Académique Documents

Professionnel Documents

Culture Documents

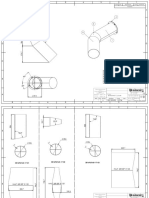

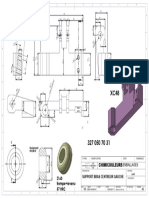

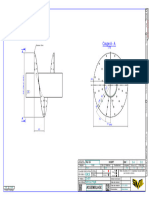

Coupe A-A Echelle 1:2 / Section A-A SCALE 1:2 A2 A2 C H: Groove SC For Seal 5,3

Transféré par

MarcoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Coupe A-A Echelle 1:2 / Section A-A SCALE 1:2 A2 A2 C H: Groove SC For Seal 5,3

Transféré par

MarcoDroits d'auteur :

Formats disponibles

Name : H-170200MEF32-202TB Rev : H Release : 2022/03/22 03:30 AM ALL DIMENSIONS ARE IN mm UNLESS OTHERWISE SPECIFIED

COUPE A-A Ø657 A2

+5

ECHELLE 1:2 Ø390 0

VOIR DETAIL 2 / C 15

/ SECTION A-A H SEE DETAIL 2 Ø335

SCALE 1:2 A2 Ø300 A

B Groove SC 1.6

3

6

Ø250

c 0.05 For

6.3

Ø720 f7

405

SEAL n 5,3

b 0.05 A

g 0.05 3.2

A MK : 004

E 4,25 0,05

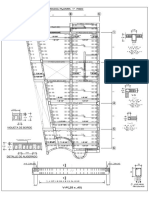

TOLERANCES GENERALES D'USINAGE POUR COTES ET POSITIONS SANS TOLERANCES INDIQUEES (par défaut en mm)

+0,3

25

52.55-0.05

-0.15

Table de tolérances selon ISO 2768 avec valeurs Alstom extrapolées pour les plus grands diamètres

30

3.2

0

VOIR DETAIL 1 / DIMENSIONS > 0.5 >6 > 30 > 120 > 315 > 1000 > 2000 > 4000 > 8000 > 12000 > 16000

(15)

NOMINALES £6 £ 30 £ 120 £ 315 £ 1000 £ 2000 £ 4000 £ 8000 £ 12000 £ 16000 £ 20000

SEE DETAIL 1 R1

LINEAIRE

6,6

CH. 2X45°

3.2 6.3 Ch0,15x0,15 Valeur ± 0.1 ± 0.2 ± 0.3 ± 0.5 ± 0.8 ± 1.2 ±2 ±3 ±4 ±5 ±6

Tolérance

G1/2" DETAIL 1 ISO 2768-m Standard Alstom

0.1

ANGLES

LONGUEUR DU COTE

DIMENSIONS > 10 > 30 > 100 > 300 > 1000 X £ 10 10 < X £ 50 50 < X £ 120 120 < X £ 400 400 < X

ECHELLE 1:1 < 10 > 3000 LE PLUS COURT

21.1

NOMINALES £ 30 £ 100 £ 300 £ 1000 £ 3000

ISO 2768-m ± 1° ± 30' ± 20' ± 10' ± 5'

/ DETAIL 1

6.3

GEOMETRIQUE

0.05 0.1 0.2 0.4 0.6 0.8 1

ANGLES CASSES ARRONDIS ET CHANFREINS ARRONDIS

ISO 2768-K

50

50 Ø330 SCALE 1:1 0.4 0.6 0.8 1 0.5 < X £ 3 3 < X £ 6 6 < X £ 30 30 < X £ 120 120 < X £ 315

149

Hauteur NOMINALE

± 0.2 ± 0.5 ±1 ±2 ±4

Rayon Ext.

