Académique Documents

Professionnel Documents

Culture Documents

FR 3700 Extended TDS - METRIC 10 - 2022

Transféré par

jhTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FR 3700 Extended TDS - METRIC 10 - 2022

Transféré par

jhDroits d'auteur :

Formats disponibles

LAST-A-FOAM® FR-3700 RIGID POLYURETHANE FOAM (Metric Units)

PROPERTY Test Method FR-3703 FR-3704 FR-3705 FR-3706 FR-3707 FR-3708 FR-3710 FR-3712 FR-3715 FR-3718 FR-3720 FR-3725 FR-3730 FR-3740

Density (kg/m3) ASTM D-1622 48 64 80 96 112 128 160 192 240 288 320 400 481 641

Compressive Strength (kPa)

Parallel to Rise

-54°C 480 830 1,250 1,650 2,050 2,500 3,450 4,150 7,600 11,000 13,400 20,300 27,200 40,000

24°C 310 480 760 1,050 1,250 1,500 2,050 2,550 5,000 7,600 8,600 15,200 20,300 31,000

ASTM D-1621

93°C 240 410 550 690 860 1,034 1,450 1,650 2,900 4,150 4,950 8,600 11,700 13,800

121°C 170 280 410 520 620 760 1,050 1,300 2,150 2,950 3,400 5,600 7,600 11,400

Perpendicular to Rise

-54°C 450 690 1,150 1,600 2,050 2,500 3,500 4,250 7,600 11,000 13,100 21,400 29,000 44,100

24°C 280 450 760 1,050 1,300 1,600 2,200 2,750 5,200 7,600 9,000 15,200 20,300 31,000

ASTM D-1621

93°C 210 340 480 690 830 1,050 1,400 1,700 3,100 4,400 5,200 8,900 12,100 18,600

121°C 170 280 380 520 660 850 1,100 1,400 2,200 3,100 3,450 5,800 7,900 11,700

Compressive Modulus (kPa)

Parallel to Rise

-54°C 12,100 20,300 29,300 37,900 44,800 55,800 75,800 92,400 152,000 211,000 272,000 312,000 383,000 514,000

24°C 8,600 14,100 22,800 31,000 37,900 47,600 66,200 80,700 131,000 181,000 218,000 282,000 355,000 498,000

ASTM D-1621

93°C 6,800 11,400 17,200 23,400 27,600 35,900 50,300 60,000 102,000 144,000 175,000 265,000 352,000 526,000

121°C 4,900 8,300 13,400 18,600 22,100 29,000 39,300 49,600 81,000 112,000 124,000 197,000 258,000 381,000

Perpendicular to Rise

-54°C 11,000 16,900 26,200 35,200 43,400 53,800 74,500 91,000 154,000 216,000 270,000 325,000 404,000 557,000

24°C 7,600 12,100 20,700 29,000 36,500 46,200 64,100 80,700 133,000 186,000 221,000 283,000 352,000 488,000

ASTM D-1621

93°C 5,700 9,000 15,200 21,700 26,900 34,100 47,600 60,000 104,000 148,000 173,000 273,000 363,000 543,000

121°C 4,500 7,600 12,400 17,200 21,400 27,200 37,900 46,900 81,000 114,000 125,000 204,000 268,000 399,000

Tensile Strength (kPa)

Parallel to Rise 520 690 900 1,150 1,250 1,500 2,000 2,350 3,700 5,100 5,700 9,700 12,800 19,000

ASTM D-1623 Type A Specimens

Perpendicular to Rise 480 660 860 1,100 1,250 1,550 2,050 2,400 3,800 5,200 5,500 9,700 13,100 20,000

Shear Strength (kPa)

ASTM C273 in Compression

Rise Parallel to Specimen Width 280 450 620 690 950 1,150 1,550 1,800 3,050 3,950 4,750 6,700 9,000 13,800

*Modified sample size = 0.64cm x 2.54cm x 7.62cm

Flexural Strength (kPa)

Rise Parallel to Test Span 450 690 1,100 1,450 1,700 2,150 2,950 3,450 5,700 7,900 8,600 14,500 19,000 28,600

ASTM D-790 Method 1-A

Rise Parallel to Beam Thickness 410 690 1,100 1,500 1,850 2,300 3,100 3,850 5,900 7,900 8,600 14,500 17,200 28,600

Flexural Modulus (kPa)

Rise Parallel to Test Span 14,800 23,100 33,400 42,700 51,700 62,100 88,900 119,000 182,000 245,000 288,000 441,000 578,000 862,000

ASTM D-790 Method 1-A

Rise Parallel to Beam Thickness 16,900 24,800 37,600 50,300 58,600 75,800 97,200 121,000 187,000 252,000 292,000 451,000 585,000 876,000

