Académique Documents

Professionnel Documents

Culture Documents

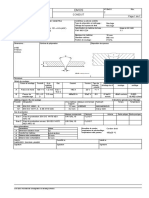

Baking Colour Code Pre Heat/Post Heat PWHT Weld Visual NDT: Nominal Composition

Transféré par

dada shaikTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Baking Colour Code Pre Heat/Post Heat PWHT Weld Visual NDT: Nominal Composition

Transféré par

dada shaikDroits d'auteur :

Formats disponibles

PIPE Forged Fitting Wrought Fitting Process/Consumable Electrodes PWHT Scope & Inspection Frequency

Mech

YS-Mpa Pre Inter

Material Mat. Grp. SEMLESS PIPE WELDED PIPE Chem % Hold. Heat pass Post Service Hard.

MATERIAL Grade MATERIAL Grade UTS-Mpa Grade UTS ksi Grade UTS GTAW SMAW FCAW SAW SAW BC LHE-Min Temp Min Max Heat Temp. Holding Visual MPI/ RT/U Hard. Req. Impact

SPECIFICATION SPECIFICATION EL-% ksi Flux Min Time DPI T Max

Non Sour NA NA NA

upto 20mm

C-0.30, Thk. - NA

Mn-0.29-1.06, E6010 Sour Thk. >20mm 100% 200 HB NA

ASTM-A671 P-0.035, S-0.035, YS-240 593°- 649°C

Carbon Steel ASTM A106 Gr.B

IS1239-upto OD 6"

Gr.CB 60 Si-0.1, Cr-0.40, UTS-415(60ksi) A105N 70 A234-WPB 60-95 ER70S-2 (F (F No- 3) E71T-1C EM12K F7A2

(CS) IS3589-above 6" Cu-0.40, EL-25 No - 6) E7018 (F No - 6) (F No - 6) Min

OD (F No 4) 10°C Amine & For All Dia &

Mo-0.15, Ni-0.40, 350°C for 1 hr Caustic Thk Min. 1 hr NA NA NA

P1 V-0.08 or 150°C Thk. ≥ 250°C NA 100% 5% 5%

250°C for 2 hrs 25mm 650°C Min. for 1 hr / Inch

Carbonate 2 Hrs NA NA NA

80°C

E6010 Non Sour upto 20mm NA NA -46°C

C-0.03, Mn-0.29- YS-240 ER70S-G (F No- 3) EM12K Thk. - NA

LTCS ASTM A333 Gr.6 ASTM-A671 Gr.CC 60 1.06, P-0.025, S- UTS-415(60ksi) A350-LF2 60 A420-WPL6 60-85 (F No - 6) E7018-1 ------ (F No - 6) F7A5 Sour

Thk. >20mm

100% 200 HB -46°C

0.025, Si-0.10 EL-30-L, 16.5-T

(F No 4) 593°- 649°C

60-85/70- ER80S-B2 E8018-B2 E81T1-B2M EB2-B2

P4 P11 P11 1.25 Cr, 0.5 Mo A182-F11 60/70/75 A234-WP11 95 (F No - 6) (F No 4) (F No - 6) (F No - 6) F8P0 150°C 250°C A335-P11 704°-746°C 100% 10% 100% 100% 225HB NA

ER90S-B3 E9018-B3

P5A P22 P22 2.25 Cr, 1 Mo A182-F22 60-75 A234-WP22 60-85 (F No - 6) (F No 4) ___ ___ ___ 200°C 300°C A335-P22 704°-760°C 100% 10% 100% 100% 225HB NA

Low Alloy Steel YS-240 300°C Min. 2 hrs

ASTM A335 ASTM-A691 UTS-415(60ksi) 350°C for 2 hrs 150°C for 1 /2

(LAS) EL-25 hr 1 hr / Inch

P5B P5 P5 5 Cr, 0.5 Mo A182-F5 70 A234-WP5 60-95 ER80S-B6 E8018-B6 E81T-B6 (F EB6-B6 F8PZ 250°C 350°C A335-P5 704°-760°C 100% 10% 100% 100% 241HB NA