0.2

ISO 2768-m Standard Alstom

SYMBOLES ISO DES TOLERANCES DE FORME ET DE POSITION

406 USINAGE 12.5

(276)

FORME

RECTITUDE CYLINDRICITE INCLINAISON SYMETRIE

3 10

25 D Groove SB 1.6 GENERAL PLANEITE PARALLELISME

BATTEMENT

SIMPLE

POSITION

DE LIGNE

BATTEMENT

A2

TOTAL

100% DPT 10

1. For SAUF INDICATIONS CONTRAIRES CIRCULARITE PERPENDICULARITE COAXIALITE

ELEMENT DE

REFERENCE

FORME

DE SURFACE

6

SEAL n7

TROUS LISSES ET TARAUDES (Standard Alstom)

E LES ARRETES VIVES SERONT ABATTUES

Pour Alternateurs : arrêtes cassées (0.3 ... 0.5) x 45° DIAMATRE NOMINAL Ø 2<Ø£5 5 < Ø £ 10 10 < Ø £ 22 22 < Ø

Ø769 THEORIQUE A2 MK : 001

LES DIAMETRES DE LAMAGE

TOLERANCE DE POSITION Ø 0.25 Ø 0.5 Ø 0.75 Ø1

SONT DES MINIMAS

THEORITICAL GENERAL MACHINING TOLERANCES FOR SIZE AND LOCATION WITHOUT SPECIFIED TOLERANCES (by default in mm)

0,05

Ch0,15x0,15 Table of tolerances based on ISO 2768 with Alstom extended figures for bigger diameters

NOMINAL > 0.5 >6 > 30 > 120 > 315 > 1000 > 2000 > 4000 > 8000 > 12000 > 16000

3.2

404 DIMENSIONS £6 £ 30 £ 120 £ 315 £ 1000 £ 2000 £ 4000 £ 8000 £ 12000 £ 16000 £ 20000

D

5,25

5 R1

LINEAR

(2 Ø230 H7( +0.046 ± 0.1 ± 0.2 ± 0.3 ± 0.5 ± 0.8 ± 1.2 ±2 ±3 ±4 ±5 ±6

ASSURER CONTINUITE DU

4.

71

0 )* Tolerance

Value ISO 2768-m Alstom Standard extension

SE 2) T SEE NOTE 8,75 +0,3

ANGLES

SHORTEST SIDE

PROFIL ENTRE PIECES 32-201 NOMINAL > 10 > 30 > 100 > 300 > 1000

25 X £ 10 10 < X £ 50 50 < X £ 120 120 < X £ 400 400 < X

0 DIMENSIONS

< 10

£ 300 £ 1000 £ 3000

> 3000 LENGTH

ET 32-202. A RACCORDER PAR E he 0.05 A £ 30 £ 100

ISO 2768-m ± 1° ± 30' ± 20' ± 10' ± 5'

NO or

MEULAGE EN ATELIER. TE ica 0.05 B H 0.05 0.1 0.2 0.4 0.6 0.8 1

GEOMETRIC

BROKEN EDGES FILLETS AND CHAMFERS FILLETS

l*

ISO 2768-K

Ø168*

(29)

ENSURE SMOOTH PROFILE SEE NOTE C DETAIL 2

0.4 0.6 0.8 1

NOMINAL Height or

0.5 < X £ 3 3 < X £ 6

± 0.2 ± 0.5

6 < X £ 30 30 < X £ 120 120 < X £ 315

±1 ±2 ±4

Ext. Radius

0.2

BETWEEN ITEM 32-201 AND 32-202 ISO 2768-m Alstom Standard extension

ACHIEVED BY GRINDING ISO SYMBOLS OF FORM AND POSITION TOLERANCES

DURING SHOP ASSEMBLY. Ø238* THEORIQUE GENERAL 12.5 STRAIGHTNESS CYLINDRICITY SLOPE SYMMETRY PROFILE

THEORITICAL B LONGUEUR COTE > 400 MACHINING FLATNESS PARALLELISM

CIRCULARITY +

POSITION TOTAL RUNOUT

SEE NOTE LE PLUS COURT

X £ 400

£ 1000 > 1000 OFF-CENTERING

ANGLES

REFERENCE SURFACE

ISO 13920-B UNLESS OTHERWISE SPECIFIED CIRCULARITY PERPENDICULARITY COAXIALITY

* : PREVOIR UNE SUR-LONGUEUR POUR PERMETTRE 407 (degrés, minutes) ± 45' ± 30' ± 20' ELEMENT PROFILE

ISO 13920-B SMOOTH AND THREADED HOLES (Alstom Standard)

± 13 ±9 ±6 SHARP EDGES SHALL BE TURNED-DOWN

L'USINAGE DU DIAMETRE Ø230 ASSEMBLE SUR LA ROUE SYMBOLE DES SOUDURES SUIVANT ISO 2553 (mm/m)

