Académique Documents

Professionnel Documents

Culture Documents

Assembly Instructions-C11 Amphenol Type N: Crimp-Crimp Types

Transféré par

Hugo BarrosTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assembly Instructions-C11 Amphenol Type N: Crimp-Crimp Types

Transféré par

Hugo BarrosDroits d'auteur :

Formats disponibles

Assembly Instructions-C11 Amphenol®

Type N

CRIMP-CRIMP TYPES

outer ferrule contact body assembly

Strip Dimensions, inches (mm) Hex Crimp Data

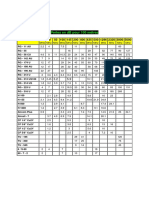

Amphenol Connector Cable

Number Type RG-/U Cavity for Cavity for Die Set for CTL Series

a b c

Contact Outer Ferrule Tool 227-944‡ Tool No.

82-332 N Plug 9, 214 .531(13.5) .234(6.0) .140(3.5) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-340 N Plug 8, 213 .531(13.5) .234(6.0) .141(3.6) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-340-1052 N Plug B9913, 9914 .539(13.7) .250(6.4) .158(4.0) .116(2.9) .429(10.9) 227-1221-63 CTL-11

82-340-1054 N Plug LMR 400 .539(13.7) .250(6.4) .157(4.0) .116(2.9) .429(10.9) 227-1221-63 CTL-11

82-4425 N Plug 9, 214, 225, 393 .687(17.4) .281(7.1) .187(4.7) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-4425-1003 N Plug 9, 214, 225, 393 .687(17.4) .281(7.1) .187(4.7) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-4426 N Plug 8, 213 .687(17.4) .281(7.1) .187(4.7) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-4426-11RFX N Plug 8, 213, 214 Eth.Cables .630(16.0) .303(7.7) .157(4.0) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-4426-1001 N Plug Ethernet Cables .687(17.4) .281(7.1) .187(4.7) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-4426-1002 N Plug Ethernet Cables .687(17.4) .281(7.1) .187(4.7) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-4427 N Plug 142, 400 .687(17.4) .281(7.1) .187(4.7) .100(2.5) .213(5.4) 227-1221-57 CTL-3

Assembly

82-4427-1006 N Plug 142, 142B, 400 .600(15.2) .275(7.0) .140(3.5) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-4440 N Angle Plug 214, 225, 393 .687(17.4) .281(7.1) .187(4.7) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-4440-1001 N Angle Plug 9, 214, 225, 393 .687(17.4) .281(7.1) .187(4.7) .100(2.5) .429(10.9) 227-1221-25 CTL-3

82-5370 N Plug 55, 142, 223 .600(15.2) .275(7.0) .140(3.5) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-5372 N Panel Jack 55, 141, 142 .600(15.2) .275(7.0) .140(3.5) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-5373 N Bulkh. Jack 55, 142, 223 .640(16.3) .315(8.0) .180(4.6) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-5374 N Angle Plug 55, 142, 223 .687(17.4) .281(7.1) .187(4.7) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-5375 N Plug 58, 141 .531(13.5) .233(5.9) .140(3.5) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-5375-RFX N Plug 58, 141 .630(16.0) .303(7.7) .157(4.0) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-5378 N Bulkh. Jack 58, 141 .640(16.3) .273(6.8) .180(4.6) .100(2.5) .213(5.4) 227-1221-57 CTL-3

82-5933 N Bulkh. Jack 316 .502(12.7) .102(2.6) .062(1.6) Solder .178(4.5) 227-1221-09 CTL-2

82-5988-1000 N Angle Plug 214, 393 .827(21.0) .492(12.5) .157(4.0) Solder .429(10.9) 227-1221-6001 CTL-3

82-5988-1004 N Angle Plug 214, 393 .827(21.0) .492(12.5) .157(4.0) Solder .429(10.9) 227-1221-6001 CTL-3

