Académique Documents

Professionnel Documents

Culture Documents

Offset

Transféré par

chabane_148549Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Offset

Transféré par

chabane_148549Droits d'auteur :

Formats disponibles

1.

INTITULES SYNONYMES OU APPARENTES

Conducteur de machine imprimer, typographe, hliograveur, flexographe, srigraphe.

2. DEFINITION

Le procd offset consiste imprimer partir d'une forme fixe sur rouleaux. La forme imprimante est traite avec une partie "noire" qui attirera l'encre et une zone "blanche" qui la repoussera. Les encres utilises sont grasses, visqueuses. Les solvants organiques sont plus ou moins lourds et plus ou moins abondants selon la qualit de l'impression voulue. Le conducteur de machine rgle et alimente sa machine pour raliser le tirage des documents par encrage d'une matrice spcifique appliqu sur un support. A ct du procd offset, il existe d'autres procds d'impression : o Typographie : Impression partir de caractres de plomb en relief sur un support l'aide d'encres assez paisses, grasses - utilisation de solvants assez lourds - Risque : poussires de plomb o Hliographie : Impression sur rotative grande vitesse partir d'un support o les caractres sont gravs en creux par morsure l'acide. L'encre trs fluide est dpose dans les alvoles - utilisation de solvants lgers en grande quantit Risque : brouillard d'encre o Flexographie, tampographie : Impression de qualit grossire partir d'un clich mou en relief - utilisation d'encre fluide et de solvants lgers en grande quantit o Lithographie : Impression sur un support partir d'une pierre o Srigraphie, pochoir : Impression sur des supports trs divers par passage de l'encre travers les mailles d'un cran de soie partiellement obtur par un vernis ou de la glatine bichromate. Les encres sont diverses et leur fixation se ralise soit par vaporation de solvants, soit par pntration et chauffage, soit par UV, soit par cuisson - Le nettoyage des crans ncessite l'emploi de solvants plus ou moins lourds ; le dgravage des crans (rcupration), des bases fortes et des solvants. Le conducteur de machine imprimer rgle et alimente sa machine pour raliser le tirage des documents par encrage d'une matrice spcifique appliqu sur un support.

Rotary Printing There are three different types of Rotary Printing Off set Lithography Rotogravure Flexography

Rotary Printing: The rotary press works by passing the stock between two rotating drums. One of the drums is applied with ink and this drum will have the image over its surface ( either on a plate or the drum itseld). This surface is 'etched' with the image that is going to be printed. the second drum presses the paper against the inked drum and the image is transferred.

Offset Lithography (Litho) : Etched aluminum plates wrapped around a cylinder transfer ink to an 'offset' rubber blanket roller and the to print surface. Sheet fed or Wed fed. This printing method the most commonly used for mass printing of printed items such as posters, packaging (paper) , fliers, etc. The printer can print any stock that will go through the machine but paper is the most common choice of stock. The process consists of rolling etched aluminum plates ( with the design on ) There are usually four sheets with each designated clour ( C, M, Y ,K ) on them but sometimes spot/special colours are used and many print machines cane print up to 6 different colors. The design is inked onto a roller which rolls it onto a rubber roll connecting with it and then onto paper. Sheet or web feed

Advantages are - it produces consistent high quality images. They produce cleaner images and type as the rubber blanket conforms to the texture of the stock. -It's quick and can do a high number of runs in a short amount of time -its the cheapest method of printing Disadvantages -the image quality is sometimes not as good as the rotogravure method of printing. -the cost of setting up the machine is quite high. So, smaller quantity of prints are printed using digital print instead.

Rotogravure (gravure) : Copper plates (with mirror image) tranfer ink directly to print surface, usually rolls. This method is similar to offset lithography interms of it being a rotary printing method with cylinders used. The difference is that the image/design is actually etched on a copper plate and printed straight onto paper. So the image is etched as a mirror image on these plates. This method of printing is preferably used to print onto thicker stock. It uses process colour ( CMYK) in the printing process. The plates are copper so they are more expensive but also more durable. It is commonly used for newspaper prints and other big runs.

Flexography (flexo) : A positive, mirror image rubber polymer plate. On a cylinder, transfer ink directly tp print surface. Usually roll feed. This method is also very similar to the Litho and Gravure printing method. However it uses plastic or rubber plates on the rubber cylindars instead of a metal one. The rubber plates make the printing process more flexible in terms of the material that it is printing onto. It is commonly used to packaging material especially, plastic sheets that go around the actually packaging itself. eg, water bottles, sweet packets etc. It is also a CMYK process.