For Generators : edges chanfered (0.3 ... 0.5) x 45° NOMINAL HOLE Ø 2<Ø£5 5 < Ø £ 10 10 < Ø £ 22 22 < Ø

DIMENSIONS >2 > 30 > 120 > 400 > 1000 > 2000 > 4000 > 8000 > 12000 > 16000

* : EXPECT AN EXTRA-LENGTH FOR THE MACHINING OF NOMINALES £ 30 £ 120 £ 400 £ 1000 £ 2000 £ 4000 £ 8000 £ 12000 £ 16000 £ 20000 > 20000 SPOT FACING DIAMETERS

ARE MINIMUM VALUES LOCATION TOLERANCE Ø 0.25 Ø 0.5 Ø 0.75 Ø1

Ø230 ASSEMBLED ON THE RUNNER D1 LINEAIRE ISO

13920-B

±1 ±2 ±2 ±3 ±4 ±6 ±8 ± 10 ± 12 ± 14 ± 16

GEOMETRIQUE ISO 13920-F SURVEILLANCE DES ETUDES EXTERIEURES PAR EDF OUI NON

1 1.5 3 4.5 6 8 10 12 14 16

H Diamètre ± Ø6 Ø8 Ø 12 Ø 20 Ø 25

Service

Ingnieur/

Projeteur

Date Visa Contrôle: VSO VAO Référence de la fiche

(ANSI) VSO - SC VSO - SV

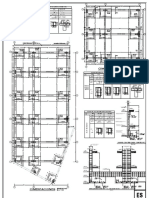

Coaxialité RAJOUT DE TOLERANCES DIMENSIONNELLES ET GEOMETRIQUES SUR LE

ASME H

Rectitude Ø 2.5 Ø4 Ø6 Ø8 Ø 10

H DIAMETRE 230 H7 POUR FACILITER LA MISE EN OEUVRE DE L'EQUILIBRAGE DE LA ROUE

21/03/22 LAFOREST ROCHEGUDE ROCHEGUDE CAE

Y14.5m Circularité

Perpendicularité

5 8 12 15 20

G MISE A JOUR LOGO + N° SPEC SOUDURE

14/12/21 LAFOREST ROCHEGUDE ROCHEGUDE -

CAE

LOGO UPDATED

45°

TOLERANCES GENERALES DE FABRICATION POUR COTES ET POSITIONS SANS TOLERANCES SPECIFIEES (par défaut en mm)

F PASSAGE CAE

02/12/19 M.JOSHUA A.ARYA ROCHEGUDE -

CAE

SHORTEST SIDE > 400 CAE STATUS

X £ 400 > 1000

LENGTH £ 1000

25 (TYP.)

E E

ANGLES

2 MODIFICATIONS 02/06/17 VILLANI GRANGEAT ROCHEGUDE BPE

ISO 13920-B

(degrees, minutes) ± 45' ± 30' ± 20'

WELDING SYMBOLS ARE ACCORDING ISO 2553

ISO 13920-B

(mm/m) ± 13 ±9 ±6

D MODIFICATIONS D 16/12/16 VILLANI GRANGEAT ROCHEGUDE BPE

Model Name : H-170200MEF32-202FTB

23°

5 MODIFICATIONS

NOMINAL

DIMENSIONS

>2

£ 30

> 30

£ 120

> 120

£ 400

> 400

£ 1000

> 1000

£ 2000

> 2000

£ 4000

> 4000

£ 8000

> 8000

£ 12000

> 12000

£ 16000

> 16000

£ 20000 > 20000 C 5 MODIFICATIONS

C 18/10/16 CHIRAG GRANGEAT ROCHEGUDE BPE

ADDED REFERENCE BALLON 407

D1

LINEAR ISO

13920-B

±1 ±2 ±2 ±3 ±4 ±6 ±8 ± 10 ± 12 ± 14 ± 16 B AJOUTEE REFERENCE 407

06/05/14 B.REY J.CALEYA T.VANRELL BPE

PASSAGE EN BPE (+1 MODI.)

GEOMETRIC ISO 13920-F

1 1.5 3 4.5 6 8 10 12 14 16 A DRAWING PASSAGE TO GFE (+1 MODI.)

