Académique Documents

Professionnel Documents

Culture Documents

BSG1035 - Rev 1

Transféré par

Xu DuaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BSG1035 - Rev 1

Transféré par

Xu DuaDroits d'auteur :

Formats disponibles

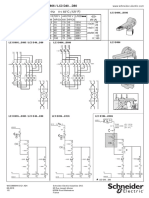

1 2 3 4 5 6

GRID LOCATION

02BSG1035 1 2/A-B 4050

02BSG1035 1 2/B-C 13'-37/16"

02BSG1035 1 2/C-D 20 2655 1350 25

13/16 8'-81/2" 4'-51/8" 1

03BSG1035 1 3/A-B

03BSG1035 1 3/B-C 603 459 31 76

03BSG1035 1 3/C-D 65 120 65 1'-113/4" 1'-61/16" 11/4 3

04BSG1035 1 4/A-B 29/16 43/4 29/16 7 8 100 100 A

C 8 D 4*20.60Ø E 75 100 75

04BSG1035 1 4/B-C

7 8 315/16 315/16

SS35 8 2- PL13 7 215/16 315/16 215/16

A 2*20.60Ø A

23/16

21/4

55

57

04BSG1035 1 4/C-D SS35 7

39/16

1/4

1/4

7

7

05BSG1035 1 5/A-B

90

23/8

60

SS35

23/8

60

39/16 39/16

711/16

195

8

90 90

05BSG1035 1 5/B-C 8

PH76

70

8

1'-2"

8

2 3/4

05BSG1035 1 8

355

5/C-D 8 PH227

20

8 250 8 8

13/16

06BSG1035 1 6/A-B PH146 8

8 8

91 /1

PH146 3 6

06BSG1035 1 6/B-C 4*20.60Ø 6

21/2

63

6 PH227 2*28.60Ø

06BSG1035 1 6/C-D

6 70

PL14 6 PL101 2 3/4

8

8 8 PH28 4*28.60Ø

PL101

3'-23/16"

970

8

3'-115/8"

02

SS3

1210

14 422

4'-111/16"

4'-111/16"

SS363

1500

1500

9/16 1'-45/8"

B B

4'-111/16"

1500

50 150 50

20

13/16

115/16 57/8 115/16 PL103 F

10*20.60Ø

8 TYP.

8

31/8 31/8

PL197 4*20.60Ø

80 80

SS302 8

8 PL254 8 PL195

TYP. 4*28.60Ø

B 8 B 5 50-200 GAP=2

10 F PL136 PH115

23/16

5 50-200

55

10

41/2

115

4*20.60Ø

13/16

21

315/16 315/16

100 100

PH202

200

39/16

77/8

3/8 23/8 31/8

10 60 80

90

6

5/16

1/4

7

8

6

23/16

55

10

3/8

PH202

152

PH194

C 250 PH194 PL136 4*20.60Ø

6

10 SS56 ( H-200X200X8X12 ) 10 E

91 /1

100 10 3 6

10 4*20.60Ø

31/4

C C

83

315/16 PH222 2*20.60Ø E-E

C-C

70

70

4

2 3/

2 3/ 70 6*28.60Ø 8 TYP.

50

4

2 3/ 8

16

1 15/

4

D AS LONG AS POSIBLE

10 8 14 2462 113 36 100 1223 60 40

9/16

4 (AVOID ACID REMAINING AFTER GALVANIZED)

