Académique Documents

Professionnel Documents

Culture Documents

Specification For Mild Steel Tubes and Tubulars Conforming To Is - 1239 (Part I) : 1990

Specification For Mild Steel Tubes and Tubulars Conforming To Is - 1239 (Part I) : 1990

Transféré par

bhichaiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Specification For Mild Steel Tubes and Tubulars Conforming To Is - 1239 (Part I) : 1990

Specification For Mild Steel Tubes and Tubulars Conforming To Is - 1239 (Part I) : 1990

Transféré par

bhichaiDroits d'auteur :

Formats disponibles

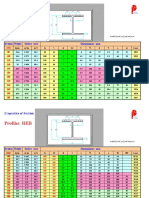

SPECIFICATION FOR MILD STEEL TUBES AND

TUBULARS CONFORMING TO IS - 1239 (PART I ) : 1990

Nominal

Bore (NB)

mm

Inches

15

(1/2)

20

Class Outside Diameter Thickness

MAX

MIN

mm

mm

mm

L

M

H

21.40

21.80

21.80

21.00

21.00

21.00

2.00

2.60

3.20

(3/4)

L

M

H

26.90

27.30

27.30

26.40

26.50

26.50

25

(1)

L

M

H

33.80

34.20

34.20

32

(11/4)

L

M

H

40

(11/2)

50

SWG

Mass of Black

Tube

P/E

S/S

Calculated Wt.

of Galvanised

Tube

P/E

S/S

Black Plain End

Kg/m

Kg/m

Kg/m

Kg/m

14

12

10

0.947

1.21

1.44

0.956

1.22

1.45

1056

826

694

3465

2710

2277

176

138

116

0.999

1.264

1.494

1.008

1.274

1.504

992

785

665

3255

2575

2182

165

131

111

2.30

2.60

3.20

13

12

10

1.38

1.56

1.87

1.39

1.57

1.88

725

641

535

2379

2103

1755

121

107

89

1.441

1.622

1.923

1.451

1.632

1.933

689

613

517

2260

2011

1696

115

102

86

33.20

33.30

33.30

2.60

3.20

4.00

12

10

8

1.98

2.41

2.93

2.00

2.43

2.95

505

415

341

1657

1362

1119

84

69

57

2.062

2.495

3.028

2.082

2.515

3.048

480

398

328

1575

1306

1076

80

66

55

42.50

42.90

42.90

41.90

42.00

42.00

2.60

3.20

4.00

12

10

8

2.54

3.10

3.79

2.57

3.13

3.82

394

323

264

1293

1060

866

66

54

44

2.641

3.207

3.887

2.671

3.237

3.917

374

309

255

1227

1014

837

62

52

43

L

M

H

48.40

48.80

48.80

47.80

47.90

47.90

2.90

3.20

4.00

11

10

8

3.23

3.56

4.37

3.27

3.60

4.41

310

281

229

1017

922

751

52

47

38

3.358

3.681

4.485

3.398

3.721

4.525

294

269

221

965

883

725

49

45

37

(2)

L

M

H

60.20

60.80

60.80

59.60

59.70

59.70

2.90

3.60

4.50

11

9

7

4.08

5.03

6.19

4.15

5.10

6.26

245

199

162

804

653

531

41

33

27

4.225

5.166

6.349

4.295

5.236

6.419

233

191

156

764

627

512

39

32

26

65

(21/2)

L

M

H

76.00

76.60

76.60

75.20

75.30

75.30

3.20

3.60

4.50

10

9

7

5.71

6.42

7.93

5.83

6.54

8.05

175

156

126

574

512

413

29

26

21

5.898

6.621

8.095

6.018

6.741

8.215

166

144

122

545

486

400

28

25

20

80

(3)

L

M

H

88.70

89.50

89.50

87.90

88.00

88.00

3.20

4.00

4.80

10

8

6

6.72

8.36

9.90

6.89

8.53

10.40

149

120

101

489

394

331

25

20

17

6.925 7.122

8.586 8.756

10.109 10.609

140

114

97

459

374

318

23

19

16

100

(4)

L

M

H

113.90 113.00

115.00 113.10

115.00 113.10

3.60

4.50

5.40

9

7

5

9.75

12.20

14.50

10.00

12.50

14.80

103

82

69

338

269

226

17

14

12

10.276 10.586

12.758 13.258

15.252 15.552

94

75

64

308

246

210

16

13

11

125

(5)

