Académique Documents

Professionnel Documents

Culture Documents

Banana PDF

Transféré par

Alexander Pesantes LázaroTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Banana PDF

Transféré par

Alexander Pesantes LázaroDroits d'auteur :

Formats disponibles

African Crop Science Conference Proceedings, Vol. 7. pp. 1267-1271 Printed in Uganda.

All rights reserved ISSN 1023-070X/2005 $ 4.00 2005, African Crop Science Society

The effect of drying methods on the quality of green banana flour

P. KADDUMUKASA, W. KYAMUHANGIRE, J. MUYONGA & F.I. MURANGA Department of Food Science and Technology, Makerere University, P.O. Box 7062, Kampala, Uganda Abstract A study was carried out to investigate the effect of different drying methods on banana flour quality. The quality of banana products produced with the traditional methods is very variable. Five methods were used in drying; two of the methods were purely convention drying (solar and biomass) methods. Three methods involved combining freeze-drying with convention drying at time intervals of 2, 4 and 6 hours. Colour, taste, ordour, texture and overall acceptability were determined. Physicochemical parameters specific gravity, solubility and sugar content were determined. Bananas that were freeze dried for two and four hours received higher scores for all sensory attributes. Low sensory scores were obtained for bananas that were convection dried. Hot air used during convection drying led to the low sensory scores. Significant differences (p<0.05) in carotene content were observed in convention dried bananas and solar dried bananas had 2953 IU while biomass dried bananas had 968.4 IU. The findings of this study indicate that using combined drying methods reduces drying time but does not significantly improve the quality of the product.

Key words: Quality, drying method, green banana flour Rsum Une tude tait conduite pour valuer leffet des diffrentes mthodes de schage sur la qualit de la farine de la banane. La qualit des produits de la banane issue des mthodes traditionnelles est trs variable. Cinq mthodes taient utilises dans le schage dont deux taient des mthodes de schage conventionnelles (solaire et biomasse). Trois mthodes comprenaient la combinaison de la conglation - schage avec la mthode de schage conventionnelle dans un intervalle de temps de 2, 4 et 6 heures. La couleur, le got, lodeur, la texture, et lacceptabilit taient dtermins. Les bananes qui taient congeles et sches pour deux et quatre heures ont reu les scores pour tous les attributs sensoriels. Les faibles scores sensoriels taient obtenus pour des bananes qui taient sches par convection. Lair chaud utilis pendant le schage par convection a conduit au faible score sensoriel. Les diffrences significatives (p<0.05) dans le contenu de la carotne taient observes dans le schage conventionnel de la banane et la banane sche avait 2953 IU alors que la biomasse de la banane sche avait 968.4 IU. Les rsultats de cette tude indiquent que lutilisation des mthodes des schages combins a rduit le temps de schage sans amliorer la qualit des produits. Mots cls: Qualit, mthodes de schage, la farine de la banane verte

Introduction

Banana processing, particularly drying using natural sun drying has been carried out for many centuries now. Processing of green bananas into flour is of interest in view of the surplus fruits often available year round in the production areas (Suntharalingam, 1993). Most banana flour, produced from the green unripe fruit is sun dried or dried in crude ovens, under these conditions the quality of the product is very variable (Wilson, 1975). Considerable losses occur during natural sun drying; lowering the qualitative and quantitative value of the dried products. The slices of unripe fruit are normally spread out on bamboo frameworks or on bare patches of earth, roofs, stone outcrops or on sheets of corrugated iron (FAO, 1995). Dried products are subject to contamination by extraneous materials such as sand, stones, soils, tree leaves and incursion by rodents, insects, animal excreta and various forms of micro-organisms (Olufayo and Ogunkule, 1996). Efforts to improve the above traditional drying methods have been going on. Drying methods have progressively improved from drying on the ground to raised racks to solar dryers, where a product is placed within an enclosed cabinet. Cabinet dryers have evolved from using solar energy alone to currently hybrid drying using both solar and other energy sources such as biomass, diesel and

electric. However, these dryers have given products with inferior quality that is reduced nutritional value, collapsed structure, reduced taste and flavor deterioration and discoloration (Inglett and Chalarambous 1979; Stover and Simmonds 1987; Muranga, 1998; Muyonga, 2000, Maskan, 2000). The discoloration during preparation and drying commonly called browning is caused by chemical or biochemical reactions or over heating due to difficulties in controlling the drying conditions notably temperature and time (Anon, 1993). In an effort to improve the quality of dried products combined drying methods (Freeze drying, osmotic drying, microwave and vacuum impregnation) have been used (Maskan, 2000; Moreno et al., 2000; Fito et al., 2001; Prothon, 2003). Currently the market prefers high quality dried products with good reconstitution properties and excellent sensory attributes. The present study was carried out to investigate the effect of different drying methods on the quality of banana flour.