PH28 10 8 8'-15/16 47/16 17/16 315/16 4'-1/8 23/8 19/16

PL150 2*20.60Ø

57

SS35 4048 2

PH76 PL152

13'-33/8" 1/16 F-F

PL465 6

PH76 PH28

90

6

PL14

90

4*20.60Ø 325 600 600 450 200 600 550 50 550 125

PH333 1'-13/16 1'-115/8" 1'-115/8" 1'-511/16" 77/8 1'-115/8" 1'-95/8" 115/16 1'-95/8" 415/16

PL157 D1 D1

PL14

PL144 6 PL465 PL152 PH76 PH227

D 6 PH146 2*28.60Ø 2*18.00Ø D

10 PL157 SS35

115/16

115/16

10

50

50

415/16

415/16

125

125

D1 - D1

15/16

33

11/16

PH333

17

PL150

415/16

415/16

125

125

115/16

115/16

16

50

50

5/8

PL144

3*18.00Ø PH28 PL13 2*28.60Ø 2*18.00Ø

A-A PL14

SS363

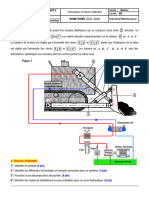

MATERIAL LIST FOR : BSG1035 15 No. Required

MARK PROFILE LENGTH No. MATERIAL AREA WEIGHT 2225 70 70 625 70 70 698 3@60 40 1

PH28 PL16X342 563 1 A572-GR.50 0.39 22.82 7'-35/8" 23/4 23/4 2'-5/8 23/4 23/4 2'-31/2" 3@23/8 19/16

PH76 PL20X294 300 1 A572-GR.50 0.20 13.85

6 3*28.60Ø

PH115 FL25X184 250 1 A572-GR.50 0.11 9.03 6 3*28.60Ø

PH146 PL20X153 234 1 A572-GR.50 0.09 5.62

6 PL254 PH194

8 6 PH115 PL195

PH194 FL14X165 310 2 A572-GR.50 0.11 5.54 8

PH194 PL254 8*20.60Ø

REVISON ALL

PH202

45/16

109

2 /8 19/16

40

PH202 PL14X250 475 1 A572-GR.50 0.26 13.05

E 8 E

PH222 PL25X323 479 1 A572-GR.50 0.23 19.10

45/16

109

PH227 PL25X103 234 1 A572-GR.50 0.07 4.73 PH115 8

3

1 /16 2 /860

200

200

77/8

77/8

PH333 PL16X56 150 1 A572-GR.50 0.02 1.06 PL197

3

40 60

PL13 PL12X161 231 2 A572-GR.50 0.07 2.94 8

PL14 PL16X347 600 1 A572-GR.50 0.43 25.05

8

9

PL101 PL12X175 200 2 A572-GR.50 0.06 2.38

PL195 SS363 PL136

PL136 PH222 PL197 8*20.60Ø

PL103 PL12X274 422 1 A572-GR.50 0.23 10.10 PH222

PL136 PL12X91 174 2 A572-GR.50 0.04 1.40

PL144 PL10X67 75 1 A572-GR.50 0.01 0.35

2675 1373

PL150 PL10X67 91 1 A572-GR.50 0.01 0.43 8'-95/16" 4'-61/16"

09.12.2023

PL152 PL10X65 67 1 A572-GR.50 0.01 0.29 1 02.12.2023 TVT NPL SD IFC

PL157 PL10X67 81 1 A572-GR.50 0.01 0.38

B-B

0 11.09.2023 TVT NPL SD IFC

PL195 FL14X95 176 1 A572-GR.50 0.04 1.55

25 87.5 25 87.5 INIT INIT INIT INIT

REV.

PL197 FL14X95 176 1 A572-GR.50 0.04 1.70 DATE STATUS REMARKS

PL254 PL12X170 174 2 A572-GR.50 0.06 2.34 1 37/16 1 37/16 NOTE: DRAWN CHECK APPR. 1 APPR. 2

A572-GR.50 1. FOR GENERAL NOTES REFER TO DRAWING: 200DWG22855-SH1 PRE = PRELIMINARY CTD = CERTIFIED DRAWING CFC = CERTIFIED FOR CONSTRUCTION ASB = AS BUILT

PL465 PL16X56 269 1 0.04 1.64 D-D

SS35 [-250X90X9X13 4005 1 SS400 3.26 138.55 2. ALL STEEL STRUCTURE SHALL BE HOT DIP GALVANIZED ACCORDING CLIENT: PROJ. NAME:

SS56 H-200X200X8X12 4034 1 SS400 4.69 201.18 TO ASTM A123 & A153, U.N.O.

