Académique Documents

Professionnel Documents

Culture Documents

14ARC2007 PP 191-196 Zein PDF

Transféré par

chatxxnoir0 évaluation0% ont trouvé ce document utile (0 vote)

9 vues6 pagesTitre original

14ARC2007 pp 191-196 Zein.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

9 vues6 pages14ARC2007 PP 191-196 Zein PDF

Transféré par

chatxxnoirDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 6

14me CRA MSG, Yaound, 26-28 Novembre 2007 14th ARC SMGE, Yaounde, 26-28 November 2007

RAPID DETERMINATION OF SOIL COMPACTION CHARACTERISTICS

USING MICROWAVE OVEN DRYING METHOD

MTHODE RAPIDE DE DTERMINATION DES CARACTRISTIQUES DE

COMPACTAGE DUN SOL LAIDE DUN FOUR MICRO-ONDES

Abdul Karim Mohammad ZEIN

Building and Road Research Institute (BRRI), Khartoum, Sudan

ABSTRACT This paper describes a practical, relatively fast and fairly accurate laboratory soil

compaction method that suits earthworks construction projects requiring high daily rates of filling.

The study is based on comparison of compaction test results obtained by the BS ordinary (2.5 kg

rammer) test and a non-standard rapid test procedure involving the determination of soil moisture

content by microwave drying technique. Seventy one soil sample pairs representing various types

including sands (SP, SM and SC) and clays of variable plasticity degrees (CL to CH) were tested in

this study. Statistical regression analysis of test data revealed very good relationships between the

compaction optimum moisture content and maximum dry density values obtained from the

standard and rapid methods.

RSUM Cet article dcrit une mthode pratique, rapide et fiable, de compactage en laboratoire,

destine au suivi de la construction des remblais, dont les volumes journaliers de mise en oeuvre

sont souvent trs importants. Ltude est base sur une comparaison entre les rsultats dessais

classiques BS (masse de 2.5 kg), et ceux dun processus plus rapide mais non standardis, qui

dtermine les teneurs en eau par schage des matriaux au four micro ondes. Soixante et onze

chantillons de matriaux divers, comprenant plusieurs varits de sables, ainsi que des sols

argileux avec des plasticits diffrentes ont t tests. Il en ressort une bonne corrlation entre les

densits et les teneurs en eau optimales des essais classiques et ceux de la mthode rapide.

1. Introduction

Soil compaction is one of the most critical components in the construction of dam embankments,

roads, airfield strips and foundations. In the construction of such earthworks, the compaction

control of the soil requires comparison of fill moisture content and dry density values obtained in

field density tests with optimum moisture content (w

opt

) and maximum dry density (

dmax

)

determined for the same fill material in the laboratory following standard compaction test methods.

For fine-grained or coarse-grained soils with appreciable fines content, field results are compared

with laboratory compaction tests performed according to procedures presented in the BS, ASTM,

DIN and other widely recognised standards, as well as the locally accepted standards.

Performance of a standard laboratory compaction test on material from each field density test point

would give the most accurate relation of the in-place material to the optimum water content and

maximum dry density. However, this is not generally feasible because testing could not keep pace

with the rate of filling. Nonetheless, standard compaction tests should be performed during

construction when:

an insufficient number of compaction curves were developed during the design phase;

borrow material is obtained from a new source, and

material similar to that being placed has not been tested previously.

In any event, standard laboratory compaction tests should be performed periodically on each

type of fill material (preferably one test for every ten field density tests) to check the optimum water

content and maximum dry density values used for correlation with the field density test results.

In addition to standard compaction methods, the construction of earthworks requiring high rates

of filling normally necessitates the use of rapid methods for determining the compaction

characteristics of the placed construction materials, to provide good approximation of optimum

water content and maximum dry density obtained from standard test results.

This paper presents the findings of a comparative experimental investigation aiming at

establishing the relationship between the compaction characteristics of soils determined by two

different procedures of laboratory test further referred to as the standard and rapid compaction

191

14me CRA MSG, Yaound, 26-28 Novembre 2007 14th ARC SMGE, Yaounde, 26-28 November 2007

methods. The standard compaction method adopted for comparison is the widely used BS ordinary

(2.5 kg rammer) laboratory test known also as standard Proctor test, whereas the rapid one is a

non-standardized compaction method developed during the construction phase of a major

embankment dam project in Sudan. The basic difference between the two compaction test

procedures is in the method of drying soil specimens during testing: the soil moisture content is

determined in the rapid compaction test by drying soil in a calibrated microwave oven as opposed

to the conventional 24 hrs drying oven method normally used in the standard compaction test

procedure.