Vous aimerez peut-être aussi

- TP CE1 Doc TechDocument5 pagesTP CE1 Doc Techchabane_148549Pas encore d'évaluation

- DiodesDocument4 pagesDiodeschabane_148549Pas encore d'évaluation

- F 2007004Document22 pagesF 2007004chabane_148549Pas encore d'évaluation

- 09 - Boucle de RegulationDocument2 pages09 - Boucle de Regulationchabane_148549100% (1)

- Mus NW NW CVDocument2 pagesMus NW NW CVchabane_148549Pas encore d'évaluation

- 3ADW000066R0707 DCS500 System Description F GDocument61 pages3ADW000066R0707 DCS500 System Description F Gchabane_148549Pas encore d'évaluation

- Bon de Sortie MatiereDocument2 pagesBon de Sortie Matierechabane_148549Pas encore d'évaluation

- Ch4 Alignement Des ArbresDocument16 pagesCh4 Alignement Des Arbreschabane_148549Pas encore d'évaluation

- Norme APA - Juin 2017Document30 pagesNorme APA - Juin 2017tailieu2015Pas encore d'évaluation

- Découvrez Les Meilleurs Livres Électroniques, Livres Audio, Magazines, Partitions Et Bien Plus Encore - ScribdDocument3 pagesDécouvrez Les Meilleurs Livres Électroniques, Livres Audio, Magazines, Partitions Et Bien Plus Encore - Scribdabdo19Pas encore d'évaluation

- Elektor 395 (May - 2011) FrancesDocument88 pagesElektor 395 (May - 2011) FrancesJoserGesalzenPas encore d'évaluation

- LGH 021 0115Document26 pagesLGH 021 0115nachazPas encore d'évaluation

- Le Fait Divers Sérialisé, Un Feuilleton MédiatiqueDocument16 pagesLe Fait Divers Sérialisé, Un Feuilleton MédiatiqueJônathas AraujoPas encore d'évaluation

- AN2 CatalinSimion Hist Litterature FR PDFDocument126 pagesAN2 CatalinSimion Hist Litterature FR PDFbasileusbyzantiumPas encore d'évaluation

- Références BibliographiquesDocument9 pagesRéférences BibliographiquescurvilignePas encore d'évaluation

- Tomi Ungerer La Traduction PalimpsesteDocument15 pagesTomi Ungerer La Traduction PalimpsesteJairo ManzurPas encore d'évaluation

- Catégories Du Blog: Recherche Dans Le BlogDocument5 pagesCatégories Du Blog: Recherche Dans Le BlogJoyce OheloPas encore d'évaluation

- Examen - Fin - Formation - Theorique - V2 CorrigéDocument11 pagesExamen - Fin - Formation - Theorique - V2 Corrigéyassine1900Pas encore d'évaluation

- Sage EtendueDocument10 pagesSage EtendueALLat ONEPas encore d'évaluation

- Syllabus Cours M1 2017Document40 pagesSyllabus Cours M1 2017Jacquie NsekaPas encore d'évaluation

- Tous Les Ebooks de Bernard Lugan en PDF Et EPUB KLDocument7 pagesTous Les Ebooks de Bernard Lugan en PDF Et EPUB KLMateus SoaresPas encore d'évaluation

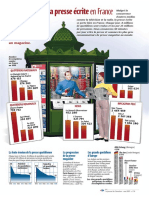

- Infographie Carrefour - La Presse Écrite en France - Mai 2001Document3 pagesInfographie Carrefour - La Presse Écrite en France - Mai 2001JustinePas encore d'évaluation

- 50 Conseils Pour Devenir ÉcrivainDocument13 pages50 Conseils Pour Devenir ÉcrivainajamotPas encore d'évaluation

- Bases en LigneDocument10 pagesBases en LigneṦAi DįPas encore d'évaluation

- Encyclopédie de La Gestion Et Du ManagementDocument315 pagesEncyclopédie de La Gestion Et Du ManagementSafa Fessi50% (2)

- Création D'entreprise Culturel, Yassmine Et Fatima100Document27 pagesCréation D'entreprise Culturel, Yassmine Et Fatima100karimabenkhaouryPas encore d'évaluation

- EXAMEN NATIONAL DU DIPLÔME DE QUALIFICATION PROFESSIONNELLE - Docx2Document8 pagesEXAMEN NATIONAL DU DIPLÔME DE QUALIFICATION PROFESSIONNELLE - Docx2waffo rostoPas encore d'évaluation

- Matériel de Base Pour Se Lancer Dans La Sérigraphie de Tee-Shirts - 1591555293904Document12 pagesMatériel de Base Pour Se Lancer Dans La Sérigraphie de Tee-Shirts - 1591555293904Juste Sassou100% (2)

- Le Roman Scout Et Le Succes de La Collection Signe de PisteDocument121 pagesLe Roman Scout Et Le Succes de La Collection Signe de PistemhdsorianoPas encore d'évaluation

- Ces Filles Sympas Qui Sabotent Leur Carriere Les 101 Pieges A Eviter 2744065609Document1 pageCes Filles Sympas Qui Sabotent Leur Carriere Les 101 Pieges A Eviter 2744065609Gibril MiaPas encore d'évaluation

- Guide Pao 08Document1 pageGuide Pao 08darkvadorPas encore d'évaluation

- Devis Magic Touch Conception Et Impression de 200 Carte de Visite PDFDocument1 pageDevis Magic Touch Conception Et Impression de 200 Carte de Visite PDFFarah SadokPas encore d'évaluation

- Philosophiascientiae 1314Document170 pagesPhilosophiascientiae 1314George AcostaPas encore d'évaluation