRECTIONChristophe MoniéPas encore d'évaluation

- 10 - La SaetaDocument1 page10 - La SaetaMiguel Delgado LópezPas encore d'évaluation

- Amor SalvajeDocument9 pagesAmor SalvajeMartín OrtegaPas encore d'évaluation

- Itte TabsDocument2 pagesItte TabsMingeun SongPas encore d'évaluation

- Fractions Corrige Serie D Exercices 4Document3 pagesFractions Corrige Serie D Exercices 4Youssef EL GHAIDAPas encore d'évaluation

- Demarrage Etoile Triangle 2sens de RotationDocument2 pagesDemarrage Etoile Triangle 2sens de Rotationhamdoudi.malakPas encore d'évaluation

- EXAMEN S2 2e Année Intro Linguistique 2019-2020Document2 pagesEXAMEN S2 2e Année Intro Linguistique 2019-2020houfani.inel7Pas encore d'évaluation

- Les Nits No Moren Mai PDFDocument7 pagesLes Nits No Moren Mai PDFXavier BatllePas encore d'évaluation

- Cinema Paradiso Love Theme - RemovedDocument18 pagesCinema Paradiso Love Theme - RemovedAnto Lopez MartinezPas encore d'évaluation

- Tabel Harga Kritik Dari R ProductDocument2 pagesTabel Harga Kritik Dari R Productmadhy0% (1)

- PIKACHU MIKE - 3 Hojas Terminada PDFDocument3 pagesPIKACHU MIKE - 3 Hojas Terminada PDFAlejandroMoraGarcía-PagePas encore d'évaluation

- Jacek, Wacek I Pankracek (M. Jaworczakowa) - Język Polski - Opracowania - PLDocument10 pagesJacek, Wacek I Pankracek (M. Jaworczakowa) - Język Polski - Opracowania - PLEdvard KorvelisPas encore d'évaluation

- Red SwanDocument3 pagesRed SwanFranco SeminarioPas encore d'évaluation

- CORTA VENAS HUAYNO YARITA - PartesDocument22 pagesCORTA VENAS HUAYNO YARITA - Partestarzan kety manPas encore d'évaluation

- Accord Des Adjectifs Controle Devaluation Feuille Dexercices - 13039Document2 pagesAccord Des Adjectifs Controle Devaluation Feuille Dexercices - 13039joy PrincePas encore d'évaluation

- Cara Sucia - FlautaDocument2 pagesCara Sucia - FlautaAriel MicolPas encore d'évaluation

- 03 - MS Office EXCEL - ThéorieDocument3 pages03 - MS Office EXCEL - ThéorieFrère ChristianPas encore d'évaluation

- Sınıf (A) - Sınıf (A) Matematik Matematik: Cevap Anahtari Cevap AnahtariDocument1 pageSınıf (A) - Sınıf (A) Matematik Matematik: Cevap Anahtari Cevap AnahtariNedim IpekPas encore d'évaluation

- Merengue'S-Visa para Un SuenoDocument65 pagesMerengue'S-Visa para Un SuenoCrissSorianoPas encore d'évaluation

- What A Wonderful World: Vibrafono, Xilofono, GlockenspielDocument3 pagesWhat A Wonderful World: Vibrafono, Xilofono, GlockenspielTriblend ProjectPas encore d'évaluation

- Deus Do Impossível - TromboneDocument1 pageDeus Do Impossível - TromboneRonaldo TrompetistaPas encore d'évaluation

- Cahier Écriture CP CE1Document29 pagesCahier Écriture CP CE1Nebrass JmalPas encore d'évaluation

- The Perfect MatchDocument7 pagesThe Perfect MatchDavid CabreraPas encore d'évaluation

- Les PartitivesDocument2 pagesLes PartitivesArturo Ángel Castro CastroPas encore d'évaluation

- Adolescente Alto SaxDocument2 pagesAdolescente Alto SaxJose Manuel Céspedes MendezPas encore d'évaluation