Académique Documents

Professionnel Documents

Culture Documents

Allied SPEED

Transféré par

Bobby DazzlerTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Allied SPEED

Transféré par

Bobby DazzlerDroits d'auteur :

Formats disponibles

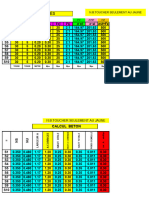

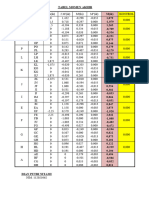

Recommended Cutting Data

GEN2 T-A® HSS Inserts | Imperial (inch)

SFM Feed Rate (IPR) by Diameter

Hardness HSS 3/8 - 33/64 - 45/64 - 31/32 - 1-13/32 - 1-29/32 - 2-19/32 - 1-29/32 -

ISO Material (BHN) Grade TiN AM200® 1/2 11/16 15/16 1-3/8 1-7/8 2-9/16 4-1/2 2-9/16

Free Machining Steel 100 - 150 HSS 200 325 0.008 0.012 0.016 0.019 0.020 0.023 0.028 0.018

1118, 1215, 12L14, etc. 150 - 200 HSS 180 300 0.007 0.011 0.015 0.017 0.020 0.023 0.028 0.018

200 - 250 HSS 160 280 0.006 0.010 0.014 0.016 0.020 0.023 0.028 0.017

Low Carbon Steel 85 - 125 HSS 170 290 0.008 0.010 0.014 0.018 0.019 0.023 0.027 0.017

1010, 1020, 1025, 1522, 1144, etc. 125 - 175 HSS 160 275 0.007 0.010 0.014 0.017 0.019 0.023 0.027 0.016

175 - 225 HSS 150 260 0.006 0.009 0.013 0.016 0.018 0.021 0.024 0.016

225 - 275 HSS 140 240 0.005 0.009 0.013 0.016 0.018 0.021 0.024 0.015

Medium Carbon Steel 125 - 175 HSS 160 275 0.007 0.010 0.014 0.017 0.019 0.023 0.027 0.018

1030, 1040, 1050, 1527, 1140, 1151, 175 - 225 HSS 150 260 0.006 0.009 0.013 0.016 0.018 0.021 0.024 0.017

etc. 225 - 275 HSS 140 240 0.006 0.009 0.013 0.016 0.018 0.021 0.024 0.017

275 - 325 SC 130 225 0.005 0.008 0.012 0.015 0.016 0.019 0.022 0.015

Alloy Steel 125 - 175 HSS 150 240 0.007 0.010 0.014 0.017 0.017 0.019 0.022 0.016

P 4140, 5140, 8640, etc. 175 - 225 HSS 140 225 0.006 0.009 0.013 0.016 0.017 0.019 0.022 0.016

225 - 275 HSS 130 210 0.006 0.009 0.013 0.016 0.017 0.019 0.022 0.016

275 - 325 SC 120 195 0.005 0.008 0.012 0.015 0.015 0.017 0.020 0.015

325 - 375 SC 110 180 0.004 0.007 0.011 0.014 0.015 0.017 0.020 0.014

High Strength Alloy 225 - 300 SC 80 125 0.006 0.009 0.011 0.013 0.014 0.017 0.020 0.012

4340, 4330V, 300M, etc. 300 - 350 SC 60 100 0.005 0.008 0.010 0.012 0.014 0.017 0.020 0.012

350 - 400 SC 50 80 0.004 0.007 0.009 0.011 0.012 0.015 0.018 0.011

Structural Steel 100 - 150 HSS 140 235 0.008 0.011 0.015 0.017 0.018 0.021 0.026 0.017

A36, A285, A516, etc. 150 - 250 HSS 120 190 0.006 0.010 0.013 0.015 0.016 0.019 0.024 0.016