14/10/13 X.ANDREU J.CALEYA S.CAÑELLAS BPE

EDITION ORIGINALE

(ANSI)

Diameter ± Ø6 Ø8 Ø 12 Ø 20 Ø 25 A0 ORIGINAL ISSUE

04/03/13 J.LOZANO J.CALEYA D.BARDINET PRE

Coaxiality

ASME Ø 2.5 Ø4 Ø6 Ø8 Ø 10 IND. ETABLI VERIFIE VISE ETAT

Straightness MODIFICATIONS DATE

REV. ESTABLISHED CHECKED APPROVED STATUS

Y14.5m Circularity

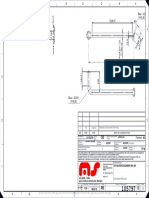

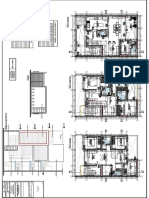

SUR Ø300, 8 TROUS Ø18 TRAVERSANTS A Perpendicularity

5 8 12 15 20

ET EQUIDISTANTS HORS AXES A GENERAL FABRICATION TOLERANCES FOR SIZE AND LOCATION WITHOUT SPECIFIED TOLERANCES (by default in mm)

ON Ø300, 8 EQUALLY SPACED THROUGH WELDING-NOTES

HOLES OF Ø18 OUT OF AXIS

WELDS SYMBOLS AS PER ISO 2553:1992

** : UNLESS OTHERWISE SPECIFIED

1 TROU G1/2" SELON INDICATION

1 HOLE G1/2" POSITION AS SHOWN A2 CLASS** 1 AS PER HSEH0400-000000001EC CHUTE DE GAVET

AND ACCEPTANCE AS PER P3WHEM6100-01

G EXECUTION DES TRAVAUX

SUR Ø300, 4 TROUS MØ16 TRAVERSANTS,

VUE EN PLAN FOR WELDS IMPACTED BY MACHINING OPERATIONS THE DRAWING SHOWS

ECHELLE 1:4 INDICATION FOR WELD REMAINING AFTER ALL MACHINING HAS BEEN DONE COMMUN AUX GROUPES

Modèle IH.*.*.8710 E

EQUIDISTANTS ET HORS AXES

POUR MANUTENTION / PLAN VIEW RECONSTITUTION OF SIMPLE SHAPES AS FLANGES,

1

ON Ø300, 4 THROUGH HOLES M16 CYLINDERS.....SHALL BE FULL PENETRATION WELDS CLASS TURBINE

SCALE 1:4

EQUALLY SPACED OUT OF AXIS ALL CHAMFERS AND TAPERING OF SITE WELD SHALL BE PREPARED ROUE

C FOR HANDLING PURPOSES VOIR PROTECTION ANTICORROSION N° IH GAVE X 100 MA 1012

IN WORKSHOP EXCEPT ON OVERLENGTH RESERVATIONS

SEE PROTECTION CORROSION PREVENTION N° POINTE DE ROUE

HEAT TREATMENT SHALL BE PERFORMED AFTER WELDING

SURFACE PROTEGEE PRELIMINAIREMENT AND BEFORE ANY MACHINING OPERATION AS PER P10HEM5400

EN ATELIER ET RECEVANT

SUR LE SITE LE

ND CONTACT AIR

- m2 PP

SYSTEME COMPLET

- m2

WELDING-NOTES

AIR CONTACT PRELIMINARY PROTECTION

GE Renewable Energy

SURFACE PROTECTION DIRECTION PRODUCTION INGENIERIE

APPLIED IN WORKSHOP, TO RECEIVE

FINAL PROTECTION SYSTEM AT SITE WELDS SYMBOLS AS PER ISO 2553:1992 DIVISION PRODUCTION ET INGENIERIE HYDRAULIQUE

CENTRE D'INGENIERIE HYDRAULIQUE

** : UNLESS OTHERWISE SPECIFIED

NOTE: CONTACT BETON SAVOIE TECHNOLAC - 73373 LE BOURGET DU LAC-CEDEX

NG CONTACT EAU - m2 B - m2

AS PER HSEH0400-000000001EC

TEL.: 04 79 60 60 60

WATER CONTACT CONCRETE CLASS** 1 G

1. TOUTES LES SOUDURES SONT EN ACIER INOX 13-4. CONTACT

AND ACCEPTANCE AS PER P3WHEM6100-01 FORMAT : A1 FOLIO : 1/1 ECHELLES : SELON INDIQUE

2. PEINTURE: PIECE EN ZONE TP. VOIR NOTE 1 m2 FOR WELDS IMPACTED BY MACHINING OPERATIONS THE DRAWING SHOWS

CI DESSOUS

NI CONTACT HUILE

- m2 TP REFER TO INDICATION FOR WELD REMAINING AFTER ALL MACHINING HAS BEEN DONE Numéro EDF : IH GAVE X 100 MTB 1323 H

OIL CONTACT NOTE BELOW TP : TECTYL 506

OR EQUIVALENT Numéro GE

RECONSTITUTION OF SIMPLE SHAPES AS FLANGES, H-1702 00 MEF 32 202 TB

