Académique Documents

Professionnel Documents

Culture Documents

VF - 21 - 22SB Iom

Transféré par

Marcin Jakub RabendaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

VF - 21 - 22SB Iom

Transféré par

Marcin Jakub RabendaDroits d'auteur :

Formats disponibles

VF-21SB / VF-22SB Series

Installation, Operation & Maintenance

Instructions

INSTALLATION

Remove the housing thread protectors from the inlet

and outlet connections. Make certain the connections

are free of all debris.

IMPORTANT:

BE SURE TO CORRECTLY IDENTIFY THE INLET

AND OUTLET CONNECTIONS TO AVOID PIPING

THE UNIT BACKWARDS.

THE UNIT WILL NOT PERFORM CORRECTLY IF

CONNECTIONS ARE REVERSED.

The petcock drain and vent valves should be installed

using Teflon tape or similar sealant.

Note: For jet fuel service, the included valves should be

replaced with items not made from brass or bronze.

Provide shut-off valves in the inlet and outlet piping as

close to the unit as possible for isolating the unit from

the systems when cartridge replacement is necessary.

Connect the housing into the piping system with a

minimum number of turns and fittings, especially on the

inlet side. For installation on fuel dispensing pumps,

connect the fuel delivery hose directly to the outlet

connection.

In order to provide electrical bonding for the housing

and prevent static discharge, a bonding cable kit (P/N

644964) is available and recommended. One end

should be attached to the sump drain ½" coupling and

the other end to the inlet or outlet 1½" piping.

Note: It is recommended that the vent and drain valves

or plug be opened once each day to permit the escape of

entrapped air and accumulated water.

644965 - C - 8/29/2019 1-(800) 223-9910

1-(918) 272-8700

facet@filtrationgroup.com

www.processtechnologies.filtrationgroup.com

VF-21SB / VF-22SB Series

Installation, Operation & Maintenance

Instructions

MAINTENANCE

Since there are no moving parts, maintenance is limited 4. Loosen (4) swing bolts, then remove the housing

to an occasional cartridge replacement, requiring only body and element.

2" (51 mm) base clearance.

Note: Every Facet replacement element available for CAUTION:

this housing comes with a new cover gasket. Install a DUE TO THE TOXIC EFFECTS OF SOME

new gasket when changing elements. ADDITIVES USED IN FILTERED FLUIDS, CARE

SHOULD BE EXERCISED IN HANDLING THE

EXPENDED CARTRIDGE AND/OR ALL INTERNAL

CARTRIDGE REPLACEMENT

PARTS THAT HAVE BEEN IN CONTACT WITH THE

PROCEDURES:

FILTERED PRODUCTS.

CAUTION: 5. Remove and discard the expended cartridge and

1. FULL FLOW MONITORS (WATER ABSORBING closure o-ring in a FIRE-SAFE place.

ELEMENTS ARE NOT FOR USE WITH FUEL 6. Flush the interior of the housing with clean,

CONTAINING ANTI-ICING ADDITIVE (FSII, processed, filtered product or a suitable solvent. A

PRIST, DI-EGME). THIS INCLUDES PRE- nonmetallic bristle brush will help to remove caked

MIXED AND MILITARY FUELS CONTAINING on debris. Rinse the housing and unit cover with

THIS ADDITIVE. clean solvent and dry with soft, lint-free wiping cloth.

2. USE ONLY NON-SPARKING TOOLS WHEN 7. Remove a new replacement cartridge from the

PERFORMING ANY MAINTENANCE OR shipping carton; closely inspect the cartridge before

SERVICE WORK ON THIS EQUIPMENT. installing it. Slide the new cartridge into the housing.

8. Install new closure o-ring. Reassemble the body

The frequency of cartridge replacement is dependent and align swing bolts with cover bolt slots. Tighten

on the following conditions: the bolts attaching the body to the housing cover.

Torque to 10ft/ lbs.