250 - 350 SC 100 160 0.005 0.009 0.012 0.013 0.014 0.017 0.020 0.015

Tool Steel 150 - 200 SC 80 125 0.004 0.007 0.010 0.012 0.012 0.015 0.017 0.012

H-13, H-21, A-4, 0-2, S-3, etc. 200 - 250 SC 60 105 0.004 0.007 0.010 0.012 0.012 0.015 0.017 0.011

High Temp Alloy 140 - 220 SC 30 45 0.004 0.007 0.009 0.011 0.012 0.015 0.017 0.012

Hastelloy B, Inconel 600, etc. 220 - 310 SC 25 40 0.004 0.006 0.008 0.010 0.010 0.012 0.014 0.010

Titanium Alloy 140 - 220 SC 35 55 0.004 0.007 0.008 0.010 0.012 0.015 0.017 0.012

S 220 - 310 SC 30 50 0.003 0.006 0.007 0.009 0.010 0.012 0.014 0.010

Aerospace Alloy 185 - 275 SC 75 110 0.006 0.008 0.009 0.011 0.014 0.016 0.020 0.015

S82 275 - 350 SC 60 100 0.005 0.007 0.008 0.010 0.012 0.014 0.018 0.012

Stainless Steel 400 Series 185 - 275 SC 75 110 0.006 0.008 0.009 0.011 0.014 0.016 0.020 0.014

416, 420, etc. 275 - 350 SC 60 100 0.005 0.007 0.008 0.010 0.012 0.014 0.018 0.011

Stainless Steel 300 Series 135 - 185 SC 75 110 0.003 0.007 0.008 0.011 0.014 0.016 0.020 0.014

M 304, 316, 17-4PH, etc. 185 - 275 SC 60 100 0.003 0.006 0.007 0.010 0.012 0.014 0.018 0.011

Super Duplex Stainless Steel 135 - 185 SC 60 85 0.003 0.007 0.008 0.011 0.014 0.016 0.020 0.014

185 - 275 SC 50 70 0.003 0.006 0.007 0.010 0.012 0.014 0.018 0.011

Wear Plate 400 SC 45 70 0.003 0.006 0.008 0.009 0.012 0.016 0.018 -

Hardox, AR400, T-1, etc. 500 SC 35 45 0.002 0.005 0.007 0.008 0.010 0.012 0.016 -

H 600 - - - 0.004 0.006 0.009 0.011 0.012 0.016 0.018 -

Hardened Steel 300 - 400 SC 50 95 - - - - - - - 0.015

400 - 500 SC 35 45 0.002 0.005 0.007 0.009 0.010 0.012 0.016 0.011

Nodular, Grey, Ductile Cast Iron 120 - 150 HSS 170 290 0.008 0.012 0.016 0.020 0.024 0.027 0.030 0.027

150 - 200 HSS 150 260 0.007 0.011 0.015 0.019 0.022 0.025 0.028 0.025

K 200 - 220 HSS 130 225 0.006 0.009 0.013 0.017 0.018 0.021 0.024 0.021

220 - 260 SC 110 190 0.005 0.008 0.011 0.014 0.014 0.017 0.020 0.017

260 - 320 SC 90 155 0.005 0.007 0.010 0.012 0.012 0.014 0.016 0.014

Cast Aluminum 30 HSS 600 - 0.009 0.015 0.018 0.023 0.022 0.025 0.025 0.019

180 HSS 300 - 0.008 0.013 0.016 0.020 0.022 0.025 0.025 0.019

Wrought Aluminum 30 HSS 600 900 0.005 0.013 0.016 0.020 0.022 0.025 0.025 0.019

180 HSS 300 650 0.005 0.007 0.012 0.014 0.022 0.025 0.025 0.019

N Aluminum Bronze 100 - 200 SC 170 270 0.006 0.009 0.012 0.015 0.017 0.019 0.021 0.024