Thermal Conductivity (W/m·K) ASTM C-518 at 24°C mean temp. 0.030 0.030 0.030 0.033 0.034 0.035 0.037 0.040 0.044 0.049 0.052 0.059 0.067 0.082

Coefficient of Thermal Expansion (m/m·K) From -45 to +93°C, GP Method 63 x 10-6

Poisson's Ratio Literature (Gibson & Ashby) ~ 0.3

Specific Heat @25°C (J/g°C) ASTM E-1269 1.477

Heat of Combustion (MJ/kg) ASTM D-240 27.16

Glass Transition Temp, Tg (°C) ASTM E-1824 138

Maximum Use Temperature (°C) 127

Fire Safety Self-extinguishing via FAR 25.853 (A) App. F (a)(1)(i) & (ii) tested vertically on 1.27 cm thick specimen using 12- and 60- second ignition with a Bunsen burner

10/14/2022

This data is subject to revision and changes due to development of and changes to the material. The data is derived from tests and historical usage. The data is averaged data and should be treated as such. These values do not constitute a sales specification. Calculations should be verified by actual tests. The data is furnished without liability

for the company and does not constitute a warranty or representation in respect to the material or its use. The company reserves the right to release new data sheets in replacement.

GENERAL PLASTICS MANUFACTURING COMPANY

4910 BURLINGTON WAY, TACOMA, WA 98409 | phone (253) 473-5000 | fax (253) 473-5104

e-mail: sales@generalplastics.com | website: www.generalplastics.com

Vous aimerez peut-être aussi

- Coudes A BrideDocument1 pageCoudes A BrideMustapha AchPas encore d'évaluation

- Brosur Daftar Harga-1Document4 pagesBrosur Daftar Harga-1Aldo PrakosoPas encore d'évaluation

- 2.1 Planilla de Metrados de Movimientos de Tierras - Volumenes Ordenados PDFDocument7 pages2.1 Planilla de Metrados de Movimientos de Tierras - Volumenes Ordenados PDFSaul Purihuaman OrdoñezPas encore d'évaluation

- Calculos Practica 1 Laboratorio de FisicoquimicaDocument9 pagesCalculos Practica 1 Laboratorio de Fisicoquimicamaria alabarranPas encore d'évaluation

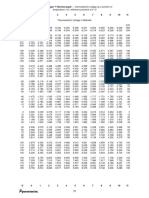

- Type K Thermocouple Reference Table PDFDocument2 pagesType K Thermocouple Reference Table PDFValeria Sanchez VillarroelPas encore d'évaluation

- Type K Thermocouple Reference Table PDFDocument2 pagesType K Thermocouple Reference Table PDFValeria Sanchez VillarroelPas encore d'évaluation

- Type K Thermocouple Reference TableDocument2 pagesType K Thermocouple Reference TableMax TerPas encore d'évaluation

- (Inc PPN) Daftar New Price List Maret 2021 Sea YogyaDocument2 pages(Inc PPN) Daftar New Price List Maret 2021 Sea YogyaMuhammad JawadPas encore d'évaluation

- 003 Acc BHP EN Ita Ing Fra Spa Rev00 2017Document1 page003 Acc BHP EN Ita Ing Fra Spa Rev00 2017Abdessamad YOUSFIPas encore d'évaluation

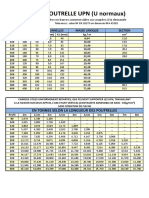

- Poutrelle UpnDocument1 pagePoutrelle UpnbederinadmlPas encore d'évaluation

- Note de Calcul ElectriciteDocument26 pagesNote de Calcul ElectriciteKheirou Djeffal100% (3)

- American Crawler Cranes Spec 1380e9Document11 pagesAmerican Crawler Cranes Spec 1380e9Jamie RichardsPas encore d'évaluation

- Quy định spool-DIN-46397Document2 pagesQuy định spool-DIN-46397Nguyen Thanh TrungPas encore d'évaluation

- Din 46397Document2 pagesDin 46397AHMET100% (1)

- Fiche TD02Document2 pagesFiche TD02mouloudPas encore d'évaluation

- SOPORTEDocument4 pagesSOPORTEGINA ARIZAPas encore d'évaluation

- Diseño Vigas Cinturon: Bora Bora C-2204Document3 pagesDiseño Vigas Cinturon: Bora Bora C-2204Leandro Enrique Bojaca ChautaPas encore d'évaluation

- Tabla FiquiDocument8 pagesTabla FiquiFabricio Daniel Chimoy AyalaPas encore d'évaluation

- Tablas TemperaturasDocument6 pagesTablas TemperaturasMontiel Luna AxelPas encore d'évaluation

