Académique Documents

Professionnel Documents

Culture Documents

Simu 15 Energ 2

Transféré par

Sulltan Sultan SultanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Simu 15 Energ 2

Transféré par

Sulltan Sultan SultanDroits d'auteur :

Formats disponibles

1

FM_07/ 2000

Utility systems

How to satisfy the energy

requirements of a process

Dr Ir Franois Marchal

LENI - DGM - EPFL

francois.marechal@epfl.ch

Laboratoire dnergtique i ndustrielle LENI -ISE-STI-EPFL

Transformation de

l'nergie

Procds

Traitements des rejets

Supports de

production

Matires

Premires

Energie

Produits

Sous-produits

Energie

Eau

Rejets et dchets

Environnement

Air

Air

Eau

Sol

Traitement

Le systme nergtique industriel

2

Laboratoire dnergtique i ndustrielle LENI -ISE-STI-EPFL

Performances dun procd

En termes montaires : Le profit

Le profit dpend :

Performances des technologies

Performances de lintgration

Agencement des technologies

Environnement Socio-conomique

Management du systme de production

opration

Laboratoire dnergtique i ndustrielle LENI -ISE-STI-EPFL

Transformation de

l'nergie

Procds

Traitements des rejets

Supports de

production

Matires

Premires

Energie

Produits

Sous-produits

Energie

Eau

Rejets et dchets

Environnement

Air

Air

Eau

Sol

Traitement

Le systme nergtique industriel

3

Laboratoire dnergtique i ndustrielle LENI -ISE-STI-EPFL

Transformation de lnergie

Combustibles

Ptrole

Gaz naturel

Dchets

Biomasse

Chaleur

Soleil

Autre industrie

Electricit

Energie utile pour le procd

Turbines

Chaudires

Compresseurs

Echangeurs

Technologies nergtiques

Racteurs

Pertes

Emissions

Resources nergtiques

Diffrentes caractristiques

Cot (march)

Emissions (lgislation)

Disponibilit

MIse en oeuvre

Technologies

Performances

Matriaux

Emissions

Investissements

Technicit

FM_07/ 2000

Heat exchanger network Investments

Identify the energy saving

heat exchanges

Utilities

Cost of Energy

Satisfy the energy requirement

Improve the MER : onion structure

Chemical processes : the onion structure

Reaction

Separation

Energy

Minimum Energy Requirements

4

FM_07/ 2000

The process utilities

Waste

Utilities

Raw

Utilities

Intermediate

Utilities

Process

Hot : fuels

Cold : Cooling Water

Thermodynamic cycles

Rankine, refrigeration,

steam networks

Raw materials

Products

and

by-products

Energy

electricity

Export

FM_07/ 2000

Engineering work method

From Goals & Constraints to Solutions ...

Analyse

Generate

Evaluate

Problem definition

Results

New problems - New goals

Goals & Constraints

Solutions

5

FM_07/ 2000

20

40

60

80

100

120

140

160

180

0 10 20 30 40 50 60 70 80 90 Q(kW)

T (C)

60

2.5

-82.5

75

-15

DH=

Hot - Cold

(KW)

Cascade

(KW)

20

80

82.5

0

75

60

0

60

62.5

-20

55

40

Utility integration

DH= 60 kW

DH= 2,5 kW

DH= -82,5 kW

DH= 75 kW

DH= -15 kW

60 kW

62,5 kW

0 kW

60 kW

0 kW

0 kW

Hot utility : above the pinch point

20 kW

Hot utility at

low T !

?

?

15 kW

Cold utility below the pinch point

Cold utility at

higher T !

Pinch point

FM_07/ 2000

Utility definition

T

H

Type of utility (e.g. : Hot stream)

Outlet conditions (T,P)

(environment, operation)

3 characteristics :

- H-T diagram (from GCC analysis)

- Cost as a function of flowrate

- Flowrate : to be determined to satisfy the

requirements at Minimum Costs.

inlet conditions (T, P)

(fuel type, combustion , operation)

6

FM_07/ 2000

Utility integration

GCC = cold stream

GCC = hot stream

Heat sink

Heat source

Self sufficient zones

Exchange process -> process

T

H Q

T

H Q

P

T

H

Q

T

H

Q

P

Counter current analogy

Hot utility -cold process

Counter current analogy

Hot process -cold utility

220

200

180

160

140

120

100

80

60

40

0 200 600 H(kW)

T(C)

D

E

F

Ambient T

Z

o

n

e

1

Z

o

n

e

2

Z

o

n

e

3

FM_07/ 2000

Multiple utilities

PINCH

T

Qhmin

(C)

Q1

T1

Q2

T2

T3

H (kW)

Identify the temperature levels

7

FM_07/ 2000

Multiple utilities

T

H

HP

LP

T3

T2

T1

F

U

M

E

S

RAD

Use of multiple utilities for different levels

-> Cost of Energy instead of Energy

FM_07/ 2000

Multiple utilities

T

H

HP

LP

T3

T2

T1

F

U

M

E

S

RAD

Minimising exergy losses

-> multiple levels : max numbers

8

Combustion : stoechiometry

Fuel : C

x

H

y

O

z

S

s

N

n

xC + xO

2

+ = xCO

2

yH +

y

4

O

2

=

y

2

H

2

O

nN + nO

2

= nNO

2

sS + sO

2

= sSO

2

x +

y

4

+ n + s

z

2

0.21

* 1 +

a

( )* (0.79N

2

) +

x +

y

4

+ n + s

z

2

0.21

*

a

( )* (0.21O

2

) + xCO

2

+

y

2

H

2

O + nNO

2

+ sSO

2

x +

y

4

+ n + s

z

2

0.21

* 1 +

a

( )* (0.21O

2

+ 0.79N

2

)