(F No - 6) (F No 4) No - 6) (F No - 6)

P5B P9 P9 9 Cr, 1 Mo A182-F9 85 A234-WP9 60-85 ER80S-B8 E8018-B8 ___ ___ ___ 250°C 350°C A335-P9 704°-760°C 100% 20% 100% 100% 241HB NA

(F No - 6) (F No 4)

ER308H E308H

P8 TP 304H TP 304H 18-20 Cr, 8-11 Ni A182-F304H 75 A403-WP304H 75 (F No - 6) (F No - 5) ___ ___ ___ TP 304H 100% 10% 100% NA NA NA

YS-170,UTS-485, EL- ER308L E308L

P8 TP 304L TP 304L 18-20 Cr, 8-13 Ni 35-L,25-T A182-F304L 70 A403-WP304L 70 (F No - 6) (F No - 5) ___ ___ ___ TP 304L 100% 10% 100% NA NA NA

ER316 E316

P8 TP 316 TP 316 A182-F316 75 A403-WP316 75 (F No - 6) (F No - 5) ___ ___ ___ TP 316 100% 5% 5% NA NA NA

16-18 Cr, 11-14 Ni, 2- YS-205,UTS-515, EL-

3 Mo 35-L,25-T

ER316H E316H

P8 TP 316H TP 316H A182-F316H 75 A403-WP316H 75 (F No - 6) (F No - 5) ___ ___ ___ TP 316H 100% 5% 5% NA NA NA

ASTM A312 ASTM A358 250°C for 2 hrs 150°C NA 175°C NA NA NA

16-18 Cr, 10-14 Ni, 2- YS-170,UTS-485, EL- ER316L E316L

P8 TP 316L TP 316L 3 Mo 35-L,25-T A182-F316L 70 A403-WP316L 70 (F No - 6) (F No - 5) ___ ___ ___ TP 316L 100% 5% 5% NA NA NA

P2000/

17-19 Cr, 9-12 Ni, 0.4- ER321 or E347 E347T1-1/4 ER 347 120S/ TP 321 or

P8 TP 321 or 321H TP 321 or 321H 0.7 Ti A182-F321 75 A403-WP321 75 ER347

(F No - 5) (F No - 6) (F NO- 6) SWAC 321H 100% 10% 100% NA NA NA

(F No - 6)

SA012

YS-205,UTS-515, EL-

35-L,25-T

P2000/

17-19 Cr, 9-13 Ni, 0.8- ER347 E347 E347T1-1/4 ER 347 120S/ TP 347 or

P8 TP 347 or 347H TP 347 or 347H 1.0 Cb A182-F347 75 A403-WP347 75 (F No - 6) (F No - 5) (F No - 6) (F NO- 6) SWAC 347H 100% 10% 100% NA NA NA

SA012

Monel 63-67 - Ni , 28-34 - YS -195 (28 ksi) UTS ERNiCu - 7 (F ENiCu- 7 Min

(ALLOY 400) P42 ASTM B165 UNS N04400 ____ UNS N04400 Cu, -480 (70 Ksi) EL -35 ASTM B564 70 ASTM B366 70 No -42) (F No -42) ____ ____ ____ 10°C 150°C NA NA 100% NA NA NA

Hastalloy (UNS 54- 57 - Ni ,14.5 - YS -283 (41 ksi) UTS ERNiCrMo4 ENiCrMo4 Min

10276) P43 ASTM B622 UNS 10276 ASTM B619 UNS 10276 16.5 - Cr , 15 - 17 - -690 (100 Ksi) EL -40 ASTM B564 100 ASTM B366 100 (F No -43) (F No -43) ____ ____ ____ 10°C 175°C NA NA 100% NA NA NA