Details of the rapid compaction method developed and the discussion of the results of the

compaction tests performed in this comparative study are described in the following sections.

2. Determination of soil moisture content by the microwave oven drying method

Microwave energy may be used for drying soil samples rapidly and thus enabling quick

determination of moisture content (ASTM, 1989). However, before applying the microwave drying

method on routine basis for soil moisture content determination, it is necessary to establish for

each soil type the correlation between the data determined by this method and by the conventional

oven method used in the standard compaction test. To achieve this objective, several test series

were planned and performed on many samples prepared from the soil types considered in this

study at widely different moisture contents. Two different microwave oven models of the rotating

table type were used for the study purpose to dry a large number of soil specimens representing

different soil types and conditions and the same results were obtained in both cases. The best

correlations with the definitive standard moisture content determination method were established

when drying times of 7 and 9 minutes were selected after many calibration trials for sandy and

clayey soil samples respectively in the microwave oven.

Details of the comparison study results and the findings drawn from the analysis of the moisture

content test data corresponding to the sandy and clayey soils are described in a separate

publication (Zein, 2002) but a summary of the main study findings is presented in the following

sections for sandy and clayey soil types respectively.

2.1 Moisture content correlation for sandy soils

Moisture content tests were performed by the standard and the microwave oven methods on 106

sample pairs of clean sand (SP/SW) and 139 sample pairs of silty and clayey sand (SM/SC) soil

types. Eight identical (50g in mass) specimens were prepared from each soil sample; five of which

were dried in the microwave oven for 7 minutes and three in the conventional oven for 24 hours.

The moisture content test results were analysed by statistical regression to define the

mathematical relationship between the data obtained according to the two different methods.

Similar correlation equations were obtained for the SP and the SM/SC soils with regression

correlation coefficient (R

2

) values very close to unity (0.986 to 0.996), thus indicating an excellent

correlation of the moisture content data determined by the standard and the microwave methods. A

single moisture content correlation relationship (with R

2

=0.994) was therefore proposed between

the standard moisture content (w

s

) and the microwave moisture content (w

m

) based on test data of

all sandy soils (245 sample pairs) tested (equation 1):

w

m

= 0.999 w

s

+ 0.11 (1)

This combined moisture content equation was developed for sandy soils (SP, SM and SC types)

with moisture content values ranging from 2.5 to 25.0 %.

2.2 Clay soils with variable degree of plasticity

Similarly, a large number of moisture content comparison tests were carried out on clay soils of

different initial moisture contents including clay samples of low plasticity (CL), intermediate

plasticity (Cl), high plasticity (CH) and very high plasticity (CV). For each sample, five specimens

were tested in the microwave oven for 9 minutes and three in the conventional oven for 24 hrs.

Statistical analysis of the data was carried out using the linear regression method for each clay

type separately. The moisture content correlation equations established between the two test data

for the clays with variable degree of plasticity were practically similar with correlation coefficient

192

14me CRA MSG, Yaound, 26-28 Novembre 2007 14th ARC SMGE, Yaounde, 26-28 November 2007

(R

2

) values ranging between 0.98 and 0.99. In practical terms, it would be desirable and preferable

to have a single moisture content correlation for all clay types as the use of individual correlation

equations would require pre-classification of each material tested which may not be known in all

instances. Based on this, the moisture content data measured in all clay soil types (451 sample

pairs) were used to develop the following combined correlation equation with R

2

=0.986:

w

m

=1.02 w

s

+ 0.96 . (2)

3. Rapid compaction test method

3.1 Preamble

Quick and good approximation of compaction characteristics of soils may be achieved by means of

few empirical methods, such as the one-point and two-point compaction methods developed in

some countries and accepted by certain authorities e.g. the USBR (U.S. Bureau of Reclamation).