M

H

140.80 138.50

140.80 138.50

4.80

5.40

6

5

15.90

17.90

16.40

18.40

63

56

207

184

11

9

16.649 17.149

18.619 19.119

58

52

190

171

10

9

150

(6)

M

H

166.50 163.90

166.50 163.90

4.80

5.40

6

5

18.90

21.30

19.50

21.90

53

47

174

154

9

8

19.700 20.300

22.322 22.922

49

44

161

144

8

7

TOLERANCE : Thickness : Light : + Unlimited

- 8%

Mtrs/Ton Ft/Ton Pcs/Bdle

Galvanised S & S

Medium / Heavy : + Unlimited

- 10%

Mtrs/Ton

Ft/Ton Pcs/Bdle

Weight : Light : 5%, Medium / Heavy : 7.5%

(For quantities per load of 10 Tonnes Minimum)

HYDRO TEST PRESSURE : 5 MPa

IS : 1239 (Part I) - 1979 Mild Steel Tubes

MAXIMUM PERMISSIBLE PRESSURE AND TEMPERATURE

FOR TUBES FOR CONVEYING STEAM

The maximum permissible pressure and temperature for tubes with screwed and socketed joints shall be as follows.

MAXIMUM PERMISSIBLE PRESSURE AND TEMPERATURE FOR TUBES

WITH STEEL COUPLINGS OR SCREWED AND SOCKETED JOINTS

Nominal Bore

mm

Up to and including 25 mm

Over 25 mm upto and including 40 mm

Over 40 mm upto and including 80 mm

Over 80 mm upto and including 100 mm

Over 100 mm up to and including 125

Over 125 mm up to and including 150 mm

Maximum Permissible

Pressure

N/mm2

1.20

1.03

0.86

0.69

0.83

0.69

0.50

Kg/cm2

12.24

10.50

8.77

7.04

8.47

7.04

5.10

Maximum Permissible

Temperature

0

C

260

260

260

260

177

171

160

Vous aimerez peut-être aussi

- AlgoDocument98 pagesAlgoBadr ZinePas encore d'évaluation

- Ch6 Pal FplaDocument33 pagesCh6 Pal Fplahassna ait aliPas encore d'évaluation

- Le Compte RenduDocument21 pagesLe Compte Rendunajat derfoufiPas encore d'évaluation

- CREDOCDocument22 pagesCREDOCZouhir Nmili50% (2)

- Économie de LaDocument76 pagesÉconomie de LaTàrik BT50% (2)

- Technologie Production FroidDocument34 pagesTechnologie Production FroidHichem Maalaoui100% (1)

- Principes & Enjeux Management Integre QSEDocument80 pagesPrincipes & Enjeux Management Integre QSEMohamed Hichem GuesmiPas encore d'évaluation

- Au Lean: QCD-ConsultingDocument111 pagesAu Lean: QCD-ConsultingFousseyni TRAOREPas encore d'évaluation

- Les Defauts TriphasesDocument12 pagesLes Defauts TriphasesBillel Soti100% (1)

- PFE Version FinalDocument90 pagesPFE Version FinalSami CharafPas encore d'évaluation

- Rapport de StageDocument59 pagesRapport de StageFarid Abdul Ogbe50% (2)

- Manuel D'atelier Yamaha FJR1300AS (V)Document158 pagesManuel D'atelier Yamaha FJR1300AS (V)jddkasPas encore d'évaluation

- JIS B2220 - Flanges 5K 10K PDFDocument1 pageJIS B2220 - Flanges 5K 10K PDFLiam Choon SengPas encore d'évaluation

- Beams CalculationDocument6 pagesBeams Calculationsaid50% (2)

- 03302005A1 Torque PernosDocument8 pages03302005A1 Torque Pernosdaviii100% (1)

- Brides Plates A Souder PN 10Document1 pageBrides Plates A Souder PN 10www.2micPas encore d'évaluation

- Brides Plates A Souder PN 10Document1 pageBrides Plates A Souder PN 10www.2micPas encore d'évaluation

- Brides Plates A Souder PN 10Document1 pageBrides Plates A Souder PN 10Mohamed ChahidPas encore d'évaluation

- Catalogo Donghua Cadenas VariasDocument46 pagesCatalogo Donghua Cadenas Variasj.arriolaPas encore d'évaluation