Mo , Fe- 4 - 7

Inconal (UNS P43 ASTM B167 UNS N 06600 ASTM B517 UNS N 06600

72 - Ni, 14-17 - Cr , 6- YS -275 (40 ksi) UTS

ASTM B564 80 ASTM B366 80

ERNiCr- 3 ENiCrFe- 2

____ ____ ____

Min

175°C NA NA 100% NA NA NA

N06600) 10 - Fe -620 (90 Ksi) EL -25 (F No -43) (F No -43) 10°C

Cr- 22-23, Ni- 4.5 - YS - 450(65 ksi) UTS ER2209 E2209 Min

P10H ASTM A 790 UNS S32205 ASTM A 928 UNS S32205 6.5, Mo- 3 - 3.5, N- -655 (95 Ksi) EL -25 A182-F 60 95 A815-S32205 95 (F No -6) (F No -5) ____ ____ ____ 10°C 150°C NA NA 100% NA 290 HB NA

0.14- 0.20

Duplex SS

Cr- 21-23, Ni- 4.5 -

P10H ASTM A 790 UNS S31803 ASTM A 928 UNS S31803 6.5, Mo- 2.5 - 3.5, N- YS -450 (65 ksi) UTS A182-F 51 90 A815-S31803 90

ER2209 E2209

____ ____ ____

Min

150°C NA NA 100% NA 290 HB NA

0.08- 0.20 -655 (95 Ksi) EL -25 (F No -6) (F No -5) 10°C

Cr- 24-26,

Super Duplex Ni- 6 - 8, YS - 550( 80ksi) UTS ER2594 E2594 Min

SS P10H ASTM A790 UNS S32750 ASTM A790 UNS S32750 Mo- 3 - 5, -800 (116 Ksi) EL -15 A182-F 53 116 A815-S32750 116 (F No -6) (F No -5) ____ ____ ____ 10°C 120°C NA NA 100% NA 300 HB NA

N- 0.24- 0.32,

Cu- 0.5

ALLOY 20 (UNS N - 32 - 38 ,

N08800, P45 ASTM B407 UNS N08800 ASTM B464 UNS N08020 Cr - 19 - 21, YS - 205( 30ksi) UTS ASTM B564 75 - 85 ASTM B366 75 - 85 ERNiCrMo3 ENiCrMo3 Min 150°C NA NA 100% NA NA

N08020, ASTM B423 UNS N08825 ASTMB705 UNS N08825 Fe - 35 -520 (75 Ksi) EL -30 ASTM B462 (F No -43) (F No -43) 10°C

N08825) Cu - 3 - 4

Baking : as per Manufacturer NOMINAL COMPOSITION LAS: Alloying elements shall not exceed 10.5% Colour Code

Pre Heat/Post Heat : As Per WPS 304 18cr & 8Ni SS: Alloying elements exceeding 10.5% IBR Red

PWHT : ASME B31.3 Section 331.1.3 316 16cr & 12Ni- Mo More than 5% chromium purging is applicable(Argon or Nitrogen can be used as purging) LTCS Redoxide

Weld Visual : ASME B31.3 Section 341.3.2 321 18cr & 10Ni-Ti Purging done upto Hot Pass NACE Violet

NDT : ASME B31.3 Section 341.3.4 347 18cr & 10Ni-Cb IBR: Design Pressure 3.0 kg/cm2 & above

Pre Heat Reinforcement Height

To slow down cooling rate of deposited weld metal & HAZ WPS PWHT: upto 6 mm 1.5 mm

as per ASME B31.3 atleast 1" on both sides of joint JOINT DESIGN QW402 Types of thermo couples K, L 6 mm to 13 mm 3 mm

as per RIL procedure 3" or 1.5 times of base metal thickness whichever is greater. BASE METAL QW403 as per RIL K type thermcople used Heat Band Width on each side 13 mm to 25 mm 4 mm

Post Heat FILLER METAL QW404 1.Nickel Chromium +ve yellow wire-non magnetic upto 1" 100 mm > 25 mm 5 mm

