Académique Documents

Professionnel Documents

Culture Documents

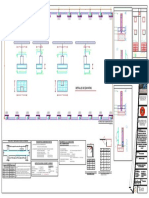

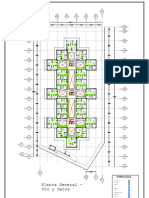

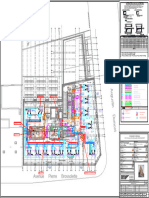

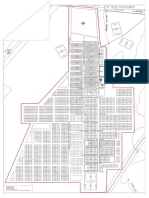

Structural Drawings For Hatchery

Transféré par

Mwesigwa DaniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Structural Drawings For Hatchery

Transféré par

Mwesigwa DaniDroits d'auteur :

Formats disponibles

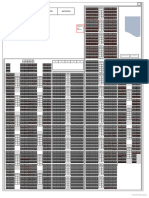

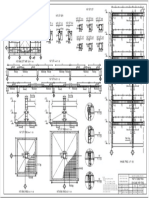

+3.

60

A B C C1 D D1 D2 E E1 F F1 F2 G H I 150

4,290 2,450 4,200 2,150 2,965 585 1,600 1,450 1,650 3,150 750 2,400 1,200 1,950

230

F1 F1 F1 F1 F1 F1 F1

C1 C1 C1 C1 C1 C1 C1

1 1

4,040

4,040

F1 F1

A252 BRC WELDED MESH C1 C1

h=150

1a A252 BRC WELDED MESH 1a

h=150 A252 BRC WELDED MESH

h=150

2,000

2,000

F1 F1 F1 F1 F1

C1 C1 C1 C1 C1

2 2

L=3650

3,150

3,150

X4 X4 X8 X8

4T12-1

3,370

F1 F1 F1 F1 F1 F1 F1

C1 C1 C1 C1 C1 C1 C1

3 3

A252 BRC WELDED MESH

h=150

2,650

2,650

37T8-125

F1 F1

C1 C1

3a A252 BRC WELDED MESH

3a

h=150

1,350

1,350

F1 F1 F1 F1 F1 F1

C1 C1 C1 C1 C1 C1

3500

4 4

2,800

2,800

F1 F1 F1

C1 C1 C1

4a 4a

A252 BRC WELDED MESH 4T12

h=150

±0.00

2,800

2,800

75

F1 F1 F1 F1

L=1850

C1 C1 C1 C1

5 5

4T12-2

1,200

1,200

F1

C1

5a F1 F1

5a

750

750

1,200

C1 C1

6 6

4,290 2,450 4,200 2,150 2,965 585 1,600 1,450 1,650 3,150 750 2,400 1,200 1,950

1680

A B C C1 D D1 D2 E E1 F F1 F2 G H I

GENERAL FOUNDATION LAY OUT

150

-1.20

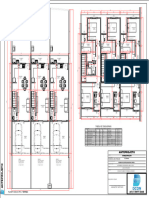

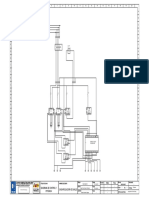

A B C C1 D D1 D2 E E1 F F1 F2 G H I A

115

4,290 2,450 4,200 2,150 2,965 585 1,600 775 675 1,650 3,150 750 2,400 1,200 1,950

180

1 RING BEAM RING BEAM RING BEAM RING BEAM RING BEAM RING BEAM 1

230

1

180

180

180

115

37T8-3-125

230 L=900 (H.Length:100)

RING BEAM

4,040

4,040

RING BEAM

RING BEAM

RING BEAM

RING BEAM

1C1

RING BEAM

(230x230)

1a RING BEAM 1a 230 mm Thick Plinth Clay Brick Wall

plastered and painted with

Bituninous paint.

2,000

2,000

150 mm mass concrete

A252 BRC welded mesh

1000 gauge Damp Proof Membrane DPC

2 2 50 mm sand blinding

Hardcore filling

75mm APC

RING BEAM

RING BEAM

RING BEAM

RING BEAM

RING BEAM

3,150

3,150

RING BEAM

Ground Beam

3 RING BEAM RING BEAM RING BEAM RING BEAM RING BEAM RING BEAM 3

230 X 690mm mass

concrete

strip foundation

2,650

2,650

RING BEAM

RING BEAM

RING BEAM

RING BEAM

SECTION

3a RING BEAM RING BEAM 3a 230mm Thick Plinth Clay Brick Wall

plastered and painted with

X4-X4

1,350

1,350

Bituninous paint.