- HeaDocument1 pageHeaYorgelis LopezPas encore d'évaluation

- Tabla Pesos IPNDocument47 pagesTabla Pesos IPNbenjaminPas encore d'évaluation

- Brides A Collorette PN 16Document1 pageBrides A Collorette PN 16Mohamed ChahidPas encore d'évaluation

- Brides Plates A Souder PN 16Document1 pageBrides Plates A Souder PN 16Mohamed ChahidPas encore d'évaluation

- Flansze DIN2573 PN6Document1 pageFlansze DIN2573 PN6PawelPas encore d'évaluation

- Square Pipe (Ok)Document4 pagesSquare Pipe (Ok)Tran Anh TuanPas encore d'évaluation

- Torque de Pernos y Caracteristicas de PernosDocument17 pagesTorque de Pernos y Caracteristicas de PernosIvan HormazabalPas encore d'évaluation

- Civata Sikma TorklariDocument1 pageCivata Sikma Torklarimakineci_67Pas encore d'évaluation

- AZ SheetpileDocument2 pagesAZ SheetpiledgrantPas encore d'évaluation

- Acoplamiento Rígido DIN116Document2 pagesAcoplamiento Rígido DIN116dem pricePas encore d'évaluation

- Catalogo TTCDocument4 pagesCatalogo TTCdaniloreaPas encore d'évaluation

- PN 6 & 10Document1 pagePN 6 & 10prabakaranPas encore d'évaluation

- Laminate - EUROPROFILE - 2011Document10 pagesLaminate - EUROPROFILE - 2011Serban TudorPas encore d'évaluation

- CMM-Tabla de Perfiles HEB - DIN 1026 PDFDocument1 pageCMM-Tabla de Perfiles HEB - DIN 1026 PDFJose RomeroPas encore d'évaluation

- Tabela Comparativa de DurezasDocument4 pagesTabela Comparativa de DurezassofiaPas encore d'évaluation

- ArmaturaDocument7 pagesArmaturaIvan KelamPas encore d'évaluation

- Din 2503 pn25 pn40 Plate Flange PDFDocument1 pageDin 2503 pn25 pn40 Plate Flange PDFTerzimehić AlenPas encore d'évaluation

- Pipe Weight SpanDocument1 pagePipe Weight SpanNIRMAL SINGHPas encore d'évaluation

- Vigas-de-acero-WF - (Alma-Llena) - AgoferDocument5 pagesVigas-de-acero-WF - (Alma-Llena) - AgoferCristian SolanoPas encore d'évaluation

- Ansat Putr Bidang Cipta Karya Tahun 2022Document102 pagesAnsat Putr Bidang Cipta Karya Tahun 2022Lola AmaliyaPas encore d'évaluation

- 08 Poutrelles HEMDocument2 pages08 Poutrelles HEMNora MazariPas encore d'évaluation

- Métré Des ConduitesDocument15 pagesMétré Des ConduitesMAPas encore d'évaluation

- Dimenssion Des ProfilesDocument2 pagesDimenssion Des ProfilesYounes ChaaPas encore d'évaluation

- 202 m55HJoxsaIepigel DIN933 - Bulon HexagonalDocument2 pages202 m55HJoxsaIepigel DIN933 - Bulon HexagonalIndian ChiefPas encore d'évaluation

- Standard Steel I Beam PropertiesDocument1 pageStandard Steel I Beam PropertiesGlenda SibongaPas encore d'évaluation

- Az Data SheetDocument2 pagesAz Data Sheetsebastian PeñalozaPas encore d'évaluation

- Gambar Jemb. Timurung PDFDocument37 pagesGambar Jemb. Timurung PDFArielPas encore d'évaluation

- Tableau Section D'acierDocument3 pagesTableau Section D'acierTouati BelghaliPas encore d'évaluation

- Tabela de TorqueDocument1 pageTabela de TorqueArtur FelipePas encore d'évaluation

- Pipa HitamDocument1 pagePipa HitamAmadeus CocaPas encore d'évaluation

- S Shape PropertiesDocument6 pagesS Shape Properties1128rosuelokeylaPas encore d'évaluation

- A1085 Dimensions and Properties Rect. HssDocument10 pagesA1085 Dimensions and Properties Rect. HssIngenieria TendPas encore d'évaluation

