Académique Documents

Professionnel Documents

Culture Documents

Tabela Pt100 PDF

Transféré par

Rafael FehlbergTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tabela Pt100 PDF

Transféré par

Rafael FehlbergDroits d'auteur :

Formats disponibles

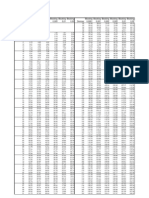

Technical Data

RTDs

Temperature Versus Resistance-100RTD

=0.003850//C

Temperature Versus Resistance-100RTD

C

-200

-190

-180

-170

-160

-150

-140

-130

-120

-110

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

0

18.52

22.83

27.10

31.34

35.54

39.72

43.88

48.00

52.11

56.19

60.26

64.30

68.33

72.33

76.33

80.31

84.27

88.22

92.16

96.09

100.00

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

22.40

26.67

30.91

35.12

39.31

43.46

47.59

51.70

55.79

59.85

63.90

67.92

71.93

75.93

79.91

83.87

87.83

91.77

95.69

99.61

21.97

26.24

30.49

34.70

38.89

43.05

47.18

51.29

55.38

59.44

63.49

67.52

71.53

75.53

79.51

83.48

87.43

91.37

95.30

99.22

21.54

25.82

30.07

34.28

38.47

42.63

46.77

50.88

54.97

59.04

63.09

67.12

71.13

75.13

79.11

83.08

87.04

90.98

94.91

98.83

21.11

25.39

29.64

33.86

38.05

42.22

46.36

50.47

54.56

58.63

62.68

66.72

70.73

74.73

78.72

82.69

86.64

90.59

94.52

98.44

20.68

24.97

29.22

33.44

37.64

41.80

45.94

50.06

54.15

58.23

62.28

66.31

70.33

74.33

78.32

82.29

86.25

90.19

94.12

98.04

20.25

24.54

28.80

33.02

37.22

41.39

45.53

49.65

53.75

57.82

61.88

65.91

69.93

73.93

77.92

81.89

85.85

89.80

93.73

97.65

19.82

24.11

28.37

32.60

36.80

40.97

45.12

49.24

53.34

57.41

61.47

65.51

69.53

73.53

77.52

81.50

85.46

89.40

93.34

97.26

19.38

23.68

27.95

32.18

36.38

40.56

44.70

48.83

52.93

57.01

61.07

65.11

69.13

73.13

77.12

81.10

85.06

89.01

92.95

96.87

18.95

23.25

27.52

31.76

35.96

40.14

44.29

48.42

52.52

56.60

60.66

64.70

68.73

72.73

76.73

80.70

84.67

88.62

92.55

96.48

18.52

22.83

27.10

31.34

35.54

39.72

43.88

48.00

52.11

56.19

60.26

64.30

68.33

72.33

76.33

80.31

84.27

88.22

92.16

96.09

C

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

0

100.00

103.90

107.79

111.67

115.54

119.40

123.24

127.08

130.90

134.71

138.51

142.29

146.07

149.83

153.58

157.33

161.05

164.77

168.48

172.17

175.86

1

100.39

104.29

108.18

112.06

115.93

119.78

123.63

127.46

131.28

135.09

138.88

142.67

146.44

150.21

153.96

157.70

161.43

165.14

168.85

172.54

176.22

2

100.78

104.68

108.57

112.45

116.31

120.17

124.01

127.84

131.66

135.47

139.26

143.05

146.82

150.58

154.33

158.07

161.80

165.51

169.22

172.91

176.59

3

101.17

105.07

108.96

112.83

116.70

120.55

124.39

128.22

132.04

135.85

139.64

143.43

147.20

150.96

154.71

158.45

162.17

165.89

169.59

173.28

176.96

4

101.56

105.46

109.35

113.22

117.08

120.94

124.78

128.61

132.42

136.23

140.02

143.80

147.57

151.33

155.08

158.82

162.54

166.26

169.96

173.65

177.33

5

101.95

105.85

109.73

113.61

117.47

121.32

125.16

128.99

132.80

136.61

140.40

144.18

147.95

151.71

155.46

159.19

162.91

166.63

170.33

174.02

177.69

6

102.34

106.24

110.12

114.00

117.86

121.71

125.54

129.37

133.18

136.99

140.78

144.56

148.33

152.08

155.83

159.56

163.29

167.00

170.70

174.38

178.06

7

102.73

106.63

110.51

114.38

118.24

122.09

125.93

129.75

133.57

137.37

141.16

144.94

148.70

152.46

156.20

159.94

163.66

167.37

171.07

174.75

178.43

8

103.12

107.02

110.90

114.77

118.63

122.47

126.31

130.13

133.95

137.75

141.54

145.31

149.08

152.83

156.58

160.31

164.03

167.74

171.43

175.12

178.79

9

103.51

107.40

111.29

115.15

119.01

122.86

126.69

130.52

134.33

138.13

141.91

145.69

149.46

153.21

156.95

160.68

164.40

168.11

171.80

175.49

179.16

10

103.90

107.79

111.67

115.54

119.40

123.24

127.08

130.90

134.71

138.51

142.29

146.07

149.83

153.58

157.33

161.05

164.77

168.48

172.17

175.86

179.53

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

78

RTDs

C

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

460

470

480

490

500

510

520

530

540

550

560

570

580

590

600

610

620

630

640

650

0

179.53

183.19

186.84

190.47

194.10

197.71

201.31

204.90

208.48

212.05

215.61

219.15

222.68

226.21

229.72

233.21

236.70

240.18

243.64

247.09

250.53

253.96

257.38

260.78

264.18

267.56

270.93

274.29

277.64

280.98

284.30

287.62

290.92

294.21

297.49

300.75

304.01

307.25

310.49

313.71

316.92

320.12

323.30

326.48

329.64

1

179.89

183.55

187.20

190.84

194.46

198.07

201.67

205.26

208.84

212.41

215.96

219.51

223.04

226.56

230.07

233.56

237.05

240.52

243.99

247.44

250.88

254.30

257.72

261.12

264.52

267.90

271.27

274.63

277.98

281.31

284.63

287.95

291.25

294.54

297.81

301.08

304.34

307.58

310.81

314.03

317.24

320.43

323.62

326.79

2

180.26

183.92

187.56

191.20

194.82

198.43

202.03

205.62

209.20

212.76

216.32

219.86

223.39

226.91

230.42

233.91

237.40

240.87

244.33

247.78

251.22

254.65

258.06

261.46

264.86

268.24

271.61

274.96

278.31

281.64

284.97

288.28

291.58

294.86

298.14

301.41

304.66

307.90

311.13

314.35

317.56

320.75

323.94

327.11

3

180.63

184.28

187.93

191.56

195.18

198.79

202.39

205.98

209.56

213.12

216.67

220.21

223.74

227.26

230.77

234.26

237.74

241.22

244.68

248.13

251.56

254.99

258.40

261.80

265.20

268.57

271.94

275.30

278.64

281.98

285.30

288.61

291.91

295.19

298.47

301.73

304.98

308.23

311.45

314.67

317.88

321.07

324.26

327.43

4

180.99

184.65

188.29

191.92

195.55

199.15

202.75

206.34

209.91

213.48

217.03

220.57

224.09

227.61

231.12

234.61

238.09

241.56

245.02

248.47

251.91

255.33

258.74

262.14

265.53

268.91

272.28

275.63

278.98

282.31

285.63

288.94

292.24

295.52

298.80

302.06

305.31

308.55

311.78

314.99

318.20

321.39

324.57

327.74

=0.003850//C

5

181.36

185.01

188.66

192.29

195.91

199.51

203.11

206.70

210.27

213.83

217.38

220.92

224.45

227.96

231.47

234.96

238.44

241.91

245.37

248.81

252.25

255.67

259.08

262.48

265.87

269.25

272.61

275.97

279.31

282.64

285.96

289.27

292.56

295.85

299.12

302.38

305.63

308.87

312.10

315.31

318.52

321.71

324.89

328.06

6

181.72

185.38

189.02

192.65

196.27

199.87

203.47

207.05