150 mm mass concrete

4 RING BEAM RING BEAM RING BEAM RING BEAM RING BEAM RING BEAM 4

A252 BRC welded mesh

RING BEAM

RING BEAM

DPC

1000 gauge Damp Proof Membrane

50 mm sand blinding

Hardcore filling

2,800

2,800

75mm APC

RING BEAM

4a RING BEAM RING BEAM 4a

RING BEAM

RING BEAM

2,800

2,800

Ground Beam

230 X 690mm mass

concrete

strip foundation

5 RING BEAM RING BEAM RING BEAM 5

RING BEAM

RING BEAM

1,200

1,200

RING BEAM

5a RING BEAM 5a

SECTION

X5-X5

750

750

6 RING BEAM 6

4,290 2,450 4,200 2,150 2,965 585 1,600 775 675 1,650 3,150 750 2,400 1,200 1,950

F1 900 / 900 (d = 230)

L=800

A B C C1 D D1 D2 E E1 F F1 F2 G H I

335

6T12-150

RING BEAM LAY OUT

900

230

b-b

a=T12-1(B1)

335

6T12-150 L=800

b=T12-1(T1) b-b

a=T12(B1)

50

c=T8-2-150

230 50

300

335 230 335

b=T12(T1)

230

900

c=T8-150

Ground Beam a-a c

a-a c

230

230

50

50

230

TYPICAL RING BEAM

TYPICAL GROUND BEAM

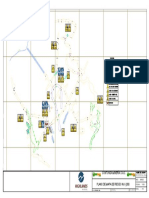

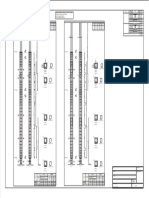

Project PROPOSED HATCHERY BLOCK TO AT LUSENKE STOCK FARM, Description GENERAL FOUNDATION LAYOUT , RING BEAM NOTES

KAYUNGA DISTRICT. LAY OUT, COLUMN REINF. DETAILS AND

FOUNDATION REINF. DETAILS 1-This drawing shall be read in conjunction with all Structural, Architectural and other relevant drawings.

2-ConcreteMixes

(a)All mass concrete to have minimum works cube strength of 15N/mm2 at 28 days with 40mm maximum aggregate size.

Client NAGRIC Client Signature Drawing Scale(s) 1:25, 1:78, 1:15, 1:20 (b)Reinforced concrete to have minimum works cube strength of 25N/mm2 at 28 days with 20mm maximum aggregate size.

STRUX 01/1 3-Reinforcement

(a)High yield bars to be ribbed bars to B.S. 4449

(b)Mild steel to be round bars to B.S.4449

Job No. JOB NO. (b)Mesh reinforcement to comply with the requirements of B.S. 4449

Date AUGUST, 2019 4-Minimum cover to all steel

Rev. No. Date Detail(s) Stamp

Stub columns=50mm, Beams=25mm, Slabs=25mm, Columns=25mm

Unless otherwise specified

5-All dimensions must be verified on site before cutting reinforcement.

Drawn By I.K

6-All dimensions must be checked on site before commencing any work.

Designed by GEEKPOINT LIMITED 7-Assumed bearing pressure is 200KN/m2 to be confirmed on site before commencement of construction.

8.All service conduits should be passed through the Solid strip regions in the slab

Reg. No. 9. Minimum prescribed laps to reinforcement

Checked by Dia 25=1200mm, Dia 20=1100mm, Dia 16=900mm, Dia 12=700mm, Dia 10=600mm

Signature

GSPublisherVersion 0.0.100.100

Vous aimerez peut-être aussi

- Final DWG SpaDocument6 pagesFinal DWG SpaSalin ShresthaPas encore d'évaluation

- p16 - Massy - Plan r+6 - 50Document1 pagep16 - Massy - Plan r+6 - 50ozelPas encore d'évaluation

- (27-5-23) PID PV Panel LocationDocument1 page(27-5-23) PID PV Panel LocationNadzri JalilPas encore d'évaluation

- IticDocument1 pageIticJose MercedesPas encore d'évaluation

- Hussain Abdul Jabaar Al Qahtani (1588) Shally 26-11-23Document7 pagesHussain Abdul Jabaar Al Qahtani (1588) Shally 26-11-23watchaemoneyPas encore d'évaluation

- Valdir - 07032022 - Est03 - Lote 03Document1 pageValdir - 07032022 - Est03 - Lote 03Rennan Neves Souza SantosPas encore d'évaluation