O2 (air)

Flue gases

Heat

Lower Heating Value

Useful heating value

Combustion

T

Fuel

O2 (air)

Stack temperature Tc

Environnement

Q

air

= m

air

cp

air

25

ta

dT = m

air

cp

air

(ta 25)

Q

fuel

= LHV+ m

fuel

cp

fuel

25

tf

dT = LHV + m

fuel

cp

fuel

(tf 25)

Q

pertes

= m

fumes

cp

fumes

25

Tc

dT = m

fumes

cp

fumes

(tc 25)

T

0

=25C

Adiabatic temperature of combustion

9

Pouvoir calorifique

Pouvoir calorifique suprieur

PCS (kJ/kg) ou HHV

Quantit dnergie obtenue par le refroidissement

jusqu 25C dans des conditions standard (1atm) des

fumes obtenues par la combustion dune unit de

combustiible avec lair stoechiomtrique (excs dair =

0) pris 25C et 1 atm.

Pour le pouvoir calorifique suprieur, on tient compte

de la condensation de leau

Pouvoir calorifique infrieur

PCI (kJ/kg) ou LHV

PCS-nergie de condensation de leau 25C

Temprature adiabatique de combustion

Temprature rsultant de la combustion

adiabatique (sans change de chaleur) dun

combustible

Profils de temprature pour une combustion

0

500

1000

1500

2000

2500

-10000 0 10000 20000 30000 40000 50000 60000

T (C)

Q(kJ/kg)

o2=10%

Stoechiometrique

Prchauffe de lair

Chemine

Condensation

Combustion du mthane

10

FM_07/ 2000

Useful heating value of a fuel

LHV

u

= cp

f

* T

ad

0

T

stack [ ]

: Useful heating value

cp

f

LHV

(T

ad

0

T

0

)

in

kW

(kg

fuel

C)

,T

0

= 25C

cp

f

cp

gc

*

m

gc

m

fuel

Intrisic Losses =1

LHV

u

LHV

Real losses = m

fuel

* LHV

u

Q

mer

Elments spciaux

Conversion du soufre : contrle cintique

0.95 * sS + 0.95 * sO

2

= 0.95* sSO

2

0.05 * sS + 0.05 *

3

2

sO

2

= 0.05* s* SO

3

0.05 * s* SO

3

+ 0.05* s* H

2

O= 0.05* s* H

2

SO

4

Affinits avec leau => temperature de condensation + leve

(+70C)

Problmes de corrosion

NO

x

= NO, N

2

O, NO

2

diffrentes formes contrles par la

cintique (vitesse) donc par T et conditions de mlange

Imbrls = combustible non bruls => cendres et poussires,

perte de pouvoir calorifique.

11

FM_07/ 2000

Fuels containing S

SO

3

(ppm) =- 27,712 + 4,331 S(%) +

29.863

O

2

(%)

- 3,707

S(%)

O

2

(%)

+ 54,396 LOG(O

2

(%))

avec SO

3

(ppm) la teneur en ppm de SO

3

dans les fumes;

S(%) le pourcentage massique de soufre dans le combustible;

O

2

(%) le pourcentage molaire de O

2

dans les fumes;

limite de validit: 0,5 <S(%) <5

1 <O

2

(%) <4

T

ra

= T

ch2o

+ T

c

= 273.15+ 100

4

[H

2

O] P + 49,7041 (

SO

3

(ppm)

H

2

O (%)

)

0.1173

avec [H

2

O] la fraction molaire de H2O dans les fumes;

T

ch2o

le point de rose de la vapeur d'eau dans les fumes;

T

c

l'avance la condensation;

T

ra

la temprature de rose acide des fumes (K);

P la pression dans la chemine (bar).

Temperature de rose acide

FM_07/ 2000

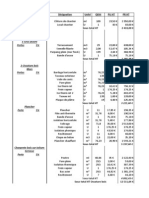

Values for different fuels

LHV

(kJ/kg)

O2

s

(kg/kg)

T

ad

s0

(K)

Tch

(K)

LHV

u

(kJ/kg)

LHV

u

Gaz naturel 39680 13,879 2270 374 38163 -3,82%

Gaz de cokerie 2780 0,696 1688 346 2685 -3,43%

Distrigaz 44945 15,693 2290 374 43225 -3,83%

Mer du Nord 47900 16,735 2292 374 46047 -3,87%

Gaz de charbon 27270 8,557 2373 376 26246 -3,75%

Essence 47798 15,003 2431 438 44665 -6,55%

Vaporizing oil 46105 15 2389 438 43023 -6,69%

Diesel 45867 14,583 2426 439 42838 -6,60%

Krozne 46924 14,826 2429 438 43850 -6,55%

Fuel lger 45316 14,454 2425 440 42303 -6,65%

Fuel lourd 44500 14,264 2423 441 41507 -6,73%

Anthracite 33220 11,53 1819 434 30256 -8,92%

Bitume 31520 10,21 1954 435 28929 -8,22%

Lignite 25450 7,23 2111 438 23488 -7,71%

12

FM_07/ 2000

CO

2

Impact

DPCU CO

2

(LHV)