210.63

214.19

217.74

221.27

224.80

228.31

231.82

235.31

238.79

242.26

245.71

249.16

252.59

256.01

259.42

262.82

266.21

269.59

272.95

276.30

279.64

282.97

286.29

289.60

292.89

296.18

299.45

302.71

305.96

309.20

312.42

315.64

318.84

322.03

325.21

328.38

7

182.09

185.74

189.38

193.01

196.63

200.23

203.83

207.41

210.98

214.54

218.09

221.63

225.15

228.66

232.17

235.66

239.13

242.60

246.06

249.50

252.93

256.35

259.76

263.16

266.55

269.92

273.29

276.64

279.98

283.31

286.62

289.93

293.22

296.50

299.78

303.03

306.28

309.52

312.74

315.96

319.16

322.35

325.53

328.69

8

182.46

186.11

189.75

193.37

196.99

200.59

204.19

207.77

211.34

214.90

218.44

221.98

225.50

229.02

232.52

236.00

239.48

242.95

246.40

249.85

253.28

256.70

260.10

263.50

266.89

270.26

273.62

276.97

280.31

283.64

286.95

290.26

293.55

296.83

300.10

303.36

306.61

309.84

313.06

316.28

319.48

322.67

325.84

329.01

9

182.82

186.47

190.11

193.74

197.35

200.95

204.55

208.13

211.70

215.25

218.80

222.33

225.85

229.37

232.87

236.35

239.83

243.29

246.75

250.19

253.62

257.04

260.44

263.84

267.22

270.60

273.96

277.31

280.64

283.97

287.29

290.59

293.88

297.16

300.43

303.69

306.93

310.16

313.39

316.60

319.80

322.98

326.16

329.32

10

183.19

186.84

190.47

194.10

197.71

201.31

204.90

208.48

212.05

215.61

219.15

222.68

226.21

229.72

233.21

236.70

240.18

243.64

247.09

250.53

253.96

257.38

260.78

264.18

267.56

270.93

274.29

277.64

280.98

284.30

287.62

290.92

294.21

297.49

300.75

304.01

307.25

310.49

313.71

316.92

320.12

323.30

326.48

329.64

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

79

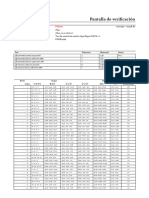

Technical Data

RTDs

Temperature Versus Resistance-100 Platinum RTD

C

-200

-190

-180

-170

-160

-150

-140

-130

-120

-110

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

C

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

0

17.14

21.46

25.80

30.12

34.42

38.68

42.91

47.11

51.29

55.44

59.57

63.68

67.77

71.85

75.91

79.96

83.99

88.01

92.02

96.02

100.00

0

100.00

103.97

107.93

111.88

115.81

119.73

123.64

127.54

131.42

135.30

139.16

143.01

146.85

150.67

154.49

158.29

162.08

165.86

=0.003916//C

Temperature Versus Resistance-100 Platinum RTD

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

21.03

25.37

29.69

33.99

38.26

42.49

46.69

50.87

55.02

59.16

63.27

67.36

71.44

75.51

79.56

83.59

87.61

91.62

95.62

99.60

1

100.40

104.37

108.32

112.27

116.20

120.12

124.03

127.93

131.81

135.68

139.55

143.39

147.23

151.06

154.87

158.67

162.46

166.24

20.59

24.93

29.26

33.56

37.83

42.07

46.27

50.45

54.61

58.74

62.86

66.96

71.04

75.10

79.15

83.19

87.21

91.22

95.22

99.20

2

100.80

104.76

108.72

112.66

116.59

120.51

124.42

128.32

132.20

136.07

139.93

143.78

147.61

151.44

155.25

159.05

162.84

166.62

20.16

24.50

28.83

33.13

37.41

41.64

45.85

50.04

54.19

58.33

62.45

66.55

70.63

74.70

78.75

82.79

86.81

90.82

94.82

98.81

3

101.19

105.16

109.11

113.06

116.99

120.91

124.81

128.71

132.59

136.46

140.32

144.16

148.00

151.82

155.63

159.43

163.22

166.99

19.73

24.07

28.40

32.70

36.98

41.22

45.43

49.62

53.78

57.92

62.04

66.14

70.22

74.29

78.34

82.38

86.41

90.42

94.42

98.41

4

101.59

105.56

109.51

113.45

117.38

121.30

125.20

129.09

132.98

136.84

140.70

144.55

148.38

152.20

156.01

159.81

163.60

167.37

19.29

23.63

27.97

32.28

36.55

40.80

45.01

49.20

53.36

57.50

61.63

65.73

69.81

73.88

77.94

81.98

86.01

90.02

94.02

98.01

5

101.99

105.95

109.90

113.84

117.77

121.69

125.59

129.48

133.36

137.23

141.09

144.93

148.76

152.58

156.39

160.19

163.97

167.75

18.86

23.20

27.53

31.85

36.13

40.38

44.59

48.78

52.95

57.09

61.21

65.32

69.41

73.43

77.53

81.58

85.60

89.62

93.62

97.61

6

102.38

106.35

110.30

114.24

118.16

122.08

125.98

129.87

133.75

137.62

141.47

145.31

149.15

152.96

156.77

160.57

164.35

168.12

18.43

22.76

27.10

31.42

35.70

39.95

44.17

48.37

52.53

56.68

60.80

64.91

69.00

73.07

77.13

81.17

85.20

89.22

93.22

97.21

7

102.78

106.74

110.69

114.63

118.56

122.47

126.37

130.26

134.14

138.00

141.86

145.70

149.53

153.35

157.15

160.95

164.73

168.50

18.00

22.33

26.67

30.99

35.27

39.53

43.75

47.95

52.12

56.26

60.39

64.50

68.59

72.66

76.72

80.77

84.80

88.82

92.82

96.81

8

103.18

107.14

111.09

115.02

118.95

122.86

126.76

130.65

134.52

138.39

142.24

146.08

149.91

153.73

157.53

161.33

165.11

168.88

17.57

21.90

26.24

30.56

34.85

39.10

43.33

47.53

51.70

55.85

59.98

64.09

68.18

72.26

76.32

80.36

84.40

88.42

92.42

96.42

9

103.57

107.53

111.48

115.42

119.34

123.25

127.15

131.04

134.91

138.77

142.63

146.46

150.29

154.11

157.91

161.70

165.48

169.25

17.14

21.46

25.80

30.12

34.42

38.68

42.91

47.11

51.29

55.44

59.57

63.68

67.77

71.85

75.91

79.96

83.99

88.01

92.02

96.02

10

103.97

107.93

111.88

115.81

119.73

123.64

127.54

131.42

135.30

139.16

143.01

146.85

150.67

154.49

158.29

162.08

165.86

169.63

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

80

RTDs

C

180

190

200

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

460

470

480

490

500

0

169.63

173.38

177.13

180.86

184.58

188.29

191.99

195.67

199.35

203.01

206.66

210.30

213.93

217.54

221.15

224.74

228.32

231.89

235.45

238.99

242.53

246.05

249.56

253.06

256.55

260.02

263.49

266.94

270.38

273.80

277.22

280.63

284.02

1

170.00

173.76

177.50

181.23

184.95

188.66

192.36

196.04

199.71

203.38

207.02

210.66

214.29

217.90

221.51

225.10

228.68

232.25

235.80

239.35

242.88

246.40

249.91

253.41

256.89

260.37

263.83

267.28

270.72

274.15

277.56

280.96

284.36

2

170.38

174.13

177.88

181.61

185.32

189.03

192.73

196.41

200.08

203.74

207.39

211.03

214.65

218.26

221.87

225.46

229.04

232.60

236.16

239.70

243.23

246.75

250.26

253.76

257.24

260.72

264.18

267.63

271.06

274.49

277.90

281.30

284.69

3

170.76

174.51

178.25

181.98

185.70

189.40

193.09

196.78

200.45

204.11

207.75

211.39

215.01

218.63

222.23

225.81

229.39

232.96

236.51

240.05

243.58

247.10

250.61

254.11

257.59

261.06

264.52