NOTE: CYLINDERS.....SHALL BE FULL PENETRATION WELDS CLASS 1

© Copyright - General Electric Les surfaces non peintes (faces usinées, alésages, filetages et taraudages....) EMETTEUR: MA1 TYPE DU PLAN : PG N~ DU MARCHE/CONTRAT : 5910080082

sont à protéger pendant les opérations de préparation de surface de peinture.

Company. All rights reserved. Not to be 1. ALL WELDS ARE OF 13-4 STAINLESS STEEL WELD. ALL CHAMFERS AND TAPERING OF SITE WELD SHALL BE PREPARED

Elles reçoivent la protection temporaire préconisée après peinture.

IN WORKSHOP EXCEPT ON OVERLENGTH RESERVATIONS Ce document est la propriété de EDF Il ne peut être utilisé, reproduit, communiqué ou divulgué sans son autorisation écrite préalable

copied, distributed or reproduced 2. PAINTING: PART IN ZONE TP. Cette protection est enlevée au montage

Fichier :

The surfaces not painted (machined faces, threads...) are to be protected EDF C

without prior approval.

during the preparation and painting operations.The surfaces receive a suitable HEAT TREATMENT SHALL BE PERFORMED AFTER WELDING

temporary protection after painting, which is removed at site prior to assembly AND BEFORE ANY MACHINING OPERATION AS PER P10HEM5400

Drawing File Name ; H-170200MEF32-202FTB

R0.0625

Ø0.125

90°

0.25

Vous aimerez peut-être aussi

- Tal044 8 054Document1 pageTal044 8 054Asim JamilPas encore d'évaluation

- Tal044 8 056Document1 pageTal044 8 056Asim JamilPas encore d'évaluation

- Vis Sans FinDocument1 pageVis Sans FinWiem HammamiPas encore d'évaluation

- NR MBDocument10 pagesNR MBSpwebconnect Website developerPas encore d'évaluation

- FONDATIONDocument1 pageFONDATIONaouaniPas encore d'évaluation

- Plan de détail - Cadre n°1Document1 pagePlan de détail - Cadre n°1aminePas encore d'évaluation

- Michelin: Unsticker RollerDocument1 pageMichelin: Unsticker RollermihaiPas encore d'évaluation

- Stairway Brace 2Document1 pageStairway Brace 2Mahmoud ElboraePas encore d'évaluation

- PGS-JOBN190587-MEC-DRW-007-01-Plan de Montage Tuyauterie Sur Réservoir BPEDocument1 pagePGS-JOBN190587-MEC-DRW-007-01-Plan de Montage Tuyauterie Sur Réservoir BPEHoussem EttwilPas encore d'évaluation

- ZB16FL0160-17 CoudeDocument2 pagesZB16FL0160-17 Coudehamza.eltaief.albarakaPas encore d'évaluation

- STE 003 01 Glissiere - Simple - GRC Vue - EnsembleDocument1 pageSTE 003 01 Glissiere - Simple - GRC Vue - EnsembleMed SbitiPas encore d'évaluation

- Sulzer PDFDocument1 pageSulzer PDFPatrick DelobellePas encore d'évaluation

- 1122 PDFDocument1 page1122 PDFSejahtranta Ginting manikPas encore d'évaluation

- E-5887 Standard Serie C Phase IiiDocument8 pagesE-5887 Standard Serie C Phase Iiiait mimounePas encore d'évaluation

- Esquema Fonte Linear JBPSDocument1 pageEsquema Fonte Linear JBPSKennedy TavaresPas encore d'évaluation

- Dossier TechniqueDocument8 pagesDossier Techniquebenchikh lindaPas encore d'évaluation