Materials and methods

East African highland bananas (Musa type AAA-EA) were used in this study. Mature bunches of cooking bananas ( Mpologoma genome AAA-EA) were purchased from the market and brought to the laboratory.

1268

P. KADDUMUKASA et al.

Banana fingers were removed form the stalk those that were badly bruised or damaged were discarded. The following dryers were used freeze dryer (Labconco, No. 267923, Missouri, 1995), biomass convection dryer and solar convection dryer. The fruits were peeled and sliced into 2mm thick slices on the same day they were received using stainless steel knives, and dipped into a solution of 2% sodium metabisulphite for 2 minutes to eliminate enzymatic browning. Slices were drained to remove excess metabisulphite. For the combined method, slices of green bananas were placed in freeze-drying flasks and were frozen in a laboratory freezer (model NJ40, TBECD, No. 970541613, Italy) for twelve hours. Frozen slices were attached onto the freeze dryer (Labconco shell freezer, No. 267923, 64132, Missouri, 1995) maintained at -40C and a pressure of 1.9510-5m bars. Green bananas were freeze dried for 2, 4 or 6 hours, after which flasks were removed and complete dehydration of the product was achieved in the biomass convection dryer. A hammer mill (PSP-12, Pulveriser, LAXMI Engineers, 1989, India) was used to mill slices to the required particle size (300 SS wire mesh). The flour was packaged into moisture proof polythene bags. Physicochemical analysis. Physicochemical parameters such as moisture content, temperature, sugar content, solubility and specific gravity were determined. Moisture content of green bananas was determined using the Draft oven method (Kirk and Sawyer, 1991). Stainless steel dishes were washed, dried (Hotbox oven Gallenkamp, UK) for 30 minutes and weighed (Sartorius, BA 2100s, Sartorius Germany). That weight was recorded as M1. A sample (5g) was placed in the dish, weighed and the combined weight recorded as M2. The dish together with the sample was then dried (Hot box Oven, Gallenkamp, UK) at 70oC until constant weight (36h). The dish and the dried sample were re-weighed and the weight was recorded as M3. The same procedure for moisture content determination was used for bananas that had been convection dried. Temperature during drying was monitored using twocentigrade mercury in glass thermometers, placed at different heights (top and bottom) within the drying chamber. Humidity was measured using the dry and wet bulb thermometers (hygrometers); one was placed inside the drying chamber and another outside the dryer. Wet bulb depression was read off a psychometric chart to get percentage humidity. Sugar content was determined according to Robyt and White, (1990). The method worked on the principle of hydrolysis on boiling. Solubility and specific gravity were determined using AOAC, with modifications (Bradley, 1994). Determination of -carotene. -Carotene was determined using a spectrophotometer (540nm) according to Ameny and Wilson, (1997). Sensory analysis. Sensory analysis was conducted on banana porridge where 50 mls of porridge was served into 100 ml disposable cups. Panelists were randomly selected from students and staff of the Faculty of Agriculture,

Makerere University. A 7-point hedonic scale was used to evaluate the sensory attributes of the products (7- like extremely, 2- like moderately, 3- like slightly, 4- neither like nor dislike, 5- dislike slightly, 6- dislike moderately, 1dislike extremely). Analysis of variance was performed using the generalized linear model of SAS package (SAS institute Inc. 1990). Mean separation was carried out using the least significant difference test (LSD).