267.97

271.41

274.83

278.24

281.64

285.03

4

171.13

174.88

178.62

182.35

186.07

189.77

193.46

197.14

200.81

204.47

208.12

211.75

215.37

218.99

222.59

226.17

229.75

233.31

236.87

240.41

243.94

247.46

250.96

254.46

257.94

261.41

264.87

268.31

271.75

275.17

278.58

281.98

285.37

5

171.51

175.26

179.00

182.72

186.44

190.14

193.83

197.51

201.18

204.84

208.48

212.11

215.74

219.35

222.94

226.53

230.11

233.67

237.22

240.76

244.29

247.81

251.31

254.80

258.29

261.75

265.21

268.66

272.09

275.51

278.92

282.32

285.71

=0.003916//C

6

171.88

175.63

179.37

183.09

186.81

190.51

194.20

197.88

201.55

205.20

208.85

212.48

216.10

219.71

223.30

226.89

230.46

234.03

237.58

241.11

244.64

248.16

251.66

255.15

258.63

262.10

265.56

269.00

272.44

275.86

279.26

282.66

286.05

7

172.26

176.01

179.74

183.47

187.18

190.88

194.57

198.25

201.91

205.57

209.21

212.84

216.46

220.07

223.66

227.25

230.82

234.38

237.93

241.47

244.99

248.51

252.01

255.50

258.98

262.45

265.90

269.35

272.78

276.20

279.61

283.00

286.39

8

172.63

176.38

180.12

183.84

187.55

191.25

194.94

198.61

202.28

205.93

209.57

213.20

216.82

220.43

224.02

227.61

231.18

234.74

238.28

241.82

245.35

248.86

252.36

255.85

259.33

262.79

266.25

269.69

273.12

276.54

279.95

283.34

286.72

9

173.01

176.75

180.49

184.21

187.92

191.62

195.31

198.98

202.64

206.30

209.94

213.56

217.18

220.79

224.38

227.96

231.53

235.09

238.64

242.17

245.70

249.21

252.71

256.20

259.67

263.14

266.59

270.03

273.46

276.88

280.29

283.68

287.06

10

173.38

177.13

180.86

184.58

188.29

191.99

195.67

199.35

203.01

206.66

210.30

213.93

217.54

221.15

224.74

228.32

231.89

235.45

238.99

242.53

246.05

249.56

253.06

256.55

260.02

263.49

266.94

270.38

273.80

277.22

280.63

284.02

287.40

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

81

Technical Data

RTDs

Tolerances for a 100

Platinum RTD per IEC 751-95

Temperature

Degree

(C)

-200

Class B

(C)1 (Ohm)

1.30

0.56

1.10

Temperature vs. Resistance

10 Copper

Tolerances for a 100

Platinum RTD per ASTM E1137-97

Tolerance

1/3 Class B

(C) (Ohm)

Temperature

Degree

(C)

Class A

(C)2 (Ohm)

0.48

0.55

0.24

-200

Class B

(C)1 (Ohm)

1.1

0.47

Tolerance

1/3 Class B

(C) (Ohm)

0.92

0.47

0.20

-100

0.80

0.32

0.60

0.24

0.35

0.14

-100

0.67

0.27

0.50

0.20

0.30

0.12

0.30

0.12

0.10

0.04

0.15

0.06

0.25

0.10

0.08

0.03

0.13

0.05

100

0.80

0.30

0.60

0.23

0.35

0.13

100

0.67

0.25

0.50

0.19

0.30

0.11

200

1.30

0.48

1.10

0.40

0.55

0.20

200

1.1

0.40

0.92

0.34

0.47

0.17

300

1.80

0.64

1.60

0.57

0.75

0.27

300

1.5

0.54

1.34

0.48

0.64

0.23

400

2.30

0.79

2.10

0.72

0.95

0.33

400

1.9

0.66

1.76

0.61

0.81

0.28

500

2.80

0.93

2.60

0.87

1.15

0.38

500

2.4

0.78

2.18

0.73

0.98

0.33

600

3.30

1.06

3.10

1.00

1.35

0.43

600

2.8

0.88

2.60

0.84

1.15

0.37

Notes: C=(.3+.005*[t])

1

C=(.15+.002*[t])

Notes: C=(.25+.0042*[t])

Tolerance Values as Function

of Temperature for a 100 RTD

per IEC 751 (1983)

C=(.13+.0017*[t])

Tolerance Values as Function

of Temperature for a 100 RTD

per ASTM E1137

4.0

2.0

3.0

3.0

2.5

2.5

Temperature vs. Resistance

120 Nickel

Resistance (ohms)

6.331

6.722

7.111

7.499

7.886

8.272

8.657

9.042

9.427

9.812

10.198

10.583

10.968

11.353

11.738

12.124

12.509

12.894

13.279

13.664

14.050

14.435

14.820

Temperature (C)

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

80

90

100

Resistance (ohms)

86.16

92.76

99.41

106.15

113.00

120.00

127.17

134.52

142.06

149.80

157.75

165.90

174.27

182.85

191.64

200.64

Temperature (C)

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

Resistance (ohms)

209.85

219.29

228.95

238.84

248.95

259.30

269.89

280.77

291.95

303.45

315.31

327.54

340.14

353.14

366.53

380.31

Temperature vs. Resistance

120 Nickel

400

350

1.5

2.0

2.5

C)

B(

C) lass

(

B

ss 1/3 C

Cla

)

s B(

( )

Clas

ss B

a

l

C

1 /3

A (C )

C la s s

C

2.0

1.5

1.0

0.5

Class A

-100

100

200

C

300

400

1.0

1/3

Cla

2.0

16.0

1.5

A(C)

Class B()

s

Cla s

)

ss B(

1/3 Cla

Class A()

0.5

0

-200

Temperature vs. Resistance

10 Copper per SAMA RC21-4-1973

1.5

0.5

0

600

ss

C

B(

ss

1.0

()

500

Cla

C)

B(

-100

100

200

300

400

500

14.0

1.0

300

Resistance ()

3.0

250

200

150

12.0

100

0.5

0

600

Resistance ()

3.5

0

-200

Temperature (C)

-70

-60

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

Class A

(C)2 (Ohm)

0.38

RTDs

10.0

50

8.0

0

-50

6.0

50

100

150

200

250

300

Temperature (C)

4.0

2.0

0

-100

-50

50

100

150

200

Temperature (C)

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

82

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

83

Technical Data

RTDs

Bridge Network Connections

Thermocouple Wire Size and Resistance Table

FIGURE C

FIGURE A

EXCITATION

LEAD RESISTANCE

EXCITATION

Rc

Ra

Rc

LEAD RESISTANCE

OUTPUT

OUTPUT

RTD

RTD

Rb

Rb

FOUR WIRE RESISTANCE TEMPERATURE DEVICE

TWO WIRE RESISTANCE TEMPERATURE DEVICE

FIGURE B

FIGURE D

ISA Type T

Copper/

Constantan

0.0186

0.0455

0.0735

0.117

0.1874

0.2991

0.4751

0.7526

1.204

1.9159

3.0431

ANSWER: 3 x .5894 = 1.7682 ohms

20 x .1466 = 2.932 ohms

Total

4.7002 ohms

ISA Type N

Nicrosil/

Nisil

0.0485

0.1225

0.1947

0.3100

0.4926

0.7812

1.2498

1.980

3.164

5.039

8.000

ISA Type S

PT-PT

10% RH

0.011

0.028

0.045

0.071

0.116

0.185

ISA Type R

PT-PT

13%RH

0.011

0.029

0.047

0.073

0.119

0.190

0.464

0.740

0.478

0.760

1.85

1.91

NOTE: Type S and R utilize extension lead wire type Copper/Copper 11.

Type B utilizes extension lead wire type Copper/Copper.

Rc

Rc

OUTPUT

LEAD RESISTANCE

80

LEADS

RTD

OUTPUT

RTD

ISA Type E

Chromel/

Constantan

0.0437

0.1099

0.1752

0.2775

0.4454

0.7030

1.1206

1.78

2.836

4.512

7.169

Thermocouple EMF Versus Temperature

Ra

Ra

ISA Type J

Iron/

Constantan

0.2185

0.0533

0.085

0.136

0.218

0.349

0.544

0.878

1.405

2.235

3.551

Resistance in Ohms per Double Foot at 68 F. For explanation

of how to use this table, see Example:

EXAMPLE: What is the external resistance to my instrument if

I use a 20 gauge Chromel/Alumel thermocouple 3 feet long

and 14 gauge Chromel/Alumel lead wire 20 feet in length?