200 - 250 SC 130 210 0.005 0.007 0.009 0.011 0.014 0.016 0.018 0.015

Brass 100 HSS 300 470 0.007 0.011 0.013 0.018 0.019 0.021 0.023 0.025

Copper 60 SC 130 190 0.003 0.004 0.007 0.010 0.009 0.011 0.012 0.014

Contact our Application Engineering department for assistance when machining these materials

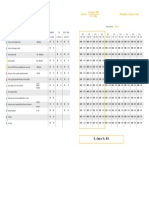

Deep Hole Drilling Speed and Feed Adjustment Formulas

Holder Length 1. RPM = (3.82 • SFM) / DIA IMPORTANT: The speeds and feeds listed above are a general starting point for all applications. Refer to the

where: Coolant Recommendation charts for coolant requirements to run at the recommended speeds and feeds.

Factory technical assistance is available through our Application Engineering department. See adjustment

RPM = revolutions per minute (rev/min)

examples on the following page.

SFM = speed (ft/min)

Extended Long Long Plus XL 3XL DIA = diameter of drill (inch)

Speed 0.90 0.85 0.80 0.80 0.75 WARNING Tool failure can cause serious injury. To prevent:

Feed - 0.95 0.90 0.90 0.90 2. IPM = RPM • IPR - When using holders without support bushing, use a short T-A® holder to establish an initial hole that is a

minimum of 2 diameters deep.

where: - Do not rotate tool holder more than 50 RPM unless it is engaged with the workpiece or fixture.

Recommended Speed and Feed Example IPM = inches per minute (in/min) Visit www.alliedmachine.com/deepholeguidelines.aspx for the most up-to-date information and procedures.

RPM = revolutions per minute (rev/min) Factory technical assistance is available for your specific applications through our Application Engineering Team.

If the recommended speed and feed is 200 SFM and 0.008 IPR

for a standard length holder, then the speed and feed using IPR = feed rate (in/rev)

a 3XL holder in the same application would be 150 SFM and

0.007 IPR. 3. SFM = RPM • 0.262 • DIA

where:

200 • 0.75 = 150 SFM 0.008 • 0.90 = 0.007 IPR

SFM = speed (ft/min)

RPM = revolutions per minute (rev/min)

DIA = diameter of drill (inch)

Vous aimerez peut-être aussi

- L'acierDocument25 pagesL'acierSaid MahmoudiPas encore d'évaluation

- Chapitre II - Traitement Thermique Des AciersDocument47 pagesChapitre II - Traitement Thermique Des AciersHeni Elhaj SalahPas encore d'évaluation

- Résumé de Métaux Ferreux PDFDocument35 pagesRésumé de Métaux Ferreux PDFhalima halima100% (1)

- Les Metaux Non FerreuxDocument22 pagesLes Metaux Non Ferreuxhalima halimaPas encore d'évaluation

- Fiche Technique Vanne A Opercule Fonte Siege Inox Din 3202 f4 Brides Pn16Document7 pagesFiche Technique Vanne A Opercule Fonte Siege Inox Din 3202 f4 Brides Pn16YASSINE EZMAMTIPas encore d'évaluation

- Chapitre 4 - Traitement Thermique Des AciersDocument35 pagesChapitre 4 - Traitement Thermique Des AciersBecem Trigui100% (2)

- Corrigé TD Met Ex 4 5 6 7Document5 pagesCorrigé TD Met Ex 4 5 6 7Mohammed El azhariPas encore d'évaluation

- PEC Table 10.1.1.9Document1 pagePEC Table 10.1.1.9Miko F. RodriguezPas encore d'évaluation

- PEC Table 10 1 1 9 PDFDocument1 pagePEC Table 10 1 1 9 PDFRick Alviento100% (1)

- Limite de Retiro Tuberias Carbon e InoxDocument1 pageLimite de Retiro Tuberias Carbon e Inoxrebeca cabello100% (1)