Results and discussion

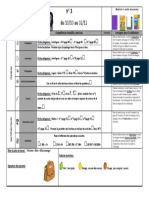

Green banana drying. The influence of dryng time on moisture loss of green bananas is shown in Figure 1. The most significant changes in moisture content took place during the first two hours of drying for bananas that were initially freeze dried and bananas that were biomass dried. Bananas that were solar dried took longer drying time during convection drying. During that time, moisture content for bananas that were freeze dried for two hours reduced from about 62% to 14% within the first sixty minutes to 1.7% within the next sixty minutes. Bananas that were dried using the combined freeze drying/convection drying method took shorter drying times during convection drying than bananas that were solely convection dried (Fig. 1). Curves for bananas dried using the combined method presented a linear shape while bananas that were dried using convection alone had a sigmoid shape (Fig. 1). A curve similar in shape to the sigmoid curve for the convection dried bananas was earlier obtained by Miller (1988). Curves for the convection dried bananas had three drying periods, the settling down period, the constant drying rate period, the falling rate period. These periods have been reported by several authors in the normal drying curve (Carpio, 1982; Miller, 1988; Felllows, 1998; Laufenderg, 2002). A short time is required to warm up the product and moisture in it to evaporation temperature (Miller, 1988). This short time is the settling down period, as the surface of the product is heated to wet bulb temperature (Fellows, 1998). Most drying occurred during the first two hours for bananas that were dried using biomass and combined freeze drying/convection drying. This period of rapid moisture loss is referred to as the constant drying rate period (Ba et al., 1981; Miller, 1988; Fellows, 1998). During this period, the plane of evaporation of moisture moves inside the food and moisture diffuses through the dry solids to the drying air (Fellows, 1998). The product behaves as if a thin layer of moisture covers the surface of the product (Brooker et al., 1992). Bananas, which were solar dried, had a longer constant drying rate period due to the variation in heat intensity during solar drying. The constant drying rate period was followed by the falling rate period. In this section, the curve was almost linear indicating that little or no moisture was lost (Fig. 1). The falling rate period is characterized by decreased drying (Miller, 1988; Brooker et al., 1992; Potter & Hotchkiss, 1995; Fellows, 1998). During this period, the rate of moisture movement from the interior of the food to the surface falls below the rate at which moisture evaporates to the surrounding air (Miller, 1988; Fellows,

Drying methods on the quality of green banana flour

1269

1998). Drying becomes very slow as the drying limit is reached and hence takes a longer time to remove all the remaining moisture (Carpio, 1981). Green banana drying rates. The method used for drying bananas influenced the time bananas took to reach target and equilibrium moisture contents (Table 1). Bananas, which were dried using the combined freeze drying/ convection drying, had reduced drying time during

90 80 70 Moisture content (%) 60 50 40 30 20 10 0 0 60 120 180

convection drying. These bananas took shorter drying times to reach equilibrium moisture content compared to bananas that were dried using convection drying alone (Table 1). All banana porridge attributes were found to be acceptable (Table 2). Bananas that were freeze dried for four hours received the highest overall acceptability. No significant difference (p>0.05) in sensory attributes was observed between bananas that were solely convection

A B C D E

240

300

360

420 480

Time (minutes)

Figure 1. Changes in moisture content (%) with drying time (minutes) for green bananas dried using different methods. A: Bananas freeze dried for 2 hours then convection dried, B: Bananas freeze dried for 4 hours then convection dried, C: Bananas freeze dried for 6 hours then convection dried, D: Bananas dried using biomass convection drying only, E: Bananas dried using solar convection drying only. Table 1. Drying rates of different methods. Method *Target moisture content Biomass Solar Freeze dried 2hrs/convection dried Freeze dried 4hrs/convection dried Freeze dried 6hrs / convection dried * Target moisture content was 10%. Table 2. Sensory attributes of green banana flour. Drying method Biomass Freeze drying Solar Freeze dried 2hrs/ Convection dried Freeze dried 4 hrs/ Convection dried Freeze dried 6hrs/ convection dried LSD Mouth feel 3.8 4.1 3.5 4.9 5.5 4.6 1.2 Colour 4.1 4.4 4.1 5.4 4.8 3.9 1.1 Ordour 4.2 4.0 3.6 5.1 4.3 4.1 1.1 Taste 3.5 3.8 3.4 5.1 4.6 4.6 0.9 Overall acceptability 3.9 4.5 4.1 4.7 5.3 4.1 1.0 2 6 1.5 1.5 0.5 Drying time (hours) Equilibrium moisture content 4 7.5 2 2 1.5