F SS302 HSS141.3X6.55 2407 1 A53-GR.B 1.06 48.93 3. WELD : WELDING SYMBOLS ARE TO BE INTERPRETED ACCORDING TO AWS A2.4: 2007

- ALL WELDS SHALL BE FILLET WELD, U.N.O

Calcasieu Pass 2 F

SS363 H194*150*6*9 1291 1 SS400 1.24 38.62

SUMMARY FOR 1 ASSEMBLY 13.09 587.25 - FILLET WELD SIZE SHALL BE A MINIMUM OF 1/4"[6mm], OR EQUAL TO 0.75 TIMES TITLE OF DRAWING:

THE THICKNESS OF THINER PLATE CONNECTING THE TWO PARTS BUNDLE TRUSS GIRDER DETAIL

BOLT LIST FOR : BSG1035 - ALL WELDS SHALL BE CONTINUOUS ALONG EDGES AND ENDS OF CONNECTING PARTS

4. ALL STEEL STRUCTURE SHALL BE PROVIDE THE VENT. HOLES SCALLOP FOR HOT DIP CONFIDENTIAL: FILE: REV.

NAME OF PRODUCT STANDARD Qty BOLT TYPE

GALVANIZED PROCESS The contents of this document are confidential BSG1035

BOLT 1"DIA A325 2"1 A325N 60 Site

5. REFER TO DRAWING : 18613-STD-SH3-SPLICE WELDING STANDARD. and constitute the exclusive property of Evapco. DRAWING No: SHEET: 1

BOLT 3/4"DIA A325 2 A325N 150 Site This document and its contents may not be made BSG1035 1/1

18613-STD-SH4-VENT HOLES & SCALLOPS. public in any manner, distributed or loaned to

BOLT 3/4"DIA A325 2 A325N 60 Site 18613-STD-SH5-WELDING FOR PIPE BRACE. others or reproduced or copied either in whole SCALE: SIZE:

BOLT 3/4"DIA A325 3 A325N 30 Site or part without the prior written consent of Evapco. 1:10 A3

1 2 3 4 5 6

BUNDLE TRUSS GIRDER DETAIL BSG1035 1 1

Vous aimerez peut-être aussi

- Flanges Norma ANSI B16.5Document61 pagesFlanges Norma ANSI B16.5FITTING CHILE SPA.Pas encore d'évaluation

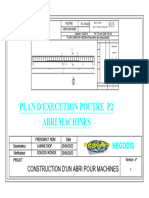

- Vue Eclatee Charpente MetalliqueDocument1 pageVue Eclatee Charpente Metalliqueabdelkader.elfkihbenahmed.etu21Pas encore d'évaluation

- OLF - OffLine FilterDocument4 pagesOLF - OffLine FilterAwliya TaqwaPas encore d'évaluation

- 3 a 50/60 Hz θ y 55°C (131°F) : LE3 D096…D506Document2 pages3 a 50/60 Hz θ y 55°C (131°F) : LE3 D096…D506Agnaldo Sousa SantosPas encore d'évaluation

- FILETAGESDocument3 pagesFILETAGESJosé VicentePas encore d'évaluation

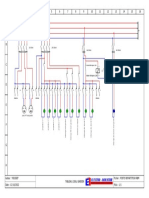

- Schema Electrique - Feux de StopDocument11 pagesSchema Electrique - Feux de StopMohamed SalamPas encore d'évaluation

- 6 Forwarder Elephant King (Plastificado)Document48 pages6 Forwarder Elephant King (Plastificado)Bruno RafaelPas encore d'évaluation

- GO Transit Brantford To BedfordDocument4 pagesGO Transit Brantford To BedfordKot IyePas encore d'évaluation

- S401-Szf2d1s-Bui Bi KoaDocument6 pagesS401-Szf2d1s-Bui Bi KoaAlexandra ApostolescuPas encore d'évaluation

- Ferraillage Poutre P2-ObjetDocument1 pageFerraillage Poutre P2-Objetlamine diopPas encore d'évaluation

- 02 Notice-Moteur-T5-Auto Filaire AutoDocument8 pages02 Notice-Moteur-T5-Auto Filaire AutoBruno GarçonPas encore d'évaluation

- Samsung Bn98-03131a S100fapc2lv0 3-46d5500r T-Con SCH PDFDocument5 pagesSamsung Bn98-03131a S100fapc2lv0 3-46d5500r T-Con SCH PDFberlusconyboy50% (2)