CO

2

(LHV

u

)

DCO

2

CO

2

(LHV)

CO

2

(LHV

u

)

Gaz naturel -3,82% 55 57 3,97% 0,00% 0,00%

Gaz de cokerie -3,43% 186 193 3,56% 239% 238%

Distrigaz -3,83% 57 59 3,98% 3,54% 3,55%

Mer du Nord -3,87% 55 58 4,03% 1,26% 1,31%

Gaz de charbon -3,75% 58 60 3,90% 5,19% 5,11%

Essence -6,55% 65 70 7,01% 19,53% 23,02%

Vaporizing oil -6,69% 69 74 7,16% 25,77% 29,63%

Diesel -6,60% 69 74 7,07% 25,71% 29,45%

Krozne -6,55% 67 72 7,01% 22,88% 26,47%

Fuel lger -6,65% 70 75 7,12% 27,08% 30,92%

Fuel lourd -6,73% 71 76 7,21% 29,29% 33,31%

Anthracite -8,92% 100 109 9,80% 81,53% 91,69%

Bitume -8,22% 86 94 8,96% 56,84% 64,35%

Lignite -7,71% 81 88 8,35% 48,39% 54,64%

FM_07/ 2000

Utilities definitions

0 20 40 60

T(K)

Q(kW)

-20

QMER

Utility cost : C(CHF/s) = cost(CHF/kg) * flow(kg/s)

Tad

Tstack

Increasing flow

Infeasible

13

FM_07/ 2000

Utilities definitions

For the same MER !!!

0 20 40 60

T(K)

Q(kW)

-20

Q2

Q1

Energy available or excess

Different utility heat

loads

Utility 1 : C1 = cost 1 * flow 1

Utility 2 : C2 = cost 2 * flow 2

Tad

2

Tad

1

FM_07/ 2000

For the example

T stack

m

fuel

k

*cp

f

* T

ad

max T

stack

min

, T

k

*

+ T

min

/2

f ( ) ( )

]

]

]

=

Q

mer

k

m

fuel

=

max

k

Q

mer

k

cp

f

* T

ad

max T

stack

min

, T

k

*

+ T

min

/2

f ( ) ( )

]

]

]

]

]

]

]

]

cp

f

LHV

(T

ad

T

0

)

en

kW

(kg

fuel

C)

,T

0

= 25C

cp

f

cp

gc

*

m

gc

m

fuel

m

fuel

max

k

Q

mer

k

*(T

ad

T

0

)

LHV * T

ad

max T

stack

min

, T

k

*

+ T

min

/2

f ( ) ( )

]

]

]

|

1

|

`

1

14

FM_07/ 2000

Intgration de la combustion

0

500

1000

1500

2000

2500

-10000 0 10000 20000 30000 40000 50000 60000

T (C)

Q(kJ/kg)

o2=10%

Stoechiometrique

Prchauffe de lair

Chemine

Condensation

Combustion du mthane

T pincement

Effet de la prchauffe

Pour un mme dbit de combustible :

plus dnergie au-dessus du pincement

Excs dair : moins dnergie disponible

FM_07/ 2000

Combustion

Prchauffe de l'air

T prchauffe : 450C

Dbit: 94,78%

0 10000 20000 30000 40000

Excs d'air 10%

Dbit = 100,67 %

Pertes

Quantit de chaleur utile fixe

Prchauffe de l'air

0

500

1000

1500

2000

2500

3000

0 10000 20000 30000 40000

Excs d'air 10%

Pertes air stoechiomtrique

Pertes avec

excs d'air

T(K)

Q(kJ/kg)

Dbit de combustible fix

Q(kJ)

PCU

PCI

Air stoechiomtrique Combustion

stoechiomtrique

Dbit = 100 %

15

FM_07/ 2000

Cogeneration : gas turbines

0 20 40 60

T(K)

Q(MW)

-20

Energy available or excess

ToT

Gaz

Air

P1

P2

H

S

E =

GT

e

* m

fuel

* LHV

fuel

m

fuel

=

max

k

Q

mer

k

GT

th

* LHV

fuel

(T

oT

T

stack

min

)

* T

oT

max T

stack

min

, T

k

*

+ T

min

/2

f ( ) ( )

T

stack

min

FM_07/ 2000

Gas Turbine : fixed size

0 20 40 60

T(K)

Q(MW)

-20

Energy available or excess

Fuel

Air

P1

P2

H

S

E =

GT

e

* m

fuel

GT

* LHV

fuel

T

stack

min

Q

GT

= m

fuel

GT

* LHV

fuel

*

GT

th

Q = m

fuel

PC

*UHV

fuel

+ m

fuel

PC

* LHV

fuel

* (

GTth

)

T

oPC

= T

0

+

m

fuel

PC

+ m

fuel

GT

* (1

GT

e

)

m

fuelPC

(T

ad

T

0

)

+

m

fuelGT

*(1

GTe

)

(T

oT

T

0

)

T

oPC

T

oGT

16

FM_07/ 2000

Cogeneration engines

0 20 40 60

T(K)