1. Effluent flow is noticeably reduced. 9. Close the drain plug or valve on the bottom of the

2. Differential pressure across the unit reaches 15 psid. housing.

3. Recommended replacement is once yearly. 10. SLOWLY open the inlet and outlet valves; allow the

unit to fill completely.

If any of the above noted conditions indicate that 11. Leave the vent valve on top of the unit open, to

cartridge replacement is necessary follow procedures allow entrapped air to escape while filling.

below. 12. When a small amount of fluid flows from the vent,

1. Close the inlet and outlet blocking valves to isolate close it tightly.

the filter from the system. 13. During initial filling, after above maintenance, and

2. Open the drain plug or drain valve on the housing while unit is in operation, examine housing and all

bottom; allow all fluid to drain from the unit. connections for leaks.

3. Open the vent valve on the cover of the housing; 14. Repair any leaks and replace damaged or deteriorated

allow the unit to thoroughly vent before opening parts such as closure o-ring, vent and drain valves or

the cover. plug as necessary.

644965 - C - 8/29/2019 1-(800) 223-9910

1-(918) 272-8700

facet@filtrationgroup.com

www.processtechnologies.filtrationgroup.com

VF-21SB / VF-22SB Series

Installation, Operation & Maintenance

Instructions

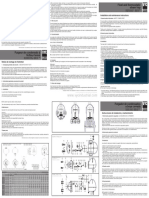

ITEM # PART # DESCRIPTION QTY. REQ

1 644548 Head/Cover/w/Pressure Gauge 1

2A 609333 21 Series Body 1

2B 684276 22 Series Body 1

3 644161 Flange Assembly 1

4 644604 Flange O-Ring 1

5 606521 Closure O-Ring 1

6 051486 1/8” Vent & Drain Valve 2

7 608440 1/2” x 1/8” Bushing 1

8 644160 Mounting Bracket Sold separately

9 Consult Factory Nameplate 1

10 644964 Bonding Cable Kit Sold Separately

Notes: Estimated Housing Weight:

All weights and Dimensions are approximate. 21 Series: (Dry) 15.5 Lbs (7.0 Kg)

Maximum Operating Pressure: 150 psi (10.34 bar) (Wet) 25.5 Lbs (11.6 Kg)

22 Series: (Dry) 18.3 Lbs (8.3 Kg)

(Wet) 31.3 Lbs (14.2 Kg)

644965 - C - 8/29/2019 1-(800) 223-9910

1-(918) 272-8700

facet@filtrationgroup.com

www.processtechnologies.filtrationgroup.com

Vous aimerez peut-être aussi

- Stiebel Electron LWZ270 PLUSDocument20 pagesStiebel Electron LWZ270 PLUSPRETOT100% (1)

- European Instruction Manual Series 353 Piston Diaphragm Type Power Pulse Valves 3 4 To 1 FR FR 5181902Document2 pagesEuropean Instruction Manual Series 353 Piston Diaphragm Type Power Pulse Valves 3 4 To 1 FR FR 5181902AirteamPas encore d'évaluation

- Montage VanneDocument11 pagesMontage Vannebouchoucha57000Pas encore d'évaluation

- European Instruction Manual Solenoid Valves Low Pressure Gaseous Fluids 040 Asco en 4914066Document2 pagesEuropean Instruction Manual Solenoid Valves Low Pressure Gaseous Fluids 040 Asco en 4914066Jose Gregorio Lira SerranoPas encore d'évaluation

- 6-Manuel D'usage Et Entretien Reservoir Air ComprimeDocument12 pages6-Manuel D'usage Et Entretien Reservoir Air ComprimeraobenPas encore d'évaluation

- European Instruction Manual Series 353 Full Immersion Pulse Tank System FR FR 5182574Document2 pagesEuropean Instruction Manual Series 353 Full Immersion Pulse Tank System FR FR 5182574AirteamPas encore d'évaluation