82-5993 N Plug LMR 600 .844(21.4) .344(8.7) .250(6.4) .176(4.5) .612(15.5) 227-1221-6001 —

82-5994 N Bulkh. Jack LMR 600 .844(21.4) .344(8.7) .250(6.4) .176(4.5) .612(15.5) 227-1221-6001 —

82-5995 N Angle Plug LMR 600 1.062(27.0) .562(14.3) .312(7.9) Solder .612(15.5) 227-1221-6001 —

82-6010 N Plug LMR 240 .610(15.5) .200(5.1) .200(5.1) Press-Fit .255(6.5) 227-1221-59,-13 CTL-1.5,8

82-6106 N Plug LMR 240 .687(17.4) .312(7.9) .187(4.7) .100(2.5) .255(6.5) 227-1221-59 CTL-5

82-5988-1000 N Angle Plug LMR 240 .827(21.0) .492(12.5) .157(4.0) .100(2.5) .255(6.5) 227-1221-59 CTL-5

82-5988-1004 N Angle Plug LMR 240 .827(21.0) .492(12.5) .157(4.0) .100(2.5) .255(6.5) 227-1221-59 CTL-5

Step 1 Step 1 Strip cable jacket, braid, and dielectric to dimensions shown. All cuts

aA are to be sharp and square. Important: Do not nick braid, dielectric,

STEP 1

bB and center conductor. Tinning of center conductor is not necessary if

c

C

contact is to be crimped. For solder method, tin center conductor

avoiding excessive heat.

Step 2 Slide outer ferrule onto cable as shown. Flare slightly end

of cable braid as shown to facilitate insertion of inner

Step 2 ferrule. Important: Do not comb out braid.

STEP 2 crimp here Place contact on cable center conductor so it butts against

cable dielectric. Center conductor should be visible

through inspection hole in contact. Crimp or solder contact

in place as follows:

Crimp Method: Use Die Set Cavity for contact indicated in

table above.Solder Method: Soft solder contact to cable center

conductor. Do not get any solder on outside surface of

Step 3 contact. Avoid excessive heat to prevent swelling of dielectric.

STEP 3

Step 3 Install cable assembly into body assembly so inner ferrule

portion slides under braid. Push cable assembly forward

until contact snaps into place in insulator. Slide outer ferrule over braid

and up against connector body. Crimp outer ferrule using Die Set

crimp here Cavity specified in table above.

Amphenol Corporation Tel: 800-627-7100 www.amphenolrf.com

283

Vous aimerez peut-être aussi

- Les Exercices de La Methode SilvaDocument11 pagesLes Exercices de La Methode Silvaعرفان باهر100% (8)

- Traité de Psychopathologie de L'adulte - Narcissisme Et Dépression by Catherine ChabertDocument440 pagesTraité de Psychopathologie de L'adulte - Narcissisme Et Dépression by Catherine ChabertFrank Eric Ciatchoua Ngoundjo100% (7)

- BM Volvo BM WebDocument24 pagesBM Volvo BM WebvalterripPas encore d'évaluation

- Senorep 2EDocument6 pagesSenorep 2Emohamed0167Pas encore d'évaluation

- Legrand Liste Des Tarifs Jan 2023 Professionnel-référence-HTDocument1 410 pagesLegrand Liste Des Tarifs Jan 2023 Professionnel-référence-HTSidali Hadj BenaliPas encore d'évaluation

- Chapitre03 Serre CablesDocument6 pagesChapitre03 Serre CablesAchraf BoudayaPas encore d'évaluation