In these two rapid compaction methods, material from the field density test is allowed to dry with

thorough mixing to obtain uniform moisture content on the dry side of estimated optimum value and

then compacted using the same apparatus and procedure used in the standard five/six points

compaction test. The moisture content and dry density of the compacted sample are then used to

estimate the optimum water content and maximum dry density values from the line of optimums

drawn on a predetermined chart consisting of compaction curves which are approximately parallel

to each other. However, these methods are only useful when the basic compaction curves define a

relatively good line of optimums. Appreciable inaccuracy in results may occur in one-point and two-

point methods if attempts are made to extrapolate optimum water content and maximum dry

density from non-uniform families of compaction curves (US Department of Army and Air Force,

1983)

In the present investigation, an attempt was made to develop an alternative quick compaction

test that enables relatively fast and reasonably accurate determination of the optimum water

content and maximum dry density values for clays and sands with appreciable fines. The main

purpose was to use this rapid test for control of field compaction in order to check within a

reasonable time whether the fill material placement acceptance criterion is met or not. The sample

preparation and procedure of the rapid compaction method proposed for use as a quality control

test are described in the following section.

3.2 Soil sample preparation and testing procedure

A bulk soil sample of about 30 kg in mass was taken from the fill materials placed in the field and

divided into two approximately equal portions and each was prepared differently as described

below for the two compaction test methods.

3.1.1. Standard compaction test method

The first sample portion was broken down into small lumps and left to dry in the air. After air drying,

the sample was further broken down to about 5 mm size and then sub-divided into six equal sub-

samples each weighing approximately 2 kg. Distilled water was added to each sub-sample in

different quantities so as to obtain a range of moisture content that is likely to encompass the

optimum water content value of the soil. Each sub-sample was then thoroughly mixed by hand in a

tray and was then placed in an airtight plastic bag and left overnight to cure.

The standard soil compaction procedure designated in the British standards (BS 1377, 1990) as

the BS Ordinary (2.5 kg rammer) method was followed in this test. All sub-samples prepared

differently, as described in Section 3.2.1, were compacted in a standard 1 litre compaction mould

in three layers of approximately equal mass; each receiving 27 rammer blows. The moisture

content of the tested soil specimens was determined after drying them at a temperature of 105-

110 C inside a conventional oven for 16-24 hours time. The compaction curves were plotted for

each soil type and the corresponding optimum water content and maximum dry density values

were determined. The standard compaction test was performed as described above on 71 soil

samples.

193

14me CRA MSG, Yaound, 26-28 Novembre 2007 14th ARC SMGE, Yaounde, 26-28 November 2007

3.1.2. Rapid compaction test method

The second soil sample portion was taken to the laboratory at its original (placement or natural)

moisture content and divided into five sub-samples after being broken down by hand into small

lumps with maximum size of 20 mm. One sub-sample was stored at its original moisture content in

a closed plastic bag, whereas distilled water was added in variable quantities to the remaining four

sub-samples to give a moisture content range encompassing the optimum water content value.

These sub-samples were thoroughly mixed with water by hand and allowed to cure in closed

plastic bags for about three hours. These samples were then compacted using the same

apparatus, compaction energy and procedure used in the standard method described in section

3.2.1. The moisture content of the soil specimens was determined by rapid drying in the microwave

oven for 7 minutes in sandy soil samples and for 9 minutes in clayey soil samples. The type of

microwave oven regularly used in this investigation for drying tested soil samples was a rotating

table National Electronics Co. (J apan) make, Model No. 6550.

The equivalent standard moisture content values were computed from the determined microwave

oven moisture content test data according to Equations (1) and (2) for the sandy and clayey soils

respectively. The rapid compaction test was performed on the second pairs of the same 71 soil

samples tested by the standard method as stated in section 3.2.1. The compaction curves were

drawn for each of the soil samples tested according to this compaction procedure and the

corresponding values of the optimum water content and maximum dry density were determined.

4. Discussion of compaction test results

The soils samples tested in this investigation covered a wide range in terms of their type and

placement conditions. According to the Unified System of Classifying Soils, these soils belong to

the SM, SC, CL and CH groups.

The compaction curves were used to determine the optimum water content and maximum dry

density values for each sample pair tested by the standard and the rapid test methods. Simple

statistical data of compaction test obtained for the 71 sample pairs tested according to the

standard and rapid methods are given in Table 1.