- CR80 FranceseDocument4 pagesCR80 FranceseJAMESPas encore d'évaluation

- Hangar de Stockage - Baraki Wilaya D'alger-1Document3 pagesHangar de Stockage - Baraki Wilaya D'alger-1RAHNI ALIPas encore d'évaluation

- UntitledDocument84 pagesUntitledBerat DeğirmenciPas encore d'évaluation

- Epreuve:: Texte de L'Epreuve 1. Documents Remis Au CandidatDocument4 pagesEpreuve:: Texte de L'Epreuve 1. Documents Remis Au CandidatMamoudou ThiamPas encore d'évaluation

- Flange PN10 250: A3 Aucun 52 KGDocument1 pageFlange PN10 250: A3 Aucun 52 KGMahmoud ElboraePas encore d'évaluation

- Tpe CNC CFMDocument19 pagesTpe CNC CFMsassi amelPas encore d'évaluation

- Disli Cark Montaji (Grup 12)Document6 pagesDisli Cark Montaji (Grup 12)Ali DoğruPas encore d'évaluation

- 133 BC 400. G - TambourDocument2 pages133 BC 400. G - Tambourbourenane bourenanePas encore d'évaluation

- Ot CM2 Tou Exe Ar05 Ele R+31 Ho 250732Document3 pagesOt CM2 Tou Exe Ar05 Ele R+31 Ho 250732Badr ADDAKIRIPas encore d'évaluation

- BETM 1500 - Annexes - FRDocument77 pagesBETM 1500 - Annexes - FRBerat DeğirmenciPas encore d'évaluation

- Travaux Monsieur Wilfrid MIDONGO Cotation - Ext (R+1) 04Document1 pageTravaux Monsieur Wilfrid MIDONGO Cotation - Ext (R+1) 04Max-well MoubambaPas encore d'évaluation

- Plan de détail - Poutre supérieur n°1Document1 pagePlan de détail - Poutre supérieur n°1aminePas encore d'évaluation

- M2 OficialDocument1 pageM2 OficialLucas SalustianoPas encore d'évaluation

- Plan Sapatura Stereo-ModelDocument1 pagePlan Sapatura Stereo-ModelMarius SimionPas encore d'évaluation

- 3Document1 page3Carla ReyesPas encore d'évaluation

- 02Document1 page02marcos perez utreroPas encore d'évaluation

- GuillenSebastian EFDocument1 pageGuillenSebastian EFSebas GuillenPas encore d'évaluation

- Seeger Tipo ADocument5 pagesSeeger Tipo Aluis alex gomez floresPas encore d'évaluation

- Suteren - 1Document1 pageSuteren - 1Alija KolakovicPas encore d'évaluation

- Support Bras Centreur GaucheDocument1 pageSupport Bras Centreur Gauche96221858Pas encore d'évaluation

- 01 Dce Immeuble TientcheuDocument11 pages01 Dce Immeuble TientcheuIdriss TeyewoPas encore d'évaluation

- AFT - E - CTRC - SYS - 005 - A - Arm-Sas2-MatériauxDocument6 pagesAFT - E - CTRC - SYS - 005 - A - Arm-Sas2-MatériauxBest of game playPas encore d'évaluation

- P60Document1 pageP60Caleb KOIDIMAPas encore d'évaluation

- PLANO ALIGERADO 1er PISODocument1 pagePLANO ALIGERADO 1er PISOvaleriano juvenal quispe pumaPas encore d'évaluation

- VIS Bras Perseuse Radial GiovanniDocument1 pageVIS Bras Perseuse Radial GiovanniAymen HammiPas encore d'évaluation

- 1017 STR PDFDocument17 pages1017 STR PDFSINIMMAR CONS.Pas encore d'évaluation

- 4 Chemin - Cable: S.E. Tuyauterie Liaison GB-TB Portion Type 1Document1 page4 Chemin - Cable: S.E. Tuyauterie Liaison GB-TB Portion Type 1Mahmoud ElboraePas encore d'évaluation

- A.01 Folhas de TrabalhoDocument13 pagesA.01 Folhas de TrabalhoPaulo Caifás CPas encore d'évaluation

- Arq. 01Document1 pageArq. 01CONSTRUCTORA INNODICONPas encore d'évaluation

- AFT - E - CTRC - SYS - 003 - A - Arm-Sas1-MatériauxDocument6 pagesAFT - E - CTRC - SYS - 003 - A - Arm-Sas1-MatériauxBest of game playPas encore d'évaluation