EXCITATION

EXCITATION

ISA Type K

Chromel/

Alumel

0.0365

0.0916

0.1466

0.2331

0.3706

0.5894

0.9368

1.4901

2.3811

3.768

5.984

Diameter

Inches

0.1285

0.0808

0.0641

0.0508

0.0403

0.0320

0.0253

0.0201

0.0159

0.0126

0.0100

AWG No

8

12

14

16

18

20

22

24

26

28

30

SWITCHING NETWORK

Ra

Thermocouples

70

Rb

Rb

60

K

FOUR WIRE RESISTANCE TEMPERATURE DEVICE

Millivolts

THREE WIRE RESISTANCE TEMPERATURE DEVICE

50

40

30

R

S

20

B

10

2400

2300

2200

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

Temperature (C)

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

84

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

85

Technical Data

Thermocouples

Thermocouple Characteristics Table

SP

SN

Generic

Names

Copper

Constantan, Nominal

Composition: 55% Cu, 45% Ni

Iron

Constantan, Nominal

Composition: 55% Cu, 45% Ni

Chromel, Nominal

Composition: 90% Ni, 10% Cr

Constantan, Nominal

Composition: 55% Cu, 45% Ni

Chromel, Nominal

Composition: 90% Ni, 10% Cr

Alumel, Nominal

Composition:

95% Ni, 2% Mn, 2% Al

Nicrosil, Nominal

Compositions: 84.6% Ni,

14.2% Cr, 1.4% Si

Nisil, Nominal

Composition: 95.5% Ni,

4.4% Si, 1% Mg

Platinum 10% Rhodium

Pure Platinum

RP

RN

C*

ANSI/ASTM

T

Symbol

Single

TP

TN

JP

JN

EP

EN

KP

KN

NP

NN

Tolerance of Thermocouples

Color Coding

Overall Jacket

Individual

Extension

Conductor

Grade Wire

Blue

Blue

Red

White

Red

Black

Purple

Purple

Magnetic

Yes/No

X

X

X

X

X

Red

Yellow

Environment

(Bare Wire)

Mild Oxidizing, Reducing.

Vacuum or Inert. Good where moisture is present.

Reducing Vacuum, Inert.

Limited use in oxidizing at High Temperatures.

Not recommended for low temps.

Oxidizing or Inert. Limited

use in Vacuum or Reducing.

X

Yellow

Red

Orange

ANSI/ASTM

T

Clean Oxidizing and Inert.

Limited use in Vacuum or Reducing.

Clean Oxidizing and Inert.

Limited use in Vacuum or Reducing.

Orange

Red

Black

Red

Green

X

X

Platinum 13% Rhodium

Pure Platinum

Black

Red

Green

X

X

BP

BN

Platinum 30% Rhodium

Platinum 6% Rhodium

Gray

Red

Gray

X

X

P

N

Tungsten 5% Rhenium

Tungsten 26% Rhenium

Green

Red

Red

X

X

Blue

Red

White

Red

Purple

Red

Yellow

Red

Orange

Red

Brown

R or S

B

C*

Oxidizing or Inert Atmospheres.

Do not insert in metal tubes.

Beware of contamination.

Oxidizing or Inert Atmospheres.

Do not insert in metal tubes.

Beware of contamination.

Oxidizing or Inert Atmospheres.

Do not insert in metal tubes.

Beware of contamination.

Vacuum, Inert, Hydrogen

Atmospheres. Beware of Embrittlement.

J

E

K

N

TP (+)

TN (-)

JP (+)

JN (-)

EP (+)

EN (-)

KP (+)

KN (-)

NP (+)

NN (-)

Copper

Constantan

Iron

Constantan

Chromel

Constantan

Chromel

Alumel

Nicrosil

Nisil

Temperature Range

-200 to -67

-67 to -62

-62 to 125

125 to 133

133 to 370

0 to 275

275 to 293

293 to 760

-200 to -170

-170 to 250

250 to 340

340 to 870

-200 to -110

-110 to 0

0 to 275

275 to 293

293 to 1260

0 to 275

275 to 293

293 to 1250

0 to 600

600 to 1480

870 to 1700

0 to 426

426 to 2315

C

Standard

1.5% T

1

1

1

0.75% T

2.2

2.2

0.75% T

1% T

1.7

1.7

0.5% T

2% T

2.2

2.2

2.2

0.75% T

2.2

2.2

0.75% T

1.5

0.25% T

0.5% T

4.4

1% T

Special

0.8% T*

0.8% T*

0.5

0.4% T

0.4% T

1.1

0.4% T

0.4% T

1*

1*

0.4% T

0.4% T

1.1

0.4% T

0.4% T

1.1

0.4% T

0.4% T

0.6

0.1% T

0.25%

Temperature Range

-328 to -88

-88 to -80

-80 to 257

257 to 272

272 to 700

32 to 527

527 to 560

560 to 1400

-328 to -274

-274 to 482

482 to 644

644 to 1600

-328 to -166

-166 to 32

32 to 527

527 to 560

560 to 2300

32 to 527

527 to 560

560 to 2300

32 to 1112

1112 to 2700

1600 to 3100

32 to 800

800 to 4200

F

Standard

1.5% (T-32)

1.8

1.8

1.8

0.75% (T-32)

3.96

3.96

0.75% (T-32)

1% (T-32)

3.06

3.06

0.5% (T-32)

2% (T-32)

3.96

3.96

3.96

0.75% (T-32)

3.96

3.96

0.75% (T-32)

2.7

0.25% (T-32)

0.5% (T-32)

8

1% (T-32)

Special

0.8% (T-32)*

0.8% (T-32)*

0.9 *

0.4% (T-32)

0.4% (T-32)

1.98

0.4% (T-32)

0.4% (T-32)

1.8*

1.8*

0.4% (T-32)

0.4% (T-32)

1.98

0.4% (T-32)

0.4% (T-32)

1.98

0.4% (T-32)

0.4% (T-32)

1.08

0.1% (T-32)

0.25% (T-32)

1.8

4.0

3.0

4.0

4.0

9.0

9.0

7.6

6.7

0.110 mV

0.9

2.0

1.8

2.0

2.0

Tolerances of Thermocouple Extension Wire

TX

JX

EX

KX

NX

SX

RX

BX1

B2

C

Thermocouple Extension Wire Characteristics

T

Thermocouples

Brown

-60

0

0

0

0

0

0

0

0

0

to

to

to

to

to

to

to

to

to

to

100

200

200

200

200

200

200

200

100

200

1.0

2.2

1.7

2.2

2.2

5.0

5.0

4.2

3.7

0.110 mV

0.5

1.1

1.0

1.1

1.1

-75

32

32

32

32

32

32

32

32

32

to

to

to

to

to

to

to

to

to

to

200

400

400

400

400

400

400

400

400

400

Special tolerance grade compensating extension wires are not available.

Proprietary alloy compensating extension wire is available for use over a wide temperature range.

2

Special compensating extension wires are not necessary with Type B over the limited temperature range 0 to 50 C (32 to 125 F), where the use of non-compensated

(copper/copper) conductors introduces no significant error. For a somewhat larger temperature gradient of 0 to 100 C (32 to 210 F) across the extension portion of the circuit, the

use of non-compensated (copper/copper) extension wires may result in small errors, the magnitude of which will not exceed the tolerance values given in the table above for

measurements above 100 C (1800 F).

*Special tolerances below 0 C (32 F) are unofficial and are provided as a basis of discussion between Conax and our customers.

Type C was previously designated as W5.

Brown

Brown

Brown

*Type C was previously designated as W5.