Q(MW)

-20

Energy available or excess

Fuel

Air

V1

V2

H

S

E =

ENG

e

* m

fuel

ENG

*LHV

fuel

T

stack

min

120C

T

cg

500C

T

cg

T

c

Q

cg

=

ENG

tcg

* m

fuel

ENG

* LHV

fuel

Q

c

=

ENGt

c

* m

fuelENG

* LHV

fuel

T

c

80 90C

FM_07/ 2000

Combined heat and power

Example : Rankine cycle

Condensation

Heat source

Heat sink

Pompe

Vaporisation

Turbine

W

W Heat sink

Condens

Vapo

Heat source

T

H

17

FM_07/ 2000

Steam network and restricted matches

Process 1

Process 2

H

C

fuel

Cooling system

FM_07/ 2000

Combined heat and power

Q+W

T

W

Q

W

Q

Q+W

Q

MER

Hotu

+

W

Q

MER

Coldu

W

18

FM_07/ 2000

Combined heat and power

T

Q1

Q3-W

Q3

Q

3

W +

Q

4

=

Q

MER

Coldu

W

Q2

W

Q

1

+

W +

Q

2

=

Q

MER

Hotu

+

W

W

Q1+W

Q4

FM_07/ 2000

Combined heat and power

Q+W

T

Q

Q

MER

Hotu

+

W +

Q

Q

MER

Coldu

+

Q

W

19

FM_07/ 2000

How to integrate mechanical power production ?

Q+W

W

Q

0

Q

W

Q+W

Q+W

Q

W

T

F10+W

F9-Q

F8-Q

F7

F6

F5

F4

F3

F2

F1

F10

F9

F8

F7

F6

F5

F4-Q-W

F3-Q-W

F2-W

F1-W

F10+(Q+W)

F9

F8

F7

F6

F5+Q

F4+Q

F3+Q

F2+Q

F1+Q

Above the pinch point :

1 thermal kW

=

1mechanical kW

Below the pinch point :

1 cold utility kW

=

1 mechanical kW

Across the pinch point:

Energy penalty

0 !!!

0 !!!

FM_07/ 2000

Pincement

Recrues

Recrues On rentre du boulot

On y retourne

On rentre du boulot

Allez auTravail

Allez auTravail

Cognration

20

FM_07/ 2000

Max flowrate

Q

Choose the appropriate pressure levels

Exploit the self sufficient zones to maximise the

mechanical power production : insert rectangles

P =

T 273

100

4

E

Carnot

=

Q *(1

Tv

Tc

)

Max

Expansion

Ratio

Tc

Tv

0

5000 10000 15000 20000 25000 30000 35000

Q(kW)

300

350

400

450

500

550

600

T(K)

650

115 bar

58 bar

35 bar

7,7 bar

1,5 bar

1,0 bar

FM_07/ 2000

Estimate the mechanical power production

Above the pinch point: A is the area of the integrated

rectangles =

E = q

c

T

v

T

c

T

v

c

T

v

T

c

( )

=

A

T

v

c

T

v

T

c

( )

E = q

v

c

T

v

T

c

T

v

=

c

A

T

v

Below the pinch point A is the area of the integrated

rectangles =

21

FM_07/ 2000

Utilities : combined heat and power

0 2000 4000 6000 8000 10000

200

300

400

500

600

700

800

900

1000

1100

T(K)

Q(kW)

12000

Gas turbine ?

Fuels ?

Gas engines ?

Enriched air ?

Preheating ?

Steam ?

Organic Rankine Cycles ?

Liquid Fuel ?

Natural gas ?

PSA ?

VSA ?

Membrane ?

Cryogenic ?

Temperature ?

Pressure ?

Turbine ?

FM_08/2002 Laboratory of Industrial EnergySystems

LENI -ISE-STI-EPFL s.a.

BELSIM Together wit h

Heat pump and refrigeration

CONDENSATION

HIGH TEMPERATURE

EVAPORATION

LOW TEMPERATURE

COMPRESSOR

EXPANSION

VALVE

Cold utility (cooling water)

Process stream

T

Q

E

k

E

k

22

FM_07/ 2000

Heat pump

T

Q+W

Q

Q

MER

Hotu

(

Q +

W )

Q

MER

Coldu

Q

W

FM_07/ 2000

Heat pump

T

Q

MER

Hotu

(

W )

Q

MER

Coldu

+

W

W

Q+W

Q

Above pinch point

W

Q+W

Q

Below pinch point

23

FM_07/ 2000

Definition des niveaux de recompression

250

300

350

400

450

500

550

600

650

700

0 10000 20000 30000 40000 50000 60000

T(K)

Q(kW)

Grand composite curve

Emec

FM_07/ 2000

Integrating MVR

Q+W

W

Q

0

Q

W

Q+W

Q+W

Q

W

T

F10-W

F9+Q

F8+Q

F7

F6

F5

F4

F3

F2

F1

F10

F9

F8

F7

F6

F5

F4+Q+W

F3+Q+W

F2+W

F1+W

F10-(Q+W)

F9-(Q+W)

F7-(Q+W)

F6

F5-Q

F4-Q

F3-Q

F2-Q

F1-Q

Above the pinch point:

Wmec = hot utility

Below the pinch point :

Wmec = hot utility !!!