- SwingDocument33 pagesSwingKarim KarimPas encore d'évaluation

- ACFrOgAIR NzmLaV4T0aMyRCZ7myPuOJnCHtT3dvsD9ulP82nc2n6AiXI3Y0OIuk5qgmqT-JIJOqBmOl7dPKyo9BcW2bePMioQh6q3oQRtAUGB0yHsPaARc99QEYQudLV3AQOV-6WZo3gcye LBFDocument2 pagesACFrOgAIR NzmLaV4T0aMyRCZ7myPuOJnCHtT3dvsD9ulP82nc2n6AiXI3Y0OIuk5qgmqT-JIJOqBmOl7dPKyo9BcW2bePMioQh6q3oQRtAUGB0yHsPaARc99QEYQudLV3AQOV-6WZo3gcye LBFHugo BarrosPas encore d'évaluation

- U1000rvfv PDFDocument4 pagesU1000rvfv PDFDODOHICHAMPas encore d'évaluation

- DTP 411.1Document5 pagesDTP 411.1JI MIPas encore d'évaluation

- DTP 411.1Document5 pagesDTP 411.1JI MIPas encore d'évaluation

- ViakonDocument2 pagesViakonRiGo MartinezPas encore d'évaluation

- Materiale de Adaos EWMDocument176 pagesMateriale de Adaos EWMRogo CatalinPas encore d'évaluation

- Reaction ForceDocument8 pagesReaction ForcesafwanPas encore d'évaluation

- Lapter PerkerasanDocument66 pagesLapter PerkerasanaxlPas encore d'évaluation

- 12 Volt - Agm - Intimidator® - Valve Regulated: Effective July 5, 2022Document4 pages12 Volt - Agm - Intimidator® - Valve Regulated: Effective July 5, 2022JEFF MOUNTPas encore d'évaluation

- Cable Current Carry IECDocument2 pagesCable Current Carry IECjonyoliuPas encore d'évaluation

- U 1000 RVFV ArvfvDocument6 pagesU 1000 RVFV ArvfvBALLOUK SoufianePas encore d'évaluation

- Prirubnice Ansi B 16 9Document3 pagesPrirubnice Ansi B 16 9Vladan TimotijevicPas encore d'évaluation

- LP 5Document2 pagesLP 5Oth MellalPas encore d'évaluation

- Catalogue Oerlikon ConsommablesDocument90 pagesCatalogue Oerlikon ConsommablesNAIFARBILELPas encore d'évaluation

- Tarif Leg SNC 202101Document1 299 pagesTarif Leg SNC 202101Alan GrossetPas encore d'évaluation

- Interaction Sous Chargement Horizontale MosquéeDocument4 pagesInteraction Sous Chargement Horizontale MosquéeKhouthir BeloucifPas encore d'évaluation

- Fiche N°2Document60 pagesFiche N°2SafePas encore d'évaluation

- Route - Convertor - v2 - 6 Universal - 00-48-08Document6 pagesRoute - Convertor - v2 - 6 Universal - 00-48-08kyaw kyawPas encore d'évaluation

- BATIFIL Mise À La Terre H07V-U H07V-R1Document1 pageBATIFIL Mise À La Terre H07V-U H07V-R1ahmed chakrounPas encore d'évaluation

- Tablas de TuberiaDocument17 pagesTablas de Tuberiafelix alcudiaPas encore d'évaluation

- 24 GRP Tag - DuDocument39 pages24 GRP Tag - DuShreyas GaurPas encore d'évaluation

- Kan-PusDocument6 pagesKan-PusMyint ZawPas encore d'évaluation

- Unit Price & Retail Price September 2021-1Document3 042 pagesUnit Price & Retail Price September 2021-1Heva SonjayaPas encore d'évaluation

- Catalogue LuminaireDocument84 pagesCatalogue LuminairechahbounnabilPas encore d'évaluation

- Tabela - Dimensionamento A CompressãoDocument10 pagesTabela - Dimensionamento A CompressãoMagno de Oliveira SantosPas encore d'évaluation

- Armaturne TabliceDocument2 pagesArmaturne TabliceVincent TylerPas encore d'évaluation