- Columnas 1Document1 pageColumnas 1ALADINO RAMIREZ AGUILARPas encore d'évaluation

- L01 - Sarf - Est - PF - 01 - 10Document1 pageL01 - Sarf - Est - PF - 01 - 10Samuel Vicencio JaraPas encore d'évaluation

- Detalle de Zapatas: Ø5/8"c/0.25 L 2.05 Ø5/8"c/0.25 L 1.32 Ø5/8"c/0.25 L 2.05 Ø5/8"c/0.25 L 1.32Document1 pageDetalle de Zapatas: Ø5/8"c/0.25 L 2.05 Ø5/8"c/0.25 L 1.32 Ø5/8"c/0.25 L 2.05 Ø5/8"c/0.25 L 1.32WALON OROSCO QUISPEPas encore d'évaluation

- Tableau Elements200910 VertDocument2 pagesTableau Elements200910 VertniconeusyPas encore d'évaluation

- Élévation Type A Élévation Type B Élévation Type C Élévation Type D Élévation Type E Élévation Type F Élévation Type G Élévation Type IDocument1 pageÉlévation Type A Élévation Type B Élévation Type C Élévation Type D Élévation Type E Élévation Type F Élévation Type G Élévation Type Ifc55hccwvbPas encore d'évaluation

- Capblanc 09 STR Pla 003 - B0Document1 pageCapblanc 09 STR Pla 003 - B0MohamedPas encore d'évaluation

- Grand Plan BesanconDocument2 pagesGrand Plan BesanconIon LunguPas encore d'évaluation

- Pci - Packing UvaDocument1 pagePci - Packing UvaMarcelo Rodrigues Mota BorgesPas encore d'évaluation

- BWH Auditorium Plan New 2018 Seat DescriptionsDocument1 pageBWH Auditorium Plan New 2018 Seat DescriptionsRitikaPas encore d'évaluation

- 26280-220-V11-VA30-00434 - R4 - Agua PotableDocument1 page26280-220-V11-VA30-00434 - R4 - Agua Potablecarlos becerraPas encore d'évaluation

- Señaletica H.Las Palmas II V1-Layout1Document1 pageSeñaletica H.Las Palmas II V1-Layout1Rodrigo Arturo Rivas LuceroPas encore d'évaluation

- ATA - Tekerlek Seti (Orj)Document1 pageATA - Tekerlek Seti (Orj)MEHDİPas encore d'évaluation

- R02 Plan FundatiiDocument1 pageR02 Plan FundatiiBogdan MurgilaPas encore d'évaluation

- Aligerado A2Document1 pageAligerado A2ELMERPas encore d'évaluation

- Tableau Périodique HelhaDocument2 pagesTableau Périodique Helhazozolaterreur3Pas encore d'évaluation

- Lot. t3 b008 Résidence L'etoffe Du Cailly .28Document5 pagesLot. t3 b008 Résidence L'etoffe Du Cailly .28Paul MoboulaPas encore d'évaluation

- Manual EngargoladoraDocument1 pageManual EngargoladoraMARIO RAMIREZ CABRERA0% (1)

- 01 DEBO 22300 - SS U1 01 - VA - 2023-12-21 - Deü1.KG-22300 - SS U2 01Document1 page01 DEBO 22300 - SS U1 01 - VA - 2023-12-21 - Deü1.KG-22300 - SS U2 01Suad HalilovicPas encore d'évaluation

- The Aristocats - Everybody Wants To Be A CatDocument11 pagesThe Aristocats - Everybody Wants To Be A CatMaria Paula BarrientosPas encore d'évaluation

- PL DEF ANIMAUX - 2 Et 3 05.07.22Document1 pagePL DEF ANIMAUX - 2 Et 3 05.07.22mustafa irgragnePas encore d'évaluation

- Tri MartolodDocument2 pagesTri MartolodzfeaPiano100% (1)

- Vigas Cintamento 1Document1 pageVigas Cintamento 1Wil OliveiraPas encore d'évaluation

- D11.01.02 - AO - V1 - Novembre19 - D1.23.01 LS-EPI-GEN-F - 41 - CSD-CSDGC - PLA - 00002-A - Inst ChantierDocument1 pageD11.01.02 - AO - V1 - Novembre19 - D1.23.01 LS-EPI-GEN-F - 41 - CSD-CSDGC - PLA - 00002-A - Inst ChantierMMPas encore d'évaluation

- Estrutura Djalma 9 17Document1 pageEstrutura Djalma 9 17Marcelo PereiraPas encore d'évaluation