Accross the pinch point:

Wmec => energy savings: W+Q

0 !!!

0 !!!

24

FM_07/ 2000

Pincement

On rentre du boulot

! On y retourne ?

Au travail

On y retourne

Au travail

Ne me dit pas

quon y retourne ?

On rentre du boulot

Tout a pour a !

Ca valait

pas la peine !

Pompe chaleur

Au travail

FM_07/ 2000

Refrigeration

T

Q

c

+

Q

r

+

W =

Q

MER

Coldu

+

W

W

Q

c

Q

r

+W

Ambient T

Q

r

25

FM_07/ 2000

Refrigeration cycle integration

C/W

1

2

(a)

T

A

Tamb

B

D

E

C

F

1 2

Qr

H (b)

Single stage cooling

C/W

1

2

T

A

Tamb

B

D

E

C

F

1 2

Qr

H (d)

3 4

(c)

4

Two stages cooling

1

2

T

A

Tamb

B

D

E

C

F

1

2

H (f)

3 4

5 6

7 8

B'

D'

(e)

6

5

7

8

3

4

C/W

Three stages cooling

+ condensation

FM_07/ 2000

Combined heat and power : important rules

Producing mechanical power

Above : 1 thermal kW for 1 mechanical kW

Below : 1 kW cold utility becomes 1 mechanical kW

Use self sufficient zones

Appropriate placement : Never accross the pinch

Using mechanical power

Use if:

Hot utility at low temperature

Cold utility at high temperature

Small temperature difference

Take heat below the pinch and sent it back above

26

FM_07/ 2000

Utilities

0 2000 4000 6000 8000 10000

200

300

400

500

600

700

800

900

1000

1100

T(K)

Q(kW)

12000

Gas turbine ?

Fuels ?

Gas engines ?

Enriched air ?

Preheating ?

Steam ?

Heat pumps ?

Organic Rankine Cycles ?

Water ?

Air ?

refrigeration ?

Liquid Fuel ?

Natural gas ?

PSA ?

VSA ?

Membrane ?

Cryogenic ?

Compressor ?

Absorption ?

Refrigerant ?

Pressure ?

Compressor ?

Temperature ?

Pressure ?

Turbine ?

FM_07/ 2000

Energy balance of a temperature interval

Integrating heat producers and consumers

Sharing energy by counter current heat exchange

Excess of energy from the upper intervals

Energy for the hot streams in interval i

Energy for the cold streams in interval i

Energy to the lower intervals

T

i +1

T

i

*

*

For each utility stream

Unknown flowrate-> f

j

: Continuous variable

Use YES/NO ? -> y

j

:Interger variable 1/0

R

i+1

R

i

f

j

q

ji

f

j

q

ji

27

FM_07/ 2000

Optimalisation

Submit to :

f

min,j

y

j

f

j

f

max,j

y

j

0; R

1

=0; R

ni+1

=0

y

j

{0,1}

min

R

i

, f

j

, y

j

Cost =

n

u

j=1

C1

j

y

j

+C2

j

f

j

Minimum cost of energy requirement (MCER)

Mixed Integer Linear Programming (MILP)

Heat balance

Utility

2nd principle

ideal HEN model

Hot stream j in interval i

R

i+1

+

n

c

j=1

f

j

q

ji

=1

- R

i

=0

n

f

j

f

j -

q

ji

Cold stream j in interval i

R

i

(2)

(1)

FM_07/ 2000

Combined mechanical power production

- Export of electricity

Linear constraints

Mechanical power consumption

- Operating cost

Cost = (C1

w

y

w

+ C2

w

f

w

) + Cel Wel - Celv

Welv

w

w

f

w

w

+ Wel - Wp 0

w=1

w

w

f

w

w

+ Wel - Welv - Wp = 0

w=1

nu

w=1

nu

Process requirement

Production from the utilities(W

w

> 0 )

Electricity import

Electricity export

sell

buy

nu

Welv

(3.1)

(3.2)

(1)

28

FM_07/ 2000

Use of integer variables

1 integer variable for each flowrate

y

j

= 0 : the utility j is not used

y

j

= 1 : the utility j is used

f

min,j

y

j

f

j

f

max,j

y

j

Linear constraint

if y

j

=0 =>f

min,j

0 f

j

f

max,

j

0

=> 0 f

j

0 => f

j

=0

if y

j

=1=> f

min,j

f

j

f

max,j

j is not selected

j is selected

= y

Cost

j

C1

j

j

+C2

j

f

j

if y

j

=0=>Cost

j

= C1

j

0 +C2

j

0 =0

if y

j

=1=>Cost

j

= C1

j

+C2

j

f

j

Linear cost :

j is not selected

j is selected

FM_08/2002 Laboratory of Industrial EnergySystems

LENI -ISE-STI-EPFL s.a.

BELSIM Together wit h

MILP formulation

Subj ect to

Electricity consumption

Electricity production

Feasibility

Technology selection

Operating cost

Fixed maintenance

I nvestment

29

FM_08/2002 Laboratory of Industrial EnergySystems

LENI -ISE-STI-EPFL s.a.

BELSIM Together wit h

Targeting the optimal integration : model

MILP formulation

Gas turbine g : hot stream from T

oT

to T

stack

Fuel

Electricity

Operating cost

I nvestments

Part load efficiency

unknown

FM_08/2002 Laboratory of Industrial EnergySystems

LENI -ISE-STI-EPFL s.a.