- Royaume Du Maroc: Marché N°: 40 /21Document10 pagesRoyaume Du Maroc: Marché N°: 40 /21Abdellatif ASSAOUDPas encore d'évaluation

- 25A 300ma 32A 30ma 10A 300ma 16A 300ma: Bobine Télérupteur 220vDocument1 page25A 300ma 32A 30ma 10A 300ma 16A 300ma: Bobine Télérupteur 220vOracle CasaPas encore d'évaluation

- Schéma de Raccordement Vidéo 2 Entrées .VA200 Sans Coax Et Platines MIHP7, MIVID1 - D032205Document2 pagesSchéma de Raccordement Vidéo 2 Entrées .VA200 Sans Coax Et Platines MIHP7, MIVID1 - D032205abdessbouafiaPas encore d'évaluation

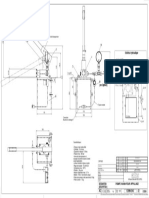

- 12599-EnS Pompe À Main Pour AffalageDocument1 page12599-EnS Pompe À Main Pour AffalageGrégory EcallePas encore d'évaluation

- PGS-JOBN190587-MEC-DRW-007-01-Plan de Montage Tuyauterie Sur Réservoir BPEDocument1 pagePGS-JOBN190587-MEC-DRW-007-01-Plan de Montage Tuyauterie Sur Réservoir BPEHoussem EttwilPas encore d'évaluation

- Spears-Sch 80 Elbow 90 (Soc) - Print5Document1 pageSpears-Sch 80 Elbow 90 (Soc) - Print5F. AhmadPas encore d'évaluation

- pdf24 Merged PDFDocument10 pagespdf24 Merged PDFAKPas encore d'évaluation

- 16X 1/4" A Travers Tout 5/16-18 Unc A Travers Tout 2 9/16" Ref. 3 7/16" Ref. 5 9/16" 90,0°Document2 pages16X 1/4" A Travers Tout 5/16-18 Unc A Travers Tout 2 9/16" Ref. 3 7/16" Ref. 5 9/16" 90,0°monk.djooPas encore d'évaluation

- C20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2: 20 20 Meza 20 20 Meza 20 20 Meza 20 20 MezaDocument1 pageC20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2: 20 20 Meza 20 20 Meza 20 20 Meza 20 20 Mezaben ammar walidPas encore d'évaluation

- Spare Parts UFO 2009-05 (R19530062)Document50 pagesSpare Parts UFO 2009-05 (R19530062)Дмитрий МайерPas encore d'évaluation

- Cooling Parts - Fan Blade: F A N B L A D EDocument2 pagesCooling Parts - Fan Blade: F A N B L A D Eكلاركات أوناشPas encore d'évaluation

- Xue980 V2.1Document2 pagesXue980 V2.1france etuvesPas encore d'évaluation

- Mini Pro Jet 7 Ion Testeur Circuits Integres Et AOPDocument3 pagesMini Pro Jet 7 Ion Testeur Circuits Integres Et AOPMohamed Ben FredjPas encore d'évaluation

- Stairway Brace 2Document1 pageStairway Brace 2Mahmoud ElboraePas encore d'évaluation

- VIGA PRINCIPALDocument1 pageVIGA PRINCIPALofitecaiPas encore d'évaluation

- HW UEF2122 2023-2024 EnoncéDocument1 pageHW UEF2122 2023-2024 EnoncéAbdelhay MaachouPas encore d'évaluation

- Luca 58 262 KsDocument13 pagesLuca 58 262 KsNdriqim BerishaPas encore d'évaluation

- Ferraillage Poutres SilianaDocument11 pagesFerraillage Poutres SilianaMamoudou SarrePas encore d'évaluation

- ferraillage escalierDocument1 pageferraillage escalierlassaad.ing1988Pas encore d'évaluation

- Shift LockDocument2 pagesShift LockISAAC SIDIBEPas encore d'évaluation

- A4 EE Et MA Mini Etau de Serrage 2Document1 pageA4 EE Et MA Mini Etau de Serrage 2Rodolphe Sounou100% (1)