- SOMDA Zienlet Jocelyn EXAMEN Robot PDFDocument22 pagesSOMDA Zienlet Jocelyn EXAMEN Robot PDFJocelyn zienlet SOMDAPas encore d'évaluation

- Es 01Document1 pageEs 01jhonatan danton pocoy ramirezPas encore d'évaluation

- GCT ST Is 400 03Document2 pagesGCT ST Is 400 03Oussama MoujahedPas encore d'évaluation

- SpireDocument1 pageSpirejosePas encore d'évaluation

- C20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2: 20 20 Meza 20 20 Meza 20 20 Meza 20 20 MezaDocument1 pageC20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2 C20.1 A C20.2: 20 20 Meza 20 20 Meza 20 20 Meza 20 20 Mezaben ammar walidPas encore d'évaluation

- TSMFM 2 Pratique Enonce 2008 PDFDocument5 pagesTSMFM 2 Pratique Enonce 2008 PDFOUZLIG MohamedPas encore d'évaluation

- TSMFM 1 Teorie Enonce-08Document10 pagesTSMFM 1 Teorie Enonce-08Rzdx 991Pas encore d'évaluation

- Dedusting Filter: Silo BT2 80mDocument1 pageDedusting Filter: Silo BT2 80mMahmoud ElboraePas encore d'évaluation

- Plan D'execution - PoteauxDocument1 pagePlan D'execution - PoteauxYao DousiPas encore d'évaluation

- AFT E CTRC SYS 006 A Arm-sas2-Plan-équipDocument6 pagesAFT E CTRC SYS 006 A Arm-sas2-Plan-équipBest of game playPas encore d'évaluation

- Tsa 500-2-330-7-D-Grs-Ab-A-D-E-11-E: PoidsDocument2 pagesTsa 500-2-330-7-D-Grs-Ab-A-D-E-11-E: PoidsSARL MASERTECHPas encore d'évaluation

- Plan N°tur-01x - Chapeau de TurbineDocument1 pagePlan N°tur-01x - Chapeau de Turbinesebastien.cherfiPas encore d'évaluation

- Regard de Vannage VatomasinaDocument1 pageRegard de Vannage VatomasinaSetra Rado RAMANGALAHYPas encore d'évaluation

- E38102247g01 - Corps Joint Huile CT Itp FRDocument3 pagesE38102247g01 - Corps Joint Huile CT Itp FRMarcoPas encore d'évaluation

- Modèle P-FSCDocument8 pagesModèle P-FSCMarcoPas encore d'évaluation

- Modèle - P-FIN 1Document2 pagesModèle - P-FIN 1MarcoPas encore d'évaluation

- E38102247g01 - Corps Joint Huile CT - KSL STR - FRDocument2 pagesE38102247g01 - Corps Joint Huile CT - KSL STR - FRMarcoPas encore d'évaluation

- Verbi Irregolari InglesiDocument4 pagesVerbi Irregolari InglesiMaria Vittoria MorettiPas encore d'évaluation

- Modèle P-ANT1Document3 pagesModèle P-ANT1MarcoPas encore d'évaluation

- Scheda Tecnica Caratteristiche Ventilatore - DTIE 568Document1 pageScheda Tecnica Caratteristiche Ventilatore - DTIE 568MarcoPas encore d'évaluation

- Manuale Pressostati PS 150 - PS 500Document3 pagesManuale Pressostati PS 150 - PS 500Marco100% (1)

- Scheda Tecnica Caratteristiche Ventilatore - DTIE 568Document1 pageScheda Tecnica Caratteristiche Ventilatore - DTIE 568MarcoPas encore d'évaluation

- Manuale Pressostati PS 150 - PS 500Document3 pagesManuale Pressostati PS 150 - PS 500Marco100% (1)

- LES CONTRAINTES Relatives Aux Acquisitions Par Effet de Levier - Hugues RacovskiDocument36 pagesLES CONTRAINTES Relatives Aux Acquisitions Par Effet de Levier - Hugues RacovskiNaoufal FouadPas encore d'évaluation

- Exercices de 1 À 10 Sans Le 7 Cours Du 2910Document3 pagesExercices de 1 À 10 Sans Le 7 Cours Du 2910Amine Chouad0% (1)