To increase the difussion of hydrogen & other gas out of weld metal WELD.POSITION QW405 2.Nickel Aluminium -ve red wire-magnetic 1" to 3" 150 mm as per B 31.3 table 341.3.2

PREHEAT QW406 upto 6" 1 thermocouple at 0° 4" to 6" 200 mm

Electrode Last Digit PWHT QW407 above 6" to 12" 2 thermocouples at 180° > 6" 200 mm

0 Cellulose Sodium, DCEP -Cellulose Electrodes ELECT.CHARCT QW409 above 12" 3 thermocouples at 120°

1 Cellulose Potassium -Cellulose Electrodes WELD. TECH QW410 CS LTCS LAS SS

2 Rutile Titanium Sodium AC, DCEP & DCEN -Rutile Electrodes ASTM A106 Gr. B Seamless ASTM-A333Gr6 Seamless ASTM-A335 Seamless ASTM-A312 Seamless&Weld

3 Rutile Titanium Potassium AC, DCEP & DCEN -Rutile Electrodes IS1239-upto OD 6" Seamless&Weld ASME-A671Gr-CC60 Welded ASTM-A691 Welded ASTM A358 Welded

4 Iron Powder Titanium IS3589-above 6" OD Welded

5 Low Hydrogen Sodium, DCEP -Basic Electrodes ASTM-A671 Gr.CB 60 Welded RT examination with ASME SEC.8 Div.1 Appendix 4. & Procedure as ASME SEC V Article II

6 Low Hydrogen Potassium, AC & DCEP -Basic Electrodes MPT examination with ASME SEC.8 Div.1 Appendix 6. & Procedure as ASME SEC V. Article VII

7 Low Hydrogen, Iron Powder, Iron Oxide -Basic Electrodes DPT examination with ASME SEC.8 Div.1 Appendix 8. & Procedure as ASME SEC V. Article VI

8 Low Hydrogen, Iron Powder -Basic Electrodes UT examination with ASME SEC.8 Div.1 Appendix. 12. & Procedure as ASME SEC V Article IV

ASME IX Hydro test Procedure as ASME SEC V Article X

Article I Welding General Requirements Visual Inspection test Procedure as ASME SEC V Article IX

Article II Welding Procedure Qualification

Article III Welding Performance Qualificatn

Article IV Welding Data

Article V Std. Welding Procedure Specifion

Vous aimerez peut-être aussi

- WPs Magi Inx11111Document7 pagesWPs Magi Inx11111Danem HalasPas encore d'évaluation

- BpsDocument1 pageBpsErick OlavarriaPas encore d'évaluation

- Ansi-Asme B16.47 B (Api 605)Document2 pagesAnsi-Asme B16.47 B (Api 605)aauppalPas encore d'évaluation

- CP 189 2020 Draft - FRDocument23 pagesCP 189 2020 Draft - FRFatehi GuermaPas encore d'évaluation

- API DimensionsDocument2 pagesAPI Dimensionsemmas18Pas encore d'évaluation

- Présentation Impact Test ASME B 31.3Document20 pagesPrésentation Impact Test ASME B 31.3bounatiro Hatem100% (1)

- 0196f - Formulaire de Demande DexamenDocument4 pages0196f - Formulaire de Demande DexamenalirichePas encore d'évaluation

- Steel Pipe Dimensions Chart Ansi b36.10 36.19Document1 pageSteel Pipe Dimensions Chart Ansi b36.10 36.19حمزة العريبي100% (1)

- RAL Color CodeDocument6 pagesRAL Color Codemanoj983@gmail.comPas encore d'évaluation

- API 1104 Illustrations D'imperfections de SouduresDocument2 pagesAPI 1104 Illustrations D'imperfections de SouduresFethi BELOUISPas encore d'évaluation