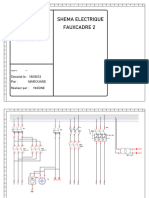

- Shema Fauxcadre 18Document8 pagesShema Fauxcadre 18alirajawi541Pas encore d'évaluation

- Exercice 1:: Mot ADocument2 pagesExercice 1:: Mot Azenazel miloudPas encore d'évaluation

- Split Star DeltaDocument5 pagesSplit Star Deltabudi sugiartoPas encore d'évaluation

- Esquema Fonte Linear JBPSDocument1 pageEsquema Fonte Linear JBPSKennedy TavaresPas encore d'évaluation

- L4Document1 pageL4Maria Lucia Cuellar BustamantePas encore d'évaluation

- Dce Lincrusta - Plan 12 Plan Plot B - R+2Document1 pageDce Lincrusta - Plan 12 Plan Plot B - R+2AEMa CCCPas encore d'évaluation

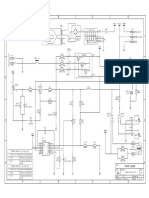

- Peugeot 207 TU3AE5 Injection ADocument3 pagesPeugeot 207 TU3AE5 Injection Aian pichardoPas encore d'évaluation

- Mise en Plan Fin ServofinDocument1 pageMise en Plan Fin Servofinمهدي الرقيقPas encore d'évaluation

- Dce Lincrusta - Plan 11 Plan Plot B - R+1Document1 pageDce Lincrusta - Plan 11 Plan Plot B - R+1AEMa CCCPas encore d'évaluation

- A25 Dessin Densemble Scie Sauteuse - Doc Eleve A Completer - Les CoupesDocument1 pageA25 Dessin Densemble Scie Sauteuse - Doc Eleve A Completer - Les CoupesStef TfhPas encore d'évaluation

- Detalles EstructuralesDocument1 pageDetalles EstructuralesSantiago Velez ColoradoPas encore d'évaluation

- S1a1959500 02Document3 pagesS1a1959500 02Romuald Eric TefongPas encore d'évaluation

- Ilovepdf MergedDocument12 pagesIlovepdf Mergedhacene sedratiPas encore d'évaluation

- Ens Filtre RegulateurDocument1 pageEns Filtre Regulateurc2m.t13Pas encore d'évaluation

- Coupe A-A Echelle 1:2 / Section A-A SCALE 1:2 A2 A2 C H: Groove SC For Seal 5,3Document1 pageCoupe A-A Echelle 1:2 / Section A-A SCALE 1:2 A2 A2 C H: Groove SC For Seal 5,3MarcoPas encore d'évaluation

- 20 - 20 - 2060 200502 20990 203 20 - 20 - 20 - 20B2 Ares 506-606 RHB SYS EL HY FR TA04 TA06 PDFDocument42 pages20 - 20 - 2060 200502 20990 203 20 - 20 - 20 - 20B2 Ares 506-606 RHB SYS EL HY FR TA04 TA06 PDFbillll43Pas encore d'évaluation

- DTDocument3 pagesDTMrnadhir MecaniquePas encore d'évaluation

- Podovi PrizemljeDocument1 pagePodovi PrizemljeAleksandraElaKraljevicPas encore d'évaluation

- 01 IndaDocument41 pages01 IndaDhiffallah Dhiya EddinePas encore d'évaluation

- BETM 1500 - Annexes - FRDocument77 pagesBETM 1500 - Annexes - FRBerat DeğirmenciPas encore d'évaluation

- Gyor Gonyu 2Document1 pageGyor Gonyu 2Tamas TatarPas encore d'évaluation

- 088 - CopieDocument2 pages088 - CopieMekki GhaziPas encore d'évaluation

- Ferraillage Poutre de FondationsDocument1 pageFerraillage Poutre de Fondationsosmanovic2020Pas encore d'évaluation

- 2 2 Poutre n01 Niveau n01 Etude de Poutre Porte D'Entre 2 2 Poutre n01 Niveau n01 Etude de Poutre Porte D'EntreDocument2 pages2 2 Poutre n01 Niveau n01 Etude de Poutre Porte D'Entre 2 2 Poutre n01 Niveau n01 Etude de Poutre Porte D'EntreBassem ChebbiPas encore d'évaluation