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

86

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

87

Technical Data

General Information

Temperature Conversion Chart

Common Thermometry Fixed Points

Enter the table in the center column of bold face type marked Temp with the temperature either Celsius or Fahrenheit that you

wish to convert into the other scale. If converting from Fahrenheit to Celsius, the equivalent temperature will be found in the

column to the left, and if converting from Celsius to Fahrenheit, the equivalent temperature will be found in the column to the right.

Fixed Points from the Practical International

Temperature Scale ITS-90

Celsius=5/9(F-32)

C

-17.8

-17.2

-16.7

-16.1

-15.6

-15.0

-14.4

-13.9

-13.3

-12.8

-12.2

-11.7

-11.1

-10.6

-10.0

-9.4

-8.9

-8.3

-7.8

-7.2

-6.7

-6.1

-5.6

-5.0

-4.4

-3.9

-3.3

-2.8

-2.2

-1.7

-1.1

-0.6

0.0

0.6

1.1

1.7

2.2

2.8

3.3

3.9

4.4

5.0

5.6

6.1

6.7

7.2

Temp

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

F

32.0

33.8

35.6

37.4

39.2

41.0

42.8

44.6

46.4

48.2

50.0

51.8

53.6

55.4

57.2

59.0

60.8

62.6

64.4

66.2

68.0

69.8

71.6

73.4

75.2

77.0

78.8

80.6

82.4

84.2

86.0

87.8

89.6

91.4

93.2

95.0

96.8

98.6

100.4

102.2

104.0

105.8

107.6

109.4

111.2

113.0

Fahrenheit=9/5(C)+32

C Temp F

7.8

46 114.8

8.3

47 116.6

8.9

48 118.4

9.4

49 120.2

10.0 50 122.0

10.6 51 123.8

11.1 52 125.6

11.7 53 127.4

12.2 54 129.2

12.8 55 131.0

13.3 56 132.8

13.9 57 134.6

14.4 58 136.4

15.0 59 138.2

15.6 60 140.0

16.1 61 141.8

16.7 62 143.6

17.2 63 145.4

17.8 64 147.2

18.3 65 149.0

18.9 66 150.8

19.4 67 152.6

20.0 68 154.4

20.6 69 156.2

21.1 70 158.0

21.7 71 159.8

22.2 72 161.6

22.8 73 163.4

23.3 74 165.2

23.9 75 167.0

24.4 76 168.8

25.0 77 170.6

25.6 78 172.4

26.1 79 174.2

26.7 80 176.0

27.2 81 177.8

27.8 82 179.6

28.3 83 181.4

28.9 84 183.2

29.4 85 185.0

30.0 86 186.8

30.6 87 188.6

31.1 88 190.4

31.7 89 192.2

32.2 90 194.0

32.8 91 195.8

Kelvin=C+273.15

C Temp

F

33.3

92

197.6

33.9

93

199.4

34.4

94

201.2

35.0

95

203.0

35.6

96

204.8

36.1

97

206.6

36.7

98

208.4

37.2

99

210.2

37.8 100 212.0

43.3 110 230.0

48.9 120 248.0

54.4 130 266.0

60.0 140 284.0

65.6 150 302.0

71.1 160 320.0

76.7 170 338.0

82.2 180 356.0

87.8 190 374.0

93.3 200 392.0

98.9 210 410.0

100.0 212 413.6

104.4 220 428.0

110.0 230 446.0

115.6 240 464.0

121.1 250 482.0

126.7 260 500.0

132.2 270 518.0

137.8 280 536.0

143.3 290 554.0

148.9 300 572.0

154.4 310 590.0

160.0 320 608.0

165.6 330 626.0

171.1 340 644.0

176.7 350 662.0

182.2 360 680.0

187.8 370 698.0

193.3 380 716.0

198.9 390 734.0

204.4 400 752.0

210.0 410 770.0

215.6 420 788.0

221.1 430 806.0

226.7 440 824.0

232.2 450 842.0

237.8 460 860.0

Rankine=F+459.67

C Temp F

243.3 470 878.0

248.9 480 896.0

254.4 490 914.0

260.0 500 932.0

265.6 510 950.0

271.1 520 968.0

276.7 530 986.0

282.2 540 1004.0

287.8 550 1022.0

293.3 560 1040.0

298.9 570 1058.0

304.4 580 1076.0

310.0 590 1094.0

315.6 600 1112.0

321.1 610 1130.0

326.7 620 1148.0

332.2 630 1166.0

337.8 640 1184.0

343.3 650 1202.0

348.9 660 1220.0

354.4 670 1238.0

360.0 680 1256.0

365.6 690 1274.0

371.1 700 1292.0

376.7 710 1310.0

382.2 720 1328.0

387.8 730 1346.0

393.3 740 1364.0

398.9 750 1382.0

404.4 760 1400.0

410.0 770 1418.0

415.6 780 1436.0

421.1 790 1454.0

426.7 800 1472.0

432.2 810 1490.0

437.8 820 1508.0

443.3 830 1526.0

448.9 840 1544.0

454.4 850 1562.0

460.0 860 1580.0

465.6 870 1598.0

471.1 880 1616.0

476.7 890 1634.0

482.2 900 1652.0

487.8 910 1670.0

493.3 920 1688.0

C Temp

F

498.9 930 1706.0

504.4 940 1724.0

510.0 950 1742.0

515.6 960 1760.0

521.1 970 1778.0

526.7 980 1796.0

532.2 990 1814.0

537.8 1000 1832.0

548.9 1020 1868.0

560.0 1040 1904.0

571.1 1060 1940.0

582.2 1080 1976.0

593.3 1100 2012.0

604.4 1120 2048.0

615.6 1140 2084.0

626.7 1160 2120.0

637.8 1180 2156.0

648.9 1200 2192.0

660.0 1220 2228.0

671.1 1240 2264.0

682.2 1260 2300.0

693.3 1280 2336.0

704.4 1300 2372.0

715.6 1320 2408.0

726.7 1340 2444.0

737.8 1360 2480.0

748.9 1380 2516.0

760.0 1400 2552.0

771.1 1420 2588.0

782.2 1440 2624.0

793.3 1460 2660.0

804.4 1480 2696.0

815.6 1500 2732.0

826.7 1520 2768.0

837.8 1540 2804.0

848.9 1560 2840.0

860.0 1580 2876.0

871.1 1600 2912.0

882.2 1620 2948.0

893.3 1640 2984.0

904.4 1660 3020.0

915.6 1680 3056.0

926.7 1700 3092.0

937.8 1720 3128.0

948.9 1740 3164.0

960.0 1760 3200.0

C

Temp

F

971.1 1780 3236.0

982.2 1800 3272.0

993.3 1820 3308.0

1004.4 1840 3344.0

1015.6 1860 3380.0

1026.7 1880 3416.0

1037.8 1900 3452.0

1048.9 1920 3488.0

1060.0 1940 3524.0

1071.1 1960 3560.0

1082.2 1980 3596.0

1093.3 2000 3632.0

1098.9 2010 3650.0

1104.4 2020 3668.0

1110.0 2030 3686.0

1115.6 2040 3704.0

1121.1 2050 3722.0

1126.7 2060 3740.0

1132.2 2070 3758.0

1137.8 2080 3776.0

1143.3 2090 3794.0

1148.9 2100 3812.0

1154.4 2110 3830.0

1160.0 2120 3848.0

1165.6 2130 3866.0

1171.1 2140 3884.0

1176.7 2150 3902.0

1182.2 2160 3920.0

1187.8 2170 3938.0

1193.3 2180 3956.0

1198.9 2190 3974.0

1204.4 2200 3992.0

1210.0 2210 4010.0

1215.6 2220 4028.0

1221.1 2230 4046.0

1226.7 2240 4064.0

1232.2 2250 4082.0

1237.8 2260 4100.0

1243.3 2270 4118.0

1248.9 2280 4136.0

1254.4 2290 4154.0

1260.0 2300 4172.0

1265.6 2310 4190.0

1271.1 2320 4208.0

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

88

General Information

Triple Point of Hydrogen

Boiling Point of Hydrogen

Triple Point of Neon

Triple Point of Oxygen

Triple Point of Argon

Triple Point of Mercury

Triple Point of Water

Melting Point of Gallium

Freezing Point of Indium

Freezing Point of Tin

Freezing Point of Zinc

Freezing Point of Aluminum

Freezing Point of Silver

Freezing Point of Gold

Freezing Point of Copper

C

-259.35

-256.15

-248.59

-218.79

-189.34

-38.83

0.01

29.76

156.59

231.93

419.53

660.32

961.78

1064.18

1084.62

F

-434.82

-429.07

-415.47

-361.82

-308.81

-37.90

32.02

85.57

313.86

449.47

787.15

1220.58

1763.20

1947.52

1984.32

NEMA Standard Definitions

TYPE 4

Type 4 enclosures are intended for indoor or

outdoor use primarily to provide a degree of

protection against windblown dust and rain,

splashing water, hose-directed water and external

ice formation.