- DOC0000010 DT SOLO 744VDocument4 pagesDOC0000010 DT SOLO 744VLaurent BresteauPas encore d'évaluation

- Jentends Arp TabDocument1 pageJentends Arp TabLEDOUXPas encore d'évaluation

- F104-0138 Hydraulique PrintDocument1 pageF104-0138 Hydraulique PrintAdotevi eric AkuePas encore d'évaluation

- Instalación Voz y DatosDocument4 pagesInstalación Voz y DatosEduardo B.Pas encore d'évaluation

- CC017 Appliquons-Nous A Ç Connai ÉtreDocument1 pageCC017 Appliquons-Nous A Ç Connai ÉtreLydia NicolePas encore d'évaluation

- Estrela (Bass Line)Document1 pageEstrela (Bass Line)Auriu IrigoitePas encore d'évaluation

- 140 - E - 611 - 05 RSF - Toit TerrasseDocument1 page140 - E - 611 - 05 RSF - Toit TerrasseERIOLA mendelPas encore d'évaluation

- El Gato Montes - Manuel Padilla V Raul Soares PDFDocument2 pagesEl Gato Montes - Manuel Padilla V Raul Soares PDFamartinbPas encore d'évaluation

- Corp C - Calea Victoriei Nr. 176: Detaliu 2 AR 417Document1 pageCorp C - Calea Victoriei Nr. 176: Detaliu 2 AR 417Mara ManolescuPas encore d'évaluation

- Mar Exe CVC PLN r+6 208 CDocument1 pageMar Exe CVC PLN r+6 208 Cnoob pubgmPas encore d'évaluation

- 18DENOVIEMBREDocument1 page18DENOVIEMBREruben jujuyPas encore d'évaluation

- 10-Plan de Revêtement Et Drainage Du Terre PleinDocument1 page10-Plan de Revêtement Et Drainage Du Terre PleinKina BouhafsPas encore d'évaluation

- Carte Université Paris-SaclayDocument2 pagesCarte Université Paris-SaclayMessadi AnesPas encore d'évaluation

- RATBA EL GOURMAT-Mode2lDocument1 pageRATBA EL GOURMAT-Mode2lratiba.elgormat125Pas encore d'évaluation

- FERIA DE JULIO, Guión COMPLETODocument20 pagesFERIA DE JULIO, Guión COMPLETOMaria De Fátima DiasPas encore d'évaluation

- Prancha 3Document1 pagePrancha 3carlos eduardoPas encore d'évaluation

- DABT2 - Nguyen Luc Hoang Hiep - Ban Ve A4Document1 pageDABT2 - Nguyen Luc Hoang Hiep - Ban Ve A4Long HoangPas encore d'évaluation

- Bartender Trumpet PDFDocument1 pageBartender Trumpet PDFAlessandro SalaroliPas encore d'évaluation

- CCC02 01 PT1 - 0Document1 pageCCC02 01 PT1 - 0Miguel Cuya CamposPas encore d'évaluation

- C MÚSICA ARRANJAMENTS Cocaleca Mambo Particellas 05 TrompesDocument1 pageC MÚSICA ARRANJAMENTS Cocaleca Mambo Particellas 05 TrompesJosep FerrerPas encore d'évaluation

- Marine c18 WiringDocument2 pagesMarine c18 Wiringzoman zomanPas encore d'évaluation

- SkrzypeczkiDocument1 pageSkrzypeczkiBid OnPas encore d'évaluation

- Avignon: DirectionDocument2 pagesAvignon: DirectionjjcalePas encore d'évaluation

- LUTEMOSDocument2 pagesLUTEMOSJacob Israel RibeiroPas encore d'évaluation

- Sonata 3 Allegro VivoDocument6 pagesSonata 3 Allegro VivotbiytcPas encore d'évaluation

- Universidad Autonoma de Baja California Campus Tijuana: Área Académica Administración Y ServiciosDocument1 pageUniversidad Autonoma de Baja California Campus Tijuana: Área Académica Administración Y ServiciosAle BarreraPas encore d'évaluation

- Estructural 1PDocument1 pageEstructural 1PRoger MedranoPas encore d'évaluation

- Lant P2C3 Ugs DR Sty 30004 02 DDocument1 pageLant P2C3 Ugs DR Sty 30004 02 DsubhashkumarmandalamcivilPas encore d'évaluation