- Daewoo XG-332V, 334V, 335V, 336VDocument31 pagesDaewoo XG-332V, 334V, 335V, 336Vfingersound100% (1)

- Infos CORPS DE FILTRE RETOUR 310599 RFM 165Document8 pagesInfos CORPS DE FILTRE RETOUR 310599 RFM 165contactPas encore d'évaluation

- Instructions Box - EngDocument2 pagesInstructions Box - EngVictor Ruiz FuentesPas encore d'évaluation

- HSC ManualDocument26 pagesHSC Manualait.koufiPas encore d'évaluation

- TéléchargementDocument12 pagesTéléchargementzak loujPas encore d'évaluation

- Instructions S353A730-engDocument2 pagesInstructions S353A730-engVictor Ruiz FuentesPas encore d'évaluation

- Aircalo Centrale Air Mistral 04 22 Mes FRDocument24 pagesAircalo Centrale Air Mistral 04 22 Mes FROliverPas encore d'évaluation

- Reservoir Galvanise Acz Notice 00Document4 pagesReservoir Galvanise Acz Notice 00chouaib kennichePas encore d'évaluation

- Pompes Anti-IncendieDocument28 pagesPompes Anti-Incendieel harsal hichamPas encore d'évaluation

- Fiche Technique ELECAP12Document6 pagesFiche Technique ELECAP12Anas OUBOULMANEPas encore d'évaluation

- ViewerDocument23 pagesViewerrania BakkaliPas encore d'évaluation

- Hotte Aspirante Rosières RHC638Document9 pagesHotte Aspirante Rosières RHC638David DelplacePas encore d'évaluation

- A600-1 Enroleur A 1 TuyauDocument19 pagesA600-1 Enroleur A 1 TuyauGrandia 2019Pas encore d'évaluation

- Mise en Service Choc FortDocument2 pagesMise en Service Choc FortAmeur YaakoubiPas encore d'évaluation

- 243 enDocument2 pages243 enlesonspkPas encore d'évaluation

- Airton TAC 09 CHSA - H Air ConditionerDocument24 pagesAirton TAC 09 CHSA - H Air ConditionergfhdhgfhdPas encore d'évaluation

- Manuel Osmoseur Domestique en FrancaisDocument17 pagesManuel Osmoseur Domestique en FrancaisAmin ThabetPas encore d'évaluation

- Maintenance Ebv FRGB 05 2007Document2 pagesMaintenance Ebv FRGB 05 2007zorgh23Pas encore d'évaluation

- KOMAKINO1 39610 1518101559509 Notice EQFK11TX Rev ADocument1 pageKOMAKINO1 39610 1518101559509 Notice EQFK11TX Rev AZakia MoutikPas encore d'évaluation

- Pumps Euro TechSheet FRDocument2 pagesPumps Euro TechSheet FRFreddy PAVADEPas encore d'évaluation

- h000 SecuriteDocument6 pagesh000 SecuriteRiyadhPas encore d'évaluation

- FKD Series - Manual PDFDocument12 pagesFKD Series - Manual PDFhenrengPas encore d'évaluation

- EPR0000000000000000000007556020021Document3 pagesEPR0000000000000000000007556020021abdoPas encore d'évaluation

- Instruction Montage Maintenance Vanne PapillonDocument5 pagesInstruction Montage Maintenance Vanne PapillonsaidloubarPas encore d'évaluation

- Man.3.1.01 GB5-FB80 en V2.0Document66 pagesMan.3.1.01 GB5-FB80 en V2.0Alfredo VianaPas encore d'évaluation

- DRF - NT16 0716 BDDocument24 pagesDRF - NT16 0716 BDMarbrerie RS MARECHALPas encore d'évaluation

- SFADocument6 pagesSFAGer ManouchPas encore d'évaluation

- Séparateur D'eau Et Filtre À Carburant (Primaire) - Dépose Et PoseDocument2 pagesSéparateur D'eau Et Filtre À Carburant (Primaire) - Dépose Et PoseelyeszebdaPas encore d'évaluation