- Cópia de Planilha GERENCIAMENTO Alves BlazeDocument4 pagesCópia de Planilha GERENCIAMENTO Alves BlazeLucas NevesPas encore d'évaluation

- 3 Phase Production Separator C-321Document51 pages3 Phase Production Separator C-321Tengku Nizarul Aslami100% (1)

- MagnétoDocument5 pagesMagnétoIlyes kPas encore d'évaluation

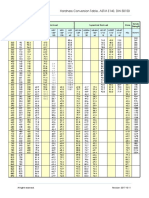

- Bevel To Degree Conversion ChartDocument1 pageBevel To Degree Conversion ChartScott NorrisPas encore d'évaluation

- Hardness Conversion Table Tokushu Kinzoku ExcelDocument2 pagesHardness Conversion Table Tokushu Kinzoku Excelreddy anekalla100% (1)

- Formation en Méthodes Utilisées Pour Le Revêtement Et Enrobage Du PipeDocument3 pagesFormation en Méthodes Utilisées Pour Le Revêtement Et Enrobage Du PipeTarekNacer100% (2)

- Iso 9934-1 2016Document24 pagesIso 9934-1 2016Idriss BrahmiPas encore d'évaluation

- REGLEMENTATIONDocument2 pagesREGLEMENTATIONOlss BbzoPas encore d'évaluation

- DMOS11Document1 pageDMOS11sakina laabidPas encore d'évaluation

- S-0100-1520-105 - 2-Welding Req PDFDocument28 pagesS-0100-1520-105 - 2-Welding Req PDFAliZenatiPas encore d'évaluation

- Pipe Wall - Thickness - TableDocument1 pagePipe Wall - Thickness - TableChing HungPas encore d'évaluation

- Heat Exchanger Inspection FRDocument2 pagesHeat Exchanger Inspection FRKali AbdennourPas encore d'évaluation

- Hydrotest REPORTDocument2 pagesHydrotest REPORTTouil Houssem100% (1)

- Hardness Conversion TableDocument1 pageHardness Conversion TableFatma BoukraiemPas encore d'évaluation

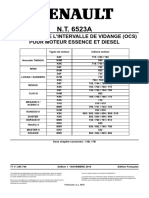

- N.T. 6523aDocument10 pagesN.T. 6523aEric VollereauPas encore d'évaluation

- POLYSTRIA v01Document3 pagesPOLYSTRIA v01mastercssiPas encore d'évaluation

- Arcal Mag PDocument1 pageArcal Mag Plaz_kPas encore d'évaluation

- CWB QualificationDocument166 pagesCWB QualificationCyrille BeauchesnePas encore d'évaluation

- Questionnaire ISO 3834 Part 2Document6 pagesQuestionnaire ISO 3834 Part 2zineb SaaoufPas encore d'évaluation

- Application POLYKOTEDocument2 pagesApplication POLYKOTEL'acteur VictimePas encore d'évaluation

- Aquaprox PC7300-Fiche TechDocument2 pagesAquaprox PC7300-Fiche TechRedhouane OudjidaPas encore d'évaluation

- Api 579Document1 pageApi 579Sabrine Mekki100% (1)

- NF EN ISO 15626 - Novembre 2013Document19 pagesNF EN ISO 15626 - Novembre 2013Qualité En ENTREPRISEPas encore d'évaluation

- Radiographic Test ReportDocument2 pagesRadiographic Test Reportalinor_tnPas encore d'évaluation

- DS1Document4 pagesDS1Msta Eff100% (1)

- Raccords Pour Camions Citernes - CatPage0 - Section3 - FR-EnDocument62 pagesRaccords Pour Camions Citernes - CatPage0 - Section3 - FR-Entom.nezotPas encore d'évaluation

- Catalogue - Vérins Actionneurs Vérins Actionneurs Spéciaux 437 00343Document8 pagesCatalogue - Vérins Actionneurs Vérins Actionneurs Spéciaux 437 00343JoseIslasAguirrePas encore d'évaluation