Table 1. Ranges, average values and standard deviation of compaction optimum water contents

and maximum dry densities of the tested soils

Compaction test Standard method Rapid method

Compaction property w

opt

(%)

dmax

(Mg/m

3

) w

opt

(%)

dmax

(Mg/m

3

)

Range 13.0-26.8 1.47-1.88 10.0-25.9 1.45-1.90

Average value 21.1 1.62 21.7 1.61

Standard deviation 4.2 0.12 4.2 0

It is interesting to note from the data given in Table 1 that the two different compaction methods

yielded practically the same values of the average optimum water content w

opt

and the average

maximum dry density

dmax

as well as the standard deviation values for the same compaction

properties.

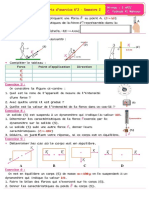

To compare the test results, the optimum water content and maximum dry density values

determined by the standard and the rapid compaction methods were plotted against each other in

Figures 1 and 2, respectively, for the 71 sample pairs tested. The trends indicated in both figures

show that there is a good agreement between the two sets of results pertaining to the two different

compaction test procedures. The degree of data scatter is generally small, as may be noted in

Figures 1 and 2, but it is more significant in the case of clayey soils (CL, CH types) which are

known to exhibit higher optimum water contents and lower maximum dry densities, as compared to

those normally achieved in sandy soils.

A good consistency between the two sets of data was also indicated by the coincidence of the

frequency curves plotted using results from both compaction test methods for optimum water

content values lower than 20% and maximum dry density values higher than 1.63 Mg/m

3

of the

tested soil types. These optimum water content and maximum dry density values are typical of

coarse grained materials represented by the SP/SW and SM/SC soil types.

194

14me CRA MSG, Yaound, 26-28 Novembre 2007 14th ARC SMGE, Yaounde, 26-28 November 2007

Statistical analysis was performed on the standard and rapid compaction test data shown

graphically in Figures 1 and 2 by regression methods to establish the relationship between the two

sets of data in mathematical forms and evaluate the degree of correlation between them. The

regression analysis carried out revealed that the compaction properties (OMC and MDD)

determined by the standard and rapid compaction test compare favourably for the sandy and

clayey soil types considered in the present study.

8

10

12

14

16

18

20

22

24

26

28

8 10 12 14 16 18 20 22 24 26 28

O

p

t

i

m

u

m

w

a

t

e

r

c

o

n

t

e

n

t

(

S

t

a

n

d

a

r

d

m

e

t

h

o

d

)

,

%

Optimum water content (Rapid method), %

Figure 1. Relationship between the optimum water contents obtained by the standard and the rapid

compaction methods

1.40

1.45

1.50

1.55

1.60

1.65

1.70

1.75

1.80

1.85

1.90

1.95

2.00

1.40 1.45 1.50 1.55 1.60 1.65 1.70 1.75 1.80 1.85 1.90 1.95 2.00

Maximum dry density (Rapid method), Mg/m

3

M

a

x

i

m

u

m

d

r

y

d

e

n

s

i

t

y

(

S

t

a

n

d

a

r

d

m

e

t

h

o

d

)

,

M

g

/

m

3

Figure 2. Relationship between the maximum dry densities obtained by the standard and the rapid

compaction methods

The relationships between the optimum water content w

opt

and the maximum dry density

dmax

determined according to the two compaction tests may be expressed by the following two

equations:

(w

opt

)

s

=1.7556 (w

opt

)

r

0.8083

, (3)

(

dmax

)

s

=0.8794 (

dmax

)

r

+0.2018 . (4)

195

14me CRA MSG, Yaound, 26-28 Novembre 2007 14th ARC SMGE, Yaounde, 26-28 November 2007

The subscripts s and r in above equations denote the standard and rapid compaction tests

respectively and reasonably high correlation coefficients (R

2

) of 0.86 and 0.92 were obtained for

the optimum water content and maximum dry density data respectively, indicating close

relationships between the results of the two compaction methods.