- SensorkennlinienDocument2 pagesSensorkennlinienHerbertPas encore d'évaluation

- 3db3f33ke TFC c01 PDFDocument1 page3db3f33ke TFC c01 PDFIsrael YepezPas encore d'évaluation

- Assingment 2Document3 pagesAssingment 2Nabil IbrahimPas encore d'évaluation

- PinchDocument6 pagesPinchRobertoPas encore d'évaluation

- EVM Series Kem P Industrial Vibration MotorsDocument8 pagesEVM Series Kem P Industrial Vibration MotorsM HishamPas encore d'évaluation

- Brosur RCP - BC - Ud - DubDocument5 pagesBrosur RCP - BC - Ud - DubHeraldy BhazkaraPas encore d'évaluation

- InstrumentaciónDocument2 pagesInstrumentaciónErick Napa CastillaPas encore d'évaluation

- WINCHEDocument4 pagesWINCHED VPas encore d'évaluation

- Masa Specifica Piulite PDFDocument1 pageMasa Specifica Piulite PDFFlorin JipaPas encore d'évaluation

- Piulite GreutateDocument1 pagePiulite GreutateRadu PopPas encore d'évaluation

- Donnée Par CR Zagora 2022Document21 pagesDonnée Par CR Zagora 2022Ghizlane NamiriPas encore d'évaluation

- COLUMNASDocument15 pagesCOLUMNASMick Tirado SilvaPas encore d'évaluation

- Tabela Termopares Tipo TDocument2 pagesTabela Termopares Tipo TnssantanaPas encore d'évaluation

- T - Type ThermocoupleDocument2 pagesT - Type ThermocoupleSaladin AliPas encore d'évaluation

- Cas Agde MarineDocument10 pagesCas Agde MarineEnzo0% (1)

- CatalogoUnipecas - CorrentesDocument30 pagesCatalogoUnipecas - CorrentesfabioPas encore d'évaluation

- LS418 Tabela V A4Document5 pagesLS418 Tabela V A4Mgc ElektronikPas encore d'évaluation

- Micro 1 EssayDocument19 pagesMicro 1 Essaydevanshah101Pas encore d'évaluation

- Pesos de Tubos de CobreDocument2 pagesPesos de Tubos de CobreJackson BravosPas encore d'évaluation

- Latihan ExcelDocument5 pagesLatihan ExcelX ThrxPas encore d'évaluation

- Theoretical & Actual WeightDocument1 pageTheoretical & Actual WeightGeorge babuPas encore d'évaluation

- Assignment 2Document6 pagesAssignment 2myatnoe pwintPas encore d'évaluation

- Tablas TrenDocument6 pagesTablas TrenEduardo LariosPas encore d'évaluation

- HENRAD Alto Extrait Manuel TechniqueDocument6 pagesHENRAD Alto Extrait Manuel TechniqueBINPas encore d'évaluation

- Extrait CPC ClimDocument3 pagesExtrait CPC ClimMuhcinePas encore d'évaluation

- Tabela de Preços DEZEMBRO - 2008Document2 pagesTabela de Preços DEZEMBRO - 2008SergioPas encore d'évaluation

- Formato de MezclaDocument16 pagesFormato de MezclaRonald AvilaPas encore d'évaluation

- Data Raw JeparaDocument104 pagesData Raw JeparaExen DesigngraphicPas encore d'évaluation

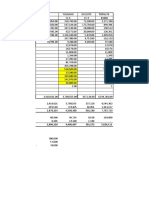

- Classeur 1Document5 pagesClasseur 1melisa kadiriPas encore d'évaluation

- Awwa FlangesDocument5 pagesAwwa Flangesbardianabavi.bnPas encore d'évaluation

- Grafico CalorDocument5 pagesGrafico Calorantonio130901lalalaPas encore d'évaluation

- All Chapters EditedDocument1 pageAll Chapters EditedZinko kokyawPas encore d'évaluation

- Ugiweb 731485Document4 pagesUgiweb 731485Belgacem ArramiPas encore d'évaluation

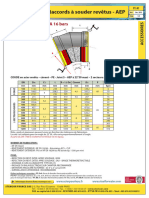

- FtA1-Raccords A Souder Revetus Pour Tubes EnterresDocument9 pagesFtA1-Raccords A Souder Revetus Pour Tubes Enterreseblva7078Pas encore d'évaluation

- TECNONSerie ElasticosDocument5 pagesTECNONSerie Elasticosfranco vergaraPas encore d'évaluation

- Tabla de Tiro Obus 122 HumoDocument13 pagesTabla de Tiro Obus 122 HumoBrandon CaballeroPas encore d'évaluation