- edlpob Vzuwz (:: NouveauDocument1 pageedlpob Vzuwz (:: Nouveaunicovlad96Pas encore d'évaluation

- 3 - 01 - Oligocyclique X5CrNiMo17 12 2Document3 pages3 - 01 - Oligocyclique X5CrNiMo17 12 2bagueneau YOUTUBEPas encore d'évaluation

- BlueSteel RPT PneuDocument4 pagesBlueSteel RPT Pneusiuluis1Pas encore d'évaluation

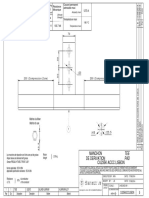

- T TapDocument1 pageT TapOktovianus TeguhPas encore d'évaluation

- 220107-Ens-Frc 125-150-400-200Document1 page220107-Ens-Frc 125-150-400-200Fidele KinlePas encore d'évaluation

- Abri Vehicules Lourds 1 PDFDocument1 pageAbri Vehicules Lourds 1 PDFCONSTRUBEST BEJAIAPas encore d'évaluation

- 0250 - FT - Monoetilenglicol - Abr.19 - FRDocument1 page0250 - FT - Monoetilenglicol - Abr.19 - FRk.bilalPas encore d'évaluation

- Repair SleeveDocument1 pageRepair SleeveOktovianus TeguhPas encore d'évaluation

- Huawei Sun2000 3 10ktl m1 Fiche Technique FRDocument2 pagesHuawei Sun2000 3 10ktl m1 Fiche Technique FRYoussef AmalouPas encore d'évaluation

- Document - La Prothese Sur Mesure - 08-2023 - FRDocument1 pageDocument - La Prothese Sur Mesure - 08-2023 - FROvidiu SingeorzanPas encore d'évaluation

- Pompe 8Document3 pagesPompe 8BabacarPas encore d'évaluation

- D-EUGP1-TPT-F-TUN-GEO-DRW-1070 - Copy-Model PDFDocument1 pageD-EUGP1-TPT-F-TUN-GEO-DRW-1070 - Copy-Model PDFghansaPas encore d'évaluation

- Dessin Zone 2-Drainage Ti SousDocument1 pageDessin Zone 2-Drainage Ti Sousfedor remyPas encore d'évaluation

- Barres en Bronze Caracteristicas Mecanicas FR FRDocument3 pagesBarres en Bronze Caracteristicas Mecanicas FR FRkaroooma99Pas encore d'évaluation

- 3 PV Table 3Document1 page3 PV Table 3Waei SiasyPas encore d'évaluation

- Gente FT FastoDocument2 pagesGente FT FastoAPas encore d'évaluation

- Tuyaux Pour Hydrocarbures - CatPage0 - Section1 - FR-EnDocument38 pagesTuyaux Pour Hydrocarbures - CatPage0 - Section1 - FR-Entom.nezotPas encore d'évaluation

- Fartools Rex 120 - DescDocument1 pageFartools Rex 120 - DesceuromarketPas encore d'évaluation

- Bisse SavieseDocument2 pagesBisse SavieseegegPas encore d'évaluation

- TESCOM Extrait Gamme DéverseursDocument20 pagesTESCOM Extrait Gamme DéverseursMachinPas encore d'évaluation

- Les CaracteristiquesDocument6 pagesLes CaracteristiquesinaskourdaniPas encore d'évaluation

- Support de Fixation Sur Panne MétalliqueDocument3 pagesSupport de Fixation Sur Panne MétalliqueMehdi ArroubPas encore d'évaluation

- FR Gamme de Machines Pour L'hygiene Publique (Lavage - Desinfection)Document6 pagesFR Gamme de Machines Pour L'hygiene Publique (Lavage - Desinfection)Sanji VinsmokePas encore d'évaluation

- Plan - BA - Details Des FondationsDocument1 pagePlan - BA - Details Des Fondationsosmanovic2020Pas encore d'évaluation