Equations 3 and 4 are of empirical nature and may be used to estimate the standard compaction

characteristics, which normally take relatively long time to determine (typically 3 to 4 days), from

the rapid compaction data, which can be obtained within a much shorter time (3 to 6 hours). This

information is desirable to be known in many cases for quality control evaluation at the various

construction stages of earthworks, including material selection, preparation and treatment in the

borrow areas and stockpiles, and material placement on the formation. This would particularly be

very useful in certain situations when some information is urgently needed to evaluate the quality

of completed earthfill construction works in respect to its compliance with the specifications

required by the design or supervision engineers of the project.

5. Conclusions

A rapid laboratory compaction test method was developed for determining the compaction

characteristics of sandy and clayey soils within the same working day (3 to 6 hours time) which can

be used in the quality control testing during the construction of earthworks projects. Soils of

different types and conditions included silty and clayey sands (SM, SC) and clays of variable

degree of plasticity (CL to CH) were considered in this study. Microwave energy was used in this

method for the determination of moisture content in a very short time (about 15-20 minutes) using

a previously established correlation relationships between the standard 24 hrs conventional oven

drying method for the same soil types.

The study results were analysed by statistical regression to evaluate the relationship between the

optimum moisture content (w

opt

) and the maximum dry density (

dmax

) determined by the BS

standard ordinary (2.5 kg rammer) test and the rapid compaction test procedures. Analysis of

compaction test data revealed the existence of strong mathematical relationships (expressed in

Equations 3 and 4) between the optimum water content and maximum dry density values obtained

in the two different compaction test methods for the soil types considered.

The results of the present study suggest that the rapid compaction method described in this

paper could be used as a quality control test for the construction of earthworks fill materials with

reasonable degree of accuracy and confidence.

6. References

American Society for Testing and Materials (1989). Standard test method for determination of

water content by the microwave oven method Standard D4643-87, Vol. 04.09, ASTM

Philadelphia, Pa. USA.

BS 1377:1990. British Standard Methods of test for soils for civil engineering purposes. British

Standards Institute, UK.

US Departments of the Army and Air Force (1983). Backfill for subsurface structures. Technical

Manual No. 5-818-4, Chapter 5, Washington DC.

Zein A.K.M. (2002). Rapid determination of moisture content by the microwave oven drying

method. Sudan Engineering Society Journal, Vol. 48, No. 40, pp. 43-54.

196

Vous aimerez peut-être aussi

- Les 7 MetauxDocument107 pagesLes 7 Metauxredvelvetmask2343Pas encore d'évaluation

- Djermaya Solar EIES Centrale PV RevE v2Document413 pagesDjermaya Solar EIES Centrale PV RevE v2Kalosoiretrotchgmail.com KalosoPas encore d'évaluation

- Regles Parasismiques Algeriennes Rpa 99Document6 pagesRegles Parasismiques Algeriennes Rpa 99Aggad ImanePas encore d'évaluation

- TH T2430 RsadekDocument261 pagesTH T2430 Rsadekgabin demsPas encore d'évaluation

- CPS Etudes - Titre I - 15Document4 pagesCPS Etudes - Titre I - 15chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 17Document2 pagesCPS Etudes - Titre I - 17chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 18Document1 pageCPS Etudes - Titre I - 18chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 16Document3 pagesCPS Etudes - Titre I - 16chatxxnoirPas encore d'évaluation

- Som MaireDocument1 pageSom MairechatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 8Document11 pagesCPS Etudes - Titre I - 8chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 12Document7 pagesCPS Etudes - Titre I - 12chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 14Document5 pagesCPS Etudes - Titre I - 14chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 10Document9 pagesCPS Etudes - Titre I - 10chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 11Document8 pagesCPS Etudes - Titre I - 11chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 10Document5 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 10chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 13Document6 pagesCPS Etudes - Titre I - 13chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 9Document10 pagesCPS Etudes - Titre I - 9chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 14Document1 pageNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 14chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 6Document13 pagesCPS Etudes - Titre I - 6chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 7Document12 pagesCPS Etudes - Titre I - 7chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 2Document17 pagesCPS Etudes - Titre I - 2chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 2Document17 pagesCPS Etudes - Titre I - 2chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 2Document17 pagesCPS Etudes - Titre I - 2chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 13Document2 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 13chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 12Document3 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 12chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 11Document4 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 11chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 7Document12 pagesCPS Etudes - Titre I - 7chatxxnoirPas encore d'évaluation

