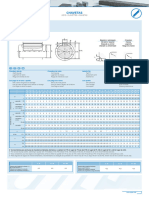

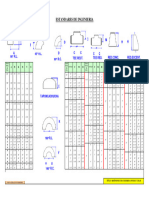

Specifying Rectangular Keyways

Specifying and dimensioning metric keys and keyways varies significantly

from the English and American systems. In the English and American system, it is the standard practice to specify the key size. In the English and

American system, the keyway in the hub is dimensioned by the width and

the depth at the side, but in the metric system the keyway is dimensioned

by the width and the depth measured from the raduis of the shaft to the

center of the keyway. One of the following methods should be used to

specify keyways:

Metric:

WxH Key

W x T2 Keyway

ISO Standard

Shaft

Diameter

D

>

So

6

8

10

12

17

22

30

38

44

50

58

65

75

85

95

110

130

150

170

200

230

260

290

330

380

440

British:

WxH12 Key

W x H Keyway

mm

Imperial Standard -Inches

Groove

Width

T1

T2*

W

2

3

4

5

6

8

10

12

14

16

18

20

22

25

28

32

36

40

45

50

56

63

70

80

90

100

2

3

4

5

6

7

8

8

9

10

11

12

14

14

16

18

20

22

25

28

32

32

36

40

45

50

1.2

1.8

2.5

3.0

3.5

4.0

5.0

5.0

5.5

6.0

7.0

7.5

9.0

9.0

10.0

11.0

12.0

13.0

15.0

17.0

20.0

20.0

22.0

25.0

28.0

31.0

1

1.4

1.8

2.3

2.8

3.3

3.3

3.3

3.8

4.3

4.4

4.9

5.4

5.4

6.4

7.4

8.4

9.4

10.4

11.4

12.4

12.4

14.4

15.4

17.4

19.5

8

10

12

17

22

30

38

44

50

58

65

75

85

95

110

130

150

170

200

230

260

290

330

380

440

500

* Groove dimensions for woodruff keys DIN 6888 in

accordance with DIN 6885 Sheet 1 (with back clearance)

Shaft

Diameter

D

>

S.

'I.

'/,

'I.

1

1 'I.

1 'I,

1 'I.

2

2'/'

3

3 'I,

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

,/,

'I.

1

1 'I.

1 'I,

1 'I.

2

2'/,

3

3 'I,

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Groove

Width

T1

T2*

'I.

0.072

0.107

0.142

0.146

0.150

0.186

0.190

0.260

0.299

0.370

0.441

0.518

0.599

0.740

0.818

0.897

0.975

1.114

1.195

1.273

1.413

1.492

1.571

1.711

1.791

1.868

2.010

0.060

0.088

0.115

0.112

0.108

0.135

0.131

0.185

0.209

0.264

0.318

0.366

0.412

0.526

0.573

0.619

0.666

0.777

0.823

0.87

0.98

1.026

1.072

1.182

1.229

1.277

1.385

W

'I.

:SIll

'I.

S/,.

3/18

'I.

'I.

7/,.

'f,

'I.

'I.

5/,.

S/,.

7/,.

'I.

'I.

'I,

'I.

'I.

1

1 'I.

1 'f,

1 'I.

2

2 'I.

2 'k

2'/.

3

3 'I.

3 'k

3 'I.

4

4 'I.

4'k

4'/.

5

'I.

'I.

1

1 'I.

1 'I.

1 'I,

1 'I.

1 'I.

2

2 'I.

2 'I.

2 'I,

2 'I.

2 'I.

3

3 'I.

3 'I.

# Tolerance each on T1 and T2 (1" -14") is - .000/+.006"

# Tolerance

each on T1 and T2 (16"

20")

is

.000/+.010"

BS 4235 Pt. 1 - 1972

Keyway Dimensions to BS 46 Part 1

In the absence of specific details, manufacturing will be

basedupon DIN 6885 T1

[Link]

?OO?/?OnA.

m~rvl:::lnrl

m~hi~

- 1958