TYPE 4X

Type 4X enclosures are intended for indoor or

outdoor use primarily to provide a degree of

protection against corrosion, windblown dust and

rain, splashing water, hose-directed water, and

external ice formation.

TYPE 7

Type 7 enclosures are intended for use indoors in

locations classified as Class I, Groups A, B, C, or

D as defined in the National Electrical Code.

American Wire Gauge Size To Inches

American Wire

Gauge (AWG)

6/0

5/0

4/0

3/0

2/0

1/0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Size O.D

Inches

0.5800

0.5165

0.4600

0.4096

0.3648

0.3249

0.2893

0.2576

0.2294

0.2043

0.1819

0.1620

0.1443

0.1285

0.1144

0.1019

0.0907

0.0808

0.0720

0.0641

0.0571

0.0508

0.0453

0.0403

0.0359

0.0320

0.0285

0.0253

American Wire

Gauge (AWG)

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Size O.D

Inches

0.0226

0.0201

0.0179

0.0159

0.0142

0.0126

0.0113

0.0100

0.00893

0.00795

0.00708

0.00630

0.00561

0.00500

0.00445

0.00396

0.00353

0.00314

0.00280

0.00249

0.00222

0.00198

0.00176

0.00157

0.00140

0.00124

0.00111

0.00099

Factors and Prefixes for Forming Decimal

Multiples and Sub-Multiples for the SI Units

Factor Prefix Symbol

1012

tera

T

109

giga

G

106

mega

M

103

kilo

k

hecto

h

102

Factor Prefix Symbol

10

deka

da

10-1

deci

d

-2

10

centi

c

10-3

milli

m

10-6 micro

m

Factor

10-9

10-12

10-15

10-18

Prefix Symbol

nano

n

pico

p

femto

f

atto

a

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

89

Technical Data

General Information

Corrosive Service Guide to Materials

Corrosive Service Guide to Materials

Chemical

Condition

Material

Chemical

Condition

Material

Acetic Acid

to 50% to 212 F

to 75% to 300 F

to 99% to 250 F

316 Stainless Steel

Titanium

Hastelloy C

Citric Acid

to 50% 212 F

All conc. to B.P.

316 Stainless Steel

Hastelloy C

All conc. to 212 F

304 Stainless Steel

Acetic Anhydride

All conc. to B.P.

Monel 400

All conc. to B.P.

316 Stainless Steel

Acetone

All conc. to B.P.

304 SS, Aluminum

to 212 F

304 Stainless Steel

Acetylene

Alcohol, Ethyl

304 SS, Aluminum

General Information

Copper Nitrate

Copper Sulphate

Cyanogen Gas

Dowtherm

C1018 Steel

Chemical

Condition

Material

Chemical

Condition

Material

to 37% and 150 F

Hastelloy B

Salicylic Acid

to 250 F

Nickel

70 F

304 Stainless Steel

Sodium Bicarbonate

to 20% and 212 F

304 Stainless Steel

to 800 F

304 Stainless Steel

Sodium Carbonate

to 25% and 212 F

304 Stainless Steel

Nickel Chloride

to 80% and 200 F

Hastelloy C

Sodium Chloride

Saturated to 212 F

Nickel Sulphate

25% and 125 F

304 Stainless Steel

316 Stainless Steel

Alloy 556

to 40% and 180 F

All conc. to 370 F

304 Stainless Steel

Tantalum

Sodium Fluoride

10% - 70 F

Monel 400

Muriatic Acid

Naphtha

Natural Gas

Nitric Acid

70 F 212 F

304 Stainless Steel

Aluminum Sulphate

to 25% and 212 F

to 50% and 212 F

304 Stainless Steel

316 Stainless Steel

Ethyl Acetate

to 150 F

Monel 400

Nitrobenzene

to 212 F

Carpenter 20CB3

Ammonia gas or liquid

All concentrations

304 Stainless Steel

Ferric Chloride

to 50% & B.P.

Tantalum

Oleic Acid

to 212 F

316 Stainless Steel

Sodium Peroxide

1100-1114 Aluminum

Ferric Sulphate

to 30% & B.P.

Hastelloy C

Oleum

to 70 F

316 Stainless Steel

Sodium Sulphate

to 25% and 212 F

304 Stainless Steel

All conc. to B.C.

Hastelloy C

Oxalic Acid

All conc. to 212 F

Monel 400

Sodium Sulphide

to 25% and 212 F

304 Stainless Steel

70 F

Liquid Oxygen

Elevated Temps.

C1018 Steel

304 Stainless Steel

304 Stainless Steel

Sodium Sulphite

5% to 212 F

304 Stainless Steel

Sulphur Dioxide

to 800 F

316 Stainless Steel

100% at 439 F

316 Stainless Steel

Sulphur

to 850 F

to 1600 F

316 Stainless Steel

Alloy 556

1-60%, 75-100%, 176 F

to 60% & B.P.

All conc. to 370 F

Carpenter 20CB3

Hastelloy B

Tantalum

Ammonium Hydroxide

Ether

304 Stainless Steel

Ammonium Phosphate

to 25% and 212 F

304 Stainless Steel

Ferrous Sulphate

Ammonium Nitrate

All conc. to 212 F

316 Stainless Steel

Formaldehyde

All conc. to 150 F

304 Stainless Steel

Ammonium Sulphate

All conc. to B.P.

to 45% and 212 F

316 Stainless Steel

Monel 400

Formic Acid

All conc. to 212 F

304 Stainless Steel

304 Stainless Steel

Gallic Acid

Amylacetate

Aniline

All concentrations

Freon

316 Stainless Steel

to 212 F

Gasoline or Petroleum

Oxygen

Palmitic Acid

Monel 400

Pentane

304 Stainless Steel

Phenol

304 Stainless Steel

Phosphoric Acid

304 Stainless Steel

Tannic Acid

to 212 F

304 Stainless Steel

to 212 F

316 Stainless Steel

Tartaric Acid

All conc. to 212 F

304 Stainless Steel

75% to 180 F

Hastelloy C

to 250 F

304 Stainless Steel

Potassium Carbonate

to 50% and 212 F

All conc. to B.P.

304 Stainless Steel

Hastelloy C

Barium Hydroxide

to 50% 212 F

C1018 Steel

Glycerine

304 Stainless Steel

Alloy 556

Glycerol

304 Stainless Steel

Hastelloy C

Hydrobromic Acid

40% to 65 F

48% to 212 F

Titanium

Hastelloy B

Monel 400

Hydrochloric Acid

to 37% and 150 F

Hastelloy B

316 Stainless Steel

Hydrofluoric Acid

All conc. to B.P.

Hastelloy C

Potassium Chlorate

to 25% and 212 F

316 Stainless Steel

Monel 400

Hydrogen Peroxide

to 212 F

316 Stainless Steel

Potassium Hydroxide

to 50% and B.P.

316 Stainless Steel

Copper, Aluminum

Hydrogen Sulphide

Dry to 1000 F

316 Stainless Steel

Potassium Nitrate

to 80% and 212 F

304 Stainless Steel

Iodine

to 70 F

Tantalum

Potassium Permanganate

to 50% and 75 F

Hastelloy C or Titanium

to B.P.

Aluminum, 316 SS

Potassium Sulphate

to 20% and 212 F

304 Stainless Steel

304 Stainless Steel

Pyrogallic Acid

All conc. to B.P.