1270

P. KADDUMUKASA et al.

Table 3. Physicochemical parameters of convection dried green bananas. Drying method Biomass Solar LSD Specific gravity 1.6 0.1 1.8 0.18 0.8 -carotene 968.4 31.2 2953 62.7 206 Sugars 0.5 0.2 0.4 0.2 0.6 Solubility 1.1 0.4 1.9 0.4 1.0

dried and those dried using the combined method. However bananas that were dried using the combined method had improved organoleptic scores. Bananas dried using the combined method received better scores probably due to the low temperatures that were used during freeze drying. The low temperatures and the absence of air prevents deterioration due to oxidation or chemical modification of the product (Lin et al., 1999). The method gives minimal damage to the products (VegaMercado et al., 2001) with little or no alteration in the structure or molecular integrity of the products (Achanta et al., 1995; Lin et al., 1999). Freeze drying is applied to circumvent heat damage and produces products with excellent structural retention (Lin et al., 1999). Bananas that were solar dried received lower scores for most of the attributes (mouthfeel, colour and taste). This was probably due to the long drying time the slices spent in the dryer. The high temperature and long drying time associated with convectional hot air drying causes heat damage and adversely affects texture (Lin et al., 1999). A significant difference (p<0.05) in ordour was observed for bananas that were solar dried. This was probably due to the loss of some volatile compounds during hot air drying. Volatile compounds are vaporized and lost with water vapor (Yongsawatdigul and Gunasekaran, 1996). This causes significant loss of characteristic flavor in the dried products. Bananas that were solar dried had higher -carotene contents than bananas that were biomass dried (Table 3). This may have been due to hot air used in the biomass dryer. Hot air drying causes degradation of - carotene and therefore a decrease in both and - carotene content (Lin et al., 1999). Air dehydration exposes carotenoids to oxygen, which can cause extensive degradation of carotenoids (Fennema, 1996). Green banana sugar contents were low. This was probably because green bananas contained high percentages of starch and trace amounts of sugar. Green unripe bananas have average values of 25% and 18% starch content (Cordenunsi et al., 1995; Prabha 1998). The starch reserve is still high but this disappears during ripening to about 18% sugar content (Prabha, 1998) or 20% sugar content (Fennema, 1996).

developing countries is done on small scale, inexpensive and uncomplicated drying methods would be most appropriate.

Acknowledgements

The author acknowledges the DAAD scholarship scheme for providing funds for this study. I would like to thank Dr. W. Kyamuhangire and Dr. J. Muyonga of the Department of Food Science, Makerere University for all constructive criticisms and advice given during this work. The assistance given by Dr. F. I. Muranga of the Department of Food Science and Technology during the inception of this work and Mr. Kawongolo of the Department of Agricultural Engineering, Faculty of Agriculture for his expertise in solar drying is appreciated.

References

Achanta, S. & Okos, M.R. 1995. Impact of drying on biological product quality. Changes in food during processing and storage. USA. pp. 638-653. Ameny, M.A. & Wilson, P.W. 1997. HPLC Determination of carotenoids in white fleshed African sweet potatoes and Apios a mericana . African Crop Science Proceedings Ba, A., Banzet, C. & Degbe, J.M. 1981. Drying of onions in Niger in Yacuik, G (ed). Food Drying. Proceedings of a workshop held at Edmonton, Alberta. Brooker, D. B., Bakker- Arkema, F. W. & Hall, C. W. 1992. Drying and storage of Grains and Oilseeds. pp. 71-73. Carpio, E. V. 1982. Drying fish in Philippines in Yaciuk, G. (Ed). Food Drying. Ottawa, Canada. Cordenunsi, B. R. & Lajolo, M. F. 1995. Starch breakdown during Banana Ripening: Sucrose Synthase and Sucrose phosphate synthase. Journal of Agricultural Food Chemistry 43, 347 351. FAO, 1995. Fruits and vegetable processing. No.119. Rome, Italy. FAO, 2004. http://faostat.fao.org Fellows, P. J. 1998. Food processing technology. Principles and practice. Wood head Publishing Limited. Abington, Cambridge. England. pp. 281 -311. Fennema, O. R. 1996. Food Chemistry. Marcell Dekker Inc. pp. 680-681, 950-952. Fito, P., Chiralt, A., Barat, J. M. Andres, A., MartinezMonzo, J. & Martinez-Navarrete, N. 2001. Vacuum impregnation for development of new dehydrated products. Journal of Food Engineering 49, 297-302.