- Hitachi Dh40mrDocument6 pagesHitachi Dh40mrcristimarioPas encore d'évaluation

- VERINS A TIRANTS Ø 25 À 200 MM - Double Effet CNOMO 06-07-02 - AFNOR Avec Amortissement Pneumatique RéglableDocument8 pagesVERINS A TIRANTS Ø 25 À 200 MM - Double Effet CNOMO 06-07-02 - AFNOR Avec Amortissement Pneumatique Réglableyouri594900% (1)

- StandardsDocument84 pagesStandardsHumaid Shaikh0% (1)

- Perte Cable PDFDocument4 pagesPerte Cable PDFcheikh196Pas encore d'évaluation

- CODAPDocument19 pagesCODAPOur SalahEddine100% (1)

- Tabla SateliteDocument5 pagesTabla SateliteTito Contreras SepuPas encore d'évaluation

- Data Pesawat Tugas Statistik Adrian G.K.Document8 pagesData Pesawat Tugas Statistik Adrian G.K.Adrian Gabriel KezhandraPas encore d'évaluation

- Torsade Aerienne Reseau NDocument2 pagesTorsade Aerienne Reseau NMahalmadanePas encore d'évaluation

- Annex 4 Bill of Quantities - Mep BuildingDocument97 pagesAnnex 4 Bill of Quantities - Mep BuildingEJPas encore d'évaluation

- Catu - Catalogue - Solutions Pour Industrie, Construction, Tertiaire - 2022Document244 pagesCatu - Catalogue - Solutions Pour Industrie, Construction, Tertiaire - 2022ZorbanfrPas encore d'évaluation

- Choix D'un Appareil de ForageDocument6 pagesChoix D'un Appareil de ForageLabib BiboPas encore d'évaluation

- Tabela PerfisDocument35 pagesTabela PerfisPC 90'sPas encore d'évaluation

- Electrovanne 3/2 356: À Commande Directe 1/8 - 1/4Document2 pagesElectrovanne 3/2 356: À Commande Directe 1/8 - 1/4Dimi HeesPas encore d'évaluation

- Aiwa nsx-s116-223Document30 pagesAiwa nsx-s116-223Humberto De Andrade CordovezPas encore d'évaluation

- En 12516 1 2005 Ac 2007Document3 pagesEn 12516 1 2005 Ac 2007Kishor JadhavPas encore d'évaluation

- Tablas ConductoresDocument6 pagesTablas Conductoresdiego abarcaPas encore d'évaluation

- 58 Fiche 0 PDFDocument1 page58 Fiche 0 PDFDebelmePas encore d'évaluation

- STAADOUTPUTDocument23 pagesSTAADOUTPUTfrancis sebastian lagamayoPas encore d'évaluation

- Resistencia de Tornillos AISC 360 16Document1 pageResistencia de Tornillos AISC 360 16Diego DíazPas encore d'évaluation

- Flanges ASME B16.5Document22 pagesFlanges ASME B16.5Madhu KarakkadPas encore d'évaluation

- NSX 303Document16 pagesNSX 303api-3703813100% (1)

- DISTRIFOR - Catalogue Tubes Micropieux - WEB, 2020Document2 pagesDISTRIFOR - Catalogue Tubes Micropieux - WEB, 2020Antoine PhilippePas encore d'évaluation

- Gear5 01Document100 pagesGear5 01PIMAL59Pas encore d'évaluation

- 90 Long Radius ElbowDocument0 page90 Long Radius ElbowSathishkumar Srinivasan100% (1)

- PUNTOS Examen RecuperaciónDocument11 pagesPUNTOS Examen RecuperaciónMiguel GuevaraPas encore d'évaluation

- Le syndrome périodique associé à la cryopyrine (CAPS)D'EverandLe syndrome périodique associé à la cryopyrine (CAPS)Pas encore d'évaluation

- Schema-Cablage-Renault-4 Modeles-1964-1966Document2 pagesSchema-Cablage-Renault-4 Modeles-1964-1966John Baker Silva MoncaleanoPas encore d'évaluation