304 Stainless Steel

Brines

Bromine Dry

Butane

Butylacetate

Monel 400, Hastelloy C

to 212 F

to 250 F

to 212 F

Butyl Alcohol

Calcium Chlorate

to 30% and 212 F

304 Stainless Steel

Calcium Hydroxide

to 50% and 212 F

Hastelloy C or Titanium

Ketones

Carbonic Acid

All conc. to 300 F

316 Stainless Steel

Kerosene

Carbon Dioxide

to 1300 F

304 Stainless Steel

Lactic Acid

Chlorine Gas

Moist to 212 F

Hastelloy C or Titanium

Chromic Acid

10% at 150 F

Hastelloy C

304 Stainless Steel

316 Stainless Steel

Hastelloy B

Glucose

All conc. to B.P.

316 Stainless Steel

10% & 70 F

to 90% and 215 F

Hastelloy C

Boracic Acid

Sulphuric Acid

Fused

316 Stainless Steel

25% to B.P.

Black Liquor

Sodium Nitrate

304 Stainless Steel

to 700 F

Barium Chloride

70 F

Sodium Hydroxide

Picric Acid

Potassium Bromide

to 212 F

Tantalum

Quinine Bisulphate

Dry

316 Stainless Steel

Magnesium Chloride

to 40% of 212 F

Monel 400

Quinine Sulphate

Dry

316 Stainless Steel

Magnesium Sulphate

to 50% 212 F

Monel 400

Sea Water

Toluene

Turpentine

304 Stainless Steel

Whiskey and Wine

316 Stainless Steel

Xylene

Copper

Zinc Chloride

to 25% and 130 F

All conc. to B.P.

Carpenter 20CB3

Monel 400

Zinc Sulphate

to 25% to 212 F

to 40% to B.P.

316 Stainless Steel

Hastelloy C

Monel 400

WARNING: The corrosive service material selection information provided in this table is to be used only as a guide. Thermowell application environment variations may affect

actual performance. Environment variations include process temperature, pressure, flow rate, concentration, purity and solids content. If you have questions relating to thermowell

performance in a specific application, we recommend that you contact the factory.

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

90

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

91

Technical Data

General Information

Speed of Response

General Information

Relative Magnitude of Pressure Differential

The purpose of the information on this page is to give you

some general guidelines in estimating the speed of response

you might expect from a thermocouple or an RTD.

a) the mass of the probe surrounding the active temperature

sensitive point

b) the thermoconductivity of materials used in manufacturing the

transducer

c) the mass and conductivity of the measured fluid

d) the velocity of the fluid over the probe

In defining any transient condition such as a temperature

change, it is important that a standard measuring point be

established to provide a basis of comparison. In temperature

transducers, the time constant is defined as the time required,

in seconds, for the temperature sensor to respond through

63.2% of the total temperature change.

From the above, it is obvious that a probe of small diameter

made of highly conductive materials will respond most rapidly

to temperature change. Since thermocouple materials will have

shorter conductive paths, a thermocouple probe will respond

more rapidly than an RTD probe of equal diameter. This is

verified by the bar charts:

The factors affecting the response rate of a temperature probe

in a fluid are:

Hundredth Seconds

3 4 5 6

Tenth Seconds

7 8 91

3 4

Vacuum Units of Measure

psia

Atmospheric Pressure

Gage

Pressure

(psig)

Absolute Pressure

Torr

mtorr

(mm Hg) (micron)

Pa

(N/m2)

14.696

760

760,000

101,292

0.193

1,000

133.28

1.93x10-5

1.00x10-3

0.133

Low Vacuum

Medium Vacuum

Atmospheric

Pressure

High Vacuum

Seconds

5 6 7 8 91

3 4

6 7 8 9 10

Absolute Vacuum

Thermocouples

Absolute

Pressure

(psia)

30 AWG Bare Wire B

24 AWG Bare Wire B

20 AWG Bare Wire B

18 AWG Bare Wire B

0.040" G

0.040" U

0.062" G

0.062" U

0.125" G

0.125" U

0.187" G

0.187" U

0.250" G

0.250" U

NPT Pipe Thread Sizes

Vacuum

Absolute

Vacuum

RTDs

0.125" Diameter

Pipe Size NPT

1/8

1/4

3/8

1/2

3/4

1

1-1/4

1-1/2

2

Pipe O.D.

0.405

0.540

0.675

0.840

1.050

1.315

1.660

1.900

2.375

0.187" Diameter

0.250" Diameter

.01

.02 .03

0.1

In determining time constants for the bar charts above, tests were

performed in still water going through an instantaneous step

change from 32 F to 212 F.

For guidelines for determining the time constant for specific

probes under other conditions, multiply the time constant from the

chart by the following factors:

0.2 0.3 0.4 0.5 0.6

Condition

Factor

Still Air

20X

3 4 5 6 7 8

Air @ 10 ft/Sec.

4X

Water @ 15 ft/Sec.

.25X

DIAMETER indicated in decimals refers to standard Conax Buffalo

probe diameters. Letters G, U and B correspond with various

styles of tip configurations.

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

92

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

93

Custom Design Sensor Form

Conax Buffalo can custom engineer special sensors, mountings and assemblies for virtually any application, with nearly limitless

combinations of termination styles, mounting methods and sealing assemblies. Many of our original custom designs become

industry standards. Our knowledgeable sales engineers welcome the opportunity to discuss your application and recommend

solutions. Complete this form and fax a copy to 716-684-7433 or call 1-800-223-2389.

Name:

Company:

Phone:

Fax:

E-mail:

Date:

Explain your application/need or sketch your assembly:

The following information would also be helpful, but is not mandatory:

Probe Diameter:

Probe Length:

Probe Material:

Maximum Service Temperature:

Maximum Pressure:

Mounting Method:

Termination Head Type:

Environment in which the sensor will be used:

For more information call: 1 - 8 0 0 - 2 2 3 - 2 3 8 9 e-mail: c o n a x b u f @ c o n a x b u f fa l o . c o m visit our website: w w w. c o n a x b u f fa l o . c o m

94

Vous aimerez peut-être aussi

- Iec 751 TermorezDocument2 pagesIec 751 TermorezMorosanu Andreea-DianaPas encore d'évaluation

- TD TempératureDocument2 pagesTD TempératureAyoub MarzakPas encore d'évaluation

- TABLE 30 100: Temperature in FDocument4 pagesTABLE 30 100: Temperature in Fpabloperezmtz1Pas encore d'évaluation

- PT100Document2 pagesPT100Константин ГордеевPas encore d'évaluation

- Tabla Pt100Document3 pagesTabla Pt100llargatu2419Pas encore d'évaluation

- Bài 1. Dòng chảy chất lỏngDocument11 pagesBài 1. Dòng chảy chất lỏngVy CaoPas encore d'évaluation

- Te Sensor Solutions Applicationnote Table RTD Resistance TemperatureDocument6 pagesTe Sensor Solutions Applicationnote Table RTD Resistance TemperatureMaulana RahmanPas encore d'évaluation

- Taller 1Document6 pagesTaller 1Nelson José Gómez PerezPas encore d'évaluation

- Pt100 TableDocument2 pagesPt100 Tablehs1986Pas encore d'évaluation

- Termoresistencia PT100Document2 pagesTermoresistencia PT100Engenharia - MAXSULPas encore d'évaluation

- PT100 - Tabela TermoresistenciaDocument2 pagesPT100 - Tabela TermoresistenciaJardel100% (1)

- TABLE 31 100: Temperature in CDocument2 pagesTABLE 31 100: Temperature in CMarvin ZuñigaPas encore d'évaluation

- Resposta Segunda Avaliação 2022 - 2Document5 pagesResposta Segunda Avaliação 2022 - 2Kelisson DinizPas encore d'évaluation

- Pt100 Resistance Chart A4Document5 pagesPt100 Resistance Chart A4jrnoel11Pas encore d'évaluation

- Termoresistenze Al Platino PT100 - Tabella Ohm - Gradi - CelsiusDocument3 pagesTermoresistenze Al Platino PT100 - Tabella Ohm - Gradi - CelsiusIulian MariusPas encore d'évaluation