Conclusion

Freeze drying is a useful drying method, however it is expensive. Combining it with other drying methods reduces drying time but does not greatly improve the quality of the products. Since most of the drying in

Drying methods on the quality of green banana flour

1271

Kirk, R. S. & Sawyer, R. 1991. Pearsons Composition and Analysis of Foods. Longman group Limited. United Kingdom. pp. 343-345. Laufenberg, G. 2002. Drying Technology. Bonn, Germany. pp. 1-9. Lin, T. M., Durance, T. D. & Scaman,C. H. 1999. Characterization of vacuum microwave, air and freeze dried carrot slices. Food Research International. Canadian Institute of Food Science & Technology. Elsevier Science 31(2), 111 Maskan, M. 2001. Microwave/air and microwave finish drying of banana. Journal of Food Engineering. pp. 71-78. Miller, D. F. 1988. Drying as a unit operation in the processing of ready to eat breakfast cereals. Basic principles In Caldwell, E. F. (ed). Cereal Foods World. California, U. S. A. 33(1). Moreno, J., Chiralt, A., Eschriche, I. & Serra, J. A. 2000. Effect of blanching/Osmotic dehydration combined methods on quality and stability of minimally processed strawberries. Food Research International 37 (7), 609-616. Muranga, F. I. 1998. Physicochemical characteristics of banana starches. PhD Thesis. NARO (National Agricultural Research Organization), 1999. Farmer participatory Banana Research at Kisekka Benchmark site Masaka District : Progress report.

Olufayo, A. A. & Ogunkule, O. J. 1996. Natural drying of cassava chips in the Humid. Potter, N. N. & Hotchkiss, J. H. 1995. Food Science 5th edition. Chapman & Hall. pp. 201-211. Prabha, T. N. & Bhagyalakshmi, N. 1998. Carbohydrate metabolism in ripening banana fruit. Photochemistry. Elsevier Science Limited. Zone of Nigeria. Bioresource Technology 58(1), 89-91. Prothon, F. 2003. Combined dehydration methods from fresh fruit to high quality ingredients. Swedish Institute for Food & Biotechnology. Department of Food Engineering. Lund Institute of Technology. Elsevier science Limited. pp. 19-25 pp 271- 289. Robyt, J. F. & White, B. J. 1990. Biochemical techniques and practice. Waveland press Inc. Illinois. pp. 217. Stover, R. H. & Simmonds, N. W. 1987. Bananas. Longman Group Limited. London, UK. pp. 391- 397. Tushemereirwe, W. K., Karamura, D., Ssali, H., Bwamiki, D., Kashaija, C., Nankinga, C., Bagamba, F., Kangire, A & Ssebuliba, R. 2001. Mukiibi (ed). Agriculture in Uganda. Volume 2. Crops. NARO. pp. 281-283, 297299. Yongsawatdigul, Y. & Gunasekaran, S. 1996. Microwavevacuum drying of Cranberries. Part 1. Energy use and Efficiency. Journal of Food processing and preservation 20. 1996. Press Inc. Trumbull CT 06611. Food & Nutrition . pp. 121-143.

Vous aimerez peut-être aussi

- Adobe Illustrator CC Le Support de Cours OfficielDocument479 pagesAdobe Illustrator CC Le Support de Cours OfficielAly Bernard Ndiaye86% (7)

- Ue201718 213 S3 PDFDocument120 pagesUe201718 213 S3 PDFIman FalahPas encore d'évaluation

- Du de La Des de de L ExercisesDocument2 pagesDu de La Des de de L Exercisesapi-262811896Pas encore d'évaluation

- BUDAI Erika - Les SirenesDocument9 pagesBUDAI Erika - Les SirenesHélène RichardeauPas encore d'évaluation

- 2008 Position de L'exiléDocument25 pages2008 Position de L'exilé1234Pas encore d'évaluation