- Comment Choisir Une Vanne - AVK FranceDocument4 pagesComment Choisir Une Vanne - AVK FrancelhabsPas encore d'évaluation

- Manual D Installation Mural Split v2 5Document40 pagesManual D Installation Mural Split v2 5NizarChouchenePas encore d'évaluation

- ComapDocument8 pagesComapslawny77Pas encore d'évaluation

- Consignes D'entretienDocument14 pagesConsignes D'entretienIsmael ZerboPas encore d'évaluation

- AKU - AKU EKO (FR) (SL) v2020.1Document16 pagesAKU - AKU EKO (FR) (SL) v2020.1Emanuel LucaPas encore d'évaluation

- B02-Ideo325 FL NoticeDocument16 pagesB02-Ideo325 FL Noticemahmoudk.btsPas encore d'évaluation

- Correction Travail de Session P 2090462Document17 pagesCorrection Travail de Session P 2090462alpha jshadjkPas encore d'évaluation

- Manuel Atelier Dink Street 125i en FrancaisDocument257 pagesManuel Atelier Dink Street 125i en Francaislioferliofer67% (3)

- Bombas FlotecDocument40 pagesBombas FlotecAdán Castro GallegosPas encore d'évaluation

- Indications Generales: A - StockageDocument4 pagesIndications Generales: A - StockageCherif GhalebPas encore d'évaluation

- Markbass Tte 501 Manuel Utilisateur en 53406Document8 pagesMarkbass Tte 501 Manuel Utilisateur en 53406Juan MarínPas encore d'évaluation

- Transtube258efx ManualDocument36 pagesTranstube258efx Manual021000088Pas encore d'évaluation

- Eaton 9PX 10000i-1500i-2200i-3000i-EBM 48V-EBM 72V - Manuel D'installation Et D'utilisationDocument40 pagesEaton 9PX 10000i-1500i-2200i-3000i-EBM 48V-EBM 72V - Manuel D'installation Et D'utilisationAzerPas encore d'évaluation

- 14 PSC M FDocument6 pages14 PSC M FkifpaddlePas encore d'évaluation

- Mode Emploi GF2012Document20 pagesMode Emploi GF2012Monem BahriPas encore d'évaluation

- 2319 Safe CleanerDocument4 pages2319 Safe Cleanerhjayekoue01Pas encore d'évaluation

- Notice Montage CapteurDocument4 pagesNotice Montage CapteurroblinPas encore d'évaluation

- SHRM Codigos de FallaDocument43 pagesSHRM Codigos de FallaMarcelo RamirezPas encore d'évaluation

- QOSAMK Surge Arrester Mounting Kit QOSAMK Accesorio de Montaje Del Supresor de Tramsitorios QOSAMK Kit de Montage de Suppresseur de SurtensionDocument2 pagesQOSAMK Surge Arrester Mounting Kit QOSAMK Accesorio de Montaje Del Supresor de Tramsitorios QOSAMK Kit de Montage de Suppresseur de SurtensionZts MksPas encore d'évaluation

- Npu - Laz T SB Mc2 Desinfectant FR v1.0 - DevatecDocument10 pagesNpu - Laz T SB Mc2 Desinfectant FR v1.0 - DevatecJan OlivierPas encore d'évaluation

- Notice Membrane Osmp50Document2 pagesNotice Membrane Osmp50Frederic KfPas encore d'évaluation

- NT 1370 G CanalfastDocument9 pagesNT 1370 G CanalfastKushalKallychurnPas encore d'évaluation

- Afe 424 UsersDocument15 pagesAfe 424 UsersPaul DavisPas encore d'évaluation

- Enrouleurs LO3KDocument6 pagesEnrouleurs LO3KBrahim TelliPas encore d'évaluation