- Termoresistenze Al Platino PT100 - Tabella Ohm - Gradi - Celsius PDFDocument3 pagesTermoresistenze Al Platino PT100 - Tabella Ohm - Gradi - Celsius PDFIulian MariusPas encore d'évaluation

- DATADocument1 pageDATAmarcoPas encore d'évaluation

- PT100 PT1000 TablesDocument4 pagesPT100 PT1000 TablesZawZawAung76Pas encore d'évaluation

- Perno Astm A325Document1 pagePerno Astm A325Cristian CortesPas encore d'évaluation

- Data Demo Lapisan MiringDocument33 pagesData Demo Lapisan MiringSulaiman NurhidayatPas encore d'évaluation

- SPECS For Switch SGE 1Document1 pageSPECS For Switch SGE 1Sharma DesignersPas encore d'évaluation

- SensorkennlinienDocument2 pagesSensorkennlinienHerbertPas encore d'évaluation

- 5217SUELDOS UNI MZO 2022 Segun INST 03 22Document2 pages5217SUELDOS UNI MZO 2022 Segun INST 03 22Franco PPas encore d'évaluation

- Thermocouple Instruments - PT100 Resistance TableDocument2 pagesThermocouple Instruments - PT100 Resistance Tablevettypiya100% (2)

- Temperature Curves V1Document1 pageTemperature Curves V1Roy VPas encore d'évaluation

- Circulo de Mohr CoulombDocument3 pagesCirculo de Mohr CoulombVictor QuispePas encore d'évaluation

- Erlang B TableDocument18 pagesErlang B TableAnjit RajkarnikarPas encore d'évaluation

- ErlangDocument18 pagesErlangprisha4Pas encore d'évaluation

- Hoja de MetradoDocument13 pagesHoja de MetradoJavier Antúnez AntúnezPas encore d'évaluation

- CalculosDocument1 pageCalculosPedro CesarPas encore d'évaluation

- Valeur Des Sondes LGDocument5 pagesValeur Des Sondes LGLAURENT RITTIPas encore d'évaluation

- DWM D8SJ1-6000-BWM-DDocument6 pagesDWM D8SJ1-6000-BWM-DaymanPas encore d'évaluation

- Encomendas PRATA 31.01.2022Document19 pagesEncomendas PRATA 31.01.2022fabio garciaPas encore d'évaluation

- PT1000電阻表Document3 pagesPT1000電阻表書淯張Pas encore d'évaluation

- Tableau Carraussels Plancia Euro 5Document38 pagesTableau Carraussels Plancia Euro 5Asebaho BadrPas encore d'évaluation

- Work ShopDocument2 pagesWork ShopDuncan KiokoPas encore d'évaluation

- Work ShopDocument2 pagesWork ShopDuncan KiokoPas encore d'évaluation

- I1profiler Pantalla de VerificaciónDocument2 pagesI1profiler Pantalla de VerificaciónFrancisco José SilvaPas encore d'évaluation

- Reservas FinalDocument182 pagesReservas FinalpronasubPas encore d'évaluation

- Grupo1 PortafolioDocument52 pagesGrupo1 PortafolioAdriana Paola Aparicio CastilloPas encore d'évaluation

- Daerp 82202110Document2 pagesDaerp 82202110Luiz Eduardo Liandro de OliveiraPas encore d'évaluation

- Tabel Desain PondasiDocument1 pageTabel Desain PondasiWang ColllPas encore d'évaluation

- Catalogo Donghua Cadenas VariasDocument46 pagesCatalogo Donghua Cadenas Variasj.arriolaPas encore d'évaluation

- AllDocument777 pagesAlldunglee160810Pas encore d'évaluation

- Encomendas-OURO-31 01 2022Document17 pagesEncomendas-OURO-31 01 2022fabio garciaPas encore d'évaluation

- HTTP ProxiesDocument18 pagesHTTP Proxieshevertz412Pas encore d'évaluation

- Valeurs Des Sondes Passives en Ohms - ts6300d Valeurs OhmiquesDocument2 pagesValeurs Des Sondes Passives en Ohms - ts6300d Valeurs OhmiquesjscmtPas encore d'évaluation

- TablesDocument20 pagesTablessara avendanoPas encore d'évaluation

- Ydq5 4 5683Document2 pagesYdq5 4 5683turbo385Pas encore d'évaluation

- Compte Rendu TP Mesure de TempératureDocument13 pagesCompte Rendu TP Mesure de Températurekhalfallah hamzaPas encore d'évaluation

- Dew Point Variables at PressureDocument1 pageDew Point Variables at PressurejaredPas encore d'évaluation

- Sujets de Théorie 1Document7 pagesSujets de Théorie 1titounanoPas encore d'évaluation

- Alphabetically: InstructionsDocument3 pagesAlphabetically: InstructionsquentinfollinaPas encore d'évaluation

- Vicia Faba (La Féve)Document85 pagesVicia Faba (La Féve)Martine FatouPas encore d'évaluation

- Carte Tiers Payant Thomas MoulignerDocument2 pagesCarte Tiers Payant Thomas MoulignerGUIARDEPas encore d'évaluation

- Esquema ElectricoDocument67 pagesEsquema ElectricoGonçalo Filipe SousaPas encore d'évaluation

- Are 2Document28 pagesAre 2Ndoumbe BaPas encore d'évaluation

- KOUMENDocument73 pagesKOUMENSerigne WadePas encore d'évaluation

- Appareil LocomoteurDocument2 pagesAppareil LocomoteurTASMINE HAMZAPas encore d'évaluation

- Camera Infrarouge PDFDocument11 pagesCamera Infrarouge PDFsensaadPas encore d'évaluation

- TP JarDocument4 pagesTP JarAY YàPas encore d'évaluation

- The Very Hungry CaterpillarDocument3 pagesThe Very Hungry Caterpillarkinito kPas encore d'évaluation

- Conception de Moule-2Document3 pagesConception de Moule-2elking gingstarsPas encore d'évaluation

- Cours 2 - Principales Caractéristiques Des VégétauxDocument29 pagesCours 2 - Principales Caractéristiques Des VégétauxMouhamadou DiopPas encore d'évaluation

- 3g Chimie TousDocument6 pages3g Chimie Tousapi-502752268Pas encore d'évaluation

- Animaux ExercicesDocument5 pagesAnimaux Exercicesmansouri100% (1)

- Physiopathologie NeuroscienceDocument46 pagesPhysiopathologie NeuroscienceYas MiiinaaPas encore d'évaluation

- Ca 203 FR 1501 - LRDocument4 pagesCa 203 FR 1501 - LRjlopezPas encore d'évaluation

- ProcrastinationDocument2 pagesProcrastinationBRAKNESSPas encore d'évaluation

- 3 As - Projet 2 - Le Débat DidéesDocument37 pages3 As - Projet 2 - Le Débat Didéesryad133192% (171)

- PEF Zizou Corriger - GENERAL - Khouloud Nchalla NejhaDocument56 pagesPEF Zizou Corriger - GENERAL - Khouloud Nchalla Nejhakhouloud rouissiPas encore d'évaluation

- Genie Civil Questions WatermarkDocument11 pagesGenie Civil Questions WatermarkBenhmaida HananPas encore d'évaluation

- Contentieux Du TravailDocument37 pagesContentieux Du Travailmarc soubeigaPas encore d'évaluation

- Whirlpool ADG 676 NBDocument12 pagesWhirlpool ADG 676 NBChristian AlbertiniPas encore d'évaluation

- Disjoncteur C60H-DC - A9N61522Document2 pagesDisjoncteur C60H-DC - A9N61522Paul DayPas encore d'évaluation

- PRAL Des Aliments Alcalinisants Et Acidifiants - InternetDocument10 pagesPRAL Des Aliments Alcalinisants Et Acidifiants - InternetsauvagePas encore d'évaluation

- Lenovo-Pc20200624145014 PDFDocument3 pagesLenovo-Pc20200624145014 PDFMOUMOUPas encore d'évaluation

- Préparation MentaleDocument19 pagesPréparation Mentaleardis murejPas encore d'évaluation