- L'habitat Semi CollectifexpoDocument62 pagesL'habitat Semi CollectifexpoWalid Cherai78% (23)

- Dessalement de L'eau de Mer - Avantages de La Distillation - Techniques de L'ingénieur PDFDocument4 pagesDessalement de L'eau de Mer - Avantages de La Distillation - Techniques de L'ingénieur PDFLabed HacenPas encore d'évaluation

- AmpouleDocument2 pagesAmpouleDayana LaurentPas encore d'évaluation

- MemoireFinal 111111Document69 pagesMemoireFinal 111111JOEL KOUADIOPas encore d'évaluation

- Revision Quickie On Future PlansDocument1 pageRevision Quickie On Future PlansahyolkPas encore d'évaluation

- Arbitrage Technique - NPS TAEKWONDODocument10 pagesArbitrage Technique - NPS TAEKWONDOClément AvilaPas encore d'évaluation

- TD1 Ing2 RoutRes 2022-2023Document4 pagesTD1 Ing2 RoutRes 2022-2023Oumayma LimemePas encore d'évaluation

- Mohamedamine Ben MeftehDocument11 pagesMohamedamine Ben Meftehamira dbichePas encore d'évaluation

- Série 2Document3 pagesSérie 2Mourad Kattass100% (1)

- Politique de RemunerationDocument6 pagesPolitique de Remunerationmed_kerroumi76Pas encore d'évaluation

- Avis Ccja Portee Abrogatoire Du Droit Ohada Et Champ de Competence Du Droit InterneDocument1 pageAvis Ccja Portee Abrogatoire Du Droit Ohada Et Champ de Competence Du Droit Internedarryl IbePas encore d'évaluation

- Carnet de Bord Peugeot 307 PDFDocument0 pageCarnet de Bord Peugeot 307 PDFAbraham NdongPas encore d'évaluation

- L'Audit Du Stock Dans Les Societes de Collecte Et Traitement Des DechetsDocument116 pagesL'Audit Du Stock Dans Les Societes de Collecte Et Traitement Des DechetsZaid SoufianePas encore d'évaluation

- GUI-6002 Plan de CoursDocument15 pagesGUI-6002 Plan de CoursnoumowankoPas encore d'évaluation

- TD 2 TresorerieDocument4 pagesTD 2 Tresoreriekouassicharles152Pas encore d'évaluation

- 0 DebutDocument7 pages0 DebutKakou Light Malan100% (1)

- SM 205-900,A75-95,FR,2004-04Document902 pagesSM 205-900,A75-95,FR,2004-04mlynch451Pas encore d'évaluation

- Micro Seance1Document27 pagesMicro Seance1Wilson CamaraPas encore d'évaluation

- Télécharger Convention de Stage Pro AlphaDocument2 pagesTélécharger Convention de Stage Pro AlphaTahiri MehdiPas encore d'évaluation

- Les Banques Et La MonétiqueDocument3 pagesLes Banques Et La Monétiquedjingar ngarhouba michaelsonPas encore d'évaluation

- Définition Et GénéralitéDocument2 pagesDéfinition Et GénéralitéwacabamaPas encore d'évaluation

- Module 5 3ème Année Veux Tu Jouer Avec MoiDocument18 pagesModule 5 3ème Année Veux Tu Jouer Avec MoiEzzeddine Belloumi100% (1)

- Copie de Dimensionnement Des ArbresDocument2 pagesCopie de Dimensionnement Des ArbresaurelotbPas encore d'évaluation

- VF Présentation Bank of Africa - 150420 VF - 0Document38 pagesVF Présentation Bank of Africa - 150420 VF - 0RtchPas encore d'évaluation

- Petit Jean-Pierre - L'Ambre Et Le Verre Histoire de L'électricitéDocument33 pagesPetit Jean-Pierre - L'Ambre Et Le Verre Histoire de L'électricitéichbin1199Pas encore d'évaluation

- Exercice Gestion Et Conrole BudgétaireDocument8 pagesExercice Gestion Et Conrole BudgétaireKhalid EDIANIPas encore d'évaluation

- Travaux Dirigé - EDocument5 pagesTravaux Dirigé - EDavidPas encore d'évaluation

- Méthode e CascadeDocument13 pagesMéthode e Cascadeبرشلونة العريقPas encore d'évaluation