- Achouri Amira NouhaDocument135 pagesAchouri Amira NouhaEmmanuel AvegnonPas encore d'évaluation

- Une Biodiversité MenacéeDocument1 pageUne Biodiversité Menacéeniu sauPas encore d'évaluation

- Consignes Leadership-Seance 1 - DefinitionDocument1 pageConsignes Leadership-Seance 1 - DefinitionAmadou BarryPas encore d'évaluation

- 3sc ds1Document44 pages3sc ds1wala.ayhemPas encore d'évaluation

- Les Mille Visages de L IndianOceanieDocument110 pagesLes Mille Visages de L IndianOceanieAli Abbas100% (1)

- Cahier Des Charges Installation PV SBC 2022Document20 pagesCahier Des Charges Installation PV SBC 2022youssefPas encore d'évaluation

- Symfony2 Un Tutoriel Pour Debuter Avec Le Framework Symfony2Document200 pagesSymfony2 Un Tutoriel Pour Debuter Avec Le Framework Symfony2Bryan Fury JimmyPas encore d'évaluation

- Le Labfab de Rennes 2012-2013: DiaporamaDocument14 pagesLe Labfab de Rennes 2012-2013: DiaporamalabfabfrPas encore d'évaluation

- DT2022-18 Document Travail Grille de DensiteDocument26 pagesDT2022-18 Document Travail Grille de Densitefrederic amadonPas encore d'évaluation

- T 7h2uw 2022 1Document1 pageT 7h2uw 2022 1MamPas encore d'évaluation

- Présentation Leader 2Document14 pagesPrésentation Leader 2Rosine PergamentPas encore d'évaluation

- RazafindrakotoJacquelin ESPA MAST 2017Document217 pagesRazafindrakotoJacquelin ESPA MAST 2017ABINAPas encore d'évaluation

- Organisation Fonctionnelle D'un ProduitDocument2 pagesOrganisation Fonctionnelle D'un ProduitMIMFSPas encore d'évaluation

- Achar2Bases de Calcul de lEC3Document19 pagesAchar2Bases de Calcul de lEC3Omar OmarPas encore d'évaluation

- Personal SkillsDocument11 pagesPersonal SkillsAgathe GrenonPas encore d'évaluation

- Spe645 Annexe2 22-1 1063862Document20 pagesSpe645 Annexe2 22-1 1063862tpolenorPas encore d'évaluation

- RespirationDocument19 pagesRespirationarselbleez441Pas encore d'évaluation

- Rapport de Stage Complete Sur La Gestion Des Opérations de CréditDocument44 pagesRapport de Stage Complete Sur La Gestion Des Opérations de Créditrogerkom.profsPas encore d'évaluation

- ReclamationDocument1 pageReclamationBoukidi AminePas encore d'évaluation

- EB2-Epreuve1 Production de L'ecritDocument2 pagesEB2-Epreuve1 Production de L'ecritElissa Naalaband100% (1)

- Bibliographie Stress Au Travail 2017-10-27Document15 pagesBibliographie Stress Au Travail 2017-10-27mael bikoroPas encore d'évaluation

- Sup de Cours Education Et InstructionDocument7 pagesSup de Cours Education Et InstructionRolfo FlrPas encore d'évaluation

- Physique-du-globe-et-meteorologie-Alphonse Berget-1904 PDFDocument379 pagesPhysique-du-globe-et-meteorologie-Alphonse Berget-1904 PDFAnonymous 4MLEo9TVQPas encore d'évaluation

- Chapitre1 Méthodes Et Moyens de Lutte Et Lutte IntégréeDocument6 pagesChapitre1 Méthodes Et Moyens de Lutte Et Lutte Intégréemayline pyramidePas encore d'évaluation

- Processeur M MoireDocument66 pagesProcesseur M Moiresayedyoussef390Pas encore d'évaluation

- Energie EolienneDocument51 pagesEnergie Eoliennedalila AMMARPas encore d'évaluation