- Optimisation Paramètres D'usinage - TD1Document4 pagesOptimisation Paramètres D'usinage - TD1Younes AblePas encore d'évaluation

- Vitesse de Coupe ForetsDocument2 pagesVitesse de Coupe Foretsfarid said errahmaniPas encore d'évaluation

- Mat Grades Chemical & Mech - 180222Document16 pagesMat Grades Chemical & Mech - 180222Tushaar SethPas encore d'évaluation

- 07 585 Conversions Nuances Metalliques Et Caracteristiques Pour JointsDocument1 page07 585 Conversions Nuances Metalliques Et Caracteristiques Pour Jointspascal.lebbrechtPas encore d'évaluation

- Tableaux Des Matières PDFDocument14 pagesTableaux Des Matières PDFTheo SantonPas encore d'évaluation

- Q2 Ion Analytical Program-Al - MatrixDocument1 pageQ2 Ion Analytical Program-Al - Matrixsreechamun venturesPas encore d'évaluation

- Q2 Ion Analytical Program-Fe - MatrixDocument1 pageQ2 Ion Analytical Program-Fe - Matrixsreechamun venturesPas encore d'évaluation

- Acier S355 Fiche Technique, S355J0, S355J2, S355JR Caractéristiques Mécaniques - Matière Du MondeDocument5 pagesAcier S355 Fiche Technique, S355J0, S355J2, S355JR Caractéristiques Mécaniques - Matière Du MondeVonjinantenaina Volamalala100% (1)

- AluminiumDocument2 pagesAluminiumsolideo85Pas encore d'évaluation

- WerkstoffdatenDocument21 pagesWerkstoffdatenersinPas encore d'évaluation

- Fiche Technique Volant VanneDocument2 pagesFiche Technique Volant VannemikabtpPas encore d'évaluation

- UntitledDocument9 pagesUntitledRajasekar RPas encore d'évaluation

- Semelle Continue Sous MurDocument22 pagesSemelle Continue Sous Murtechno samirPas encore d'évaluation

- Alloys DataDocument3 pagesAlloys DatamdkhandavePas encore d'évaluation

- CuNi Size ChartDocument1 pageCuNi Size ChartShivakumar KPas encore d'évaluation

- Directives de Surtaraudage D'écrous Et de Filets IntérieursDocument1 pageDirectives de Surtaraudage D'écrous Et de Filets IntérieursVincent BourgeoisPas encore d'évaluation

- Grafik de DFDocument4 pagesGrafik de DFRichard Innocentius NatelPas encore d'évaluation

- NF EN 10210-1 Steel S460NHDocument3 pagesNF EN 10210-1 Steel S460NHBahloul HaythemPas encore d'évaluation

- Face Milling Cutter OE45 - en - WebDocument2 pagesFace Milling Cutter OE45 - en - WebTodorPas encore d'évaluation

- Brocas Dixi DicutDocument1 pageBrocas Dixi DicutFábioVidalPas encore d'évaluation

- Table 10.1.1.9 PDFDocument1 pageTable 10.1.1.9 PDFcjay ganirPas encore d'évaluation

- Dossier Ressource - EleveDocument100 pagesDossier Ressource - Eleveimad elgzaPas encore d'évaluation

- Tabela de Folgas de Mancais DINDocument1 pageTabela de Folgas de Mancais DINfelipelintzPas encore d'évaluation

- Fiche Technique Safer G48 NDocument1 pageFiche Technique Safer G48 NdttPas encore d'évaluation

- Shimano Stella 20000FA Fishing ReelDocument32 pagesShimano Stella 20000FA Fishing ReelbabyintanPas encore d'évaluation

- Section 1 HRSDocument16 pagesSection 1 HRSFrancisPas encore d'évaluation

- DEF2Document1 pageDEF2foryouuonly1234Pas encore d'évaluation

- Calcul Des SemellesDocument13 pagesCalcul Des SemellesChaimaPas encore d'évaluation