- Gibraltar CorsDocument8 pagesGibraltar CorsSTARMANPas encore d'évaluation

- Dalle PleineDocument3 pagesDalle PleineMohamed Di StifPas encore d'évaluation

- Liste Des Corps D'étatDocument30 pagesListe Des Corps D'étatabdiasmbeusPas encore d'évaluation

- Création de La Maquette Complète Non Structurée: 3.1. Création Des Murs Et Fenêtres Du Niveau 1Document1 pageCréation de La Maquette Complète Non Structurée: 3.1. Création Des Murs Et Fenêtres Du Niveau 1Nourhane RdissiPas encore d'évaluation

- EN 772-21 (2011f (Marked)Document6 pagesEN 772-21 (2011f (Marked)amaliaconstantinPas encore d'évaluation

- INNORPI Guide Normes Et Marches PublicsDocument22 pagesINNORPI Guide Normes Et Marches PublicsAbdelPas encore d'évaluation

- Chapitre 5 - Produits CéramiqueDocument28 pagesChapitre 5 - Produits CéramiqueAbderrahman ZAMOUCHIPas encore d'évaluation

- DTP 225.1 Clotures TransformateursDocument36 pagesDTP 225.1 Clotures TransformateursJonathan ColePas encore d'évaluation

- Fiche Technique MaisonDocument1 pageFiche Technique Maisoncorentin BajardPas encore d'évaluation

- Exercice 1: A. On Considère Les Quatre Éléments Suivants: Béton Plein, Le Bois, Le Polystyrène Et L'aluminium deDocument3 pagesExercice 1: A. On Considère Les Quatre Éléments Suivants: Béton Plein, Le Bois, Le Polystyrène Et L'aluminium deMazighi SaadPas encore d'évaluation

- PCT 339817jDocument25 pagesPCT 339817jjosuePas encore d'évaluation

- 03 Bpu-3Document41 pages03 Bpu-3albert simoPas encore d'évaluation

- Por Dalle PleineDocument205 pagesPor Dalle PleineMANEL DERRIJPas encore d'évaluation

- Din 18218Document3 pagesDin 18218Amine NassimPas encore d'évaluation

- Laclassification Des TST Oct 06Document27 pagesLaclassification Des TST Oct 06Chatnoir NoirPas encore d'évaluation

- FR Pre Dalco 2020Document56 pagesFR Pre Dalco 2020johnPas encore d'évaluation

- Projet ODC Usine de Production D'agglomeré Et de PavéDocument40 pagesProjet ODC Usine de Production D'agglomeré Et de PavéWolo StarPas encore d'évaluation

- Cours Forage Dirge Le - Forage - Horizontal - Procedes Generaux de Construction PDFDocument8 pagesCours Forage Dirge Le - Forage - Horizontal - Procedes Generaux de Construction PDFabidine100% (1)

- Diop MoussaDocument1 pageDiop MoussakaderPas encore d'évaluation

- Calcul Volume de Mortier 1Document8 pagesCalcul Volume de Mortier 1HILALPas encore d'évaluation

- Abattoirs Et Postes D'abattoirDocument85 pagesAbattoirs Et Postes D'abattoirmoisePas encore d'évaluation

- BOIS - FNB - Traitement Par Haute TempératureDocument8 pagesBOIS - FNB - Traitement Par Haute TempératureproutPas encore d'évaluation

- RPRT D STG Lamiae El Boukhari Tsgo1cDocument35 pagesRPRT D STG Lamiae El Boukhari Tsgo1cismail el kettany100% (1)

- ST Genie Civil Notions EnseignementDocument13 pagesST Genie Civil Notions EnseignementEtienne kongui TounkaraPas encore d'évaluation

- NFP 31-301 TuilesDocument30 pagesNFP 31-301 Tuileschouidi0% (1)

- Catalogue CommercialDocument48 pagesCatalogue Commercialbouyahi mohamedPas encore d'évaluation

- Bases Des Operations de Construction IIIDocument14 pagesBases Des Operations de Construction IIIAHMED INFOPas encore d'évaluation

- Devis Quantitatif Et Estimatif Du Presbytere de L'eglise St-Andre Avec ObservationsDocument5 pagesDevis Quantitatif Et Estimatif Du Presbytere de L'eglise St-Andre Avec ObservationsSeydi AliwuPas encore d'évaluation

- Fiche CharpenteDocument1 pageFiche CharpenteZemali OmarPas encore d'évaluation

- EtancheiteDocument53 pagesEtancheitemerioumaPas encore d'évaluation

- Rapport PFA 1Document94 pagesRapport PFA 1Mouad HDPas encore d'évaluation