- Le TANTRA Et Le Massage Tantrique.Document15 pagesLe TANTRA Et Le Massage Tantrique.Alexandra GalvezPas encore d'évaluation

- Dossier Complet Belles Plantes Scolaires Textes Fiches PedagogiquesDocument59 pagesDossier Complet Belles Plantes Scolaires Textes Fiches Pedagogiquesjosdiakiese950Pas encore d'évaluation

- Les Lettres AdministrativesDocument7 pagesLes Lettres AdministrativesAyman LamzouriPas encore d'évaluation

- MONS Rue de Nimy (TEC) MONS Grands Prés (TEC) : Votre Trajet en Quelques ChiffresDocument1 pageMONS Rue de Nimy (TEC) MONS Grands Prés (TEC) : Votre Trajet en Quelques ChiffresPernelle DPas encore d'évaluation

- Integrer Un PDF Dans Un Site PDFDocument3 pagesIntegrer Un PDF Dans Un Site PDFlydiaberthomieuPas encore d'évaluation

- Grille Bfem TroisiemeDocument5 pagesGrille Bfem Troisiemepapeefi93Pas encore d'évaluation

- 11 Technique D'expression3Document17 pages11 Technique D'expression3Imene BrbPas encore d'évaluation

- Dossier Technique RéviséDocument10 pagesDossier Technique RéviséJalal Ke100% (2)

- Dwnload Full Analog Circuit Design Discrete and Integrated 1st Edition Franco Solutions Manual PDFDocument36 pagesDwnload Full Analog Circuit Design Discrete and Integrated 1st Edition Franco Solutions Manual PDFlincolnrod80100% (16)

- Cordiérite-Mullite 1 PDFDocument10 pagesCordiérite-Mullite 1 PDFkhalidPas encore d'évaluation

- Sup Deco Institut Mercure Cours Compta AnalytiqueDocument57 pagesSup Deco Institut Mercure Cours Compta AnalytiqueCheikhou Dia100% (1)

- Calendrier Previsionnel These 1.2Document5 pagesCalendrier Previsionnel These 1.2Wassim CharmantPas encore d'évaluation

- Art-Pie 1er Régiment d'Artillerie-à-Pied (Dunkerque, Calais, Boulogne)Document22 pagesArt-Pie 1er Régiment d'Artillerie-à-Pied (Dunkerque, Calais, Boulogne)DUCHAUSSOYPas encore d'évaluation

- Examen Eoae 2 Bac Eco 2012 Session Rattrapage CorrigeDocument4 pagesExamen Eoae 2 Bac Eco 2012 Session Rattrapage CorrigeAhmed Hassan SkifaPas encore d'évaluation

- Plan de Travail 3Document1 pagePlan de Travail 3Fabienne GillardPas encore d'évaluation

- Architecture J2 EEDocument27 pagesArchitecture J2 EEFaiçal YahiaPas encore d'évaluation

- COUR DE COMPTES TOGO AUDIT Thème 1Document42 pagesCOUR DE COMPTES TOGO AUDIT Thème 1Pascal SindiePas encore d'évaluation

- PNL - SubmodalitesDocument7 pagesPNL - SubmodalitessoriboPas encore d'évaluation

- Le Management de La Force de Vente Support 2Document73 pagesLe Management de La Force de Vente Support 2Soufiane Cherif100% (1)

- Compte-Rendu Diagnostic Et ExpertiseDocument23 pagesCompte-Rendu Diagnostic Et ExpertiseM'hamdi EzdiharPas encore d'évaluation

- Ces Aliments Que L'on Peut Consommer Après La Date de Péremption - Santé MagazineDocument3 pagesCes Aliments Que L'on Peut Consommer Après La Date de Péremption - Santé MagazinekiamgoPas encore d'évaluation

- Passerelle Primaire Admis 2023-2024Document6 pagesPasserelle Primaire Admis 2023-2024Chaymah ChoubouPas encore d'évaluation

- Immunite CoursDocument14 pagesImmunite CoursJulien GhandourPas encore d'évaluation

- Le Risque D'inondationDocument13 pagesLe Risque D'inondationcasaouis02Pas encore d'évaluation

- L'impact Du Choix Des FournisseursDocument9 pagesL'impact Du Choix Des FournisseursMamadou SYPas encore d'évaluation