BELSIM Together wit h

Combustion model

O2 balance

Post combustion

Post comb

Air Enriched ai r Fuels

Heat above Trad

Heat from Trad to stack

Fuels

Fuels

Enriched ai r

Enriched ai r

Preheating

Air

Air

30

FM_08/2002 Laboratory of Industrial EnergySystems

LENI -ISE-STI-EPFL s.a.

BELSIM Together wit h

Outlet temperature calculation

Stream

Add linear constraints

Compute the temperature a posteriori

FM_07/ 2000

Mechanical vapour recompression

Qb

W

Qi

Q

T

Qc+W

Qb

Qi

Qc

W

CW

Steam

An other way of changing the condenser temperature level

Combined heat and power !

31

FM_07/ 2000

MVR global solution

T

H

Q1

Q2

B

A

C

A

C

B

BB

T

H

Q1-QcA - W1

B

A

C

A

C

B

BB

T

B

A

C

A

C

B

B

B

Qb

W1

H

Qb

W2

B

A

Q2-QcA

Q1-QcA - W2

Q2-QcA

W1> W2

Integrating two distillation columns

MVR : 1 column MVR : 2 columns

FM_07/ 2000

Analyze the shape of the GCC

T

H

Q1

Q2

Qc

Qb

T

H

Q2

Qc

Qb

T

H

Hot utility at low temperature T

Cold utility at high temperature T

Small DT -> small DP

Pinch

32

FM_07/ 2000

200

300

400

500

600

700

800

900

0 2000 4000 6000 8000 10000 12000 14000

T(K)

Q(kW)

Condenser

Boiler 2

Compression 2

P = 16 bar

T= 470 K

Qmer= 6768.5 kW

6439 kW

MER

9481.33 kW

Boiler 1

Compression 1

P = 3 bar

T= 388 K

Qmer= 3422.4 kW

FM_07/ 2000

Comparing MVR and pressure changes

MVR pressure modification

Pressure increase increase or decrease

Mechanical power compressor compressor, pump

Temperature condenser boiler and condenser

Loads condenser boiler and condenser

Operation no change new set point by simulation

Integration can be self only with other

integrated columns

Technological new compressor new pressure

constraint

33

FM_07/ 2000

Evaluate the integration of a Rankine cycle

200

300

400

500

600

700

800

900

1000

1100

-1000 0 1000 2000 3000 4000 5000 6000

T(K)

Q(kW)

supplement of hot utility

HP superheating

Vaporisation

HP preheating

Rankine cycle

Other streams

MP condensation

mechanical power

production

Under cooling

FM_07/ 2000

200

300

400

500

600

700

800

900

1000

1100

0 5000 10000 15000 20000 25000 30000 35000

T(K)

Q(kW)

exothermal reactor

steam production

steam consumption

combustion

Air cooling

water cooling

Results : balanced hot and cold composite curves

Multiple pinch points

optimal use of the cheapest utility

34

FM_07/ 2000

200

300

400

500

600

700

800

900

1000

1100

0 1000 2000 3000 4000 5000 6000 7000 8000

T(K)

Q(kW)

Balanced Grand composite curve

Understand the results ?

FM_07/ 2000

RAk = Rref -

n

k

r=k

(

n

Aw

w=1

f

w

q

wr

+

n

A

i=1

Q

ir

) - Rn

k

+1

RB

kp

= 0 => R

ref

=-

n

k

r=kp

(

n

Bw

w=1

f

w

q

wr

+

n

B

i=1

Q

i r

)

Evaluate : the Integrated Composite Curves

RBk = Rref +

n

k

r=k

(

n

Bw

w=1

f wq

wr

+

n

B

i=1

Q

ir

)

Hot and cold streams

Sub-set A

Sub-set B : complement

T

Q

35

FM_07/ 2000

200

300

400

500

600

700

800

900

1000

1100

-2000 0 2000 4000 6000 8000 10000 12000 14000

T(K)

Q(kW)

Process

Utility system

ICC for utility system integration

Furnace

air cooling

water

fridge

FM_07/ 2000

200

300

400

500

600

700

800

900

1000

1100

-1000 0 1000 2000 3000 4000 5000 6000 7000

T(K)

Q(kW)

Other systems

Furnace

Excess of heat in the fumes

ICC for the integration of the fumes

36

FM_07/ 2000

200

300

400

500

600

700

800

900

1000

1100

-1000 0 1000 2000 3000 4000 5000 6000 7000 8000

T(K)

Q(kW)

"process"

"Fridge system"

ICC for refrigeration cycle integration

FM_07/ 2000

200

300

400

500

600

700

800

900

1000

1100

-1000 0 1000 2000 3000 4000 5000 6000 7000 8000

T(K)

Q(kW)

Other systems

Steam network

ICC of the steam network

Mechanical production

Energy supplement

Steam production

Steam cons.