- Matériau CompositeDocument9 pagesMatériau CompositeREGUIEG YSSAAD DEHIBAPas encore d'évaluation

- Examen 2014 CorrectionDocument4 pagesExamen 2014 CorrectionUlrich Toukam100% (1)

- Gran Baristo Class Parts DiagramDocument9 pagesGran Baristo Class Parts Diagrameddystoel2653100% (1)

- Emulseur Foam Master 3f 6Document3 pagesEmulseur Foam Master 3f 6AkramKassisPas encore d'évaluation

- Oxydation Des Metaux Dans L Air Resume de Cours 3Document2 pagesOxydation Des Metaux Dans L Air Resume de Cours 3saidPas encore d'évaluation

- Règles D'exécutions Des Travaux de Construction D'ouvrages enDocument63 pagesRègles D'exécutions Des Travaux de Construction D'ouvrages enBazizi AbdelghaniPas encore d'évaluation

- ATEx A Cycle Terre Cloison BTC 2911Document50 pagesATEx A Cycle Terre Cloison BTC 2911Jaouad IDBOUBKERPas encore d'évaluation

- Projet de Norme MarocaineDocument43 pagesProjet de Norme MarocainekhaledPas encore d'évaluation

- TP RKIK 2 (Enregistré Automatiquement)Document7 pagesTP RKIK 2 (Enregistré Automatiquement)zouaidiameni9Pas encore d'évaluation

- Devis Poste CaleDocument3 pagesDevis Poste CaleDobai Siddi boubaPas encore d'évaluation

- Sequelec GM 02 V1Document17 pagesSequelec GM 02 V1niyamei noomPas encore d'évaluation

- 9667H-0000-JSD-1300-0001-0 Spec Gener STD TuyoDocument32 pages9667H-0000-JSD-1300-0001-0 Spec Gener STD TuyoAHMED AMIRA100% (1)

- Soppec Construction FRDocument36 pagesSoppec Construction FRrheochronosPas encore d'évaluation

- s2 c03 Enveloppe DiapoDocument116 pagess2 c03 Enveloppe Diapouchiwaitachi973Pas encore d'évaluation

- C L2 Chimie MineraleDocument106 pagesC L2 Chimie MineraleFoufa BePas encore d'évaluation

- Titrages Acide BaseDocument22 pagesTitrages Acide BaseramiPas encore d'évaluation

- Pfe GC 0336Document115 pagesPfe GC 0336marius fangangPas encore d'évaluation

- TD Beton Arme Unda 2022-2023Document5 pagesTD Beton Arme Unda 2022-2023SamuelPas encore d'évaluation

- Chapitre IiDocument12 pagesChapitre IiIs Lam EdPas encore d'évaluation

- Aluminium 2Document11 pagesAluminium 2Carmen AdlerPas encore d'évaluation

- Gros OeuvreDocument8 pagesGros Oeuvrehalim.savecontrol6179Pas encore d'évaluation

- Medajoint DilDocument2 pagesMedajoint DilManiaPas encore d'évaluation

- Recommandations Professionnelles Toitures-Terrasses Avec Etancheite Jonctions Avec Parois Verticales EnterreesDocument56 pagesRecommandations Professionnelles Toitures-Terrasses Avec Etancheite Jonctions Avec Parois Verticales EnterreesMaxime Amirault100% (1)

- CliniqueDocument73 pagesCliniqueFatima Gz100% (1)

- Presentation MemoireDocument108 pagesPresentation MemoireHoussem MessadiPas encore d'évaluation

- Sikaviscocrete 522Document2 pagesSikaviscocrete 522geobelkaPas encore d'évaluation

- Cours Prof Cap Les VitragesDocument9 pagesCours Prof Cap Les VitragesgaterPas encore d'évaluation

- 2007 ActualitChimique 308-309 79-93Document16 pages2007 ActualitChimique 308-309 79-93Mehdi BnsPas encore d'évaluation