- 10 - 1 - Copie de GCI220 - ED02 - Sol - 3Document8 pages10 - 1 - Copie de GCI220 - ED02 - Sol - 3BopePas encore d'évaluation

- GRAFICODocument2 pagesGRAFICOLeslie ObregónPas encore d'évaluation

- Rapport RFIDDocument29 pagesRapport RFIDed-fer666Pas encore d'évaluation

- 1-Rem Commande - PrédictiveDocument28 pages1-Rem Commande - PrédictiveLots of lovePas encore d'évaluation

- Helicobacter PyloriDocument4 pagesHelicobacter Pyloriadjerad omarPas encore d'évaluation

- 1901 Vierendeel. Stabilite Des Constructions. Tome III PDFDocument137 pages1901 Vierendeel. Stabilite Des Constructions. Tome III PDFmouradPas encore d'évaluation

- Premior Mat - FRDocument3 pagesPremior Mat - FRgogoPas encore d'évaluation

- Revenu 1357Document28 pagesRevenu 1357concombre2607Pas encore d'évaluation

- Attachement Du ChantierDocument10 pagesAttachement Du ChantierOussamaBahloul100% (1)

- Plan Comptable Minimum NormaliséDocument32 pagesPlan Comptable Minimum NormaliséRené yvesPas encore d'évaluation

- Signalisation Routière - Verticale Et Horizontale - OrnikarDocument7 pagesSignalisation Routière - Verticale Et Horizontale - OrnikarTalloudPas encore d'évaluation

- Voyage de La Grèce PDFDocument539 pagesVoyage de La Grèce PDFspéculairePas encore d'évaluation

- Rapport de StageDocument15 pagesRapport de StageAgossa BénédictePas encore d'évaluation

- TMDDocument10 pagesTMDBANIPas encore d'évaluation

- OEIL ROUGE ConstantineDocument45 pagesOEIL ROUGE Constantinemidou113Pas encore d'évaluation

- Chapitre-Les Systèmes de ClimatisationDocument13 pagesChapitre-Les Systèmes de ClimatisationInsaf Bouazza ʚîɞ100% (2)

- CinematiqueDocument22 pagesCinematiquepaul_fredric3173Pas encore d'évaluation

- Philosophie Subtile ParacelseDocument16 pagesPhilosophie Subtile Paracelseredvelvetmask2343Pas encore d'évaluation

- BrainstormingDocument4 pagesBrainstormingndeyadiop1203Pas encore d'évaluation

- Avp Loi 67.15 FRDocument9 pagesAvp Loi 67.15 FRSerge KohemunPas encore d'évaluation

- Centre Universitaire Nour Bachir, El-Bayadh Institut Des Sciences 2ème Année Licence Génie Civil Exposé Écrit Pour Évaluation SemestrielleDocument8 pagesCentre Universitaire Nour Bachir, El-Bayadh Institut Des Sciences 2ème Année Licence Génie Civil Exposé Écrit Pour Évaluation SemestrielleMelek LakelPas encore d'évaluation

- Cahier de Poutres Bloc Administration 1Document8 pagesCahier de Poutres Bloc Administration 1Ourajim issamPas encore d'évaluation

- Première Année de Médecine Dentaire Module de Biophysique Chapitre 3 Prof Karim MANSOUR 2022Document26 pagesPremière Année de Médecine Dentaire Module de Biophysique Chapitre 3 Prof Karim MANSOUR 2022wiamePas encore d'évaluation

- Brand PriceDocument6 pagesBrand PriceBonnesAffairesConstantine100% (1)

- Dégradations de ChausséeDocument13 pagesDégradations de Chaussée'Tarik Louati50% (2)

- Introduction À La Science Des Matériaux Propriétés Générales Des MatériauxDocument27 pagesIntroduction À La Science Des Matériaux Propriétés Générales Des MatériauxDelphin Kandolo100% (1)

- Coefficient K, Devis Estimatif, Quantitatif Et PlanificationDocument21 pagesCoefficient K, Devis Estimatif, Quantitatif Et PlanificationMarco JoyPas encore d'évaluation

- Pf4 DessinDocument5 pagesPf4 Dessinfareltanda841Pas encore d'évaluation

- Chapitre 3 IRMPartie 3Document42 pagesChapitre 3 IRMPartie 3Khadhra LassouedPas encore d'évaluation

- Bulletin Service Manilles 2013.02 (FR)Document3 pagesBulletin Service Manilles 2013.02 (FR)bestoff82100% (1)

- Video RO1Document39 pagesVideo RO1lovebooksPas encore d'évaluation

- Wcms 183740Document4 pagesWcms 183740Bakaye DembelePas encore d'évaluation