37

FM_07/ 2000

Heat exchanger placement audit

250

300

350

400

450

500

550

600

650

700

-2000 0 2000 4000 6000 8000 10000 12000

T

(

K

)

Q(kW)

Existing Heat Exchanger

MER

Rest of the process

cf remaining problem

Penality

Systematic drawing of the ICC of the existing heat exchangers

Heat exchange through the pinch point

FM_07/ 2000

Heat exchanger placement audit

250

300

350

400

450

500

550

600

-1000 -500 0 500 1000 1500 2000 2500 3000

MER

Penalty of heat exchanger

Heat exchanger

Remaining

Overall process

T(K)

Q(kW)

Heat exchanger below the pinch point

38

FM_07/ 2000

Optimisation

T(K)

200

300

400

500

600

700

800

900

1000

1100

-1000 1000 2000 3000 4000 5000 6000 7000

Q(kW)

90b

30b

11b

6b

127 kW

0

436 kW

Courbes composes intgres du rseau dutilits

- Approche MER (thermique)

- Approche CMER (globale)

FM_07/ 2000

Conclusions

Analyse

using composite curves

Generate

using Mixed Integer Linear Programming

Evaluate

using a new graphical representation:

the Integrated Composite Curves

Better Understanding of the Integration of the

components of the system

processes - utilities - steam network - heat exchangers

Support to the engineers creativity

Method for targeting Minimum Cost of Energy Requirements

39

FM_07/ 2000

Restricted matches constraints

Why ?

Safety - product quality

Topology

Site scale and processes independence

Existing approaches

Cerda et al. (1983) - Papoulias and Grossmann (1983)

Energy target with constraints using large scale LP

Floudas - Grossmann and others

HEN superstructure together with energy target

Pinch technology

Restricted matches during the HEN synthesis

FM_07/ 2000

Restricted matches : our goals

Targeting the Minimum Cost Energy Requirement

taking into account the restricted matches

Energy penalty of the constraints ?

Cost of the energy penalty ?

Solve site scale problems

Find technological solutions to minimise the cost

penalty of the restricted matches

choice of the heat transfer fluids

Before the HEN synthesis task

Start HEN synthesis with the complete list of streams

40

FM_07/ 2000

The heat cascade a LP formulation

minimise R

n

k

+1

R

k

Heat balance of a temperature interval

R

k+1

+

i=1

n

h

f

i

q

ik

- R

k

-

j=1

n

c

f

j

q

jk

= 0 k=1,...n

k

R

k

0 k=1,...n

k

+1

(R

*

k,

T

k

) the MER heat cascade

(Grand composite curve)

FM_07/ 2000

The constraints

Heat balance of a temperature interval

Rk+1 +

i=1

nh

fi qik - Rk -

j=1

nc

fj qjk = 0 k=1,...nk (1)

Heat balance of a hot streami in a restricted match

j=1

ncai

Q

ijk + R

ik - f

i

q

ik - R

ik+1 = 0 k=1,...,k

i , i =1,...,n

h

(R1)

Heat cascade of the cold streamj

i=1

n

h

Q

ijk

f

j

q

jk

k=1,...,n

k

, j=1,...,n

c

(R2)

Overall heat cascade

i=1

n

h

R

ik Rk k=1,...,nk (R3)

Accepted Matches

Accepted Matches

R

ik

0 k=1,..., k

i

, i =1,...,n

h

;

R

ik+1

= 0 when k k

i

;

Q

ijk

0 k=1,..., n

k

, i =1,...,n

h

, j=1,...,n

c

New variables

41

FM_07/ 2000

Compute the energy penalty

Target the Minimum Cost Energy Requirement

without constraints

Optimal heat cascade : R

*

k

Fix the flowrates

Add the restricted matches constraints

Solve the problem (P1)

if penalty is acceptable goto HEN Synthesis

if not choose the heat transfer fluid

minimise R

n

k

+1

R

ik

, Q

ijk

, R

k

R

n

k

+1

- R

*

n

k

+1

is the energy penalty

FM_07/ 2000

Choose the heat transfer fluid

200

300

400

500

600

700

800

-6000 -4000 -2000 0 2000 4000 6000 8000 10000 12000

Rcold

1560 kJ

R hot

5250 kJ

Energy

penalty

6810 kJ

MER

4807 kJ

Heat sink

Heat source

Process pinch point

R

ik

= R

k

i=1

n

h

Grand composite curve

R

ik

i=1

n

h

Restricted matches cascade

Ro

k

=

42

FM_07/ 2000

Heat transfer fluid characteristics

Process : Hot streams

Process : Cold streams

- - - Heat transfer fluid hot stream

- - - Heat transfer fluid : cold stream

1) All the R

k

must be positive (definition of the MER);

2) R

n

k

+1

= R

*

n

k

+1

(no energy penalty is due to the use of the

intermediate stream);

3) Ro

k

= R

k

for all k =1,...,n

k

(the intermediate fluids solve the

restricted matches constraints)

Conditions to be satisfied by the heat transfer fluid

FM_07/ 2000

Choose the heat transfer fluid

200

300

400

500

600

700

800

900

0 8000

T( K)

Q( kJ )

MER

4807 kJ

Rhot

5250 kJ

4000 2000 4000 0 2000 4000 6000 0 2000

p

Col d s t r e a m

p

Hot s t r e a m

p

Add c ol d

s t r e a m

MER

10057 kJ

RMC Pr oc e s s GCC Ne w GCC

Rhot

5250 kJ

Above the pinch point

Heat to cold stream

Heat from hot stream

43

FM_07/ 2000

Choose the heat transfer fluid

360

380

400

420

440

460

480

500

520

540

- 2000 - 1000 0 1000 2000 3000 4000 5000 6000

T( K)