- Alu 2017A-AU4GDocument2 pagesAlu 2017A-AU4GBESSIEREPas encore d'évaluation

- FT - Joint de Démontage À 3 Brides DN 50-250 - 265!50!001 - Avk010 - FR - 492002Document2 pagesFT - Joint de Démontage À 3 Brides DN 50-250 - 265!50!001 - Avk010 - FR - 492002belaidmahdi010Pas encore d'évaluation

- Pipe SchedulesDocument1 pagePipe SchedulesJoe BetkerPas encore d'évaluation

- Norelem 1Document70 pagesNorelem 1Saad JebbariPas encore d'évaluation

- AMOY1Document1 pageAMOY1Vee ChanPas encore d'évaluation

- Papan-Uf - 2021 (08 Okt 2021)Document1 849 pagesPapan-Uf - 2021 (08 Okt 2021)itumafindoPas encore d'évaluation

- Doc-Tech - Etais Droit & TPDocument34 pagesDoc-Tech - Etais Droit & TPMamady CissokoPas encore d'évaluation

- Datasheet 2908 Axe D Articulation Acier Ou Inox - FRDocument2 pagesDatasheet 2908 Axe D Articulation Acier Ou Inox - FRjeanromain.bitsindouPas encore d'évaluation

- Tabel Calitati INOXDocument2 pagesTabel Calitati INOXion iosifPas encore d'évaluation

- Results Load CombinationsDocument2 930 pagesResults Load CombinationsNicolas FernandezPas encore d'évaluation

- Tabel Momen Akhir Anstruk Ii DianDocument1 pageTabel Momen Akhir Anstruk Ii DianAsep BadangPas encore d'évaluation

- Escalas y TextosDocument1 pageEscalas y TextosMaria AquinoPas encore d'évaluation

- Dimensiones-De-Tuberia 2Document1 pageDimensiones-De-Tuberia 2Cherie JohnsonPas encore d'évaluation

- Table 6-15 Tolerance Zones - Internal Dimensions (Holes) (t10 ... t5, U10... U5) (Ansi b4.2)Document1 pageTable 6-15 Tolerance Zones - Internal Dimensions (Holes) (t10 ... t5, U10... U5) (Ansi b4.2)RAVI KIRAN CHALLAGUNDLAPas encore d'évaluation

- Panne ZDocument1 pagePanne ZBlaise AtchomPas encore d'évaluation

- P265GHDocument1 pageP265GHImec InterPas encore d'évaluation

- Molas HMDocument89 pagesMolas HMJulius BaniquedPas encore d'évaluation

- Graficas y Tablas de Las Funciones Trigonometric AsDocument14 pagesGraficas y Tablas de Las Funciones Trigonometric Aservg9412081527490% (21)

- JRI JI Vulcasteel Wall Liner Profile TDS FR Context FR FR PID 020Document2 pagesJRI JI Vulcasteel Wall Liner Profile TDS FR Context FR FR PID 020y.belloute.seribatiPas encore d'évaluation

- 03 CRMBS1030Document1 page03 CRMBS1030Duong PhạmPas encore d'évaluation

- C50Document282 pagesC50Nathalia CustódioPas encore d'évaluation

- Brochure InoxDocument2 pagesBrochure InoxSmail MiloudiPas encore d'évaluation

- Euronorm Normes Nationales Correspondantes Pour Les Aciers b00001 02Document4 pagesEuronorm Normes Nationales Correspondantes Pour Les Aciers b00001 02Gregory frissotPas encore d'évaluation

- Embodied Carbon InformationDocument9 pagesEmbodied Carbon Informationzaidiamna9Pas encore d'évaluation

- Catalogue_visserie_-_boulonnerie_RECADocument48 pagesCatalogue_visserie_-_boulonnerie_RECAignismonkeyPas encore d'évaluation