- Din 272Document1 pageDin 272Ever QhPas encore d'évaluation

- Nema 2Document9 pagesNema 2lupillorivera9981Pas encore d'évaluation

- Wa0000Document7 pagesWa0000Mamadou MBAYEPas encore d'évaluation

- Wa0001.Document7 pagesWa0001.Jack Arjax Rutherford SaintPas encore d'évaluation

- Piping Manhour and CostingDocument37 pagesPiping Manhour and Costingruel buntogPas encore d'évaluation

- 4 C 598 D 2 A 0 FFFD 5 BadbccDocument15 pages4 C 598 D 2 A 0 FFFD 5 Badbccapi-704419790Pas encore d'évaluation

- Apêndice B e C - Resistência Dos Materiais R. C. Hibbeler 7 EdDocument6 pagesApêndice B e C - Resistência Dos Materiais R. C. Hibbeler 7 EdStefano Taina Silva AlvesPas encore d'évaluation

- Torque y Fuerza, MMDocument1 pageTorque y Fuerza, MMJusto AbrilPas encore d'évaluation

- Calcule Du Réseau (Version F)Document5 pagesCalcule Du Réseau (Version F)Vatimetou EL BECHIRPas encore d'évaluation

- Tabela de Peso Parafuso SXT Din 933Document1 pageTabela de Peso Parafuso SXT Din 933Gabrielle GrossoPas encore d'évaluation

- Tabela de Peso Parafuso SXT Din 933Document1 pageTabela de Peso Parafuso SXT Din 933Patricio SouzaPas encore d'évaluation

- Tabla Perfiles Acero LaminadoDocument12 pagesTabla Perfiles Acero LaminadoArq Paola LamasPas encore d'évaluation

- 管道公称直径壁厚及压力对照表Document4 pages管道公称直径壁厚及压力对照表May LeePas encore d'évaluation

- A-Columns ADocument6 pagesA-Columns AAyham AbboudPas encore d'évaluation

- H+F French Complet 2008 Screen Low PDFDocument130 pagesH+F French Complet 2008 Screen Low PDFmgualdiPas encore d'évaluation

- Presentation de L'entrepriseDocument6 pagesPresentation de L'entrepriseSoreefan YaasirPas encore d'évaluation

- 5 Formation WiltronDocument41 pages5 Formation Wiltronbenoit16000Pas encore d'évaluation

- Discours Abdeslam Ahizoune AbidjanDocument3 pagesDiscours Abdeslam Ahizoune AbidjanModeste DarjPas encore d'évaluation

- Automate Mg11a604Document157 pagesAutomate Mg11a604YaoPas encore d'évaluation

- Constitution DP & DFT Formulaires DGMDocument4 pagesConstitution DP & DFT Formulaires DGMOlss BbzoPas encore d'évaluation

- Rapport-etude-De-prix Marche de Construction de 500 LogementDocument17 pagesRapport-etude-De-prix Marche de Construction de 500 LogementBouraida El Yamouni0% (1)

- Chapitre Ii Structure de ControleDocument14 pagesChapitre Ii Structure de ControleMouNi TVPas encore d'évaluation

- Fiche Application Usage Batiment PDFDocument13 pagesFiche Application Usage Batiment PDFPV DouzPas encore d'évaluation

- VhdlexDocument10 pagesVhdlexRiyadh Ben AbdallahPas encore d'évaluation

- Rapport Electro NE 555 2Document9 pagesRapport Electro NE 555 2OUMAIMA ENNAMICHEPas encore d'évaluation

- Cwebdes PDFDocument31 pagesCwebdes PDFChristian Trésor KandoPas encore d'évaluation

- Oncf Voyages BilletDocument1 pageOncf Voyages BilletEl Mehdi EchebbaPas encore d'évaluation

- Variateurs de Vitesse - de La Régulation Cascade À La Commande Vectorielle PSIMDocument55 pagesVariateurs de Vitesse - de La Régulation Cascade À La Commande Vectorielle PSIMBALLOUK Soufiane100% (4)

- Revetement TPDocument4 pagesRevetement TPInsaf SaifiPas encore d'évaluation

- Mme Cisse PersoDocument10 pagesMme Cisse PersoCodou SallPas encore d'évaluation

- Introduction Aux Fibres OptiquesDocument7 pagesIntroduction Aux Fibres OptiquesMaxwell KevinPas encore d'évaluation

- Rapport en TSIDocument13 pagesRapport en TSIDalal AboulfadlPas encore d'évaluation