Q( kJ )

Col d s t r e a ms Hot s t r e a ms

Rc ol d

1560 kJ

Rhot

5250 kJ

27. 5 b

12 b

6 b

1. 5 b

Ene r gy pena l t y i f

1. 5 b s t e a m i s us e d

Place the heat transfer fluid between Red and Blue lines

FM_07/ 2000

Target the minimum cost of energy requirement

Add the heat transfer fluids

Hot and cold streams

Unknown flowrate

Use the MILP model

Heat cascade

Mechanical power balance

EMO models

Energy technologies

Heat transfer fluids or steam network

Restricted matches constraints

Objective function : Minimum Cost of Energy

Fuels - Electricity - CHP - Investments

SYNTHESIS

with complete list of streams

Vous aimerez peut-être aussi

- Corrige Des Exercices de Revisison Serie 1Document5 pagesCorrige Des Exercices de Revisison Serie 1JabirDargoulPas encore d'évaluation

- 1938 Rosières N 58 20120604Document32 pages1938 Rosières N 58 20120604yeshuaPas encore d'évaluation

- Les Temperatures de Referen PDFDocument2 pagesLes Temperatures de Referen PDFolivier CHOUILLOUPas encore d'évaluation

- Efficacité Énergétique Et La Thermique Des Bâtiments VFDocument80 pagesEfficacité Énergétique Et La Thermique Des Bâtiments VFHamza AbdessadekPas encore d'évaluation

- Verb List IrregularDocument25 pagesVerb List IrregularToufik DahmanePas encore d'évaluation

- Chauffe Eau Solaire ThermiqueDocument20 pagesChauffe Eau Solaire ThermiquehmissiraoufPas encore d'évaluation

- Manuel Des ProfesseursDocument80 pagesManuel Des ProfesseurssaidPas encore d'évaluation

- Bluecoif DV ElecDocument4 pagesBluecoif DV Elecjmcatalan489Pas encore d'évaluation

- Energies RenouvelablesDocument26 pagesEnergies RenouvelablesAmine DjemaaPas encore d'évaluation

- Inpl T 1992 Cachot T PDFDocument636 pagesInpl T 1992 Cachot T PDFsaoPas encore d'évaluation

- UATYQ-A-series - Product Profile - ECPFR-BE18-117 - FrenchDocument8 pagesUATYQ-A-series - Product Profile - ECPFR-BE18-117 - FrenchSidi MohamedPas encore d'évaluation

- Aire Acondicionado 30GX 082-328Document12 pagesAire Acondicionado 30GX 082-328Luis Panti EkPas encore d'évaluation

- Mémoire Fin D'études TonfackDocument113 pagesMémoire Fin D'études TonfackPatricia KengnePas encore d'évaluation

- DQEDocument3 pagesDQENicolas BayartPas encore d'évaluation

- T 5 18 EnonDocument1 pageT 5 18 Enonhalim otmanePas encore d'évaluation

- Utilisation Des Systemes Epoxy West System PDFDocument59 pagesUtilisation Des Systemes Epoxy West System PDFYvessPas encore d'évaluation

- Sécurité Incendie Des Façades - Odice-WebDocument19 pagesSécurité Incendie Des Façades - Odice-WebyeyosanchezPas encore d'évaluation

- Exercices de Révision TC - 2020Document12 pagesExercices de Révision TC - 2020BAALIPas encore d'évaluation

- Thermodynamique Appliquée Pour IngénieurDocument69 pagesThermodynamique Appliquée Pour Ingénieurإبراهيم الزايدي الكيحلPas encore d'évaluation

- Bluesteel Treuil Skydome DesenfumageDocument4 pagesBluesteel Treuil Skydome DesenfumageMoussaab MasskouriPas encore d'évaluation

- 03-2 Quelques Aspects de La Conduction ThermiqueDocument10 pages03-2 Quelques Aspects de La Conduction ThermiqueHamza El MimouniPas encore d'évaluation

- Chap6 Mec3200Document36 pagesChap6 Mec3200Nadir BettaharPas encore d'évaluation

- DELAHAYE NicolasDocument105 pagesDELAHAYE NicolasHajar AabikaPas encore d'évaluation

- PDFDocument2 pagesPDFAyoub MagroudPas encore d'évaluation

- HP 12Document47 pagesHP 12moumen Boughrara100% (1)

- GUIDE D INSTALLATION AEROCLIM EasyDocument17 pagesGUIDE D INSTALLATION AEROCLIM EasybertPas encore d'évaluation

- Chapitre 4 - La Liquéfaction, Le Transport Et Les Techniques de Stockage de GNLDocument26 pagesChapitre 4 - La Liquéfaction, Le Transport Et Les Techniques de Stockage de GNLHabib MhamedPas encore d'évaluation

- TP Metrologie Et Capteurs Vpy2Document3 pagesTP Metrologie Et Capteurs Vpy2Abdo AbdoPas encore d'évaluation

- Ventilation PDFDocument36 pagesVentilation PDFmguissePas encore d'évaluation

- Impacts Du Stress Thermique Sur Les Vaches Laitieres CnielDocument12 pagesImpacts Du Stress Thermique Sur Les Vaches Laitieres Cniellore lorePas encore d'évaluation