- R Datasheet 11521 Tube Rond - FRDocument2 pagesR Datasheet 11521 Tube Rond - FRNABIL ABDEDAIEMPas encore d'évaluation

- Lexique MétallurgiqueDocument2 pagesLexique Métallurgiquebeey2001Pas encore d'évaluation

- Matriçage (Métallurgie) - WikipédiaDocument2 pagesMatriçage (Métallurgie) - WikipédiaM K 10Pas encore d'évaluation

- 1 Presentation GeneralitesDocument78 pages1 Presentation GeneralitesHajar Ben GaraâPas encore d'évaluation

- R Désignations Des MatériauxDocument1 pageR Désignations Des MatériauxybenguennyPas encore d'évaluation

- Designation ACIERS & FONTESDocument6 pagesDesignation ACIERS & FONTESHoussam KhemissaPas encore d'évaluation

- Tech Fonderie Vincent JANV 2010Document6 pagesTech Fonderie Vincent JANV 2010Hafedh MezgarPas encore d'évaluation

- Syma32 Syma14 Ficha TecnicaDocument1 pageSyma32 Syma14 Ficha TecnicaAki LeoPas encore d'évaluation

- Petit Lexique Du Soudage Anglaus-FrançaisDocument18 pagesPetit Lexique Du Soudage Anglaus-FrançaisPierre PescayPas encore d'évaluation

- B53 3070 - Ind.J - CR & HR Technical RequirementsDocument9 pagesB53 3070 - Ind.J - CR & HR Technical Requirements3MECH015 Bhavatharan SPas encore d'évaluation

- TP 2 de SDM (Les Aciers)Document5 pagesTP 2 de SDM (Les Aciers)Fa TehPas encore d'évaluation

- Tableau Vierge de La Classification PeriodiqueDocument3 pagesTableau Vierge de La Classification PeriodiqueMariettePas encore d'évaluation

- Cours 1 Pour 1er Année PMI FAB 1Document5 pagesCours 1 Pour 1er Année PMI FAB 1Ayoub BenhajajPas encore d'évaluation

- Chap II - Les Différents Classes Des MatériauxDocument180 pagesChap II - Les Différents Classes Des Matériauxomarmarri2016Pas encore d'évaluation

- Devoir Surveillé de Science Des Matériaux 1 - EnoncéeDocument4 pagesDevoir Surveillé de Science Des Matériaux 1 - EnoncéeMohamed Kayri Zouabi100% (1)

- Chap. VI Les Traitements ThermiquesDocument9 pagesChap. VI Les Traitements ThermiquesAmin LarouiPas encore d'évaluation

- Chapitre 3Document8 pagesChapitre 3Mohsen SaidiPas encore d'évaluation

- Le PoinçonnageDocument10 pagesLe PoinçonnageMohamd BobsPas encore d'évaluation

- Chapitre 3 Etude Du Diagramme Fer Carbone ConvertiDocument14 pagesChapitre 3 Etude Du Diagramme Fer Carbone ConvertiSkanderPas encore d'évaluation

- Opcm - M03Document238 pagesOpcm - M03yousseftahhiri194Pas encore d'évaluation

- Chapitre 5 Désignation Normalisée Des MatériauxDocument12 pagesChapitre 5 Désignation Normalisée Des MatériauxAmin AhmedPas encore d'évaluation

- Information Générale DormerDocument34 pagesInformation Générale DormerRedvane MobranPas encore d'évaluation

- Corrigé MetallurgieDocument4 pagesCorrigé MetallurgieKengheu KevinPas encore d'évaluation

- Complément 1-Désignations Et Choix Des Paramètres D'usinage Et D'outillageDocument4 pagesComplément 1-Désignations Et Choix Des Paramètres D'usinage Et D'outillageZyneb EttalebiPas encore d'évaluation

- Procédés de Mise en Forme IndustrielDocument22 pagesProcédés de Mise en Forme Industrielsrhabouqi2016Pas encore d'évaluation