- CPS Etudes - Titre I - 1Document18 pagesCPS Etudes - Titre I - 1chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 8Document7 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 8chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 9Document6 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 9chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 4Document10 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 4chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 6Document8 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 6chatxxnoirPas encore d'évaluation

- NA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 5Document9 pagesNA CPI 1 5 Rev 11 PR Sentation de CEP Industrie 186 125 5chatxxnoirPas encore d'évaluation

- Sadr Memoire 2017 72.shnvslDocument54 pagesSadr Memoire 2017 72.shnvsllenin jivPas encore d'évaluation

- Fiche Sur Les Differents Types de Sechoir Solaire A Convection Naturelle Et ForceeDocument13 pagesFiche Sur Les Differents Types de Sechoir Solaire A Convection Naturelle Et Forceeromain fokamPas encore d'évaluation

- TP MostecDocument78 pagesTP MostecRached MairchiPas encore d'évaluation

- Puits CanadienDocument5 pagesPuits CanadienstarwarsPas encore d'évaluation

- TD1 NNDocument4 pagesTD1 NNMakaya EmmanuelPas encore d'évaluation

- التحسينات الكيميائية المرتبطة بالمتطلبات الأساسية للتربة الزراعيةDocument113 pagesالتحسينات الكيميائية المرتبطة بالمتطلبات الأساسية للتربة الزراعيةStar NetPas encore d'évaluation

- TD N°4 CorrigéDocument4 pagesTD N°4 Corrigéعبدالغني السوسيPas encore d'évaluation

- Cours BioclimatologieDocument115 pagesCours BioclimatologieHisham HishamPas encore d'évaluation

- Valorisation de Cartes ElectroniquesDocument23 pagesValorisation de Cartes ElectroniquesjonnyPas encore d'évaluation

- Fiche TechniqueDocument2 pagesFiche TechniqueZied JEMMALIPas encore d'évaluation

- CCTP AmoDocument7 pagesCCTP AmoKhalid KhalidiPas encore d'évaluation

- Brochure FRGA2020 DoublespagesOKDocument64 pagesBrochure FRGA2020 DoublespagesOKDeeneesh moturPas encore d'évaluation

- La République Dominicaine Continue de Nous Faire La Leçon en Matière D'énergieDocument3 pagesLa République Dominicaine Continue de Nous Faire La Leçon en Matière D'énergieJodany FortunéPas encore d'évaluation

- Rapport M2 Genot AurelienDocument49 pagesRapport M2 Genot AurelienIsraelPas encore d'évaluation

- Calco CarboniqueDocument4 pagesCalco Carboniquesarra bekriPas encore d'évaluation

- Fa24-Manuel PRP - Iso TS 22002-4 V 05-09-2022Document27 pagesFa24-Manuel PRP - Iso TS 22002-4 V 05-09-2022Eya Ben brahimPas encore d'évaluation

- 2015 65351 Vase en RouteDocument8 pages2015 65351 Vase en RoutekeltoumPas encore d'évaluation

- La Technoscience Et Ses Défis Jean-Michel MaldaméDocument9 pagesLa Technoscience Et Ses Défis Jean-Michel MaldaméIntinionPas encore d'évaluation

- CH - Delbecque Histoire Construction Terre Oct11Document22 pagesCH - Delbecque Histoire Construction Terre Oct11Jorge Vinicius Oliveira MaronPas encore d'évaluation

- 20 PDFDocument8 pages20 PDFاحمد بكريPas encore d'évaluation

- Série 4 2 Notion de ForcesDocument2 pagesSérie 4 2 Notion de Forceshoussame ben el hafiane100% (1)

- NM 21.9.001Document6 pagesNM 21.9.001sosatlantiquePas encore d'évaluation

- PC Sujets C 2005Document14 pagesPC Sujets C 2005tamere77Pas encore d'évaluation

- Cours Hydraulique Pastorale Et Gestion de L'eauDocument21 pagesCours Hydraulique Pastorale Et Gestion de L'eautaib chaimae100% (1)

- COMTE-Cours de Philosophie Positive-T.5Document783 pagesCOMTE-Cours de Philosophie Positive-T.5gramsciateguiPas encore d'évaluation

- Proximité en MarketingDocument28 pagesProximité en MarketingKOUASSIPas encore d'évaluation